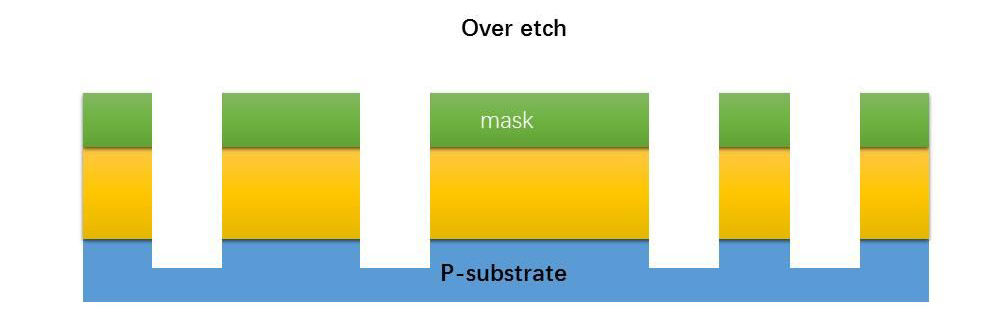

Inqubo yokubhala okomile ivamise ukuqukatha izimo ezine eziyisisekelo: ngaphambi kokuqoshwa, ukuqoshwa kancane, ukuqoshwa nje, kanye nokushumeka ngaphezulu. Izici eziyinhloko izinga lokuqopha, ukukhetha, ubukhulu obubucayi, ukufana, nokutholwa kwendawo yokugcina.

