I-Silicon carbide (SiC) i-crystal material eyodwa inobubanzi begebe lebhande elikhulu (~Si izikhathi ezi-3), ukuguquguquka okuphezulu kwe-thermal (~Si izikhathi ezingu-3.3 noma izikhathi ze-GaAs izikhathi ezingu-10), izinga lokufuduka kwe-electron ephezulu (~Si izikhathi ezingu-2.5), ukuphuka okuphezulu kukagesi inkambu (~Si 10 izikhathi noma GaAs izikhathi 5) kanye nezinye izici ezivelele.

Izinto ze-semiconductor yesizukulwane sesithathu ikakhulukazi zifaka i-SiC, i-GaN, idayimane, njll., ngoba ububanzi begebe lebhendi yayo (Isb) bukhulu noma bulingana nama-electron volts (eV) angu-2.3 (eV), owaziwa nangokuthi i-wide band gap semiconductor materials. Uma kuqhathaniswa nezinto zokwakha ze-semiconductor yesizukulwane sokuqala nesesibili, izinto zokwakha ze-semiconductor yesizukulwane sesithathu zinezinzuzo zokubamba okuphezulu okushisayo, insimu kagesi ewohlokayo, izinga eliphezulu lokufuduka kwama-electron namandla aphezulu okubopha, okungahlangabezana nezidingo ezintsha zobuchwepheshe besimanje be-elekthronikhi izinga lokushisa, amandla aphezulu, umfutho ophezulu, imvamisa ephezulu kanye nokumelana nemisebe nezinye izimo ezinzima. Inamathemba okusebenza abalulekile emikhakheni yezokuvikela kuzwelonke, ezondiza, i-aerospace, ukuhlola uwoyela, ukugcinwa kwamehlo, njll., futhi inganciphisa ukulahleka kwamandla ngaphezu kuka-50% ezimbonini zamasu eziningi ezifana nezokuxhumana nge-broadband, amandla elanga, ukukhiqiza izimoto, ukukhanya kwe-semiconductor, kanye negridi ehlakaniphile, futhi kunganciphisa umthamo wezinto zokusebenza ngamaphesenti angaphezu kwama-75, okubaluleke kakhulu ekuthuthukisweni kwesayensi yabantu nobuchwepheshe.

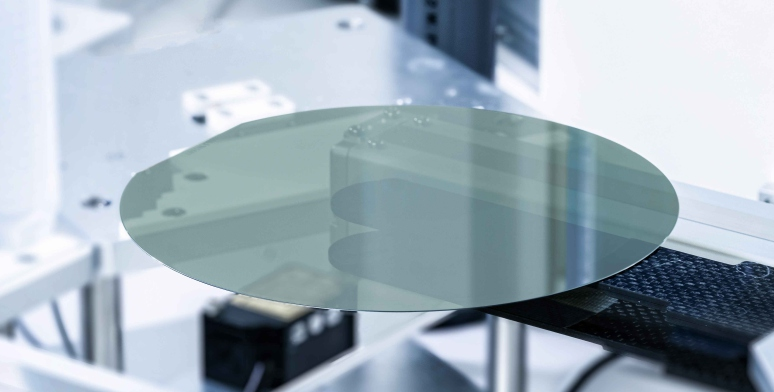

Amandla we-Semicera anganikeza amakhasimende izinga eliphezulu le-Conductive (Conductive), i-Semi-insulating (Semi-insulating), i-HPSI (i-High Purity semi-insulating) i-silicon carbide substrate; Ngaphezu kwalokho, singahlinzeka amakhasimende ngamashidi e-epitaxial e-silicon carbide e-homogeneous and heterogeneous; Singakwazi futhi ukwenza ngokwezifiso ishidi le-epitaxial ngokuya ngezidingo ezithile zamakhasimende, futhi abukho ubuncane be-oda lenani.

IMICIMBI YOKUFAKA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulating

| Into | 8-Intshi | 6-Intshi | 4-Intshi | ||

| nP | n-Pm | n-IHu | SI | SI | |

| I-TTV(GBIR) | ≤6um | ≤6um | |||

| Umnsalo(GF3YFCD)-Inani Eliphelele | ≤15μm | ≤15μm | ≤25μm | ≤15μm | |

| I-Warp(GF3YFER) | ≤25μm | ≤25μm | ≤40μm | ≤25μm | |

| I-LTV(SBIR)-10mmx10mm | <2μm | ||||

| I-Wafer Edge | Beveling | ||||

UBUHLUNGU QEDA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-Insulating

| Into | 8-Intshi | 6-Intshi | 4-Intshi | ||

| nP | n-Pm | n-IHu | SI | SI | |

| I-Surface Qeda | I-Double side Optical Polish, i-Si- Face CMP | ||||

| I-SurfaceRoughness | (10um x 10um) I-Si-FaceRa≤0.2nm I-C-Face Ra≤ 0.5nm | (5umx5um) I-Si-Face Ra≤0.2nm I-C-Face Ra≤0.5nm | |||

| Ama-Edge Chips | Akukho okuvunyelwe (ubude nobubanzi≥0.5mm) | ||||

| Izindebe | Akukho Okuvunyelwe | ||||

| Imihuzuko(Si-Face) | Ubuningi.≤5,Okuqoqekile Ubude≤0.5× ububanzi bewafa | Ubuningi.≤5,Okuqoqekile Ubude≤0.5× ububanzi bewafa | Ubuningi.≤5,Okuqoqekile Ubude≤0.5× ububanzi bewafa | ||

| Imifantu | Akukho Okuvunyelwe | ||||

| Ukukhishwa komkhawulo | 3mm | ||||