I-Semiceraiveza ngokuziqhenya unqenqemaI-GaN Epitaxyamasevisi, aklanyelwe ukuhlangabezana nezidingo ezihlala zivela zemboni ye-semiconductor. I-Gallium nitride (GaN) iwumsebenzi owaziwa ngezici zayo ezingavamile, futhi izinqubo zethu zokukhula kwe-epitaxial ziqinisekisa ukuthi lezi zinzuzo zitholwa ngokugcwele kumadivayisi akho.

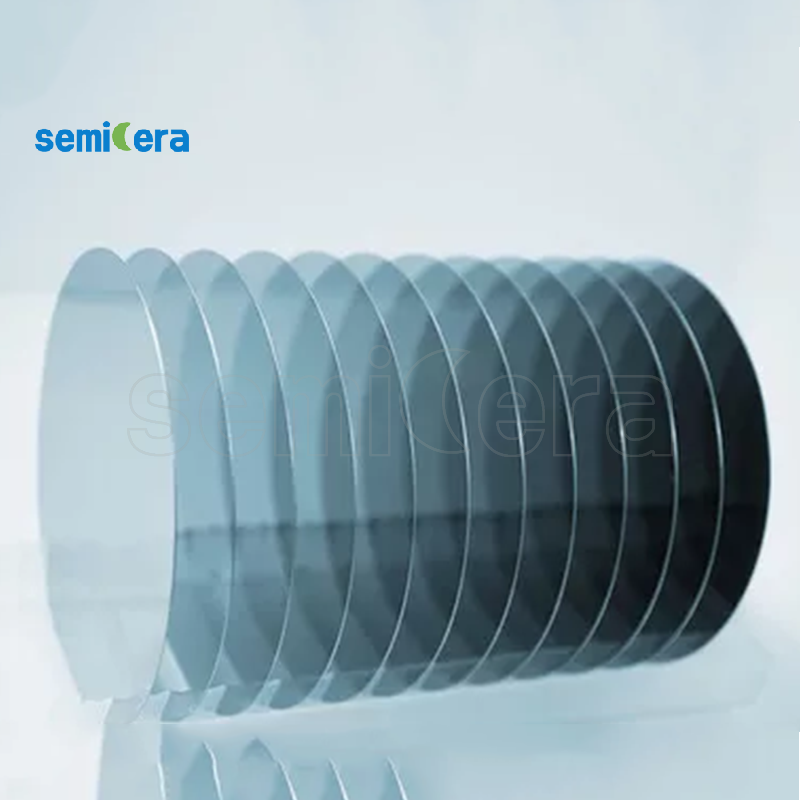

Izendlalelo ze-GaN Ezisebenza Kakhulu I-Semiceraigxile ekukhiqizeni izinga eliphezuluI-GaN Epitaxyizingqimba, ezinikeza ubumsulwa bezinto ezingenakuqhathaniswa nobuqotho besakhiwo. Lezi zingqimba zibalulekile ekusetshenzisweni okuhlukahlukene, kusukela kuma-electronics amandla kuya ku-optoelectronics, lapho ukusebenza okuphakeme nokuthembeka kubalulekile. Amasu ethu okukhula anembayo aqinisekisa ukuthi isendlalelo ngasinye se-GaN sihlangabezana nezindinganiso eziqondile ezidingekayo kumadivayisi aphambili.

Kwenzelwe Ukusebenza NgempumeleloII-GaN Epitaxyokuhlinzekwe yi-Semicera yakhelwe ngokukhethekile ukuthuthukisa ukusebenza kahle kwezingxenye zakho ze-elekthronikhi. Ngokuletha izendlalelo ze-GaN ezinesici esiphansi, ezihlanzeke kakhulu, sinika amandla amadivayisi ukuthi asebenze kumafrikhwensi aphezulu nama-voltage, ngokulahleka kwamandla okuncishisiwe. Lokhu kulungiselelwa kuyisihluthulelo sezinhlelo zokusebenza ezifana ne-high-electron-mobility transistors (HEMTs) nama-light-emitting diode (ama-LED), lapho ukusebenza kahle kubaluleke kakhulu.

Amandla Okusebenza Ahlukahlukene I-Semicera'sI-GaN Epitaxyiguquguquka, ihlinzekela uhla olubanzi lwezimboni kanye nezicelo. Kungakhathaliseki ukuthi uthuthukisa izikhulisamandla, izingxenye ze-RF, noma ama-laser diode, izendlalelo zethu ze-GaN epitaxial zinikeza isisekelo esidingekayo sokusebenza okuphezulu, amadivayisi athembekile. Inqubo yethu ingalungiselelwa ukuhlangabezana nezidingo ezithile, kuqinisekiswe ukuthi imikhiqizo yakho ithola imiphumela emihle.

