Izizathu eziyinhloko ezithinta ukufana kwe-radial resistivity yekristalu eyodwa ukuqina kwesixhumi esibonakalayo soketshezi oluqinile kanye nomthelela omncane wendiza ngesikhathi sokukhula kwekristalu.

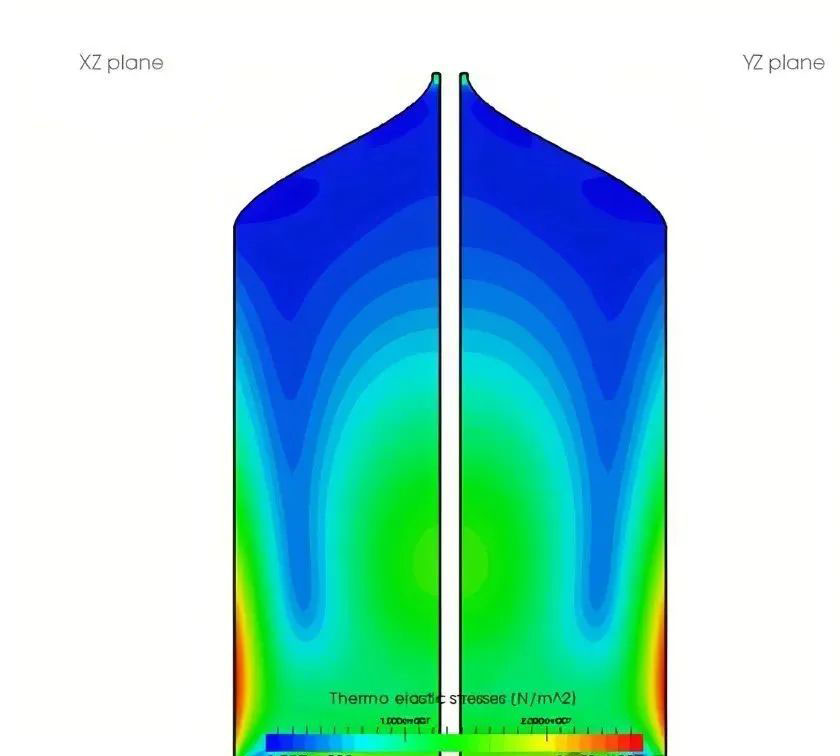

Umthelela wokucaba kwesixhumi esibonakalayo esiqinile-oketshezi Ngesikhathi sokukhula kwekristalu, uma ukuncibilika kunyakaziswa ngokulinganayo, indawo yokumelana elinganayo iyisixhumi esibonakalayo esinoketshezi oluqinile (ukugxiliswa kokungcola ekuncibilikeni kuhlukile ekugxilweni kokungcola kukristalu, ngakho-ke i-resistivity ihlukile, futhi ukumelana kuyalingana kuphela esibonakalayo esiqinile-soketshezi). Uma ukungcola okungu-K<1, i-interface convex kuya ekuncibilikeni izobangela ukumelana ne-radial ukuthi kube phezulu phakathi nendawo futhi kube phansi onqenqemeni, kuyilapho isixhumi esibonakalayo concave kuya ekuncibilikeni kuphambene. I-radial resistivity uniform of the flat solid-liquid interface ingcono. Ukuma kwesixhumi esibonakalayo esiqinile-oketshezi ngesikhathi sokudonsa kwekristalu kunqunywa izici ezifana nokusabalalisa insimu eshisayo kanye nemingcele yokusebenza yokukhula kwekristalu. Ku-crystal eyodwa edonswe ngokuqondile, ukuma kwendawo eqinile-uketshezi kuwumphumela womphumela ohlangene wezici ezifana nokusatshalaliswa kwezinga lokushisa kwesithando somlilo kanye nokuchithwa kokushisa kwekristalu.

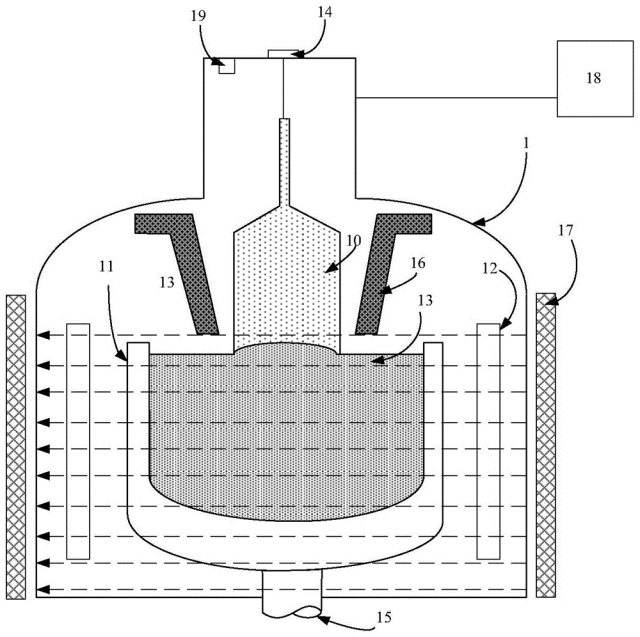

Lapho udonsa amakristalu, kunezinhlobo ezine eziyinhloko zokushintshisana kokushisa kusixhumi esibonakalayo esiqinile-soketshezi:

▪ Ukushisa okucashile koshintsho lwesigaba okukhishwa ukuqina kwe-silicon encibilikisiwe