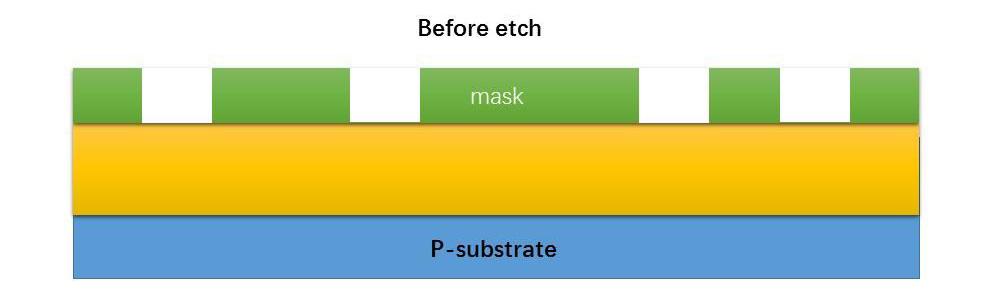

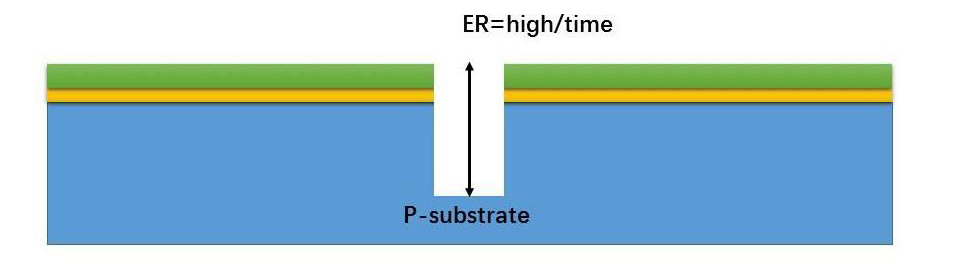

Umfanekiso 1 Ngaphambi kokutshala

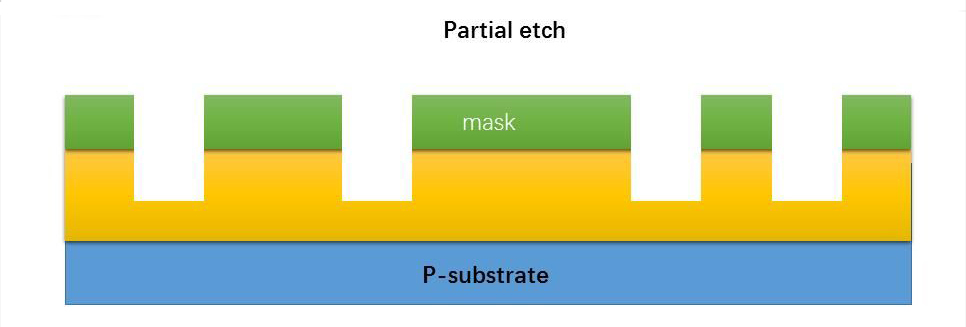

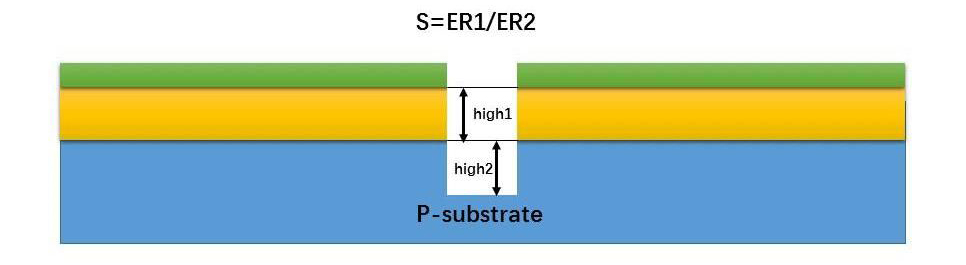

Umfanekiso 2 Ukufakwa kancane

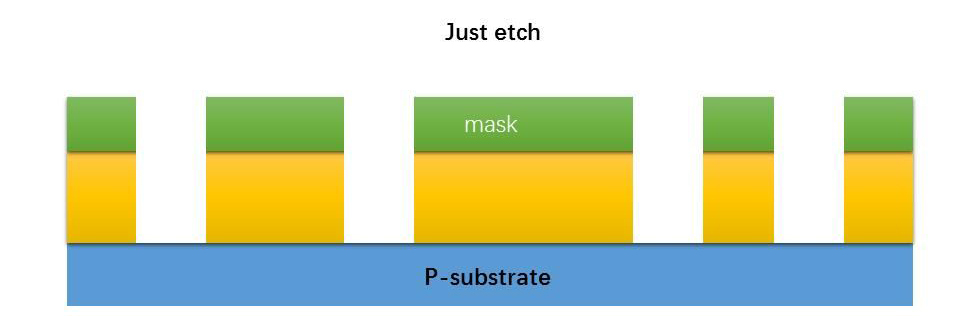

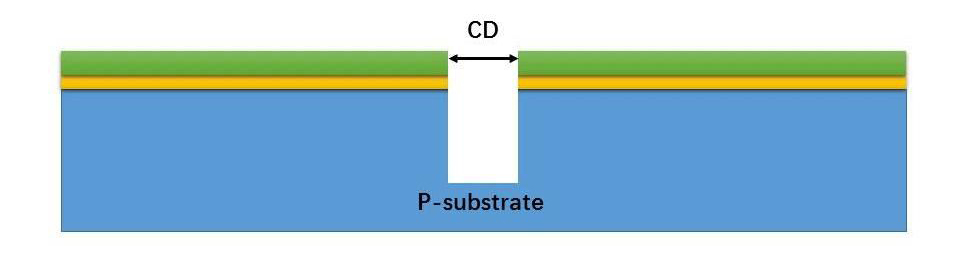

Umfanekiso 3 Ukuqoshwa nje

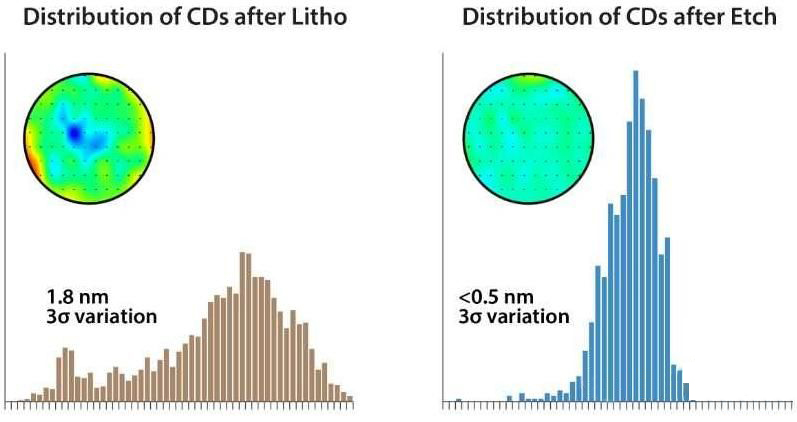

Umfanekiso wesi-4 phezu kokushisa

(1) Izinga lokuxhuma: ukujula noma ukujiya kwento eqoshiwe esusiwe ngesikhathi seyunithi.