Ukuzibophezela KukhwalithiIkhwalithi iyisisekelo seI-Semicera's approach toI-GaN Epitaxy. Sisebenzisa ubuchwepheshe obuthuthukisiwe bokukhula kwe-epitaxial kanye nezinyathelo zokulawula ikhwalithi eziqinile ukuze sikhiqize izendlalelo ze-GaN ezibonisa ukufana okuhle kakhulu, ukuminyana okunesici esiphansi, kanye nezakhiwo zezinto ezibonakalayo eziphezulu. Lokhu kuzibophezela kwikhwalithi kuqinisekisa ukuthi amadivayisi akho awahlangani nje kuphela kodwa adlule izindinganiso zomkhakha.

Amasu Okukhula Okusha I-Semiceraihamba phambili ekusunguleni izinto emkhakheni weI-GaN Epitaxy. Ithimba lethu liqhubeka lihlola izindlela ezintsha nobuchwepheshe bokuthuthukisa inqubo yokukhula, liletha izendlalelo ze-GaN ezinezici ezithuthukisiwe zikagesi nezokushisa. Lezi zinto ezintsha zihumushela kumadivayisi asebenza kangcono, akwazi ukuhlangabezana nezidingo zezinhlelo zokusebenza zesizukulwane esilandelayo.

Izixazululo ezenziwe ngezifiso zamaphrojekthi akhoNgokubona ukuthi iphrojekthi ngayinye inezidingo ezihlukile,I-SemiceraIzipesheli ezenziwe ngokwezifisoI-GaN Epitaxyizixazululo. Kungakhathaliseki ukuthi udinga amaphrofayili athile e-doping, ukujiya kwezingqimba, noma ukuqedwa kwendawo, sisebenza eduze nawe ukuze sithuthukise inqubo ehlangabezana nezidingo zakho ngqo. Umgomo wethu uwukukunikeza izendlalelo ze-GaN eziklanywe ngokunembile ukusekela ukusebenza nokuthembeka kwedivayisi yakho.

| Izinto | Ukukhiqiza | Ucwaningo | Dummy |

| I-Crystal Parameters | |||

| I-Polytype | 4H | ||

| Iphutha lokuma kobuso | <11-20 >4±0.15° | ||

| Amapharamitha kagesi | |||

| I-Dopant | n-uhlobo lweNitrojeni | ||

| Ukungazweli | 0.015-0.025ohm · cm | ||

| Mechanical Parameters | |||

| Ububanzi | 150.0±0.2mm | ||

| Ubukhulu | 350±25 μm | ||

| Umumo oyisicaba oyinhloko | [1-100]±5° | ||

| Ubude obuyisicaba obuyisisekelo | 47.5±1.5mm | ||

| Ifulethi lesibili | Lutho | ||

| I-TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| I-LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Khothama | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| I-Wap | ≤35 μm | ≤45 μm | ≤55 μm |

| Front(Si-face) roughness(AFM) | I-Ra≤0.2nm (5μm*5μm) | ||

| Isakhiwo | |||

| Ukuminyana kwe-Micropipe | <1 eya/cm2 | <10 kwe/cm2 | <15 kwe/cm2 |

| Ukungcola kwensimbi | ≤5E10 ama-athomu/cm2 | NA | |

| I-BPD | ≤1500 i-e/cm2 | ≤3000 i-e/cm2 | NA |

| I-TSD | ≤500 i-e/cm2 | ≤1000 i-e/cm2 | NA |

| Ikhwalithi Yangaphambili | |||

| Ngaphambili | Si | ||

| Ukuqedwa kobuso | I-Si-face CMP | ||

| Izinhlayiya | ≤60ea/wafer (usayizi≥0.3μm) | NA | |

| Ukuklwebheka | ≤5ea/mm. Ubude obuqongelelwe ≤Ububanzi | Ubude obuqongelelwe≤2*Ububanzi | NA |

| Ikhasi eliwolintshi/imigodi/amabala/imifantu/ukungcola | Lutho | NA | |

| Ama-Edge chips/indents/fracture/hex plate | Lutho | ||

| Izindawo ze-Polytype | Lutho | Indawo eqoqiwe≤20% | Indawo eqoqiwe≤30% |

| Ukumaka kwe-laser yangaphambili | Lutho | ||

| Ikhwalithi Emuva | |||

| Emuva ekupheleni | C-face CMP | ||

| Ukuklwebheka | ≤5ea/mm, Ubude obuqongelelayo≤2*Ububanzi | NA | |

| Ukukhubazeka kwasemuva (ama-edge chips/indents) | Lutho | ||

| Ukuhwalala emuva | I-Ra≤0.2nm (5μm*5μm) | ||

| Ukumaka kwe-laser emuva | 1 mm (kusuka emaphethelweni aphezulu) | ||

| Umphetho | |||

| Umphetho | I-Chamfer | ||

| Ukupakisha | |||

| Ukupakisha | I-Epi-ilungele ukupakishwa kwe-vacuum Ukupakishwa kwamakhasethi ama-wafer amaningi | ||

| *Amanothi: "NA" kusho ukuthi asikho isicelo Izinto ezingashiwongo zingabhekisa ku-SEMI-STD. | |||