Enqubweni yokukhiqiza i-semiconductor,etchingubuchwepheshe buyinqubo ebucayi esetshenziselwa ukususa ngokunembile izinto ezingafuneki ku-substrate ukuze kwakhiwe amaphethini esekethe ayinkimbinkimbi. Lesi sihloko sizokwethula ngokuningiliziwe ubuchwepheshe obubili bokuhlanganisa okujwayelekile - i-capacitively coupled plasma etching (CCP) kanye ne-inductively coupled plasma etching (I-ICP), futhi uhlole izinhlelo zabo zokusebenza ekujuleni izinto ezahlukahlukene.

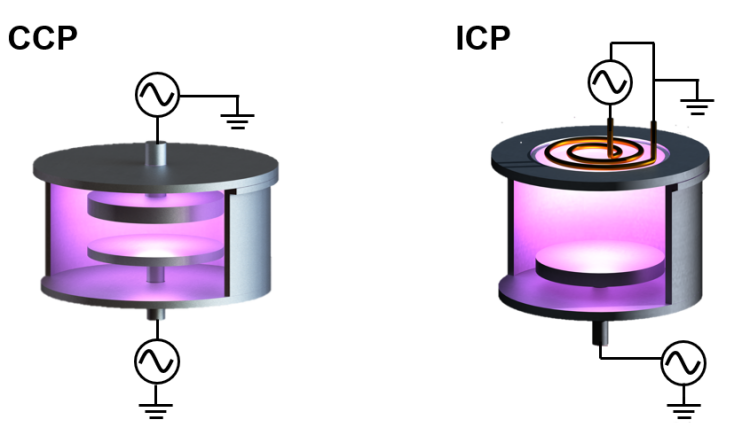

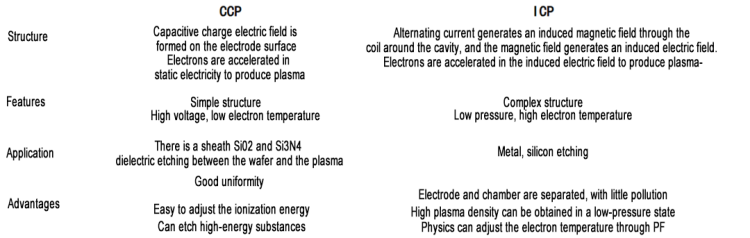

Ukufakwa kwe-plasma okuhlanganiswe ngokunamandla (CCP)

I-Capacitively coupled plasma etching (CCP) ifinyelelwa ngokusebenzisa amandla kagesi e-RF kuma-electrode amapuleti amabili ahambisanayo ngokusebenzisa i-matcher kanye ne-DC blocking capacitor. Ama-electrode amabili ne-plasma ndawonye akha i-capacitor elinganayo. Kule nqubo, i-RF voltage yenza i-capacitive sheath eduze kwe-electrode, futhi umngcele we-sheath uyashintsha ngokuzulazula okusheshayo kwe-voltage. Lapho ama-electron efinyelela kulesi sigqoko esishintsha ngokushesha, ayaboniswa futhi athole amandla, okubangela ukuhlukana noma i-ionization yama-molecule egesi ukuze akhe i-plasma. I-CCP etching ngokuvamile isetshenziswa ezintweni ezinamandla amakhulu ebhondi yamakhemikhali, njengama-dielectrics, kodwa ngenxa yezinga layo eliphansi lokunamathisela, ilungele izinhlelo zokusebenza ezidinga ukulawulwa okuhle.

