I-CVD Silicon Carbide(SiC) Etching Ring iyingxenye ekhethekile eyenziwe ngeSilicon Carbide (SiC) kusetshenziswa indlela yeChemical Vapor Deposition (CVD). I-CVD Silicon Carbide(SiC) Etching Ring idlala indima ebalulekile ezinhlobonhlobo zezinhlelo zokusebenza zezimboni, ikakhulukazi ezinqubweni ezibandakanya ukufakwa kwezinto ezibonakalayo. I-Silicon Carbide iyimpahla ye-ceramic eyingqayizivele futhi ethuthukisiwe eyaziwa ngezakhiwo zayo ezivelele, kufaka phakathi ubulukhuni obuphezulu, ukuqhutshwa kokushisa okuhle kakhulu kanye nokumelana nezindawo zamakhemikhali ezinokhahlo.

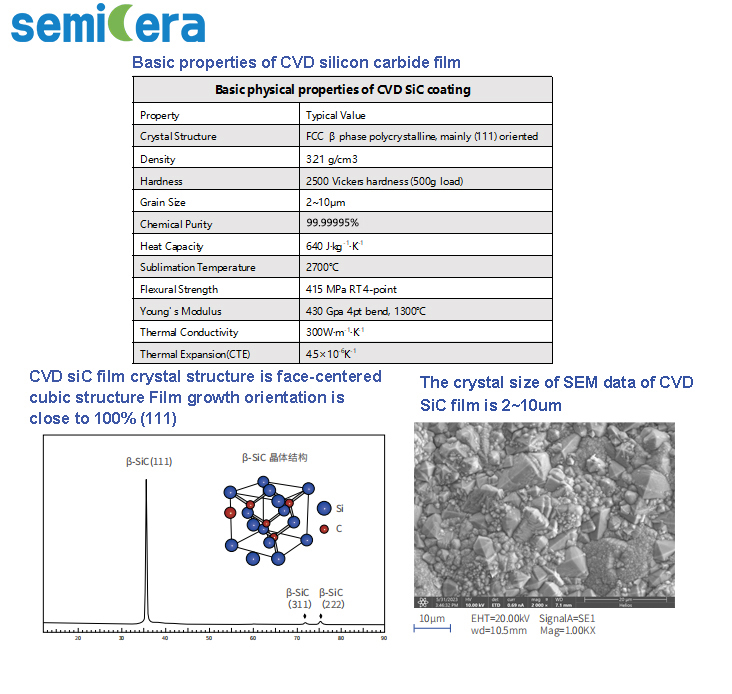

Inqubo ye-Chemical Vapor Deposition ihlanganisa ukufaka ungqimba oluncane lwe-SiC ku-substrate endaweni elawulwayo, okuholela ekuhlanzekeni okuphezulu kanye nokokusebenza okuklanywe ngokunembile. I-CVD Silicon Carbide yaziwa ngomfaniswano wayo kanye nesakhiwo esincane esiminyene, amandla emishini amahle kakhulu kanye nokuzinza okushisayo okuthuthukisiwe.

I-CVD Silicon Carbide(SiC) Etching Ring yenziwe nge-CVD Silicon Carbide, engagcini nje ngokuqinisekisa ukuqina okuhle kakhulu, kodwa futhi imelana nokugqwala kwamakhemikhali kanye nokushintsha kwezinga lokushisa okwedlulele. Lokhu kuyenza ilungele izinhlelo zokusebenza lapho ukunemba, ukwethembeka kanye nempilo kubalulekile.

✓Ikhwalithi ephezulu emakethe yaseChina

✓Isevisi enhle njalo kuwe, amahora angu-7*24

✓Idethi emfishane yokulethwa

✓I-MOQ encane yamukelekile futhi yamukelwe

✓Amasevisi angokwezifiso

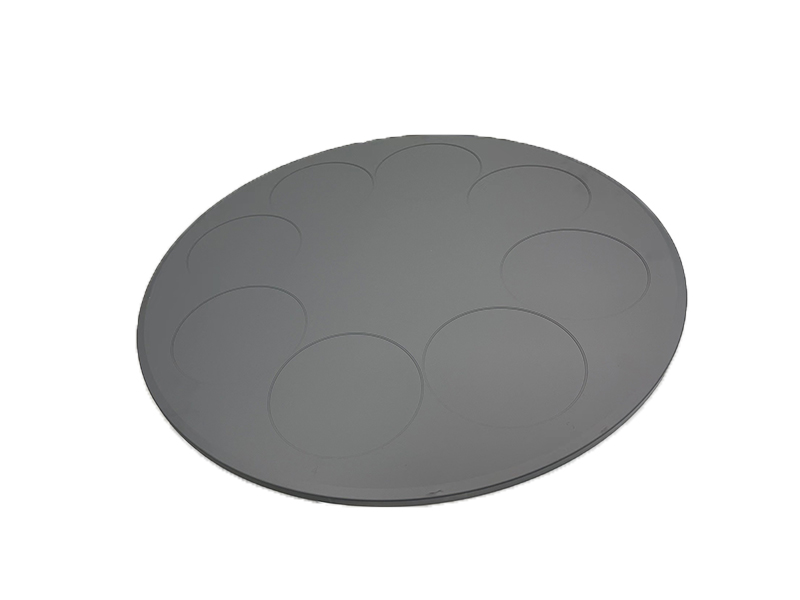

I-Epitaxy Growth Susceptor

Amawafa e-silicon/silicon carbide adinga ukudlula ezinqubweni eziningi okufanele asetshenziswe kumishini kagesi. Inqubo ebalulekile i-silicon/sic epitaxy, lapho amawafa e-silicon/sic athwalwa khona ngesisekelo segraphite. Izinzuzo ezikhethekile ze-Semicera's silicone carbide-coated graphite base zifaka ukuhlanzeka okuphezulu kakhulu, ukunamathela okufanayo, nempilo yesevisi ende kakhulu. Futhi banokuphikiswa okuphezulu kwamakhemikhali kanye nokuzinza kokushisa.

