I-Semicera iyaziqhenya ukwethula i-Ga2O3I-substrate, into esezingeni eliphezulu esilungele ukuguqula amandla kagesi nama-optoelectronics.I-Gallium oxide (Ga2O3) ama-substrateszaziwa ngama-bandgap azo abanzi kakhulu, okuzenza zilungele amadivayisi anamandla aphezulu kanye namaza aphezulu.

Izici Eziyinhloko:

• I-Ultra-Wide Bandgap: Ga2I-O3 inikeza i-bandgap ecishe ibe ngu-4.8 eV, ithuthukisa kakhulu amandla ayo okuphatha ama-voltage aphezulu namazinga okushisa uma kuqhathaniswa nezinto ezivamile ezifana ne-Silicon ne-GaN.

• I-Voltage Yokuhlukana Okuphezulu: Ngenkambu yokwahlukana eyingqayizivele, iGa2O3I-substrateilungele amadivayisi adinga ukusebenza kwe-high-voltage, iqinisekisa ukusebenza kahle okukhulu nokuthembeka.

• Ukuzinza Kwe-Thermal: Ukuzinza kwe-thermal okuphezulu kakhulu kuyenza ifanele ukusetshenziswa ezindaweni ezibucayi, igcina ukusebenza ngisho nangaphansi kwezimo ezinzima.

• Izinhlelo Ezihlukahlukene: Ilungele ukusetshenziswa kuma-transistors amandla asebenza kahle kakhulu, amadivaysi e-UV optoelectronic, nokunye okwengeziwe, okuhlinzeka ngesisekelo esiqinile samasistimu kagesi athuthukile.

Izwa ikusasa lobuchwepheshe be-semiconductor nge-Semicera'sGa2O3I-substrate. Idizayinelwe ukuhlangabezana nezidingo ezikhulayo zama-elekthronikhi anamandla aphezulu kanye nemvamisa ephezulu, le substrate ibeka izinga elisha lokusebenza nokuqina. Themba i-Semicera ukuletha izixazululo ezintsha zezinhlelo zakho zokusebenza eziyinselele kakhulu.

| Izinto | Ukukhiqiza | Ucwaningo | Dummy |

| I-Crystal Parameters | |||

| I-Polytype | 4H | ||

| Iphutha lokuma kobuso | <11-20 >4±0.15° | ||

| Amapharamitha kagesi | |||

| I-Dopant | n-uhlobo lweNitrojeni | ||

| Ukungazweli | 0.015-0.025ohm · cm | ||

| Mechanical Parameters | |||

| Ububanzi | 150.0±0.2mm | ||

| Ubukhulu | 350±25 μm | ||

| Umumo oyisicaba oyinhloko | [1-100]±5° | ||

| Ubude obuyisicaba obuyisisekelo | 47.5±1.5mm | ||

| Ifulethi lesibili | Lutho | ||

| I-TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| I-LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Khothama | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| I-Wap | ≤35 μm | ≤45 μm | ≤55 μm |

| Front(Si-face) roughness(AFM) | I-Ra≤0.2nm (5μm*5μm) | ||

| Isakhiwo | |||

| Ukuminyana kwe-Micropipe | <1 eya/cm2 | <10 kwe/cm2 | <15 kwe/cm2 |

| Ukungcola kwensimbi | ≤5E10 ama-athomu/cm2 | NA | |

| I-BPD | ≤1500 i-e/cm2 | ≤3000 i-e/cm2 | NA |

| I-TSD | ≤500 i-e/cm2 | ≤1000 i-e/cm2 | NA |

| Ikhwalithi Yangaphambili | |||

| Ngaphambili | Si | ||

| Ukuqedwa kobuso | I-Si-face CMP | ||

| Izinhlayiya | ≤60ea/wafer (usayizi≥0.3μm) | NA | |

| Ukuklwebheka | ≤5ea/mm. Ubude obuqongelelwe ≤Ububanzi | Ubude obuqongelelwe≤2*Ububanzi | NA |

| Ikhasi eliwolintshi/imigodi/amabala/imifantu/ukungcola | Lutho | NA | |

| Ama-Edge chips/indents/fracture/hex plate | Lutho | ||

| Izindawo ze-Polytype | Lutho | Indawo eqoqiwe≤20% | Indawo eqoqiwe≤30% |

| Ukumaka kwe-laser yangaphambili | Lutho | ||

| Ikhwalithi Emuva | |||

| Emuva ekupheleni | C-face CMP | ||

| Ukuklwebheka | ≤5ea/mm, Ubude obuqongelelayo≤2*Ububanzi | NA | |

| Ukukhubazeka kwasemuva (ama-edge chips/indents) | Lutho | ||

| Ukuhwalala emuva | I-Ra≤0.2nm (5μm*5μm) | ||

| Ukumaka kwe-laser emuva | 1 mm (kusuka emaphethelweni aphezulu) | ||

| Umphetho | |||

| Umphetho | I-Chamfer | ||

| Ukupakisha | |||

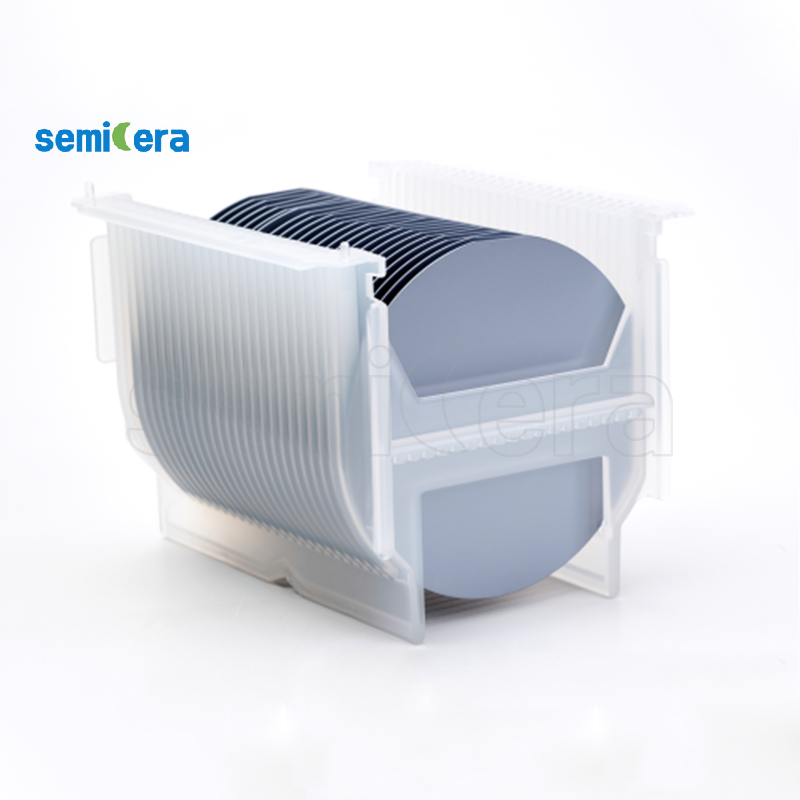

| Ukupakisha | I-Epi-ilungele ukupakishwa kwe-vacuum Ukupakishwa kwamakhasethi ama-wafer amaningi | ||

| *Amanothi: "NA" kusho ukuthi asikho isicelo Izinto ezingashiwongo zingabhekisa ku-SEMI-STD. | |||