I-CVD Silicon Carbide(SiC) Izindandatho ezihlinzekwa yi-Semicera ziyizingxenye eziyinhloko ekufakweni kwe-semiconductor, isigaba esibalulekile ekukhiqizeni idivayisi ye-semiconductor. Ukwakheka kwalawa maRings e-CVD Silicon Carbide(SiC) kuqinisekisa isakhiwo esimangelengele nesihlala isikhathi eside esingamelana nezimo ezinzima zenqubo yokuqopha. Ukufakwa komhwamuko wamakhemikhali kusiza ukwakha ungqimba lwe-SiC oluphezulu, umfaniswano kanye nominyene, okunikeza izindandatho amandla angcono kakhulu okusebenza, ukuqina okushisayo nokumelana nokugqwala.

Njengesici esibalulekile ekwenziweni kwe-semiconductor, Izindandatho ze-CVD Silicon Carbide(SiC) zisebenza njengesithiyo sokuvikela ukuvikela ubuqotho bama-semiconductor chips. Idizayini yayo enembayo iqinisekisa ukufakwa okufanayo nokulawulwayo, okusiza ekwenziweni kwamadivayisi ayinkimbinkimbi kakhulu we-semiconductor, anikeze ukusebenza okuthuthukisiwe nokuthembeka.

Ukusetshenziswa kwezinto ze-CVD SiC ekwakhiweni kwamasongo kubonisa ukuzibophezela kwekhwalithi nokusebenza ekukhiqizeni i-semiconductor. Le nto inezinto ezihlukile, okuhlanganisa ukuguquguquka okuphezulu kwe-thermal, ukungangeni kahle kwamakhemikhali, ukumelana nokuguga nokugqwala, okwenza i-CVD Silicon Carbide(SiC) Izindandatho zibe ingxenye ebalulekile ekuphishekeleni ukunemba nokusebenza kahle ezinqubweni zokuhlanganisa i-semiconductor.

I-Semicera's CVD Silicon Carbide (SiC) Ring imele ikhambi elithuthukisiwe emkhakheni wokwenziwa kwe-semiconductor, kusetshenziswa izici eziyingqayizivele zomhwamuko wamakhemikhali ofakwe i-silicon carbide ukuze kuzuzwe izinqubo zokuhlanganisa ezinokwethenjelwa nezisebenza kahle kakhulu, ezikhuthaza ukuthuthuka okuqhubekayo kobuchwepheshe be-semiconductor. Sizibophezele ekuhlinzekeni amakhasimende ngemikhiqizo emihle kakhulu kanye nokwesekwa kwezobuchwepheshe ukuze kuhlangatshezwane nesidingo semboni ye-semiconductor yezisombululo ze-etching ezisezingeni eliphezulu nezisebenzayo.

