Ukusetshenziswa okuyinhloko kwe-Alumina (Al2O3).

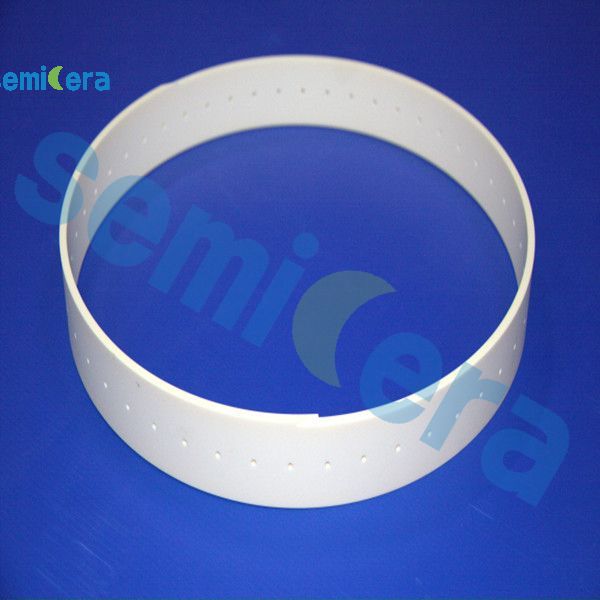

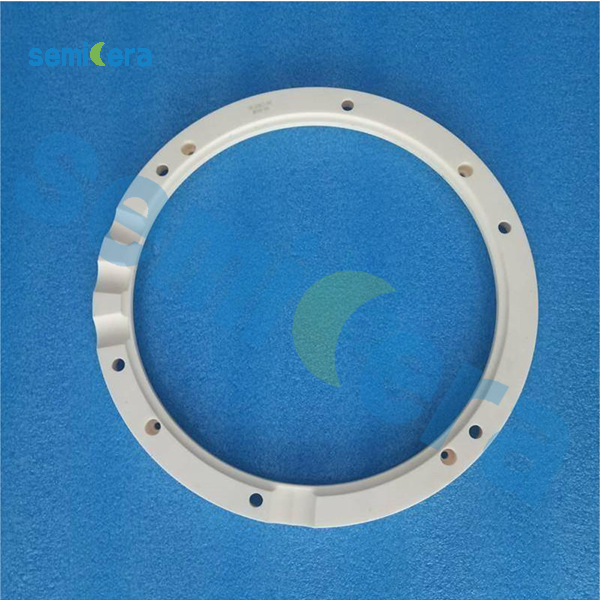

Izingxenye zemishini yokukhiqiza i-semiconductor (izingxenye zembobo, ama-insulation flange, izingxenye zemishini yokufaka, i-wafer clamp);Izingxenye zokugaya (i-classifier, i-air flow mill, i-bead mill);Izingxenye zezimboni ezijwayelekile (i-laser processing nozzle, shaft ejikelezayo, i-bearing);Ukunemba okuphezulu, ukunemba, amathuluzi e-metallurgical ukumelana nokushisa (indawo yokuma, ukulungiswa komhlangano);Gqoka izingxenye eziqinile (i-roller yomhlahlandlela yomshini wokudweba ucingo, ishaneli yocingo lwensimbi, isitimela somhlahlandlela);Izingxenye zokufakelwa kukagesi (ama-insulators, ama-gaskets, ama-bushings).

Isici

I-Alumina iyi-ceramics emhlophe noma e-opalescent, isebenzisa izakhiwo zayo ezinhle kakhulu zokufaka ugesi, zaqala ukusetshenziswa ezingxenyeni ze-elekthronikhi, ukusetshenziswa okuningi, kuyindleko ephansi kakhulu kuma-ceramics anembile.

Sihlinzeka ngemikhiqizo yokuhlanzeka okuphezulu okungu-99.5% no-99.9%.I-alumina yohlobo lokuhlanzeka okuphezulu inamandla amakhulu emishini, ukumelana nokugqwala okuhle kakhulu, futhi ingakhiqiza imikhiqizo emikhulu.

Ngaphezu kwalokho, ngenxa yokumelana kwayo okuhle kakhulu ne-plasma, ingasetshenziswa futhi kumishini ye-CVD noma ezingxenyeni zemishini yokufaka.