I-Silicon carbide (SiC) i-crystal material eyodwa inobubanzi begebe lebhande elikhulu (~Si izikhathi ezi-3), ukuguquguquka okuphezulu kwe-thermal (~Si izikhathi ezingu-3.3 noma izikhathi ze-GaAs izikhathi ezingu-10), izinga lokufuduka kwe-electron ephezulu (~Si izikhathi ezingu-2.5), ukuphuka okuphezulu kukagesi inkambu (~Si 10 izikhathi noma GaAs izikhathi 5) kanye nezinye izici ezivelele.

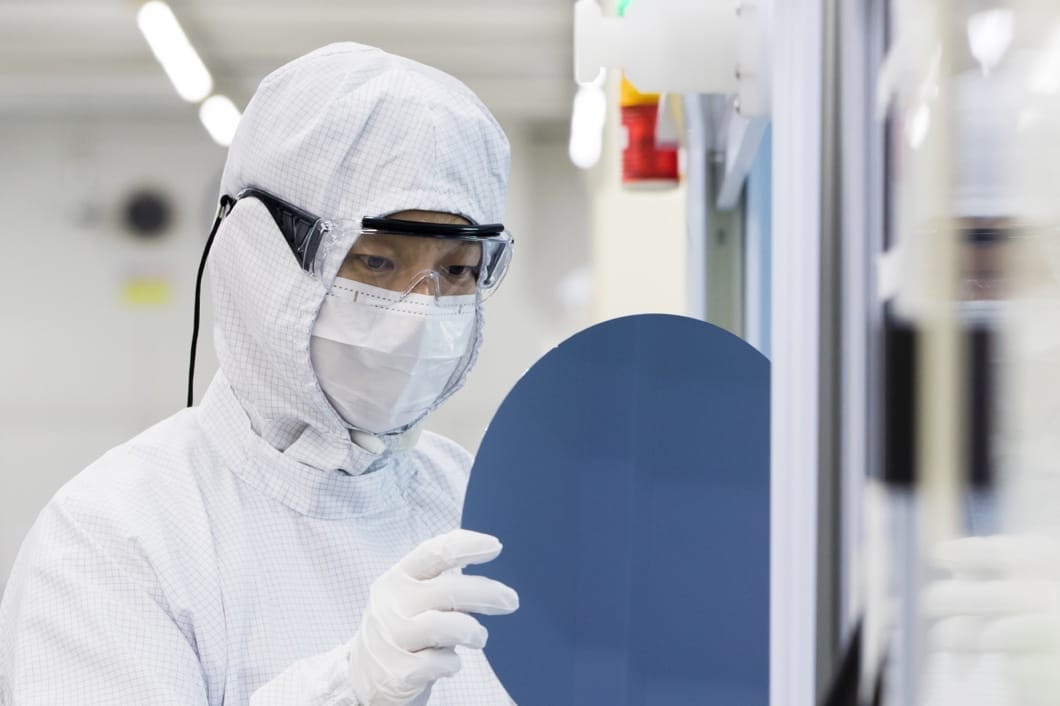

Amandla we-Semicera anganikeza amakhasimende izinga eliphezulu le-Conductive (Conductive), i-Semi-insulating (Semi-insulating), i-HPSI (i-High Purity semi-insulating) i-silicon carbide substrate; Ngaphezu kwalokho, singahlinzeka amakhasimende ngamashidi e-epitaxial e-silicon carbide e-homogeneous and heterogeneous; Singakwazi futhi ukwenza ngokwezifiso ishidi le-epitaxial ngokuya ngezidingo ezithile zamakhasimende, futhi abukho ubuncane be-oda lenani.

