Izindlela zokumboza ze-photoresist zivame ukuhlukaniswa zibe i-spin coating, i-dip coating kanye ne-roll coating, phakathi kwayo i-spin coating isetshenziswa kakhulu. Ngokugcoba nge-spin, i-photoresist idonselwa ku-substrate, futhi i-substrate ingazungeziswa ngesivinini esiphezulu ukuze kutholwe ifilimu ye-photoresist. Ngemva kwalokho, ifilimu eqinile ingatholakala ngokuyishisa epuleti elishisayo. I-Spin coating ifanele ukumbozwa kusuka kumafilimu amancane kakhulu (cishe ama-20nm) kuya kumafilimu awugqinsi angaba ngu-100um. Izici zayo zifana kahle, ubukhulu befilimu obufanayo phakathi kwama-wafers, amaphutha ambalwa, njll., futhi ifilimu enokwemboza okuphezulu ingatholakala.

Spin enamathela inqubo

Phakathi ne-spin coating, isivinini esikhulu sokuzungezisa se-substrate sinquma ukushuba kwefilimu ye-photoresist. Ubudlelwano phakathi kwejubane lokuzungezisa kanye nogqinsi lwefilimu bumi kanje:

Spin=kTn

Kufomula, i-Spin isivinini sokuzungezisa; T ukujiya kwefilimu; u-k kanye no-n yizinto ezingaguquki.

