I-CVD SiC Coating

I-Silicon carbide (SiC) epitaxy

Ithreyi ye-epitaxial, ephethe i-substrate ye-SiC yokukhulisa ucezu lwe-SiC epitaxial, ibekwe ekamelweni lokusabela futhi ithinte ngokuqondile i-wafer.

Ingxenye engenhla yengxenye yenyanga iyisithwali sezinye izesekeli zegumbi lokusabela lemishini ye-Sic epitaxy, kuyilapho ingxenye ephansi yenyanga ixhunywe kushubhu ye-quartz, yethula igesi ukushayela isisekelo se-susceptor ukuze sijikeleze.ziyalawuleka izinga lokushisa futhi zifakwe ekamelweni lokusabela ngaphandle kokuxhumana okuqondile ne-wafer.

I-epitaxy

Ithreyi, ephethe i-Si substrate yokukhulisa ucezu lwe-Si epitaxial, ibekwe egunjini lokusabela futhi ithintane ngqo ne-wafer.

Indandatho yokushisisa itholakala eringini yangaphandle yethreyi ye-Si epitaxial substrate futhi isetshenziselwa ukulinganisa nokushisa.Ifakwa ekamelweni lokusabela futhi ayithinteli ngokuqondile i-wafer.

I-epitaxial susceptor, ephethe i-Si substrate yokukhulisa ucezu lwe-Si epitaxial, olubekwe ekamelweni lokusabela futhi luthintane ngokuqondile ne-wafer.

I-Epitaxial barrel iyizici ezibalulekile ezisetshenziswa ezinqubweni ezihlukahlukene zokukhiqiza i-semiconductor, ngokuvamile esetshenziswa emishinini ye-MOCVD, enokuqina okuhle kakhulu kokushisa, ukumelana namakhemikhali nokumelana nokugqoka, okulungele kakhulu ukusetshenziswa ezinkambisweni zokushisa okuphezulu.Ixhumana namawafa.

| 重结晶碳化硅物理特性 Izakhiwo ezibonakalayo ze-Recrystallized Silicon Carbide | |

| 性质 / Isakhiwo | 典型数值 / Inani Elijwayelekile |

| 使用温度 / Izinga lokushisa lokusebenza (°C) | 1600°C (nomoya-mpilo), 1700°C (ukunciphisa imvelo) |