Umfanekiso 5 Umdwebo wesilinganiso sokulinganisa

(2) Ukukhetha: isilinganiso samazinga wokushumeka wezinto ezihlukene zokuhlanganisa.

Umfanekiso 6 Umdwebo wokukhetha

(3) Ubukhulu obubalulekile: usayizi wephethini endaweni ethile ngemva kokuqedwa kokuqoshwa.

Umfanekiso 7 Umdwebo wobukhulu obubalulekile

(4) Ukufana: ukukala ukufana kwe-critical etching dimension (CD), ngokuvamile ebonakala ngemephu egcwele ye-CD, ifomula ithi: U=(Max-Min)/2*AVG.

Umfanekiso we-8 Uniformity Schematic Diagram

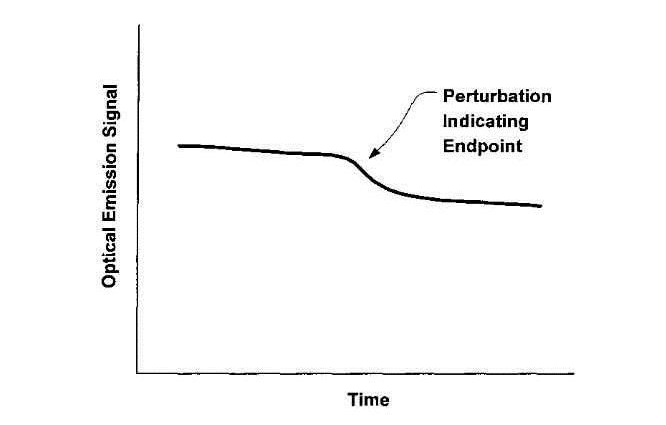

(5) Ukutholwa kwephoyinti lokugcina: Phakathi nenqubo yokufaka, ukuguqulwa kokukhanya kokukhanya kutholakala njalo. Uma amandla okukhanya athile enyuka noma ehla kakhulu, ukushumeka kuyanqanyulwa ukuze kuphawulwe ukuqedwa kongqimba oluthile lokushumeka kwefilimu.

Umfanekiso 9 Iphuzu lokugcina lomdwebo womdwebo

Ku-etching eyomile, igesi ijatshuliswa imvamisa ephezulu (ikakhulukazi i-13.56 MHz noma i-2.45 GHz). Ngengcindezi ye-1 kuya ku-100 Pa, indlela yayo yamahhala emaphakathi ingamamilimitha ambalwa ukuya kumasentimitha amaningana. Kunezinhlobo ezintathu eziyinhloko ze-etching ezomile:

•Etching ngokomzimba okomile: izinhlayiya ezisheshisiwe zigqoka umzimba we-wafer

•Chemical dry etching: igesi isabela ngamakhemikhali nendawo eyisicwecwana

•Ukufakwa kwamakhemikhali okomile ngokomzimba: inqubo yokunamathisela ngokomzimba enezici zamakhemikhali