Izinto ezithinta inqubo yokuhlanganisa i-spin

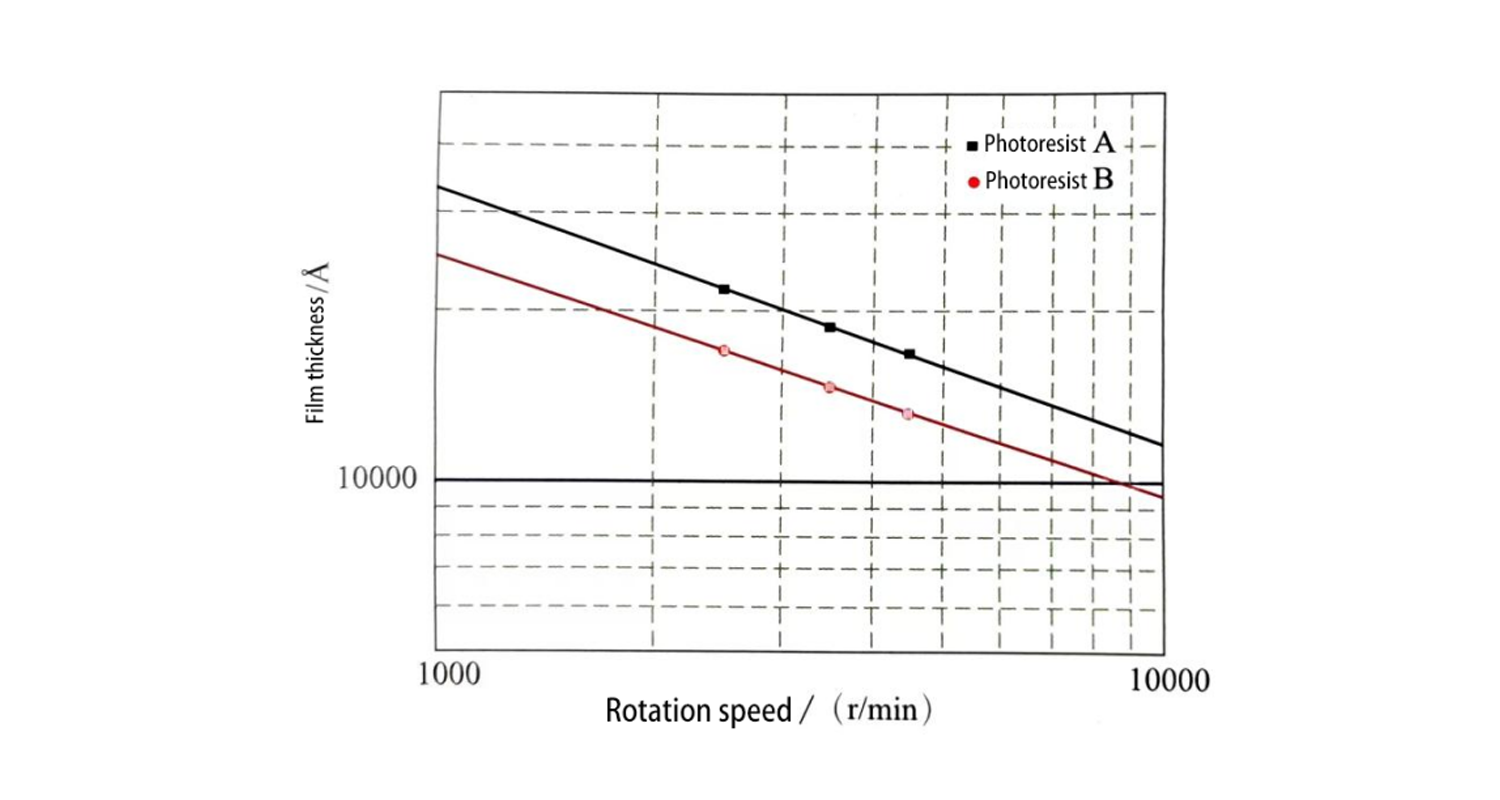

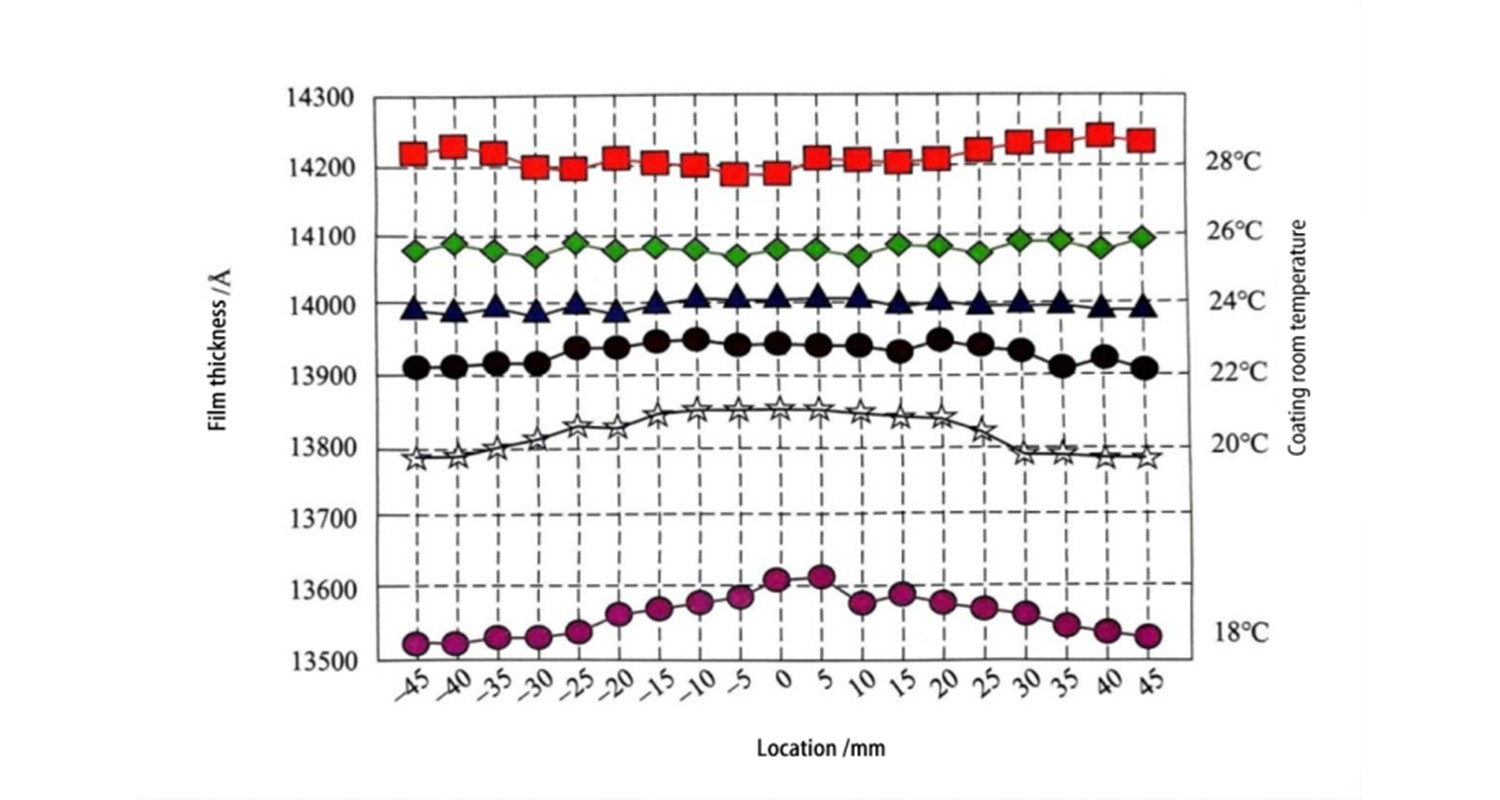

Nakuba ukushuba kwefilimu kunqunywa ijubane elikhulu lokujikeleza, liphinde lihlobene nezinga lokushisa legumbi, umswakama, i-photoresist viscosity kanye nohlobo lwe-photoresist. Ukuqhathaniswa kwezinhlobo ezihlukene zamajika enamathela e-photoresist kuboniswa kuMfanekiso 1.

Umfanekiso 1: Ukuqhathaniswa kwezinhlobo ezahlukene zamajika okugcoba ama-photoresist

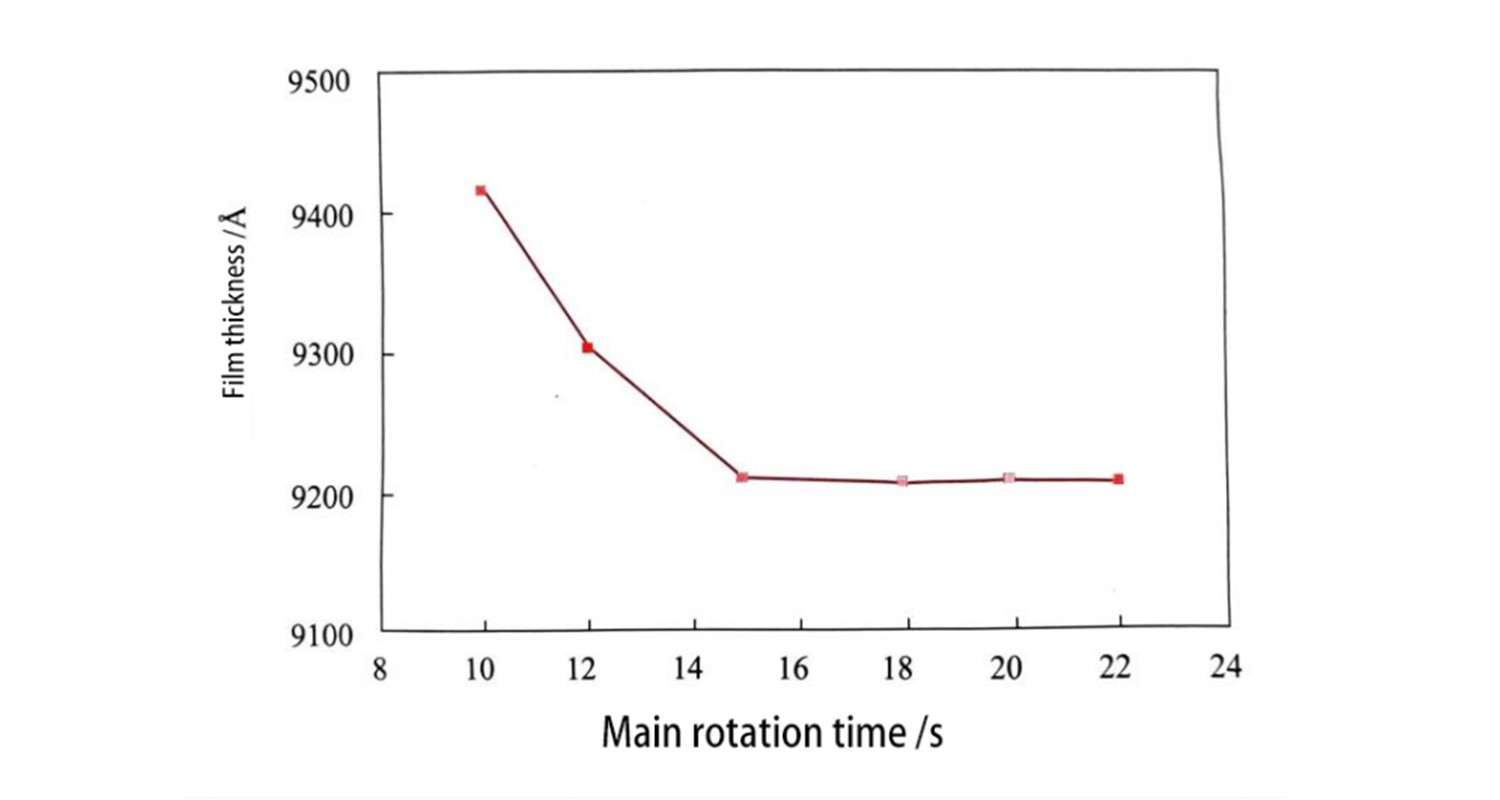

Umthelela wesikhathi sokuzungezisa esikhulu

Isikhathi esikhulu sokuzungezisa siba mfishane, sishuba kakhulu. Lapho isikhathi esiyinhloko sokujikeleza sanda, ifilimu iba mncane. Uma idlula ama-20s, ubukhulu befilimu buhlala bucishe bushintshe. Ngakho-ke, isikhathi esiyinhloko sokuzungezisa ngokuvamile sikhethwa ukuba sibe ngaphezu kwamasekhondi angu-20. Ubudlelwano phakathi kwesikhathi esiyinhloko sokuzungezisa kanye nogqinsi lwefilimu buboniswa kuMfanekiso 2.