✓Ikhwalithi ephezulu emakethe yaseChina

✓Isevisi enhle njalo kuwe, amahora angu-7*24

✓Idethi emfishane yokulethwa

✓I-MOQ encane yamukelekile futhi yamukelwe

✓Amasevisi angokwezifiso

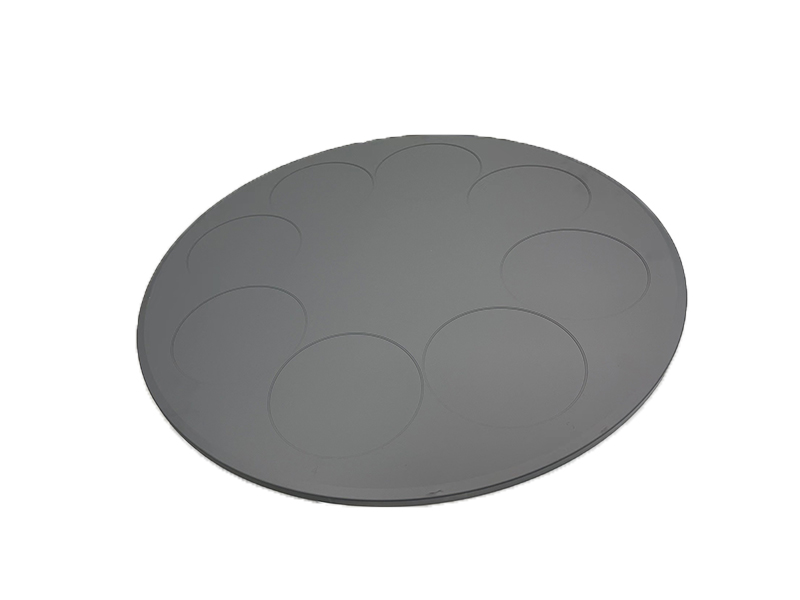

I-Epitaxy Growth Susceptor

Amawafa e-silicon/silicon carbide adinga ukudlula ezinqubweni eziningi okufanele asetshenziswe kumishini kagesi. Inqubo ebalulekile i-silicon/sic epitaxy, lapho amawafa e-silicon/sic athwalwa khona ngesisekelo segraphite. Izinzuzo ezikhethekile ze-Semicera's silicone carbide-coated graphite base zifaka ukuhlanzeka okuphezulu kakhulu, ukunamathela okufanayo, nempilo yesevisi ende kakhulu. Futhi banokuphikiswa okuphezulu kwamakhemikhali kanye nokuzinza kokushisa.

Ukukhiqizwa kwe-chip ye-LED

Ngesikhathi sokumbozwa okubanzi kwe-reactor ye-MOCVD, isisekelo seplanethi noma umthwali uhambisa i-wafer ye-substrate. Ukusebenza kwezinto eziyisisekelo kunethonya elikhulu kwikhwalithi yokugqoka, okubuye kuthinte izinga le-scrap ye-chip. Isisekelo esihlanganiswe ne-silicon carbide se-Semicera sinyusa ukusebenza kahle kokukhiqizwa kwamawafa e-LED ekhwalithi ephezulu futhi sinciphisa ukuchezuka kwamaza. Siphinde sinikeze izingxenye ezengeziwe ze-graphite zazo zonke iziphehlisi ze-MOCVD ezisetshenziswayo njengamanje. Singakwazi ukugqoka cishe noma iyiphi ingxenye nge-silicon carbide coating, noma ngabe ububanzi bengxenye bufika ku-1.5M, sisengakwazi ukugqoka nge-silicon carbide.

Inkambu yeSemiconductor, Inqubo Yokusabalalisa Kwe-oxidation, njll.

Enqubweni ye-semiconductor, inqubo yokunwetshwa kwe-oxidation idinga ukuhlanzeka okuphezulu komkhiqizo, futhi kwa-Semicera sinikeza inkambiso nezinsizakalo zokumboza ze-CVD zeningi lezingxenye ze-silicon carbide.