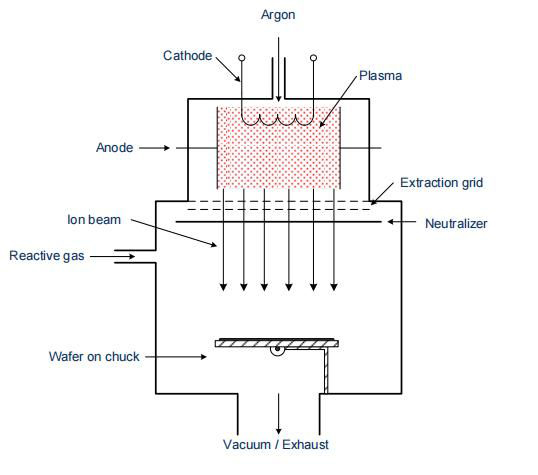

1. Ukufakwa kwe-ion beam

Ukufakwa kwe-Ion beam (Ion Beam Etching) kuyinqubo yokucubungula okomile ngokomzimba esebenzisa i-argon ion beam enamandla amakhulu namandla acishe abe ngu-1 kuya ku-3 keV ukuze kukhanye indawo ebonakalayo. Amandla we-ion beam ayibangela ukuthi ithinte futhi isuse izinto ezingaphezulu. Inqubo yokufaka i-anisotropic esimweni semishayo ye-ion yesigameko esime mpo noma esitshekile. Kodwa-ke, ngenxa yokuntuleka kwayo kokukhetha, akukho mehluko ocacile phakathi kwezinto ezisemazingeni ahlukene. Amagesi akhiqiziwe kanye nezinto ezimisiwe ziphelelwa amandla yiphampu ye-vacuum, kodwa njengoba imikhiqizo yokusabela ingewona amagesi, izinhlayiya zifakwa odongeni lwe-wafer noma lwegumbi.

Ukuvimbela ukwakheka kwezinhlayiya, igesi yesibili ingangeniswa ekamelweni. Le gesi izosabela nge-argon ion futhi ibangele inqubo yokufaka ngokomzimba namakhemikhali. Ingxenye yegesi izosabela ngezinto ezingaphezulu, kodwa izophinde ihlangane nezinhlayiya ezipholishiwe ukuze kwakheka imikhiqizo ephuma ngegesi. Cishe zonke izinhlobo zezinto zingaqoshwa ngale ndlela. Ngenxa yemisebe eqondile, ukugqoka ezindongeni eziqondile kuncane kakhulu (i-anisotropy ephezulu). Kodwa-ke, ngenxa yokukhetha kwayo okuphansi kanye nezinga lokufakwa kancane, le nqubo ayivamisile ukusetshenziswa ekukhiqizeni ama-semiconductor amanje.

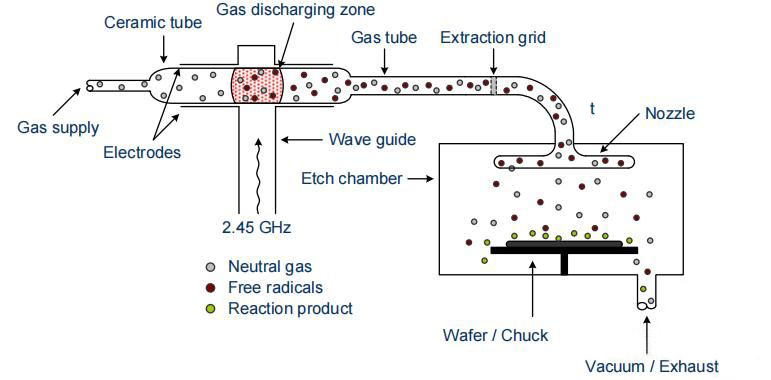

2. Ukufakwa kwe-Plasma

I-Plasma etching iyinqubo yokuhlanganisa amakhemikhali ngokuphelele, eyaziwa nangokuthi i-chemical dry etching. Inzuzo yayo ukuthi ayibangeli ukulimala kwe-ion endaweni eyi-wafer. Njengoba izinhlobo ezisebenzayo ku-etching gas zikhululekile ukuhamba futhi inqubo yokufaka i-isotropic, le ndlela ifaneleka ukususa lonke ungqimba lwefilimu (isibonelo, ukuhlanza uhlangothi olungemuva ngemuva kwe-oxidation eshisayo).

I-reactor engezansi wuhlobo lwe-reactor evame ukusetshenziselwa ukushumeka kwe-plasma. Kule reactor, i-plasma ikhiqizwa i-ionization yomthelela endaweni kagesi enemvamisa ephezulu engu-2.45GHz futhi ihlukaniswe newafa.