Umfanekiso 2: Ubudlelwano phakathi kwesikhathi esiyinhloko sokuzungezisa kanye nogqinsi lwefilimu

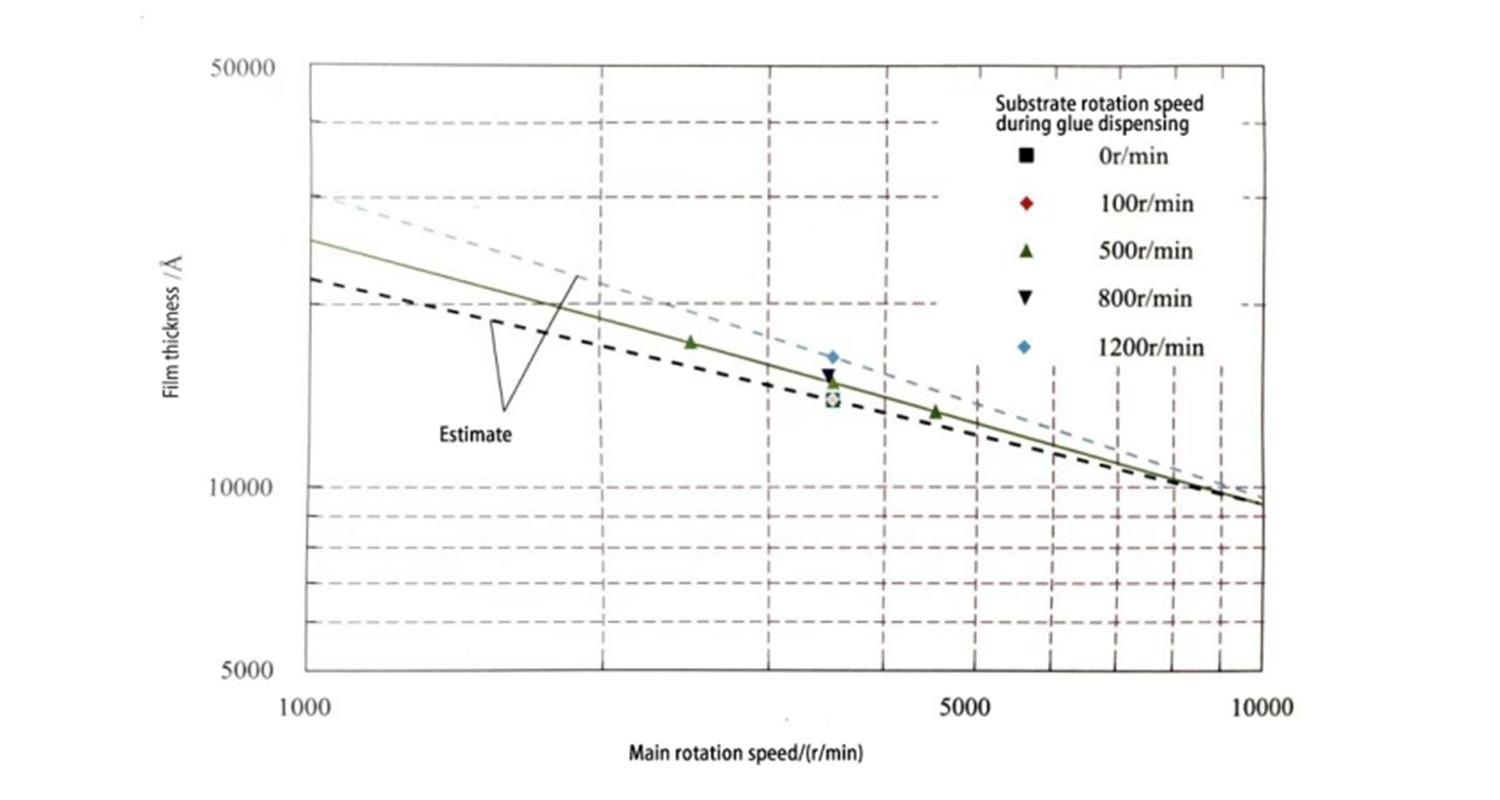

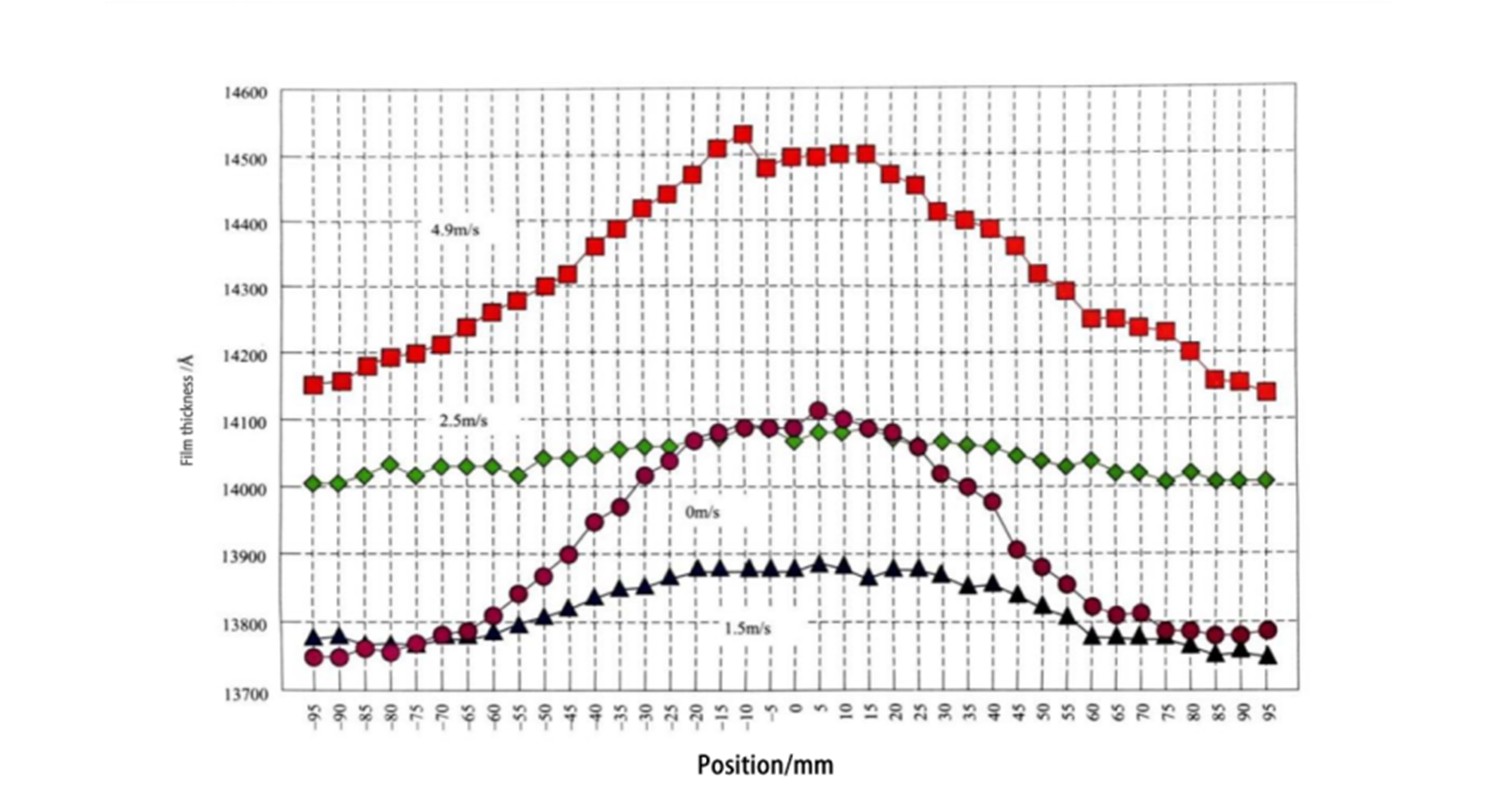

Uma i-photoresist iconselwa ku-substrate, ngisho noma isivinini sokuzungeza esiyinhloko esilandelayo siyafana, isivinini sokuzungezisa se-substrate ngesikhathi sokuconsa sizothinta ukujiya kwefilimu kokugcina. Ugqinsi lwefilimu ye-photoresist luyanda ngokukhula kwesivinini sokuzungezisa kwe-substrate ngesikhathi sokuconsa, okubangelwa umthelela wokuhwamuka kwe-solvent lapho i-photoresist imbuleka ngemva kokuconsa. Umfanekiso 3 ubonisa ubudlelwano phakathi kogqinsi lwefilimu kanye nesivinini sokuzungezisa esikhulu ngezivinini zokuzungezisa ze-substrate ngesikhathi sokuconsa kwe-photoresist. Kungabonakala emfanekisweni ukuthi ngokwanda kwejubane lokujikeleza kwe-substrate econsayo, ubukhulu befilimu bushintsha ngokushesha, futhi umehluko ubonakala ngokucacile endaweni enejubane eliphansi lokujikeleza eliyinhloko.

Umfanekiso 3: Ubudlelwano phakathi kogqinsi lwefilimu kanye nesivinini sokuzungeza esikhulu ngesivinini esihlukile sokuzungezisa i-substrate ngesikhathi sokukhipha i-photoresist.

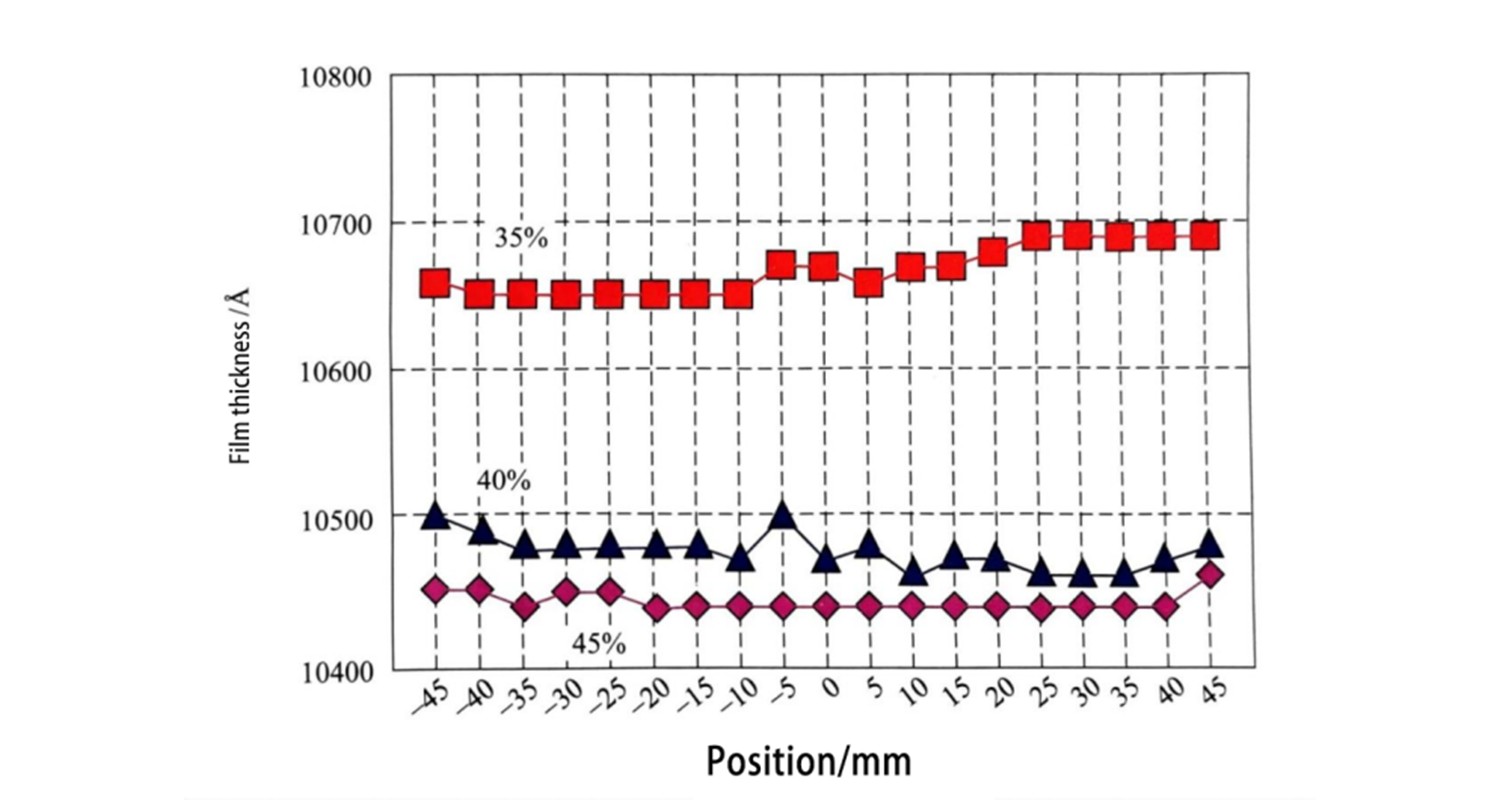

Umthelela womswakama ngesikhathi sokumboza