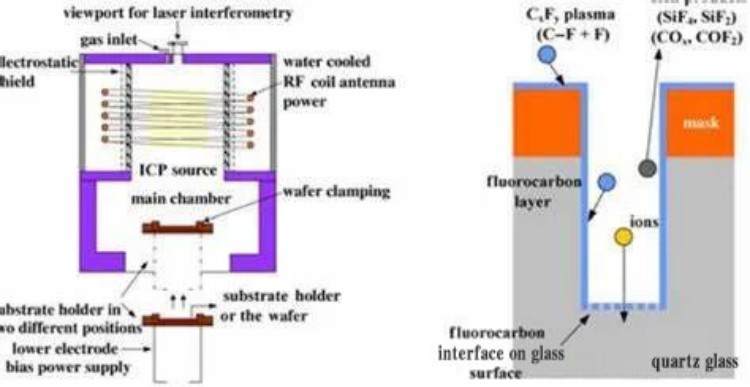

I-Plasma etching (ICP) ehlanganiswe nge-inductively

I-Plasma ehlanganisiwe ngokuzenzakalelayoetching(I-ICP) isekelwe kumgomo wokuthi i-alternating current idlula ikhoyili ukuze ikhiqize inkambu kazibuthe. Ngaphansi kwesenzo sale nsimu kazibuthe, ama-electron egunjini lokusabela ayashesha futhi aqhubeke nokusheshisa endaweni kagesi eyenziwe, agcine eshayisana nama-molecule egesi okusabela, okubangela ukuba ama-molecule ahlukane noma enze i-ionize futhi akhe i-plasma. Le ndlela ingakhiqiza izinga eliphezulu le-ionization futhi ivumele ukuminyana kwe-plasma namandla ebhomu ukuze kulungiswe ngokuzimela, okwenzaUkufakwa kwe-ICPilungele kakhulu izinto zokuqopha ezinamandla aphansi esibopho samakhemikhali, njenge-silicon nensimbi. Ngaphezu kwalokho, ubuchwepheshe be-ICP buhlinzeka ngokufana okungcono kanye nesilinganiso sokufaka.

1. Ukuhutshwa kwensimbi

I-Metal etching isetshenziswa kakhulu ekucubunguleni izixhumi kanye nezintambo zensimbi ezinezingqimba eziningi. Izidingo zayo zifaka: izinga lokuqoshwa okuphezulu, ukukhetha okuphezulu (okungaphezu kuka-4:1 kungqimba lwemaski nangaphezulu kuka-20:1 we-interlayer dielectric), ukufana okuphezulu kokushumeka, ukulawulwa okuhle kobukhulu obubalulekile, akukho monakalo we-plasma, ukungcola okuncane okuyinsalela, kanye akukho ukugqwala kwensimbi. Ukufakwa kwensimbi ngokuvamile kusebenzisa imishini yokuhlanganisa i-plasma ehlanganisiwe.

•I-Aluminium etching: I-Aluminium iyinto ebaluleke kakhulu yocingo phakathi nezigaba ezingemuva zokwenziwa kwe-chip, enezinzuzo zokungazweli okuphansi, ukufakwa kalula kanye nokushumeka. I-aluminium etching ngokuvamile isebenzisa i-plasma ekhiqizwa igesi ye-chloride (njenge-Cl2). I-Aluminium ihlangana ne-chlorine ukuze ikhiqize i-aluminium chloride eshintshashintshayo (AlCl3). Ngaphezu kwalokho, amanye ama-halide afana ne-SiCl4, BCl3, BBr3, CCl4, CHF3, njll.

• I-Tungsten etching: Ezakhiweni zokuxhuma izintambo zensimbi ezinezingqimba eziningi, i-tungsten iyinsimbi eyinhloko esetshenziselwa ukuxhuma kwengxenye emaphakathi yeshiphu. Amagesi asekelwe ku-fluorine noma asekelwe ku-chlorine angasetshenziswa ukufaka i-tungsten yensimbi, kodwa amagesi asekelwe ku-fluorine awakwazi ukukhetha kahle i-silicon oxide, kuyilapho amagesi asekelwe ku-chlorine (njenge-CCl4) enokukhetha okungcono. I-nitrogen ivamise ukungezwa kwigesi yokusabela ukuze kutholwe ukukhetha kweglue etching ephezulu, bese kufakwa umoya-mpilo ukuze kuncishiswe ukufakwa kwekhabhoni. Ukufaka i-tungsten ngegesi esekwe ku-chlorine kungafinyelela i-anisotropic etching kanye nokukhetha okuphezulu. Amagesi asetshenziswa ekufakweni okomile kwe-tungsten ikakhulukazi i-SF6, i-Ar ne-O2, phakathi kwayo i-SF6 ingaboliswa ku-plasma ukuze kuhlinzekwe ama-athomu e-fluorine kanye ne-tungsten yokusabela kwamakhemikhali ukukhiqiza i-fluoride.

