I-Silicon carbide (SiC) i-crystal material eyodwa inobubanzi begebe lebhande elikhulu (~Si izikhathi ezi-3), ukuguquguquka okuphezulu kwe-thermal (~Si izikhathi ezingu-3.3 noma izikhathi ze-GaAs izikhathi ezingu-10), izinga lokufuduka kwe-electron ephezulu (~Si izikhathi ezingu-2.5), ukuphuka okuphezulu kukagesi inkambu (~Si 10 izikhathi noma GaAs izikhathi 5) kanye nezinye izici ezivelele.

Izinto ze-semiconductor yesizukulwane sesithathu ikakhulukazi zifaka i-SiC, i-GaN, idayimane, njll., ngoba ububanzi begebe lebhendi yayo (Isb) bukhulu noma bulingana nama-electron volts (eV) angu-2.3 (eV), owaziwa nangokuthi i-wide band gap semiconductor materials. Uma kuqhathaniswa nezinto zokwakha ze-semiconductor yesizukulwane sokuqala nesesibili, izinto zokwakha ze-semiconductor yesizukulwane sesithathu zinezinzuzo zokubamba okuphezulu okushisayo, insimu kagesi ewohlokayo, izinga eliphezulu lokufuduka kwama-electron namandla aphezulu okubopha, okungahlangabezana nezidingo ezintsha zobuchwepheshe besimanje be-elekthronikhi izinga lokushisa, amandla aphezulu, umfutho ophezulu, imvamisa ephezulu kanye nokumelana nemisebe nezinye izimo ezinzima. Inamathemba okusebenza abalulekile emikhakheni yezokuvikela kuzwelonke, ezondiza, i-aerospace, ukuhlola uwoyela, ukugcinwa kwamehlo, njll., futhi inganciphisa ukulahleka kwamandla ngaphezu kuka-50% ezimbonini zamasu eziningi ezifana nezokuxhumana nge-broadband, amandla elanga, ukukhiqiza izimoto, ukukhanya kwe-semiconductor, kanye negridi ehlakaniphile, futhi kunganciphisa umthamo wezinto zokusebenza ngamaphesenti angaphezu kwama-75, okubaluleke kakhulu ekuthuthukisweni kwesayensi yabantu nobuchwepheshe.

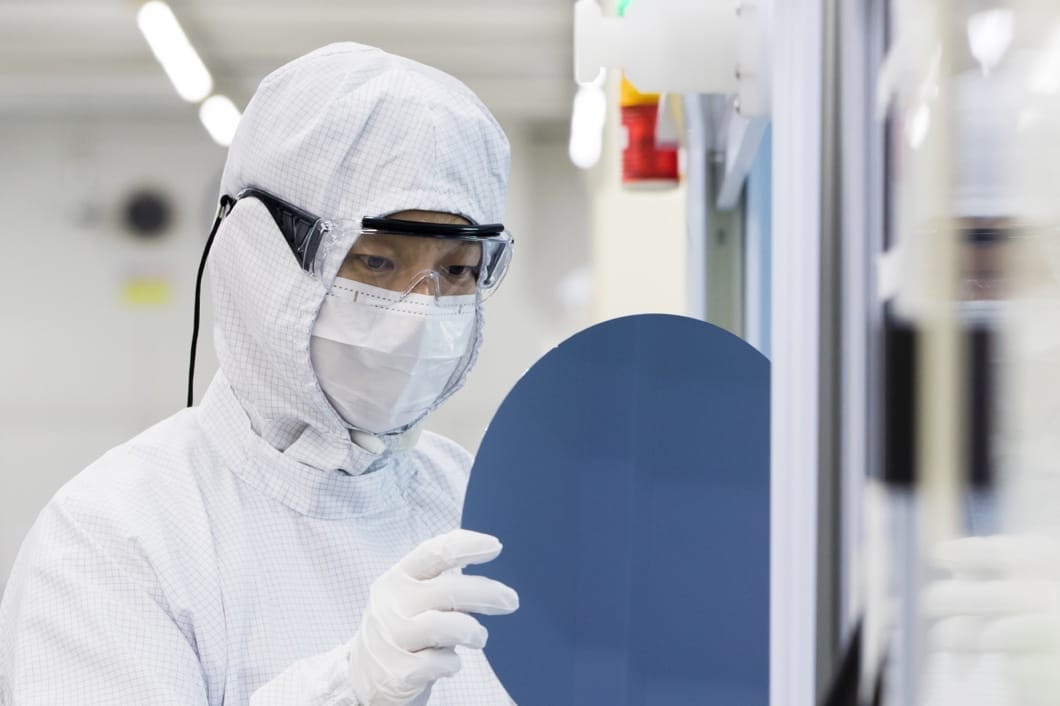

Amandla we-Semicera anganikeza amakhasimende izinga eliphezulu le-Conductive (Conductive), i-Semi-insulating (Semi-insulating), i-HPSI (i-High Purity semi-insulating) i-silicon carbide substrate; Ngaphezu kwalokho, singahlinzeka amakhasimende ngamashidi e-epitaxial e-silicon carbide e-homogeneous and heterogeneous; Singakwazi futhi ukwenza ngokwezifiso ishidi le-epitaxial ngokuya ngezidingo ezithile zamakhasimende, futhi abukho ubuncane be-oda lenani.