Lapho umswakama uyancipha, ubukhulu befilimu buyanda, ngoba ukwehla komswakama kukhuthaza ukuhwamuka kwe-solvent. Nokho, ukusatshalaliswa kogqinsi kwefilimu akushintshi kakhulu. Umfanekiso wesi-4 ubonisa ubudlelwano phakathi komswakama nokusatshalaliswa kogqinsi kwefilimu ngesikhathi sokumboza.

Umfanekiso 4: Ubudlelwano phakathi komswakamo nokusabalalisa ukushuba kwefilimu ngesikhathi sokumboza

Umthelela wezinga lokushisa ngesikhathi sokumboza

Lapho izinga lokushisa langaphakathi likhuphuka, ukushuba kwefilimu kuyanda. Kungabonakala kuMdwebo 5 ukuthi ukujiya kwefilimu ye-photoresist kuyashintsha ukusuka ku-convex kuye ku-concave. Ijika esithombeni futhi libonisa ukuthi ukufana okuphezulu kakhulu kutholakala lapho izinga lokushisa lasendlini lingu-26°C kanye nezinga lokushisa le-photoresist lingu-21°C.

Umfanekiso 5: Ubudlelwano phakathi kwezinga lokushisa nokusabalalisa ukujiya kwefilimu ngesikhathi sokumboza

Umthelela wesivinini sokukhipha umoya ngesikhathi sokumboza

Umfanekiso wesi-6 ubonisa ubudlelwano phakathi kwejubane lokuqeda amandla nokusatshalaliswa kogqinsi kwefilimu. Uma kungekho kuphelelwa amandla, kubonisa ukuthi isikhungo se-wafer sivame ukushuba. Ukwandisa isivinini sokuqeda kuzothuthukisa ukufana, kodwa uma kunyuswa kakhulu, ukufana kuzokwehla. Kungabonakala ukuthi kunevelu elilungile lejubane lokukhipha umoya.

