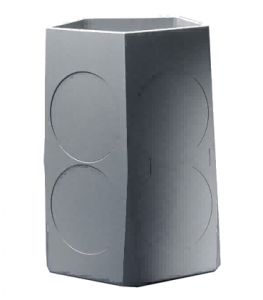

Isikebhe seSiC Wafer

Isikebhe se-silicon carbide waferiyithuluzi elithwala imithwalo lama-wafers, asetshenziswa kakhulu ezinqubweni zokusabalalisa ilanga ne-semiconductor. Inezici ezifana nokumelana nokugqoka, ukumelana nokugqwala, ukumelana nomthelela wokushisa okuphezulu, ukumelana nokuqhuma kwamabhomu e-plasma, izinga lokushisa eliphezulu elithwala amandla, ukushisa okuphezulu kwe-thermal, ukuchithwa kokushisa okuphezulu, nokusetshenziswa isikhathi eside okungelula ukugoba nokukhubazeka. Inkampani yethu isebenzisa izinto ezihlanzekile ze-silicon carbide ukuqinisekisa impilo yesevisi futhi ihlinzeka ngemiklamo eyenziwe ngokwezifiso, okuhlanganisa. ahlukahlukene mpo futhi enezingqimbaisikebhe esilucwecwana.

I-SiC Paddle

Ii-silicon carbide cantilever paddleisetshenziswa kakhulu ekunambeni (ukusabalalisa) kwama-wafers e-silicon, adlala indima ebalulekile ekulayisheni nasekuthuthweni kwamawafa e-silicon ezingeni lokushisa eliphezulu. Kuyingxenye esemqoka yeisicwecwana se-semiconductorukulayisha amasistimu futhi inezici ezilandelayo ezibalulekile:

1. Ayigogeki ezindaweni zokushisa okuphezulu futhi inamandla okulayisha aphezulu kuma-wafers;

2. Ayizwani nokubanda okukhulu nokushisa okusheshayo, futhi inomsebenzi omude wokusebenza;

3. I-coefficient yokwandisa okushisayo incane, inweba kakhulu umjikelezo wokunakekela nokuhlanza, futhi inciphisa kakhulu ukungcola.

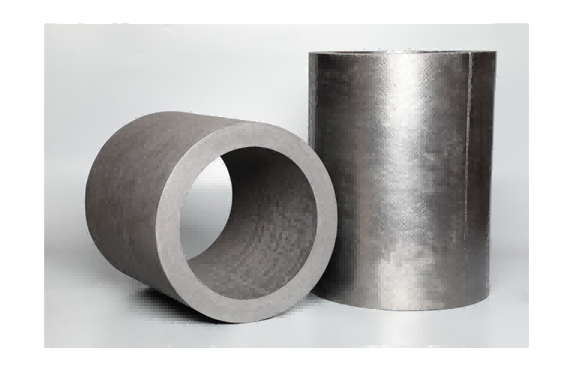

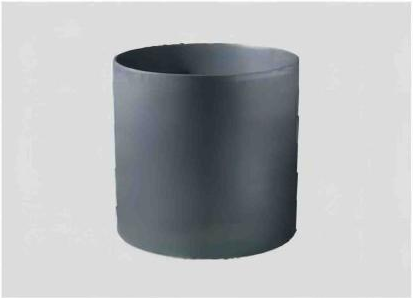

I-SiC Furnace Tube

I-Silicon carbide process tube, eyenziwe nge-high-purity SiC ngaphandle kokungcola kwensimbi, ayingcolisi i-wafer, futhi ifanele izinqubo ezifana ne-semiconductor kanye ne-photovoltaic diffusion, annealing kanye nenqubo ye-oxidation.

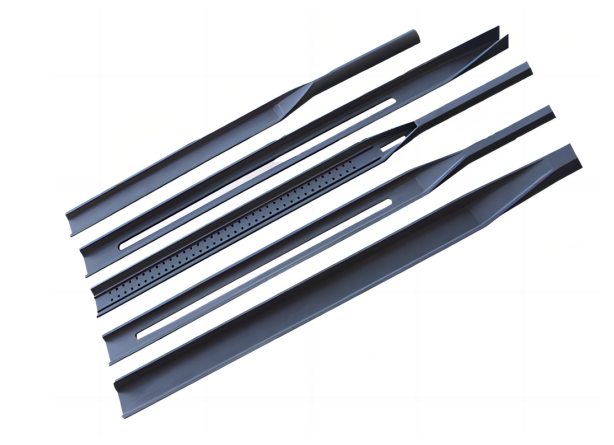

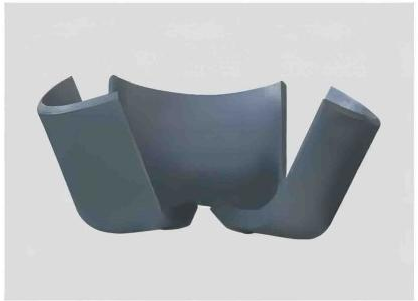

I-SiC Robot Arm

Ingalo yerobhothi ye-SiC, eyaziwa nangokuthi i-wafer transfer end effector, ingalo yerobhothi esetshenziselwa ukuthutha ama-wafers we-semiconductor futhi isetshenziswa kakhulu ku-semiconductor, i-optoelectronic, kanye nezimboni zamandla elanga. Ukusebenzisa i-silicon carbide ehlanzekile kakhulu, enobulukhuni obuphezulu, ukumelana nokugqoka, ukumelana nokuzamazama komhlaba, ukusetshenziswa kwesikhathi eside ngaphandle kokuguqulwa, impilo ende yesevisi, njll, ingahlinzeka ngezinsizakalo ezenziwe ngokwezifiso.