Ukukhiqizwa kwe-chip ye-LED

Ngesikhathi sokumbozwa okubanzi kwe-reactor ye-MOCVD, isisekelo seplanethi noma umthwali uhambisa i-wafer ye-substrate. Ukusebenza kwezinto eziyisisekelo kunethonya elikhulu kwikhwalithi yokugqoka, okubuye kuthinte izinga le-scrap ye-chip. Isisekelo esihlanganiswe ne-silicon carbide se-Semicera sinyusa ukusebenza kahle kokukhiqizwa kwamawafa e-LED ekhwalithi ephezulu futhi sinciphisa ukuchezuka kwamaza. Siphinde sinikeze izingxenye ezengeziwe ze-graphite zazo zonke iziphehlisi ze-MOCVD ezisetshenziswayo njengamanje. Singakwazi ukugqoka cishe noma iyiphi ingxenye nge-silicon carbide coating, noma ngabe ububanzi bengxenye bufika ku-1.5M, sisengakwazi ukugqoka nge-silicon carbide.

Inkambu yeSemiconductor, Inqubo Yokusabalalisa Kwe-oxidation, njll.

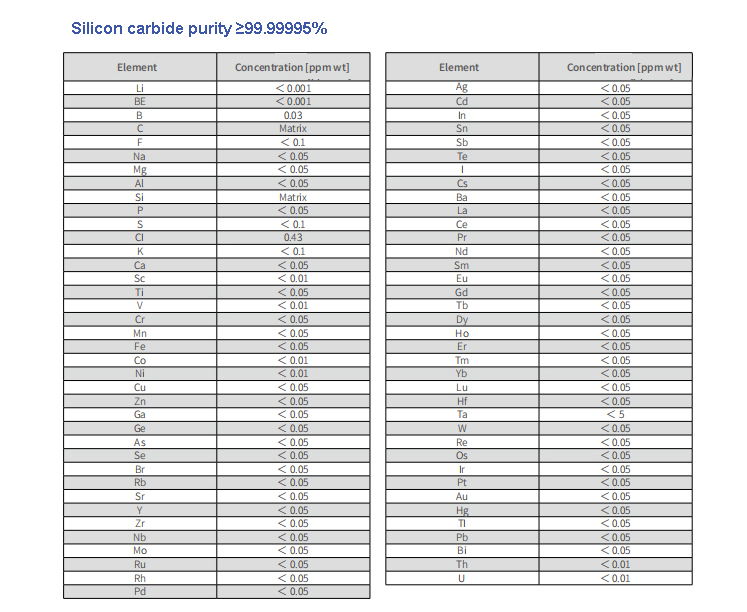

Enqubweni ye-semiconductor, inqubo yokunwetshwa kwe-oxidation idinga ukuhlanzeka okuphezulu komkhiqizo, futhi kwa-Semicera sinikeza inkambiso nezinsizakalo zokumboza ze-CVD zeningi lezingxenye ze-silicon carbide.

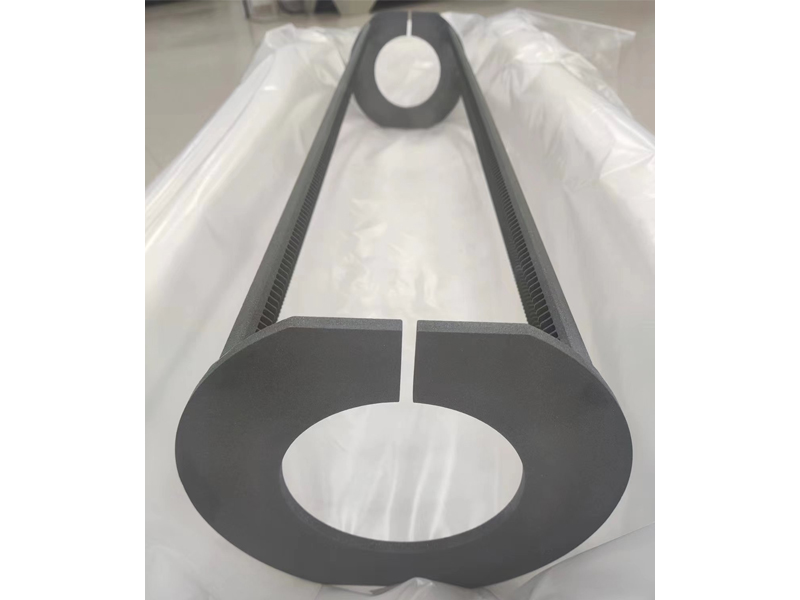

Isithombe esilandelayo sibonisa udaka lwe-silicon carbide olucutshungulwe kahle lwe-Semicea kanye neshubhu le-silicon carbide furnace elihlanzwa ku-1000-izingaengenalo uthuliigumbi. Abasebenzi bethu basebenza ngaphambi kokugqoka. Ukuhlanzeka kwe-silicon carbide yethu kungafinyelela ku-99.99%, futhi ubumsulwa be-sic coating bukhulu kuno-99.99995%

I-Raw Silicon Carbide Paddle kanye ne-SiC Process Tube in Cleaing

I-Silicon Carbide Wafer Boat CVD SiC Coated