| Okuqukethwe kwe-SiC 含量 / SiC | > 99.96% |

| 自由 Si 含量 / Mahhala Okuqukethwe kwe-Si | <0.1% |

| 体积密度 / Ukuminyana ngobuningi | 2.60-2.70 g/cm3 |

| 气孔率 / I-porosity ebonakalayo | < 16% |

| 抗压强度 / Amandla okucindezela | > 600 MPa |

| 常温抗弯强度 / Amandla okugoba abandayo | 80-90 MPa (20°C) |

| 高温抗弯强度 Amandla okugoba ashisayo | 90-100 MPa (1400°C) |

| 热膨胀系数 / Ukunwetshwa kwe-Thermal @1500°C | 4.70 10-6/°C |

| 导热系数 / I-Thermal conductivity @1200°C | 23 W/m•K |

| 杨氏模量 / I-Elastic modulus | 240 GPA |

| 抗热震性 / Ukumelana nokushaqeka okushisayo | Kuhle ngokwedlulele |

| 烧结碳化硅物理特性 Izakhiwo ezibonakalayo ze-Sintered Silicon Carbide | |

| 性质 / Isakhiwo | 典型数值 / Inani Elijwayelekile |

| 化学成分 / Ukwakheka Kwamakhemikhali | SiC>95%, Si<5% |

| 体积密度 / Ukuminyana okuningi | >3.07 g/cm³ |

| 显气孔率 / I-porosity ebonakalayo | <0.1% |

| 常温抗弯强度 / I-Modulus yokuphuka ku-20℃ | 270 MPa |

| 高温抗弯强度 / I-Modulus yokuphuka ku-1200℃ | 290 MPa |

| 硬度 / Ukuqina ku-20℃ | 2400 Kg/mm² |

| 断裂韧性 / Ukuqina kokuphuka ku-20% | 3.3 MPa · m1/2 |

| 导热系数 / I-Thermal Conductivity ku-1200℃ | 45 w/m .K |

| 热膨胀系数 / Ukunwetshwa kwe-Thermal ku-20-1200℃ | 4.5 1 ×10 -6/℃ |

| 最高工作温度 / Max.izinga lokushisa lokusebenza | 1400 ℃ |

| 热震稳定性 / Ukumelana nokushaqeka okushisayo ku-1200 ℃ | Kuhle |

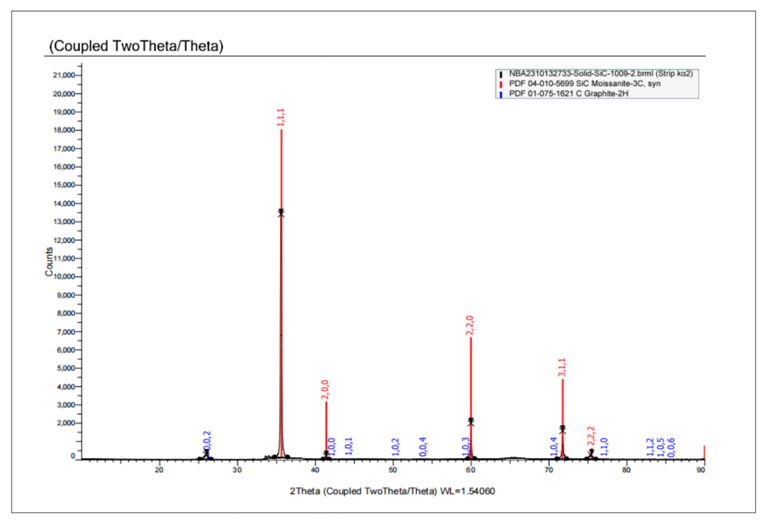

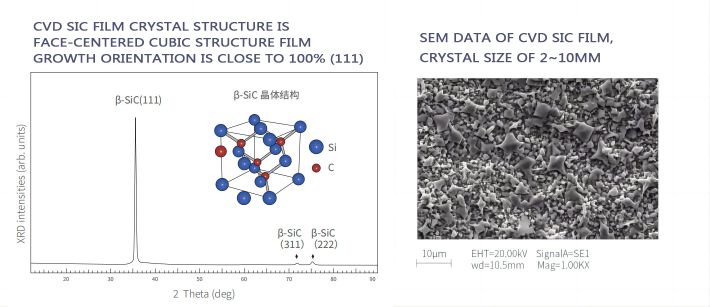

| I-CVD SiC 薄膜基本物理性能 Izakhiwo ezibonakalayo eziyisisekelo zamafilimu e-CVD SiC | |

| 性质 / Isakhiwo | 典型数值 / Inani Elijwayelekile |

| 晶体结构 / Crystal Structure | I-FCC β isigaba se-polycrystalline, ikakhulukazi (111) eqondiswe |

| 密度 / Ukuminyana | 3.21 g/cm³ |

| 硬度 / Ukuqina 2500 | 维氏硬度 (500g umthwalo) |

| 晶粒大小 / Grain SiZe | 2 ~ 10μm |

| 纯度 / Chemical Purity | 99.99995% |

| 热容 / Amandla Okushisa | 640 J·kg-1·K-1 |

| 升华温度 / I-Sublimation Temperature | 2700 ℃ |

| 抗弯强度 / Amandla e-Flexural | 415 MPa RT 4-iphoyinti |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt ukugoba, 1300℃ |

| 导热系数 / Thermal Conductivity | 300Wm-1·K-1 |

| 热膨胀系数 / Ukunwetshwa kwe-Thermal(CTE) | 4.5×10-6 K -1 |

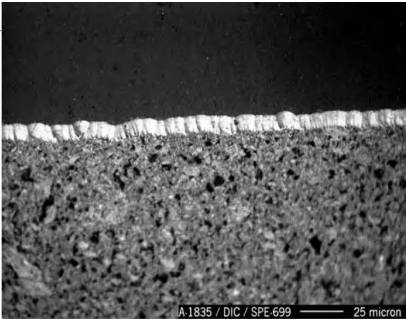

I-Pyrolytic Carbon Coating

Izici eziyinhloko

Ingaphezulu liminyene futhi alinawo ama-pores.

Ukuhlanzeka okuphezulu, okuqukethwe kokungcola okuphelele <20ppm, umoya omuhle.

Ukumelana nezinga lokushisa eliphakeme, amandla akhuphuka ngokunyuka kwezinga lokushisa lokusetshenziswa, afinyelele inani eliphakeme kakhulu ku-2750 ℃, i-sublimation ku-3600 ℃.

I-modulus enwebekayo ephansi, i-thermal conductivity ephezulu, i-coefficient ephansi yokwanda kwe-thermal, kanye nokumelana nokushaqeka okuhle kakhulu kokushisa.

Ukuzinza okuhle kwamakhemikhali, amelana ne-asidi, i-alkali, usawoti, nama-organic reagents, futhi akunawo umthelela ezinsimbi ezincibilikisiwe, i-slag, neminye imithombo yezindaba ebolayo.Ayifaki oksijini kakhulu emkhathini ngaphansi kuka-400 C, futhi izinga le-oxidation likhuphuka kakhulu ku-800 ℃.