Umfanekiso 6: Ubudlelwano phakathi kwesivinini sokuqeda kanye nokusabalalisa ubukhulu befilimu

Ukwelashwa kwe-HMDS

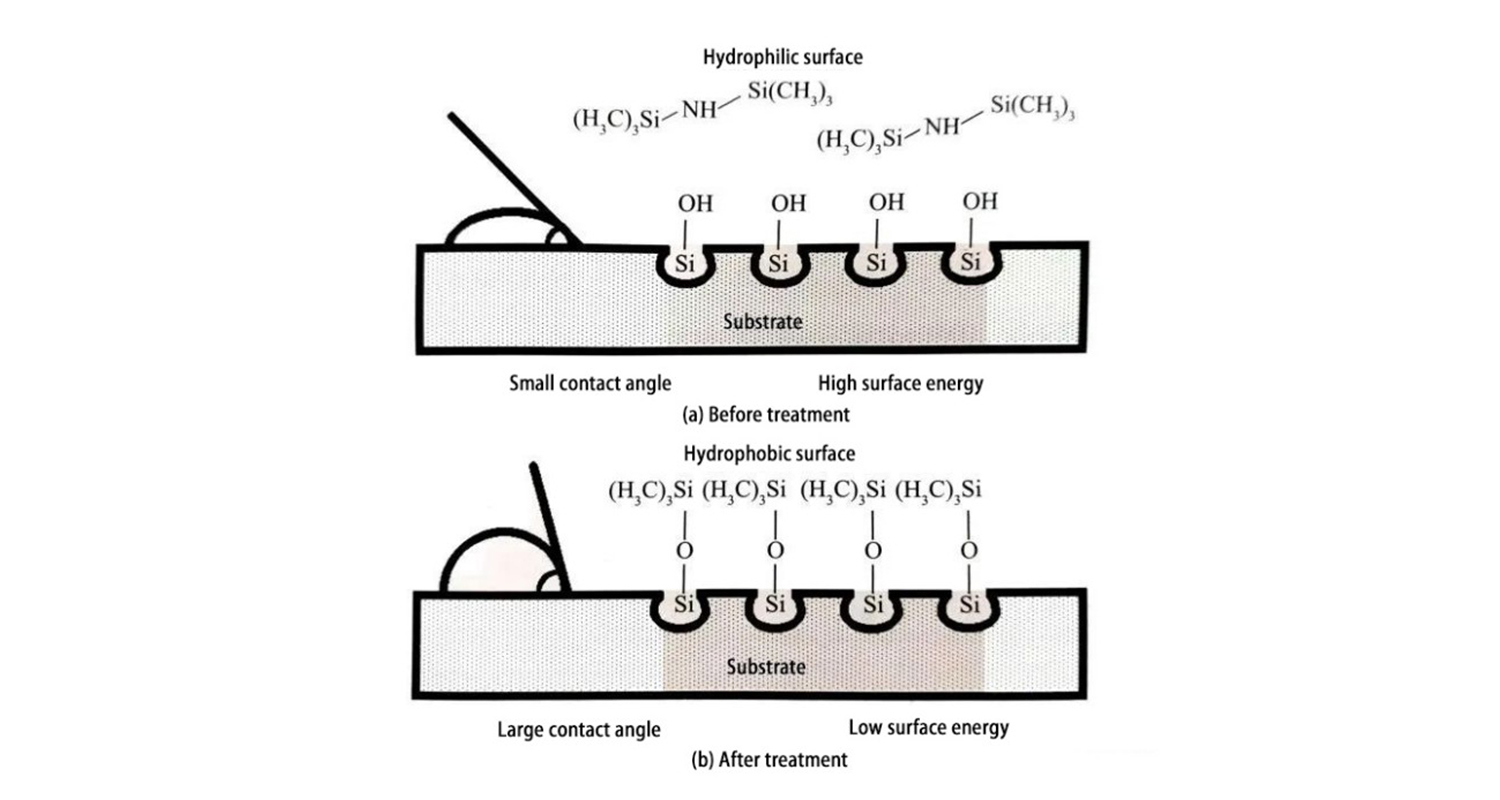

Ukuze wenze i-photoresist igqokeke kakhudlwana, iwafa idinga ukuphathwa nge-hexamethyldisilazane (HMDS). Ikakhulukazi lapho umswakama unamathele ebusweni befilimu ye-Si oxide, i-silanol iyakhiwa, okunciphisa ukunamathela kwe-photoresist. Ukuze ukhiphe umswakama futhi ubole i-silanol, i-wafer ivamise ukushiselwa ku-100-120 ° C, futhi i-HMDS yenkungu yethulwa ukuze ibangele ukusabela kwamakhemikhali. Indlela yokusabela iboniswa kuMfanekiso 7. Ngokwelashwa kwe-HMDS, indawo eyi-hydrophilic ene-engeli encane yokuxhumana iba indawo ye-hydrophobic ene-engeli enkulu yokuxhumana. Ukushisa i-wafer kungathola ukunamathela okuphezulu kwe-photoresist.