Endaweni yokukhishwa kwegesi, izinhlayiya ezihlukahlukene zikhiqizwa ngenxa yomthelela kanye nokuthakazelisa, kuhlanganise nama-radicals mahhala. Ama-radicals amahhala angama-athomu angathathi hlangothi noma ama-molecule anama-electron angagcwele, ngakho asebenza kakhulu. Enqubweni yokufaka i-plasma, amagesi athile angathathi hlangothi, njenge-tetrafluoromethane (CF4), avame ukusetshenziswa, angeniswa endaweni yokukhipha igesi ukuze kukhiqizwe izinhlobo ezisebenzayo nge-ionization noma ukubola.

Isibonelo, kugesi ye-CF4, yethulwa endaweni yokukhipha igesi futhi ibole ibe ama-fluorine radicals (F) nama-molecule e-carbon difluoride (CF2). Ngokufanayo, i-fluorine (F) ingabola isuka ku-CF4 ngokungeza umoya-mpilo (O2).

2 CF4 + O2 —> 2 COF2 + 2 F2

I-molecule ye-fluorine ingahlukana ibe ama-athomu amabili e-fluorine azimele ngaphansi kwamandla esifunda esikhipha igesi, ngalinye eliyi-fluorine free radical. Njengoba i-athomu ngayinye ye-fluorine inama-electron ayisikhombisa e-valence futhi ijwayele ukufeza ukucushwa kwe-electronic kwegesi engasebenzi, wonke ayasebenza kakhulu. Ngokungeziwe kuma-radicals mahhala e-fluorine angathathi hlangothi, kuzoba nezinhlayiya ezikhokhiswayo ezifana ne-CF+4, CF+3, CF+2, njll. endaweni yokukhipha igesi. Kamuva, zonke lezi zinhlayiya nama-radicals mahhala angeniswa ekamelweni lokunamathisela ngeshubhu le-ceramic.

Izinhlayiya ezikhokhisiwe zingavinjwa ama-gratings akhishwayo noma ahlanganiswe kabusha enqubweni yokwenza ama-molecule angathathi hlangothi ukuze alawule ukuziphatha kwawo ekamelweni lokunamathisela. Ama-radicals angenayo i-fluorine nawo azophinde ahlanganiswe ingxenye, kodwa asasebenza ngokwanele ukuze angene egunjini lokunamathisela, aphendule ngamakhemikhali endaweni eyi-wafer futhi abangele ukukhumuzeka kwempahla. Ezinye izinhlayiya ezingathathi hlangothi azihlanganyeli enqubweni yokuqopha futhi ziyadliwa kanye nemikhiqizo yokusabela.

Izibonelo zamafilimu azacile angabhalwa ku-plasma etching:

• I-Silicon: Si + 4F—> SiF4

• I-Silicon dioxide: SiO2 + 4F—> SiF4 + O2

• I-Silicon nitride: Si3N4 + 12F—> 3SiF4 + 2N2

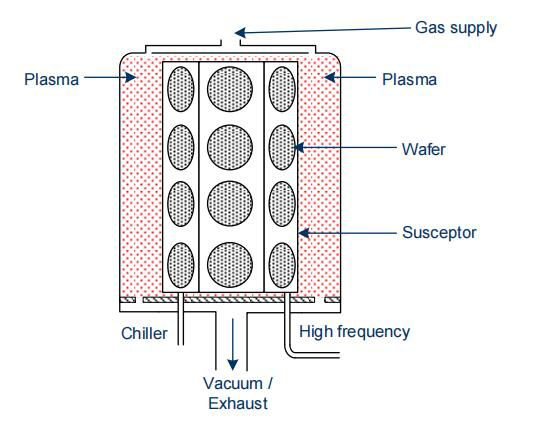

3. Ukufakwa kwe-ion okusebenzayo (RIE)

I-Reactive ion etching iyinqubo yokuhlanganisa amakhemikhali-ngokomzimba engalawula ngokunembe kakhulu ukukhetha, iphrofayili yokuqopha, izinga lokuqopha, ukufana nokuphindaphinda. Ingakwazi ukufeza amaphrofayili e-isotropic kanye ne-anisotropic etching ngakho-ke ingenye yezinqubo ezibaluleke kakhulu zokwakha amafilimu amancane amancane ekukhiqizeni ama-semiconductor.