Ngaphandle kokukhipha noma iyiphi igesi emazingeni okushisa aphezulu, ingakwazi ukugcina i-vacuum engu-10-7mmHg cishe ku-1800°C.

Isicelo somkhiqizo

I-crucible encibilikayo yokuhwamuka embonini ye-semiconductor.

Amandla aphezulu wesango leshubhu le-electronic.

Ibhulashi elithinta isilawuli sikagesi.

I-graphite monochromator ye-X-ray ne-neutron.

Izinhlobo ezihlukahlukene zama-graphite substrates kanye ne-atomic absorption tube coating.

I-pyrolytic carbon coating effect ngaphansi kwesibonakhulu esingu-500X, esinobuso obungaguquki futhi obuvalekile.

I-CVD Tantalum Carbide Coating

Ukufakwa kwe-TaC kuyisizukulwane esisha esimelana nezinga lokushisa eliphezulu, esinokuzinza okungcono kakhulu kwezinga lokushisa kune-SiC.Njengonamathela okumelana nokugqwala, okokulwa ne-oxidation kanye nenamathela engagugi, kungasetshenziswa endaweni engaphezulu kuka-2000C, esetshenziswa kabanzi ku-aerospace ultra-high heat hot end parts, isizukulwane sesithathu semiconductor single crystal growth fields.

| 碳化钽涂层物理特性物理特性 Izinto ezibonakalayo ze-TaC coating | |

| 密度/ Ukuminyana | 14.3 (g/cm3) |

| 比辐射率 /Emissivity ethile | 0.3 |

| 热膨胀系数/ I-coefficient yokunweba okushisayo | 6.3 10/K |

| 努氏硬度 /Ubunzima (HK) | 2000 HK |

| 电阻/ Ukumelana | 1x10-5 Ohm*cm |

| 热稳定性 /Ukuzinza kwe-Thermal | <2500℃ |

| 石墨尺寸变化/Usayizi weGraphite uyashintsha | - 10 ~ 20um |

| 涂层厚度/Ukuqina kwe-Coating | ≥220um inani elijwayelekile (35um±10um) |

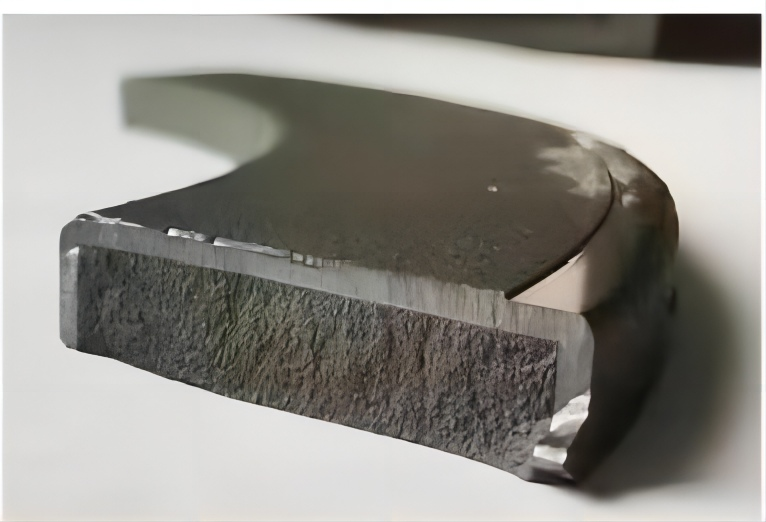

I-Solid Silicon Carbide(CVD SiC)

Izingxenye eziqinile ze-CVD SILICON CARBIDE zibonwa njengokukhetha okuyinhloko kwamasongo e-RTP/EPI nezisekelo kanye nezingxenye ze-plasma etch cavity ezisebenza kumazinga okushisa okusebenza adingekayo esistimu (> 1500°C), izimfuneko zobumsulwa ziphezulu kakhulu (> 99.9995%) futhi ukusebenza kuhle ikakhulukazi lapho amakhemikhali e-tol ukumelana ephezulu kakhulu.Lezi zinto aziqukethe izigaba zesibili onqenqemeni lokusanhlamvu, ngakho-ke izingxenye ze-theil zikhiqiza izinhlayiya ezimbalwa kunezinye izinto.Ngaphezu kwalokho, lezi zingxenye zingahlanzwa usebenzisa i-HF/HCI eshisayo ngokuwohloka okuncane, okuholela ezinhlayiyeni ezimbalwa nempilo yesevisi ende.