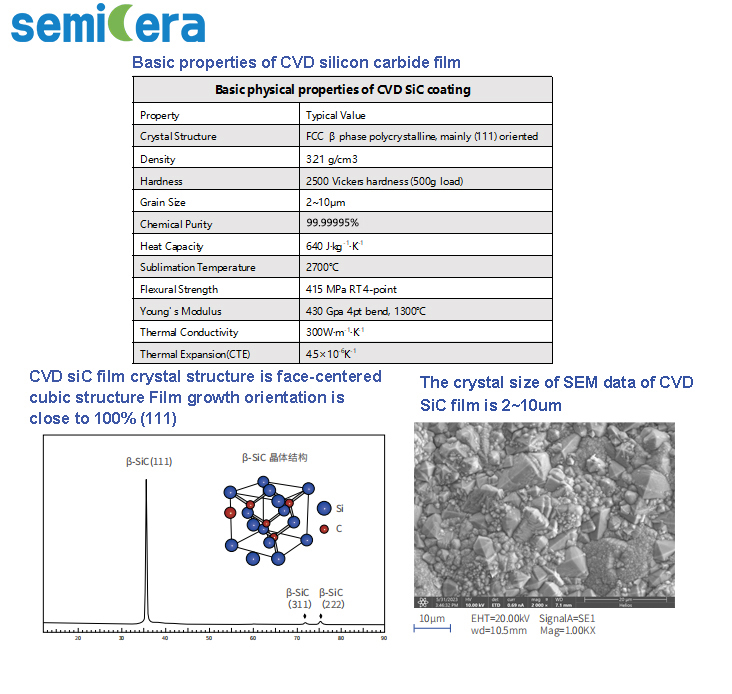

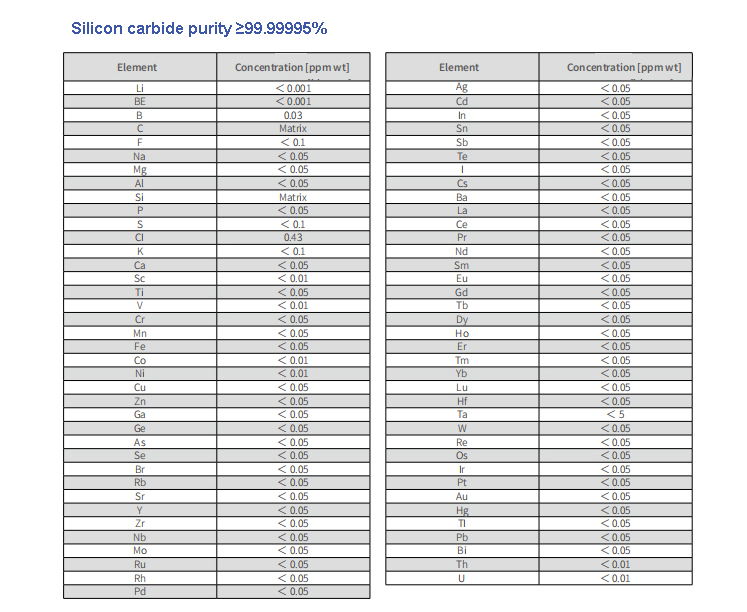

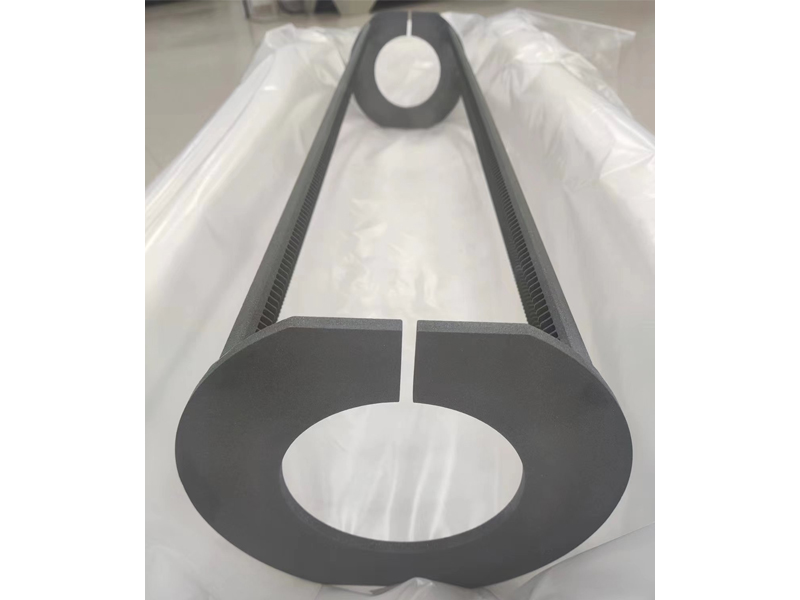

Isithombe esilandelayo sibonisa udaka lwe-silicon carbide olucutshungulwe kahle lwe-Semicea kanye neshubhu le-silicon carbide furnace elihlanzwa ku-1000-izingaengenalo uthuliigumbi. Abasebenzi bethu basebenza ngaphambi kokugqoka. Ukuhlanzeka kwe-silicon carbide yethu kungafinyelela ku-99.99%, futhi ubumsulwa be-sic coating bukhulu kuno-99.99995%.

I-Raw Silicon Carbide Paddle kanye ne-SiC Process Tube in Cleaing

I-Silicon Carbide Wafer Boat CVD SiC Coated