Umfanekiso 7: Indlela yokusabela ye-HMDS

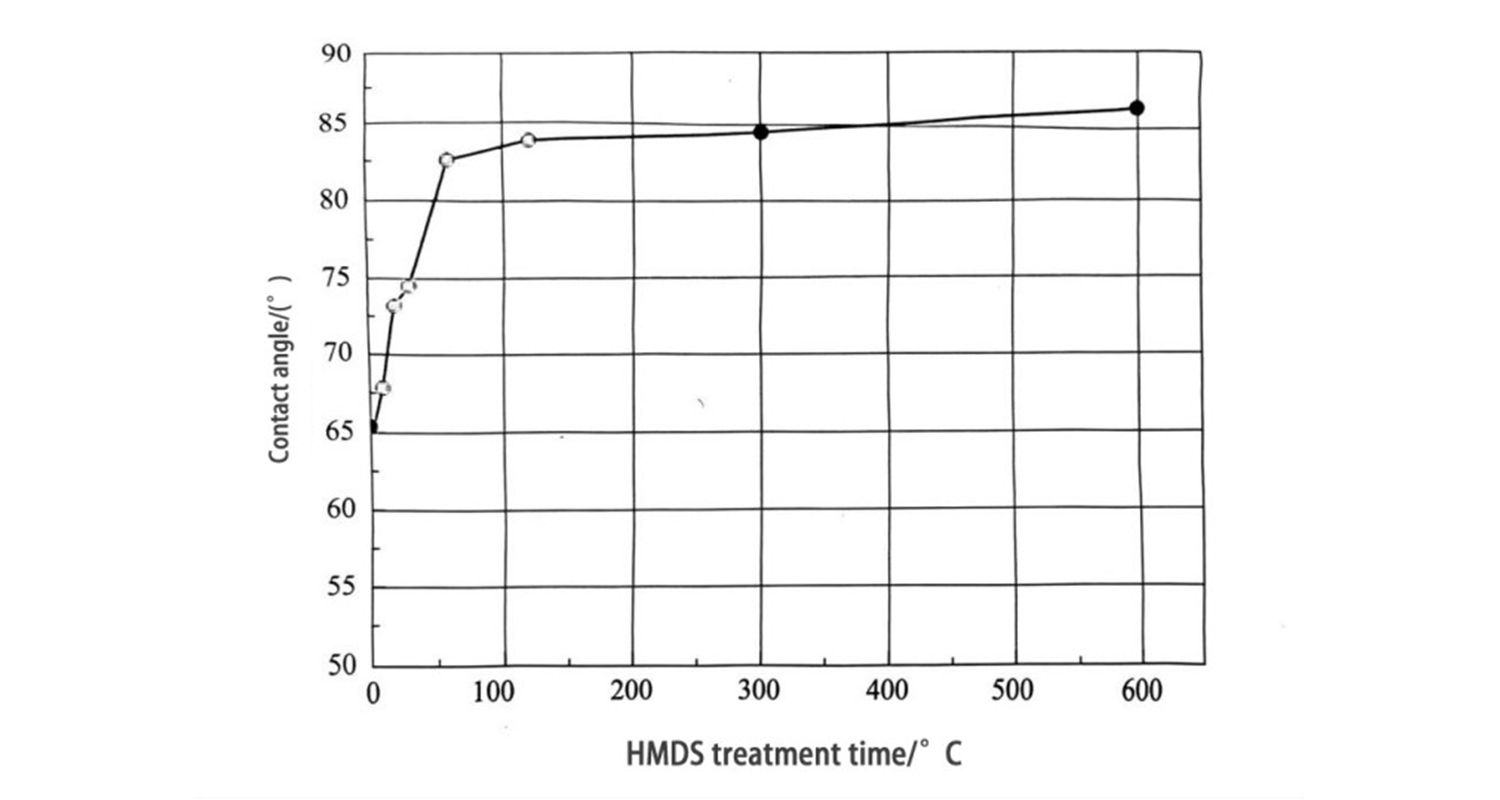

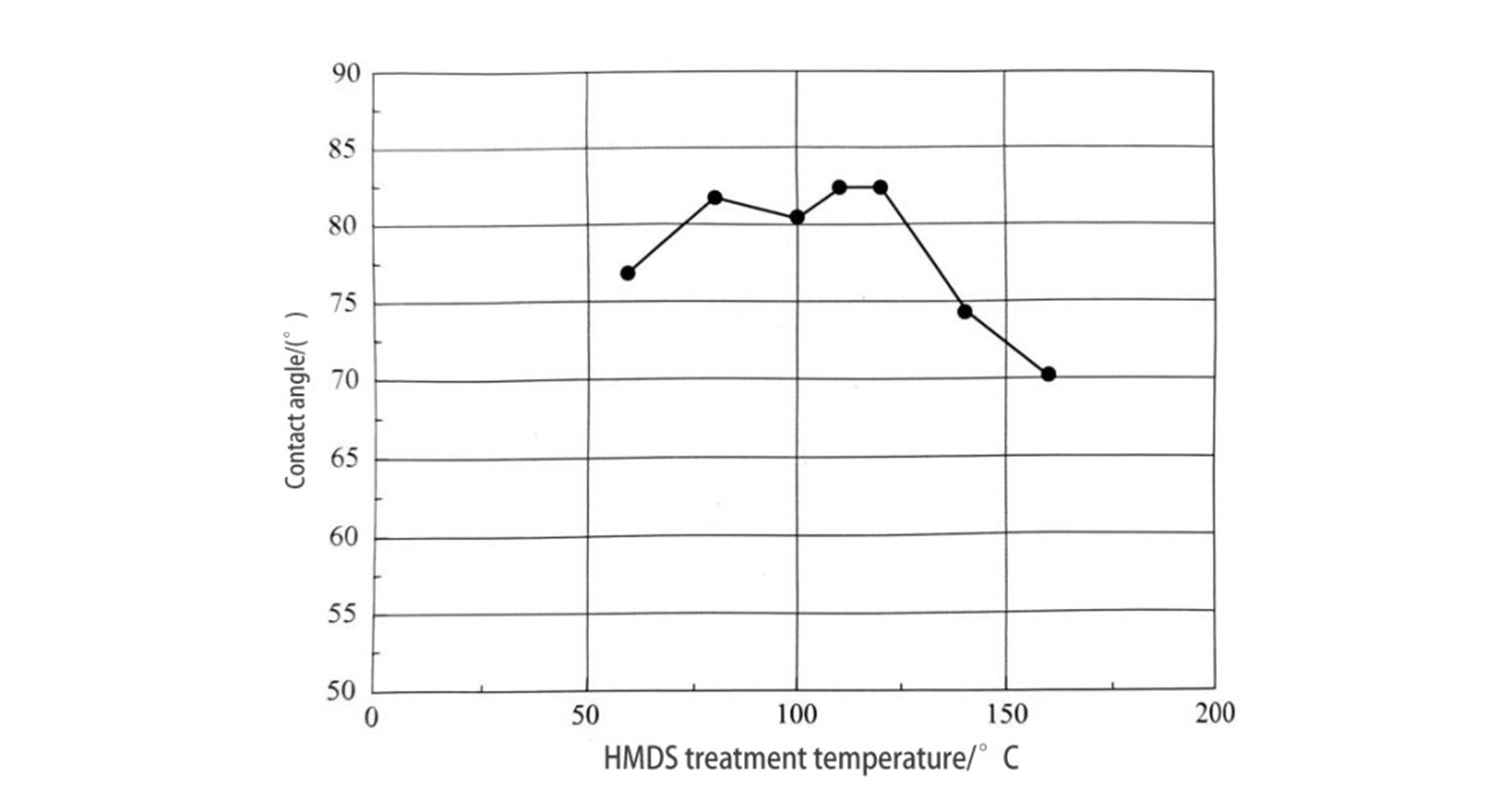

Umphumela wokwelashwa kwe-HMDS ungabonwa ngokulinganisa i-engeli yokuxhumana. Umfanekiso wesi-8 ubonisa ubudlelwano phakathi kwesikhathi sokwelashwa kwe-HMDS kanye ne-engeli yokuxhumana (izinga lokushisa lokwelapha 110°C). I-substrate i-Si, isikhathi sokwelashwa kwe-HMDS sikhulu kune-1min, i-engeli yokuxhumana inkulu kuno-80 °, futhi umphumela wokwelapha uzinzile. Umfanekiso we-9 ubonisa ubudlelwano phakathi kwezinga lokushisa lokwelashwa kwe-HMDS kanye ne-engeli yokuxhumana (isikhathi sokwelashwa ngama-60s). Uma izinga lokushisa lidlula u-120℃, i-engeli yokuxhumana iyehla, okubonisa ukuthi i-HMDS iyabola ngenxa yokushisa. Ngakho-ke, ukwelashwa kwe-HMDS kuvame ukwenziwa ku-100-110 ℃.