| Izinto | Ukukhiqiza | Ucwaningo | Dummy |

| I-Crystal Parameters | |||

| I-Polytype | 4H | ||

| Iphutha lokuma kobuso | <11-20 >4±0.15° | ||

| Amapharamitha kagesi | |||

| I-Dopant | n-uhlobo lweNitrojeni | ||

| Ukungazweli | 0.015-0.025ohm · cm | ||

| Mechanical Parameters | |||

| Ububanzi | 150.0±0.2mm | ||

| Ubukhulu | 350±25 μm | ||

| Umumo oyisicaba oyinhloko | [1-100]±5° | ||

| Ubude obuyisicaba obuyisisekelo | 47.5±1.5mm | ||

| Ifulethi lesibili | Lutho | ||

| I-TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| I-LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Khothama | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| I-Wap | ≤35 μm | ≤45 μm | ≤55 μm |

| Front(Si-face) roughness(AFM) | I-Ra≤0.2nm (5μm*5μm) | ||

| Isakhiwo | |||

| Ukuminyana kwe-Micropipe | <1 eya/cm2 | <10 kwe/cm2 | <15 kwe/cm2 |

| Ukungcola kwensimbi | ≤5E10 ama-athomu/cm2 | NA | |

| I-BPD | ≤1500 i-e/cm2 | ≤3000 i-e/cm2 | NA |

| I-TSD | ≤500 i-e/cm2 | ≤1000 i-e/cm2 | NA |

| Ikhwalithi Yangaphambili | |||

| Ngaphambili | Si | ||

| Ukuqedwa kobuso | I-Si-face CMP | ||

| Izinhlayiya | ≤60ea/wafer (usayizi≥0.3μm) | NA | |

| Ukuklwebheka | ≤5ea/mm. Ubude obuqongelelwe ≤Ububanzi | Ubude obuqongelelwe≤2*Ububanzi | NA |

| Ikhasi eliwolintshi/imigodi/amabala/imifantu/ukungcola | Lutho | NA | |

| Ama-Edge chips/indents/fracture/hex plate | Lutho | ||

| Izindawo ze-Polytype | Lutho | Indawo eqoqiwe≤20% | Indawo eqoqiwe≤30% |

| Ukumaka kwe-laser yangaphambili | Lutho | ||

| Ikhwalithi Emuva | |||

| Emuva ekupheleni | C-face CMP | ||

| Ukuklwebheka | ≤5ea/mm, Ubude obuqongelelayo≤2*Ububanzi | NA | |

| Ukukhubazeka kwasemuva (ama-edge chips/indents) | Lutho | ||

| Ukuhwalala emuva | I-Ra≤0.2nm (5μm*5μm) | ||

| Ukumaka kwe-laser emuva | 1 mm (kusuka emaphethelweni aphezulu) | ||

| Umphetho | |||

| Umphetho | I-Chamfer | ||

| Ukupakisha | |||

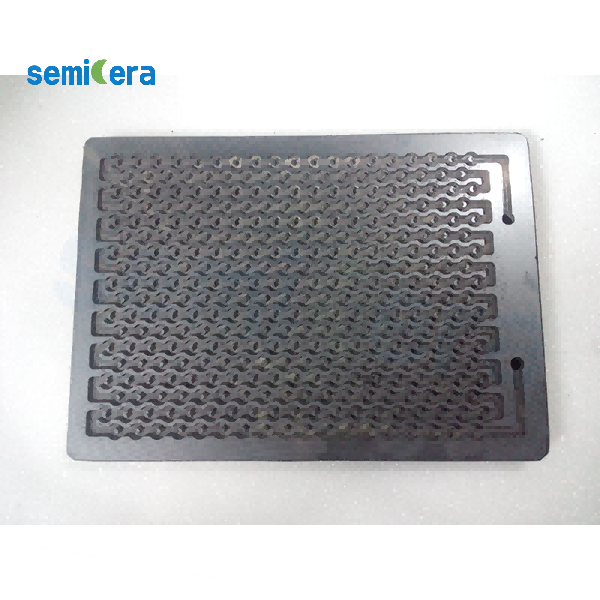

| Ukupakisha | I-Epi-ilungele ukupakishwa kwe-vacuum Ukupakishwa kwamakhasethi ama-wafer amaningi | ||

| *Amanothi: "NA" kusho ukuthi asikho isicelo Izinto ezingashiwongo zingabhekisa ku-SEMI-STD. | |||