Ngesikhathi se-RIE, i-wafer ifakwa ku-electrode ephezulu-frequency (i-HF electrode). Ngokusebenzisa i-ionization yomthelela, i-plasma ikhiqizwa lapho ama-electron amahhala nama-ion ashajwa kahle ekhona. Uma i-voltage ephozithivu isetshenziswa ku-electrode ye-HF, ama-electron amahhala anqwabelana endaweni ye-electrode futhi awakwazi ukushiya i-electrode futhi ngenxa yokuhlangana kwawo kwe-electron. Ngakho-ke, ama-electrode ashajwa ku--1000V (i-bias voltage) ukuze ama-ion ahamba kancane angakwazi ukulandela inkambu kagesi eshintsha ngokushesha ku-electrode eshajwe kabi.

Ngesikhathi sokufakwa kwe-ion (RIE), uma indlela yamahhala yama-ion iphakeme, ishaya indawo eyi-wafer ngendlela ecishe ibe yi-perpendicular. Ngale ndlela, ama-ion asheshiswayo akhipha izinto futhi enze ukusabela kwamakhemikhali ngokushutheka ngokomzimba. Njengoba izindonga eziseceleni zingathinteki, iphrofayili ye-etch ihlala i-anisotropic futhi ukugqokwa kwangaphezulu kuncane. Kodwa-ke, ukukhetha akuphakeme kakhulu ngoba inqubo yokufaka ngokomzimba nayo iyenzeka. Ukwengeza, ukusheshisa kwama-ion kubangela umonakalo endaweni eyi-wafer, okudinga ukuthuthwa okushisayo ukuze kulungiswe.

Ingxenye yekhemikhali yenqubo yokufaka iqedwa ngama-radicals amahhala asebenza endaweni kanye nama-ion ashaya into esetshenziswayo ukuze ingabeki kabusha esilungwini noma ezindongeni zegumbi, kugwenywe into yokuhlehliswa kabusha efana nokushumeka kwe-ion beam. Lapho ukwandisa ukucindezela kwegesi ekamelweni lokunamathisela, indlela yamahhala ye-ion iyancishiswa, okwandisa inani lokushayisana phakathi kwama-ion nama-molecule egesi, futhi ama-ion ahlakazeke ngezindlela ezihlukene. Lokhu kuholela ekujuleni kokuqondisa okuncane, okwenza inqubo ye-etching ibe ngamakhemikhali amaningi.

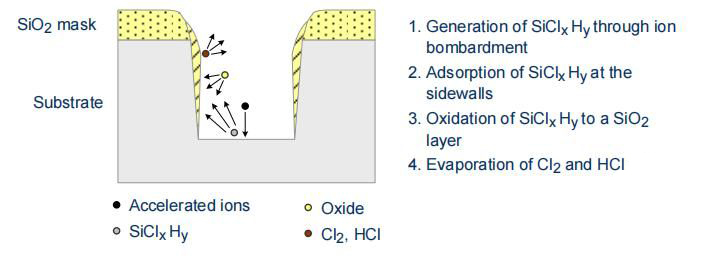

Amaphrofayili e-anisotropic etch atholwa ngokudlula izindonga ezisemaceleni ngesikhathi sokufakwa kwe-silicon. Umoya-mpilo ungeniswa egumbini lokunamathisela, lapho uhlangana khona ne-silicon egxilile ukuze yakhe i-silicon dioxide, efakwa ezindongeni ezime mpo. Ngenxa yokuqhuma kwe-ion, ungqimba lwe-oxide ezindaweni ezivundlile luyasuswa, okuvumela inqubo yokunamathisela ezinhlangothini ukuthi iqhubeke. Le ndlela ingakwazi ukulawula ukuma kwephrofayili ye-etch kanye nokukhuphuka kwama-sidewalls.