Umfanekiso 8: Ubudlelwano phakathi kwesikhathi sokwelashwa kwe-HMDS

kanye ne-engeli yokuxhumana (izinga lokushisa lokwelashwa 110 ℃)

Umfanekiso 9: Ubudlelwano phakathi kwezinga lokushisa lokwelashwa kwe-HMDS kanye ne-engeli yokuxhumana (isikhathi sokwelashwa 60s)

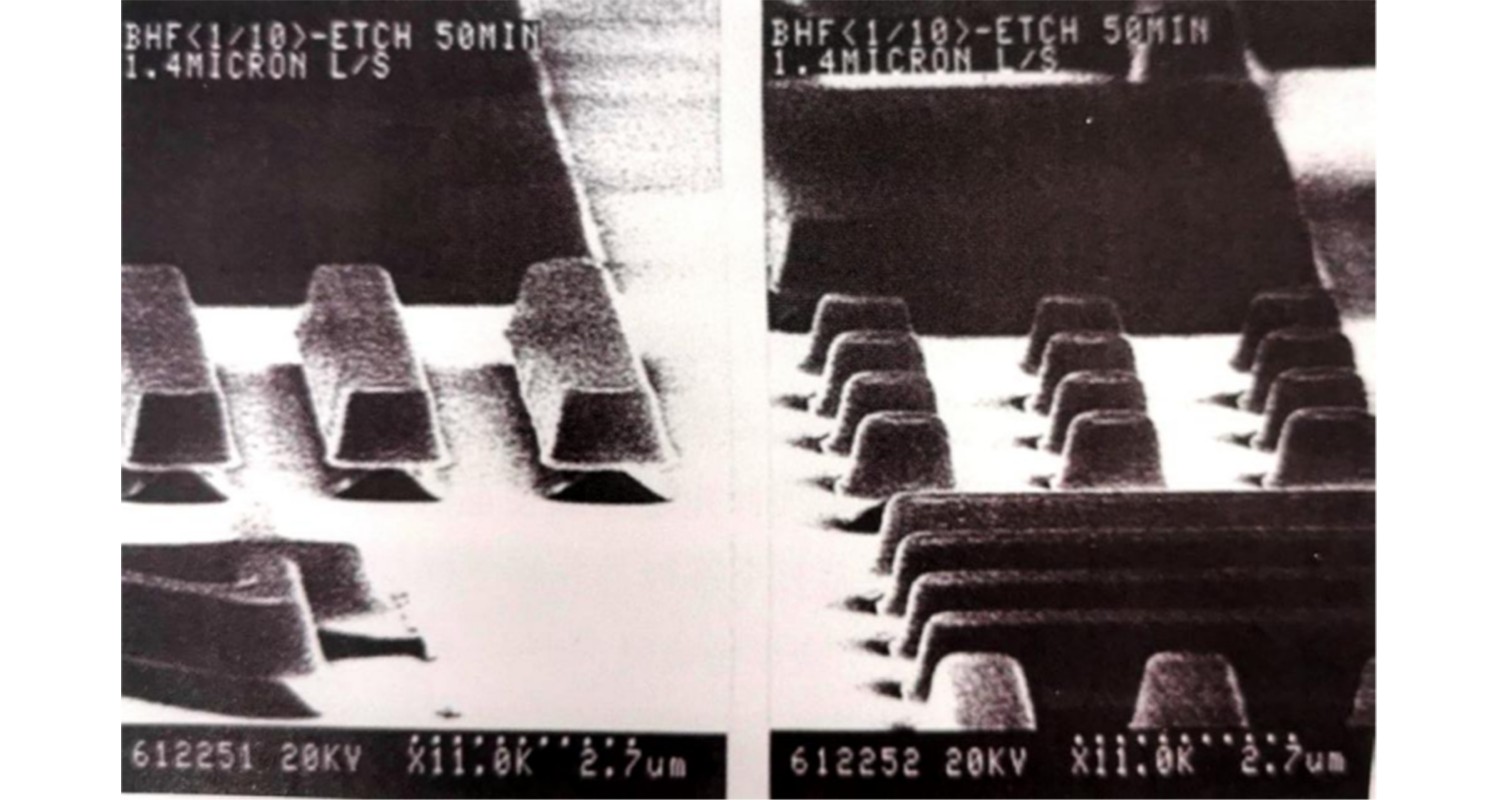

Ukwelashwa kwe-HMDS kwenziwa ku-silicon substrate enefilimu ye-oxide ukuze kwakhe iphethini ye-photoresist. Ifilimu ye-oxide ibe isiqoshwa nge-hydrofluoric acid ene-buffer eyengeziwe, futhi kutholakala ukuthi ngemva kokwelashwa kwe-HMDS, iphethini ye-photoresist ingagcinwa ukuthi ingawi. Umfanekiso we-10 ubonisa umphumela wokwelashwa kwe-HMDS (usayizi wephethini ngu-1um).

Umfanekiso 10: Umphumela wokwelapha we-HMDS (usayizi wephethini ngu-1um)