▪ Ukushisa kokuncibilika

Ukushisa kukhuphukele phezulu ngekristalu

▪ Ukushisa kwemisebe ngaphandle ngekristalu

Ukushisa okucashile kufana nayo yonke i-interface, futhi usayizi wakho awushintshi uma izinga lokukhula lingashintshi. (Ukushisa okusheshayo, ukupholisa okusheshayo, nezinga lokuqiniswa elikhulayo)

Lapho inhloko yekristalu ekhulayo iseduze nenduku yekristalu yembewu epholiswe ngamanzi yesithando somlilo esisodwa se-crystal, izinga lokushisa le-crystal likhulu, okwenza ukushisa okude kwe-crystal kukhulu kunokushisa kwemisebe engaphezulu, ngakho-ke isixhumi esibonakalayo esiqinile-soketshezi oluyi-convex kuya ekuncibilikeni.

Lapho i-crystal ikhula ibe maphakathi, ukushisa kwe-longitudinal kufana nokushisa kwemisebe engaphezulu, ngakho-ke isikhombimsebenzisi siqondile.

Emsileni wekristalu, ukuqhutshwa kokushisa kwe-longitudinal kungaphansi kokushisa kwemisebe engaphezulu, okwenza isixhumi esibonakalayo esinoketshezi oluqinile sincibilike.

Ukuze kutholwe ikristalu eyodwa enokumelana ne-radial efanayo, isixhumi esibonakalayo soketshezi oluqinile kufanele silinganiswe.

Izindlela ezisetshenziswayo yilezi:

①Lungisa isistimu ye-thermal yokukhula kwekristalu ukuze unciphise ukuthambekela kwezinga lokushisa kwe-radial yenkambu yokushisa.

②Lungisa imingcele yokusebenza kokudonsa kwekristalu. Isibonelo, ku-interface convex ukuze incibilike, khulisa isivinini sokudonsa ukuze ukhuphule izinga lokuqiniswa kwekristalu. Ngalesi sikhathi, ngenxa yokwanda kokushisa okucashile kwecrystallization okukhishwe kusixhumi esibonakalayo, izinga lokushisa elincibilikayo eliseduze nesixhumi esibonakalayo liyakhuphuka, okuholela ekuncibilikeni kwengxenye yekristalu kusixhumi esibonakalayo, okwenza isixhumi esibonakalayo sibe flat. Ngokuphambene nalokho, uma isixhumi esibonakalayo sokukhula sigobile sibheke ekuncibilikeni, izinga lokukhula lingancishiswa, futhi ukuncibilika kuzoqinisa ivolumu ehambisanayo, kwenze isixhumi esibonakalayo sokukhula sibhebhetheke.

③ Lungisa isivinini sokuzungezisa sekristalu noma i-crucible. Ukwenyusa isivinini sokuzungezisa ikristalu kuzonyusa ukugeleza koketshezi lwezinga eliphezulu lokushisa ukusuka phansi kuye phezulu kusixhumi esibonakalayo esiwuketshezi oluqinile, okwenza isixhumi esibonakalayo sishintshe ukusuka ku-convex ukuya ku-concave. Isiqondiso sokugeleza kwe-liquid okubangelwa ukujikeleza kwe-crucible kuyafana nalokho kwe-convection yemvelo, futhi umphumela uhluke ngokuphelele kulokho okujikeleza kwe-crystal.

④ Ukwenyusa isilinganiso sobubanzi bangaphakathi be-crucible kuya kububanzi bekristalu kuzothambisa isixhumi esibonakalayo soketshezi oluqinile, futhi kunganciphisa nokuminyana kokugudluzwa kanye nokuqukethwe komoyampilo kukristalu. Ngokuvamile, ububanzi be-crucible: crystal diameter = 3 ~ 2.5:1.

Umthelela womphumela wendiza encane

Ukuxhumana okuqinile koketshezi lokukhula kwekristalu kuvame ukugoba ngenxa yomkhawulo we-isotherm encibilikayo ku-crucible. Uma ikristalu iphakanyiswa ngokushesha phakathi nokukhula kwekristalu, indiza encane eyisicaba izovela kusixhumi esibonakalayo esiqinile se-germanium (111) i-germanium kanye nekristalu eyodwa ye-silicon. Yindiza (111) egcwele phama ye-athomu, ngokuvamile ebizwa ngokuthi indiza encane.

Ukugxila kokungcola endaweni yendiza encane kuhluke kakhulu kulokho okusendaweni yendiza engeyona encane. Lesi simo sokusatshalaliswa okungavamile kokungcola endaweni yendiza encane ibizwa ngokuthi umphumela wendiza encane.

Ngenxa yomphumela wendiza encane, ukuphikiswa kwendawo yendiza encane kuzokwehla, futhi ezimweni ezinzima, amapayipi amapayipi angcolile azovela. Ukuze kuqedwe i-radial resistivity inhomogeneity ebangelwa umthelela wendiza encane, isixhumi esibonakalayo esinoketshezi oluqinile sidinga ukulinganiswa.

Yamukela noma yimaphi amakhasimende avela emhlabeni wonke ukuthi asivakashele ukuze uthole enye ingxoxo!

https://www.semi-cera.com/

https://www.semi-cera.com/tac-coating-monocrystal-growth-parts/

https://www.semi-cera.com/cvd-coating/

Isikhathi sokuthumela: Jul-24-2024