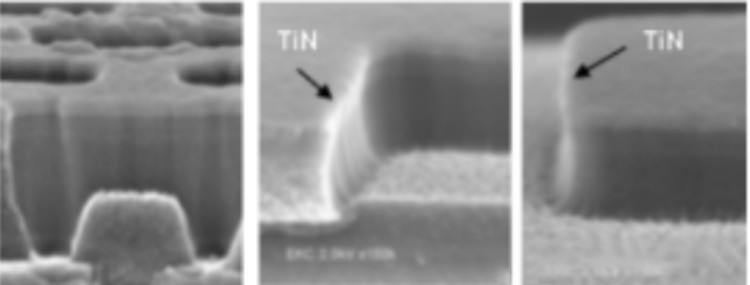

• I-Titanium nitride etching: I-Titanium nitride, njengemaski eqinile, ithatha indawo ye-silicon nitride noma imaski ye-oxide enqubweni ye-damascene ekabili. I-Titanium nitride etching isetshenziswa kakhulu ohlelweni lokuvula imaski eqinile, futhi umkhiqizo oyinhloko wokusabela yi-TiCl4. Ukukhetha phakathi kwemaski yendabuko kanye nesendlalelo se-dielectric ephansi-k akuphezulu, okuzoholela ekubukeni kwephrofayili emise okwe-arc phezulu kwesendlalelo se-dielectric ephansi-k kanye nokwandiswa kobubanzi begroove ngemva kokucwiliswa. Isikhala phakathi kwemigqa yensimbi efakiwe sincane kakhulu, esijwayele ukuvuza kwebhuloho noma ukuphuka okuqondile.

2. Ukufakwa kwe-insulator

Into ye-insulator etching imvamisa izinto ze-dielectric ezifana ne-silicon dioxide noma i-silicon nitride, ezisetshenziswa kabanzi ukwakha izimbobo zokuthintana nezimbobo zesiteshi ukuxhuma izingqimba zesekethe ezihlukene. I-Dielectric etching ngokuvamile isebenzisa i-etcher esekelwe kumgomo wokucwiliswa kwe-plasma okuhlanganiswe nge-capacitively.

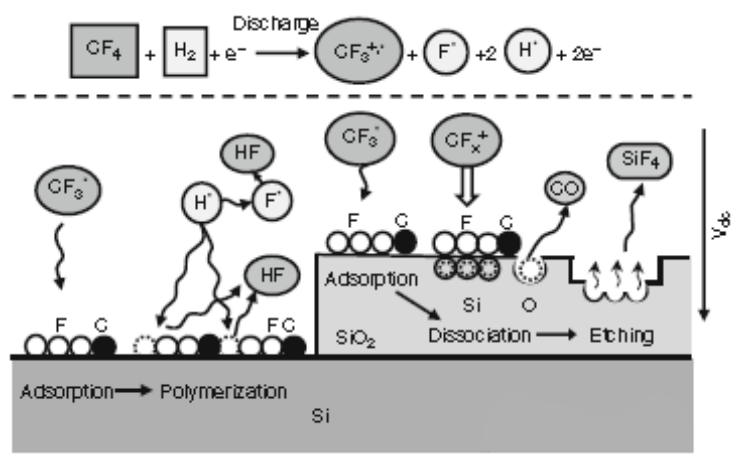

• Ukufakwa kwe-Plasma kwefilimu ye-silicon dioxide: Ifilimu ye-Silicon dioxide ivamise ukufakwa kusetshenziswa amagesi e-etching aqukethe i-fluorine, njenge-CF4, CHF3, C2F6, SF6 kanye ne-C3F8. Ikhabhoni equkethwe kugesi ebambayo ingasabela komoya-mpilo kungqimba lwe-oxide ukuze ikhiqize imikhiqizo engaphansi kwe-CO ne-CO2, ngaleyo ndlela isuse umoya-mpilo ongqimbeni lwe-oxide. I-CF4 iyigesi esetshenziswa kakhulu etching. Lapho i-CF4 ishayisana nama-electron anamandla amakhulu, ama-ion ahlukahlukene, ama-radicals, ama-athomu nama-radicals mahhala akhiqizwa. Ama-radicals mahhala e-fluorine angasabela ngamakhemikhali nge-SiO2 kanye ne-Si ukuze akhiqize i-silicon tetrafluoride eguqukayo (SiF4).

• Ukufakwa kwe-Plasma kwefilimu ye-silicon nitride: Ifilimu ye-Silicon nitride ingacushwa kusetshenziswa i-plasma etching nge-CF4 noma i-CF4 exutshwe igesi (ene-O2, SF6 ne-NF3). Ngefilimu ye-Si3N4, lapho i-plasma ye-CF4-O2 noma enye i-plasma yegesi equkethe ama-athomu ka-F isetshenziselwa ukushumeka, izinga lokunamathisela le-silicon nitride lingafinyelela ku-1200Å/min, futhi ukukhetha okubambayo kungaba phezulu njengokungu-20:1. Umkhiqizo oyinhloko yi-silicon tetrafluoride eguqukayo (SiF4) okulula ukuyikhipha.