Izinga le-etch lithintwa izinto ezinjengokucindezela, amandla ejeneretha ye-HF, igesi yenqubo, izinga langempela lokugeleza kwegesi kanye nezinga lokushisa eliyisilutshwana, futhi ububanzi balo bokushintsha bugcinwa bungaphansi kuka-15%. I-Anisotropy iyanda ngokwanda kwamandla e-HF, ingcindezi eyancipha kanye nezinga lokushisa eliyancipha. Ukufana kwenqubo ye-etching kunqunywa igesi, isikhala se-electrode kanye nezinto ze-electrode. Uma ibanga le-electrode lincane kakhulu, i-plasma ayikwazi ukuhlakazeka ngokulinganayo, okuholela ekungafanini. Ukwenyusa ibanga le-electrode kunciphisa izinga lokuqopha ngoba i-plasma isakazwa ngevolumu enkulu. Ikhabhoni iyinto ekhethwayo ye-electrode ngoba ikhiqiza i-plasma ehlungiwe iyunifomu ukuze unqenqema lwe-wafer luthinteke ngendlela efanayo nenkaba ye-wafer.

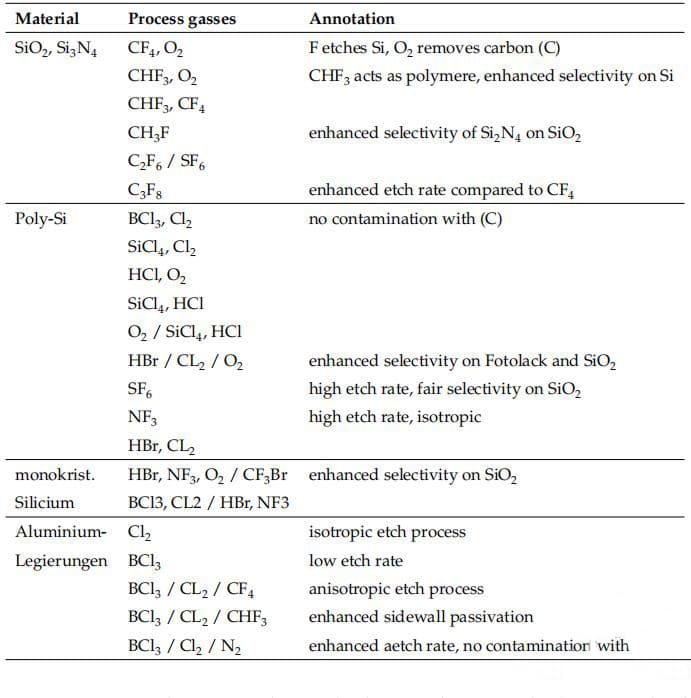

Igesi yenqubo idlala indima ebalulekile ekukhetheni nasekulinganisweni kwe-etching. Ngokuhlanganiswa kwe-silicon ne-silicon, i-fluorine ne-chlorine isetshenziselwa ikakhulukazi ukufeza ukucwiliswa. Ukukhetha igesi efanelekile, ukulungisa ukugeleza kwegesi nokucindezela, nokulawula amanye amapharamitha afana nezinga lokushisa namandla enqubeni kungafinyelela izinga le-etch elifunekayo, ukukhetha, nokufana. Ukwenziwa kahle kwalawa mapharamitha kuvame ukulungiselwa izinhlelo zokusebenza nezinto ezihlukile.

Inqubo yokufaka ayikhawulelwe kugesi eyodwa, ingxube yegesi, noma amapharamitha enqubo egxilile. Isibonelo, i-oxide yomdabu ku-polysilicon ingasuswa kuqala ngezinga eliphezulu lokucupha kanye nokukhetha okuphansi, kuyilapho i-polysilicon ingaqoshwa kamuva ngokukhetha okuphezulu okuhlobene nezendlalelo ezingaphansi.

————————————————————————————————————————————————— ————————————

I-Semicera ingahlinzekaizingxenye zegraphite, ukuzwakala okuthambile/okuqinile, izingxenye ze-silicon carbide,Izingxenye ze-CVD silicon carbide,futhiIzingxenye ezihlanganisiwe ze-SiC/TaC ngezinsuku ezingama-30.

Uma unentshisekelo kule mikhiqizo engenhla ye-semiconductor,sicela ungangabazi ukusithinta okokuqala.

Ucingo: +86-13373889683

Whatsap:+86-15957878134

Email: sales01@semi-cera.com

Isikhathi sokuthumela: Sep-12-2024