| Izinto | Ukukhiqiza | Ucwaningo | Dummy |

| I-Crystal Parameters | |||

| I-Polytype | 4H | ||

| Iphutha lokuma kobuso | <11-20 >4±0.15° | ||

| Amapharamitha kagesi | |||

| I-Dopant | n-uhlobo lweNitrojeni | ||

| Ukungazweli | 0.015-0.025ohm · cm | ||

| Mechanical Parameters | |||

| Ububanzi | 99.5 - 100mm | ||

| Ubukhulu | 350±25 μm | ||

| Umumo oyisicaba oyinhloko | [1-100]±5° | ||

| Ubude obuyisicaba obuyisisekelo | 32.5±1.5mm | ||

| Indawo eyisicaba yesibili | 90° CW kusukela efulethini lokuqala ±5°. i-silicon ibheke phezulu | ||

| Ubude befulethi besibili | 18±1.5mm | ||

| I-TTV | ≤5 μm | ≤10 μm | ≤20 μm |

| I-LTV | ≤2 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | NA |

| Khothama | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| I-Wap | ≤20 μm | ≤45 μm | ≤50 μm |

| Front(Si-face) roughness(AFM) | I-Ra≤0.2nm (5μm*5μm) | ||

| Isakhiwo | |||

| Ukuminyana kwe-Micropipe | ≤1 i-e/cm2 | ≤5 i-e/cm2 | ≤10 e/cm2 |

| Ukungcola kwensimbi | ≤5E10 ama-athomu/cm2 | NA | |

| I-BPD | ≤1500 i-e/cm2 | ≤3000 i-e/cm2 | NA |

| I-TSD | ≤500 i-e/cm2 | ≤1000 i-e/cm2 | NA |

| Ikhwalithi Yangaphambili | |||

| Ngaphambili | Si | ||

| Ukuqedwa kobuso | I-Si-face CMP | ||

| Izinhlayiya | ≤60ea/wafer (usayizi≥0.3μm) | NA | |

| Ukuklwebheka | ≤2ea/mm. Ubude obuqongelelwe ≤Ububanzi | Ubude obuqongelelwe≤2*Ububanzi | NA |

| Ikhasi eliwolintshi/imigodi/amabala/imifantu/ukungcola | Lutho | NA | |

| Ama-Edge chips/indents/fracture/hex plate | Lutho | NA | |

| Izindawo ze-Polytype | Lutho | Indawo eqoqiwe≤20% | Indawo eqoqiwe≤30% |

| Ukumaka kwe-laser yangaphambili | Lutho | ||

| Ikhwalithi Emuva | |||

| Emuva ekupheleni | C-face CMP | ||

| Ukuklwebheka | ≤5ea/mm, Ubude obuqongelelayo≤2*Ububanzi | NA | |

| Ukukhubazeka kwasemuva (ama-edge chips/indents) | Lutho | ||

| Ukuhwalala emuva | I-Ra≤0.2nm (5μm*5μm) | ||

| Ukumaka kwe-laser emuva | 1 mm (kusuka emaphethelweni aphezulu) | ||

| Umphetho | |||

| Umphetho | I-Chamfer | ||

| Ukupakisha | |||

| Ukupakisha | Isikhwama sangaphakathi sigcwaliswa nge-nitrogen futhi isikhwama sangaphandle siyacocwa. Ikhasethi le-wafer eningi, i-epi-ready. | ||

| *Amanothi: "NA" kusho ukuthi asikho isicelo Izinto ezingashiwongo zingabhekisa ku-SEMI-STD. | |||

-

Izinto Zokuphikisa Ezithengiswa Kakhulu-Izinga Lokushisa Eliphezulu...

-

I-Wafer Sucker Yekhwalithi Enhle I-Alumina Semiconductor...

-

Isephulelo esikhulu soMkhiqizo Omusha We-Ceramic Beam Silico...

-

I-China New Product Silicon Carbide Radiation Sis...

-

2019 Ikhwalithi ephezulu ye-Sic Oxide Silicon Carbide Cer...

-

I-OEM/ODM Factory Silicon Carbide/Sic Mechanical ...