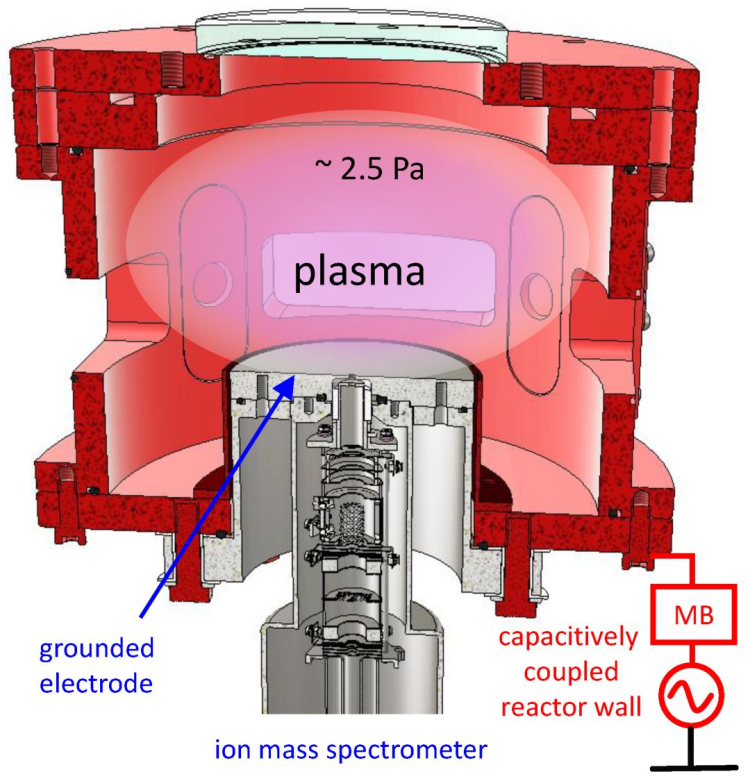

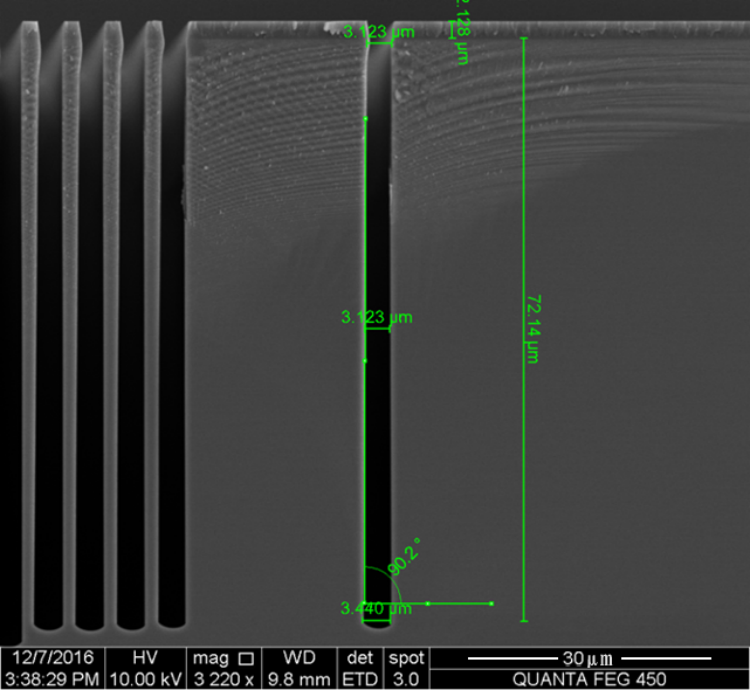

3. I-Single crystal silicon etching

I-Single crystal silicon etching isetshenziswa kakhulu ukwenza i-shallow trench isolation (STI). Le nqubo ngokuvamile ihlanganisa inqubo yempumelelo kanye nenqubo yokubhala eyinhloko. Inqubo yokuphumelela isebenzisa igesi ye-SiF4 ne-NF ukuze isuse ungqimba lwe-oxide ebusweni be-silicon eyodwa yekristalu ngokusebenzisa i-ion bombardment enamandla kanye nesenzo samakhemikhali sezakhi ze-fluorine; i-etching eyinhloko isebenzisa i-hydrogen bromide (HBr) njenge-etchant eyinhloko. Ama-bromine radicals aboliswa yi-HBr endaweni ye-plasma asabela ne-silicon ukuze akhe i-silicon tetrabromide eshintshashintshayo (SiBr4), ngaleyo ndlela isuse i-silicon. I-Single crystal silicon etching ivamise ukusebenzisa umshini wokufaka i-plasma ohlanganiswe ngendlela ethokozisayo.