I-graphite yokukhula kwekristalu

I-graphite ene-three petal crucible

I-Graphite guide tube

Indandatho ye-graphite

Isivikelo sokushisa se-graphite

I-Graphite electrode tube

I-graphite deflector

I-Graphite chuck

Zonke izinqubo ezisetshenziselwa ukukhulisa ama-semiconductor crvstals zisebenza endaweni enezinga lokushisa eliphezulu kanye ne-corronary. Indawo eshisayo yesithando somlilo sekristalu ivamise ukufakwa ngobumsulwa obuphakeme obungangeni ekushiseni futhi obungagqwali. izingxenye ze-graphite, njengezifudumezi ze-graphite, ama-crucible, amasilinda, i-deflector, ama-chucks, amashubhu, izindandatho, izibambi, amantongomane, njll Umkhiqizo wethu ophelile ungafinyelela okuqukethwe komlotha ngaphansi kuka-5ppm.

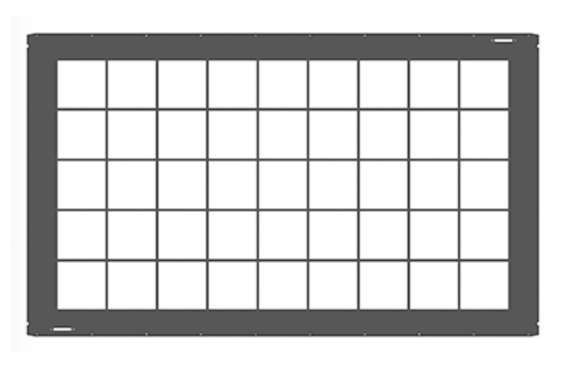

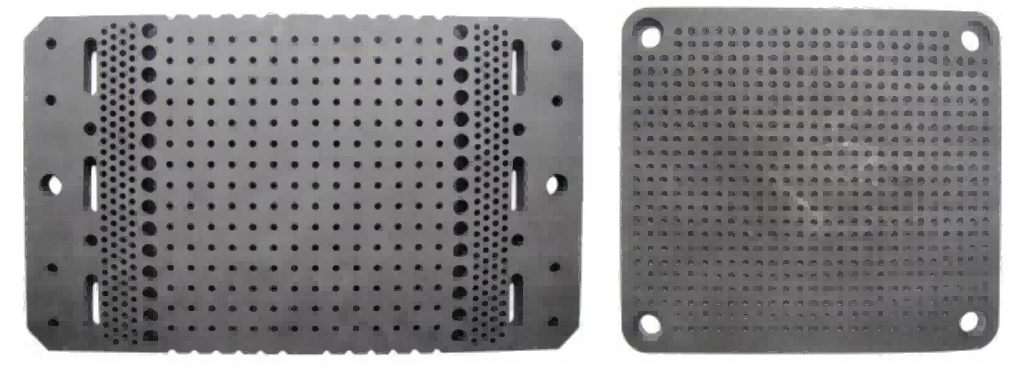

I-Graphite ye-Semidonductor Epitaxy

Izingxenye ze-MOCVD Graphite

I-Semiconductor Graphite Fixture

Inqubo ye-Epitaxial ibhekisela ekukhuleni kwe-crystal material eyodwa ku-crystal substrate eyodwa enokuhlelwa okufanayo kwe-lattice njenge-substrate. Idinga izingxenye eziningi ze-graphite zokuhlanzeka okuphezulu kakhulu kanye nesisekelo se-graphite esinokunamathela kwe-SIC. I-graphite yokuhlanzeka okuphezulu esetshenziselwa i-semiconductor epitaxy inezinhlobonhlobo zezinhlelo zokusebenza, ezingafanelana nemishini esetshenziswa kakhulu embonini, Ngesikhathi esifanayo, iphezulu kakhulu. ubumsulwa, ukunamathela okufanayo, impilo yesevisi enhle kakhulu, nokumelana namakhemikhali aphezulu kakhulu kanye nokuzinza kokushisa.

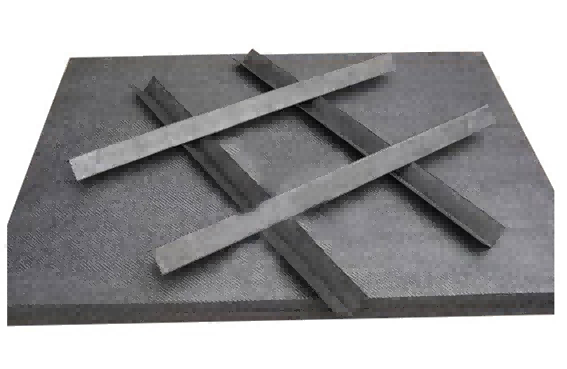

I-Insulation Material nokunye

Izinto zokufakelwa ezishisayo ezisetshenziswa ekukhiqizeni i-semiconductor ziyi-graphite ezwakalayo eqinile, ukuzwa okuthambile, i-graphite foil, izinto ezisetshenziswayo ze-carbon composite, njll. Izinto zethu zokusetshenziswa ziyizinto ze-graphite ezivela kwamanye amazwe, ezingasikwa ngokuvumelana nezinqumo zamakhasimende, futhi zingathengiswa njenge ephelele. I-Carbon composite material ivame ukusetshenziswa njengesithwali se-solar monocrystal kanye nenqubo yokukhiqiza amaseli e-polysilicon.