Ekwenziweni kwe-semiconductor, kunendlela ebizwa ngokuthi “etching” ngesikhathi sokucutshungulwa kwe-substrate noma ifilimu elincanyana elakhiwe ku-substrate. Ukuthuthukiswa kobuchwepheshe be-etching kube neqhaza ekufezekiseni isibikezelo esenziwa umsunguli we-Intel uGordon Moore ngo-1965 sokuthi “ukuminyana kokuhlanganiswa kwama-transistors kuzophindeka kabili eminyakeni engu-1.5 kuya kwemi-2” (eyaziwa kakhulu ngokuthi “uMthetho kaMoore”).

I-Etching akuyona inqubo "eyengezayo" efana nokubekwa noma ukubopha, kodwa inqubo "ekhiphayo". Ukwengeza, ngokwezindlela ezihlukene zokuklwebha, ihlukaniswe izigaba ezimbili, okungukuthi “ukukhipha okumanzi” kanye “nokukhipha okomile”. Ukuyibeka kalula nje, eyokuqala iyindlela yokuncibilika futhi lena yokugcina iyindlela yokumba.

Kulesi sihloko, sizochaza kafushane izici kanye nokwehluka kobuchwepheshe be-etching ngayinye, ukufakwa okumanzi kanye nokukhipha okomile, kanye nezindawo zokufaka isicelo lapho ngayinye ifaneleka khona.

Uhlolojikelele lwenqubo ye-etching

Ubuchwepheshe be-Etching kuthiwa bavela eYurophu maphakathi nekhulu le-15. Ngaleso sikhathi, i-asidi yayithelwa epuletini lethusi eliqoshiwe ukuze kugqweswe ithusi elingenalutho, kwakheka i-intaglio. Amasu okwelapha angaphezulu asizakala ngemiphumela yokugqwala aziwa kabanzi ngokuthi "etching."

Inhloso yenqubo yokuhlanganisa ekwenziweni kwe-semiconductor ukusika i-substrate noma ifilimu ku-substrate ngokomdwebo. Ngokuphinda izinyathelo zokulungiselela zokubunjwa kwefilimu, i-photolithography, kanye ne-etching, isakhiwo sepulani sicutshungulwa sibe yisakhiwo esinezinhlangothi ezintathu.

Umehluko phakathi kwe-etching emanzi kanye ne-etching eyomile

Ngemuva kwenqubo ye-photolithography, i-substrate eveziwe iba manzi noma yomile iqoshwe ngenqubo yokunamathisela.

Ukucwiliswa okumanzi kusebenzisa isixazululo ukuze kucishwe futhi kunwenwe indawo engaphezulu. Nakuba le ndlela ingacutshungulwa ngokushesha futhi eshibhile, okubi kwayo ukuthi ukunemba kokucubungula kuphansi kancane. Ngakho-ke, i-etching eyomile yazalwa cishe ngo-1970. I-etching eyomile ayisebenzisi isisombululo, kodwa isebenzisa igesi ukushaya indawo engaphansi kwe-substrate ukuyiklwebha, ebonakala ngokunemba okuphezulu kokucubungula.

"Isotropy" futhi "Anisotropy"