Ukubhaka kusengaphambili

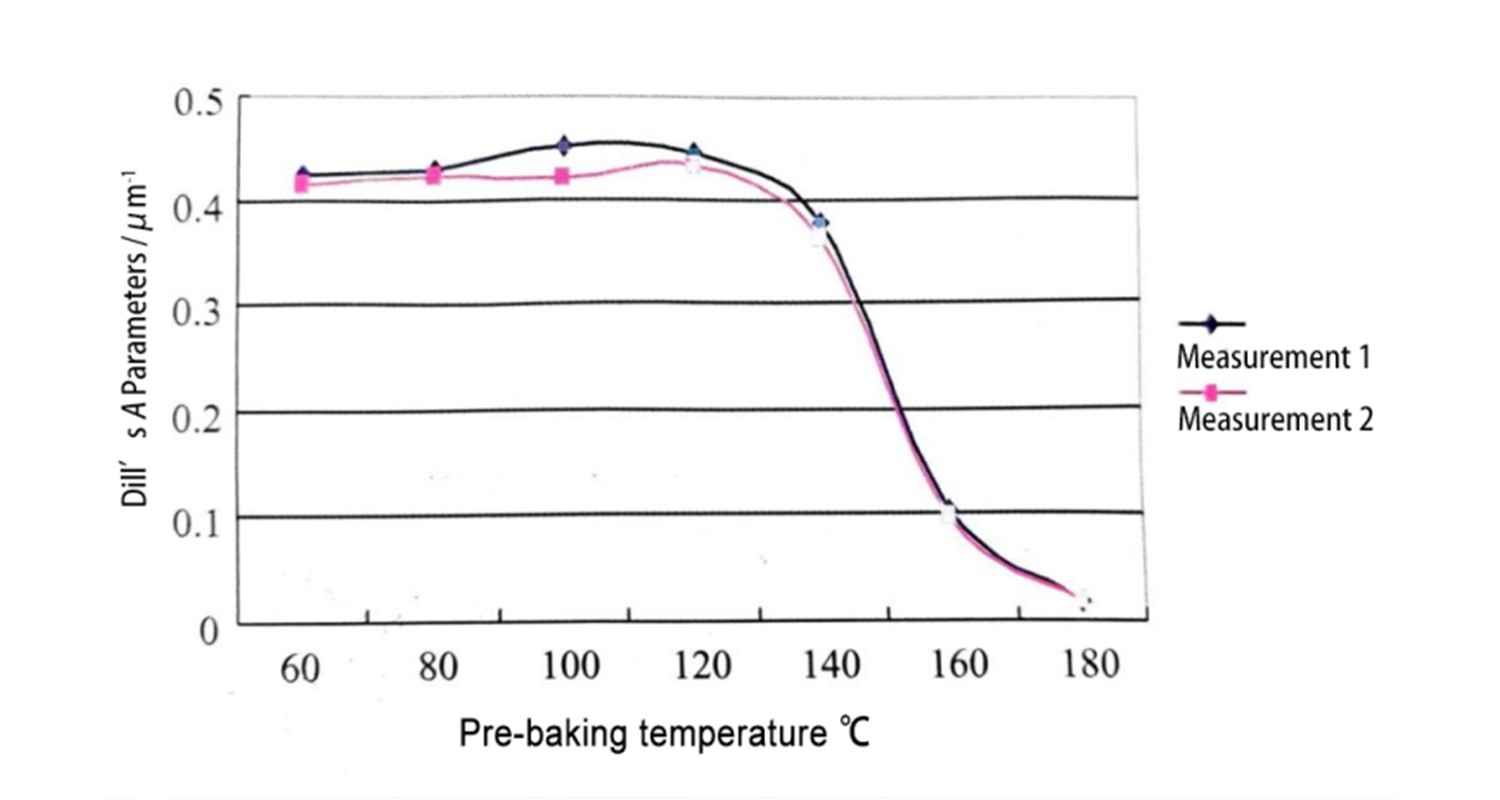

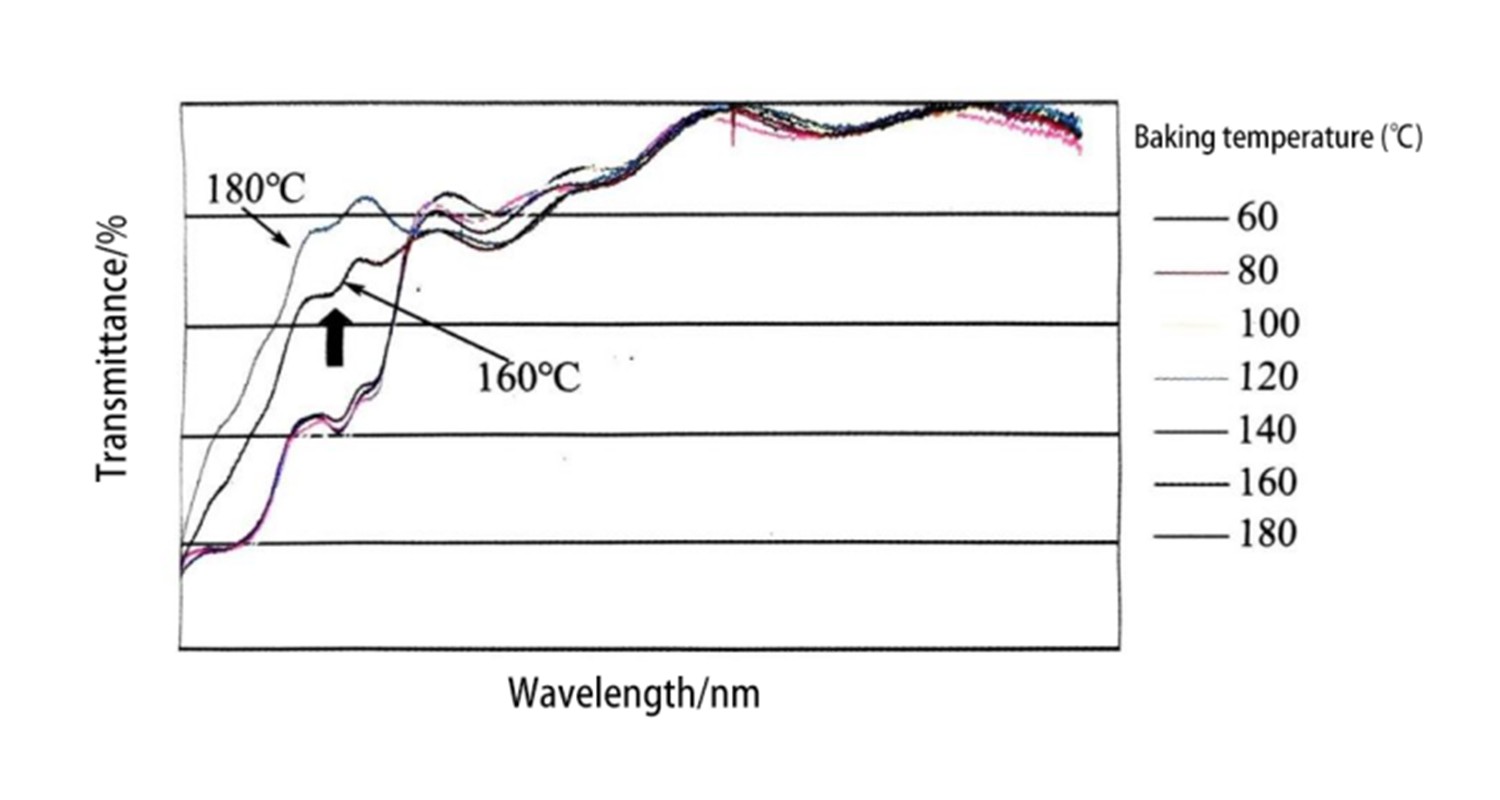

Ngejubane elifanayo lokuzungezisa, lapho izinga lokushisa lokubhaka liphezulu, liba lincane ukujiya kwefilimu, okubonisa ukuthi uma izinga lokushisa liphezulu, i-solvent iyahwamuka, okuholela ekushukeni kwefilimu encane. Umfanekiso we-11 ubonisa ubudlelwane phakathi kwezinga lokushisa langaphambi kokubhaka kanye nepharamitha ye-Dill's A. Ipharamitha engu-A ikhombisa ukugcwala kwe-ejenti ezwelayo. Njengoba kungabonakala emfanekisweni, lapho izinga lokushisa langaphambi kokubhaka likhuphukela ngaphezu kuka-140 ° C, ipharamitha ye-A iyancipha, ebonisa ukuthi i-agent ye-photosensitive ibola ekushiseni okuphezulu kunalokhu. Umfanekiso we-12 ubonisa ukudluliswa kwe-spectral emazingeni okushisa ahlukene angaphambi kokubhaka. Ku-160°C naku-180°C, ukwanda kokudluliselwa kungabonwa ebangeni le-wavelength lika-300-500nm. Lokhu kuqinisekisa ukuthi i-photosensitive agent iyabhakwa futhi ibole emazingeni okushisa aphezulu. Izinga lokushisa langaphambi kokubhaka linenani elifanele, elinqunywa izici zokukhanya nokuzwela.

Umfanekiso 11: Ubudlelwano phakathi kwezinga lokushisa langaphambi kokubhaka kanye nepharamitha ye-Dill's A

(inani elilinganiselwe lika-OFPR-800/2)

Umfanekiso 12: I-Spectral transmittance emazingeni okushisa ahlukene angaphambi kokubhaka

(OFPR-800, 1um ukujiya kwefilimu)

Ngamafuphi, indlela yokugcoba i-spin inezinzuzo eziyingqayizivele njengokulawula okunembile kokuqina kwefilimu, ukusebenza kwezindleko eziphezulu, izimo zenqubo emnene, nokusebenza okulula, ngakho-ke kunemiphumela ebalulekile ekunciphiseni ukungcola, ukonga amandla, nokuthuthukisa ukusebenza kwezindleko. Eminyakeni yamuva nje, i-spin coating ibilokhu ithola ukunakwa okwandayo, futhi ukusetshenziswa kwayo kuye kwasakazeka kancane kancane emikhakheni ehlukahlukene.

Isikhathi sokuthumela: Nov-27-2024