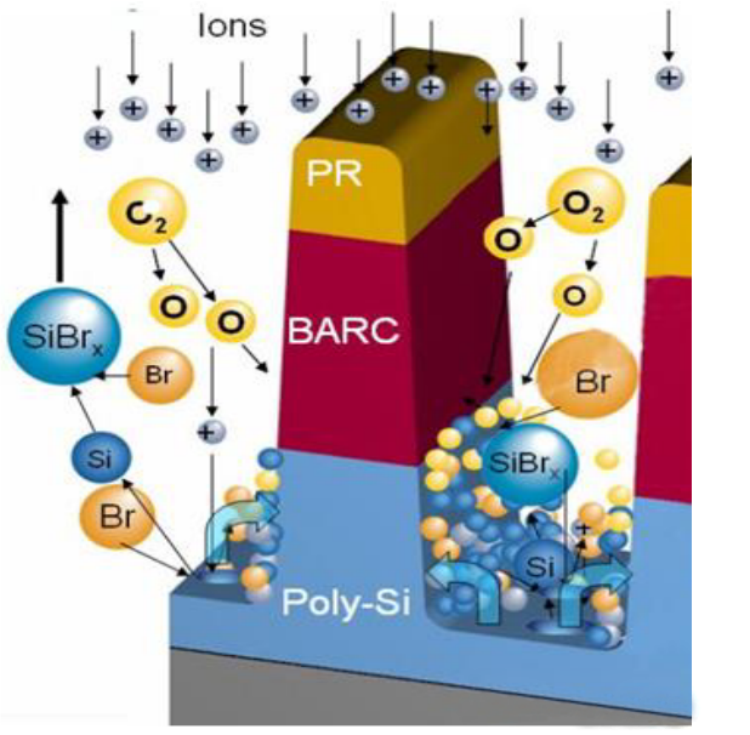

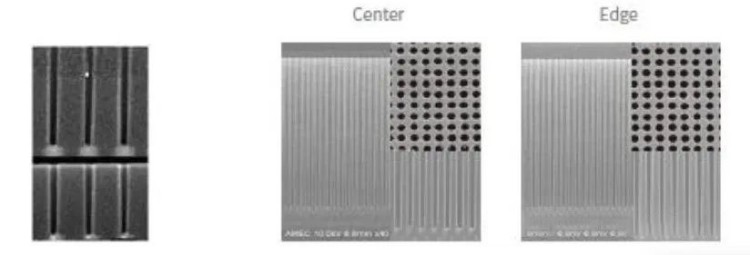

4. I-Polysilicon Etching

I-Polysilicon etching ingenye yezinqubo ezibalulekile ezinquma usayizi wesango lama-transistors, futhi usayizi wesango uthinta ngqo ukusebenza kwamasekethe ahlanganisiwe. I-Polysilicon etching idinga isilinganiso esihle sokukhetha. Amagesi e-halogen afana ne-chlorine (Cl2) ngokuvamile asetshenziselwa ukufeza i-anisotropic etching, futhi abe nesilinganiso esihle sokukhetha (kufika ku-10:1). Amagesi asuselwa ku-Bromine njenge-hydrogen bromide (HBr) angathola isilinganiso esiphezulu sokukhetha (kufika ku-100:1). Ingxube ye-HBr ne-chlorine nomoya-mpilo ingakhuphula izinga lokushaya. Imikhiqizo yokusabela yegesi ye-halogen ne-silicon ifakwa emaceleni ukuze idlale indima yokuvikela. I-polysilicon etching ivamise ukusebenzisa umshini wokufaka i-plasma ohlanganiswe ngokungenasici.

Kungakhathaliseki ukuthi i-plasma etching ehlanganiswe ngokunamandla noma i-plasma etching ehlanganiswe ngokungenisa, ngayinye inezinzuzo zayo ezihlukile nezici zobuchwepheshe. Ukukhetha ubuchwepheshe be-etching obufanelekile ngeke nje kuthuthukise ukusebenza kahle kokukhiqiza, kodwa futhi kuqinisekise isivuno somkhiqizo wokugcina.

Isikhathi sokuthumela: Nov-12-2024