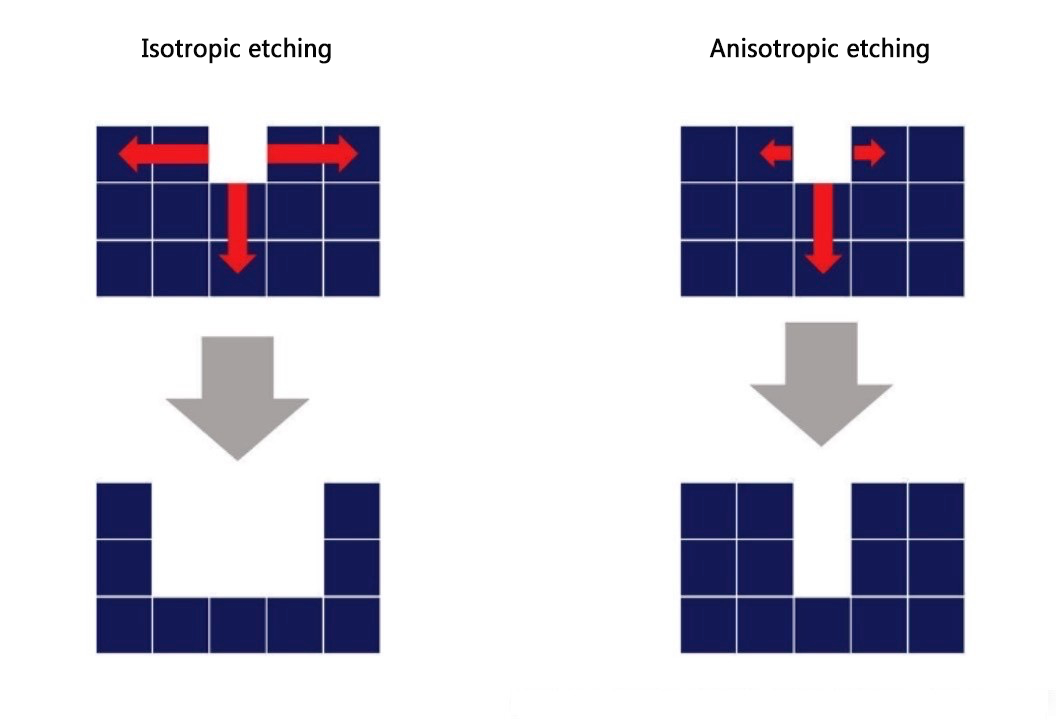

Lapho wethula umehluko phakathi kokuchotshozwa okumanzi kanye ne-etching eyomile, amagama abalulekile athi “isotropic” kanye “ne-anisotropic”. I-Isotropy isho ukuthi izakhiwo ezibonakalayo ze-matter kanye nomkhathi aziguquki ngokuqondiswa, futhi i-anisotropy isho ukuthi izakhiwo ezibonakalayo ze-matter kanye nomkhathi ziyahlukahluka ngokuya ngendlela.

I-Isotropic etching isho ukuthi ukuhlanganisa kuqhubeka ngenani elifanayo endaweni ethile, futhi ukukopisha kwe-anisotropic kusho ukuthi ukushumeka kuqhubeka ngezindlela ezihlukene endaweni ethile. Isibonelo, ekujuleni ngesikhathi sokukhiqiza i-semiconductor, i-anisotropic etching ivamise ukukhethwa ukuze kukwalwe indawo okuqondiswe kuyo kuphela, kushiye ezinye izikhombisi-ndlela ziphelele.

Izithombe ze-"Isotropic Etch" kanye "ne-Anisotropic Etch"

Izithombe ze-"Isotropic Etch" kanye "ne-Anisotropic Etch"

I-etching emanzi usebenzisa amakhemikhali.

I-etching emanzi isebenzisa ukusabela kwamakhemikhali phakathi kwekhemikhali ne-substrate. Ngale ndlela, i-anisotropic etching ayinakwenzeka, kodwa inzima kakhulu kune-isotropic etching. Kunemikhawulo eminingi ekuhlanganisweni kwezixazululo nezinto zokwakha, futhi izimo ezinjengokushisa kwe-substrate, ukugxila kwesisombululo, kanye nenani lokwengeza kufanele kulawulwe ngokuqinile.

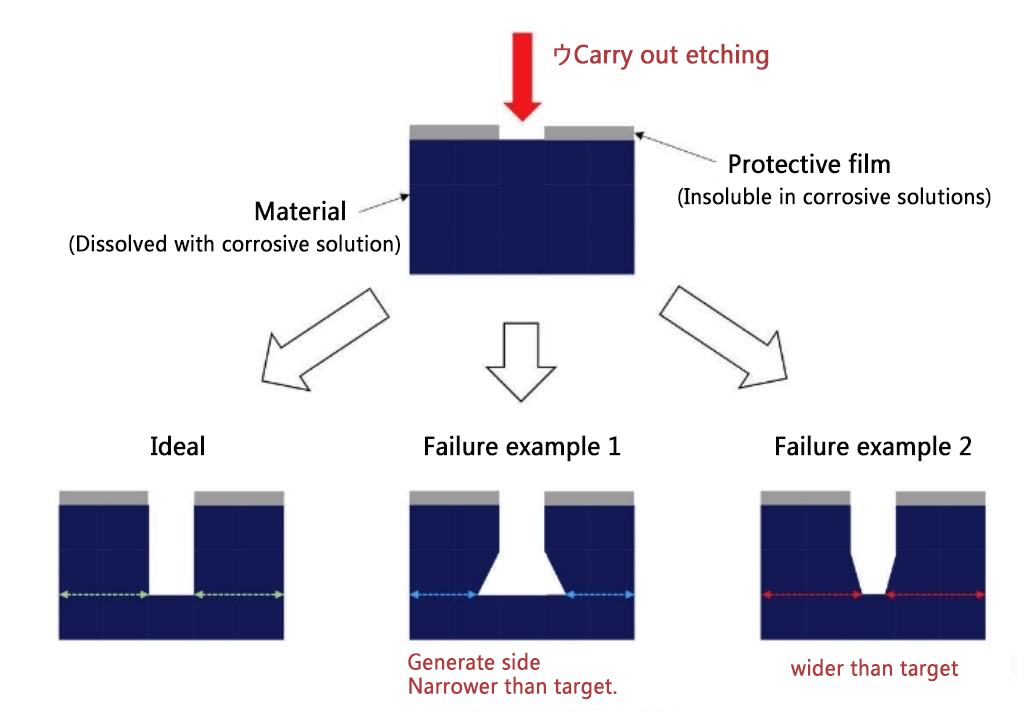

Kungakhathaliseki ukuthi izimo zilungiswa kahle kangakanani, ukufakwa okumanzi kunzima ukufeza ukucutshungulwa okuhle okungaphansi kwe-1 μm. Isizathu esisodwa salokhu isidingo sokulawula ukushumeka ohlangothini.

I-undercutting yinto eyaziwa nangokuthi i-undercutting. Ngisho noma kuthenjwa ukuthi impahla izoncibilika kuphela ekuqondeni mpo (isiqondiso esijulile) ngokufaka okumanzi, akunakwenzeka ukuvimbela ngokuphelele isisombululo ekushayeni izinhlangothi, ngakho-ke ukuchithwa kwezinto ngendlela efanayo kuzoqhubeka nakanjani. . Ngenxa yalesi simo, ukujula okumanzi kukhiqiza ngokungahleliwe izigaba ezincane kunobubanzi obuqondiwe. Ngale ndlela, lapho ucubungula imikhiqizo edinga ukulawulwa kwamanje okunembile, ukukhiqiza kabusha kuphansi futhi ukunemba akuthembeki.

Izibonelo Zokwehluleka Okungenzeka Ekuhumeni Okumanzi

Izibonelo Zokwehluleka Okungenzeka Ekuhumeni Okumanzi

Kungani i-etching eyomile ilungele i-micromachining

Incazelo ye-Related Art Dry etching elungele i-anisotropic etching isetshenziswa ezinqubweni zokukhiqiza ze-semiconductor ezidinga ukucutshungulwa okunembayo okuphezulu. Ukukhipha okomile kuvame ukubizwa ngokuthi i-reactive ion etching (RIE), okungase kuhlanganise nokushumeka kwe-plasma kanye nokukhipha ama-sputter ngomqondo obanzi, kodwa lesi sihloko sizogxila ku-RIE.

Ukuze uchaze ukuthi kungani i-anisotropic etching ilula ngokubhala okomile, ake sibhekisise inqubo ye-RIE. Kulula ukuyiqonda ngokuhlukanisa inqubo yokushumeka okomile kanye nokukhuhla ingxenye engaphansi ibe izinhlobo ezimbili: “i-chemical etching” kanye “ne-physical etching”.

Ukufakwa kwamakhemikhali kwenzeka ngezinyathelo ezintathu. Okokuqala, amagesi asebenzayo adsorbed phezulu. Imikhiqizo yokusabela iyakhiwa kusuka kugesi yokusabela kanye ne-substrate material, futhi ekugcineni imikhiqizo yokusabela iyasuswa. Ku-etching ngokomzimba okulandelayo, i-substrate iqoshwa iqonde phansi ngokufaka i-argon gas iqonde ku-substrate.

Ukufakwa kwamakhemikhali kwenzeka ngokwe-isotropical, kuyilapho ukushona komzimba kungenzeka nge-anisotropically ngokulawula isiqondiso sokusebenza kwegesi. Ngenxa yalokhu kuhlotshaniswa komzimba, i-etching eyomile ivumela ukulawula okungaphezulu kokuqondisa kwe-etching kune-etching emanzi.

Ukufakwa okomile nokumanzi nakho kudinga izimo eziqinile ezifanayo nokushumeka okumanzi, kodwa kunokuphindaphindeka okuphezulu kunokokucwilisa okumanzi futhi kunezinto eziningi okulula ukuzilawula. Ngakho-ke, akungabazeki ukuthi ukucwiliswa okomile kulungele kakhulu ukukhiqizwa kwezimboni.

Kungani Ukucwiliswa Okumanzi Kusadingeka

Uma usuqonda ukomisa okomile okubonakala kunamandla onke, ungase uzibuze ukuthi kungani i-wet etching isekhona. Nokho, isizathu silula: ukucwiliswa okumanzi kwenza umkhiqizo ushibhe.

Umehluko omkhulu phakathi kwe-etching eyomile kanye ne-etching emanzi yizindleko. Amakhemikhali asetshenziswa ekufakweni okumanzi awabizi kangako, futhi intengo yezinto zokusebenza ngokwazo kuthiwa icishe ibe yi-1/10 yaleyo mishini yokucwilisa okomile. Ngaphezu kwalokho, isikhathi sokucubungula sifushane futhi ama-substrates amaningi angacutshungulwa ngesikhathi esifanayo, ukunciphisa izindleko zokukhiqiza. Ngenxa yalokho, singakwazi ukugcina izindleko zomkhiqizo ziphansi, okusinika inzuzo ngaphezu kwezimbangi zethu. Uma izidingo zokunemba kokucubungula zingekho phezulu, izinkampani eziningi zizokhetha ukucwiliswa okumanzi kokukhiqizwa kwenqwaba.

Inqubo ye-etching yethulwa njengenqubo edlala indima kubuchwepheshe be-microfabrication. Inqubo yokufaka ihlukaniswe ihlukaniswe ibe i-etching emanzi kanye ne-etching eyomile. Uma izindleko zibalulekile, okokuqala kungcono, futhi uma i-microprocessing engaphansi kwe-1 μm iyadingeka, lokhu okugcina kungcono. Ngokufanelekile, inqubo ingakhethwa ngokusekelwe kumkhiqizo ozokhiqizwa kanye nezindleko, kunokuba yimuphi ongcono.

Isikhathi sokuthumela: Apr-16-2024