Amadivayisi kagesi we-semiconductor athatha isikhundla esiyinhloko ezinhlelweni zikagesi zamandla, ikakhulukazi kumongo wokuthuthukiswa okusheshayo kobuchwepheshe obufana nobuhlakani bokwenziwa, ukuxhumana kwe-5G nezimoto zamandla amasha, izidingo zokusebenza kwazo zithuthukisiwe.

I-silicon carbide(I-4H-SiC) isiphenduke into efanelekile yokukhiqiza imishini yamandla e-semiconductor asebenza kahle kakhulu ngenxa yezinzuzo zayo ezifana ne-bandgap ebanzi, ukuhanjiswa kwe-thermal ephezulu, amandla enkundla yokuwohloka okuphezulu, izinga eliphezulu lokugcwala kwamanzi, ukuzinza kwamakhemikhali nokumelana nemisebe. Kodwa-ke, i-4H-SiC inobulukhuni obuphezulu, i-brittleness ephezulu, ukungabi namandla kwamakhemikhali, kanye nobunzima bokucubungula okuphezulu. Izinga eliphezulu le-wafer ye-substrate libalulekile ezinhlelweni zokusebenza zedivayisi enkulu.

Ngakho-ke, ukuthuthukisa ikhwalithi ephezulu ye-4H-SiC substrate wafers, ikakhulukazi ukususa isendlalelo esilimele endaweni yokucubungula i-wafer, kuyisihluthulelo sokufeza ukusebenza kahle, ukulahlekelwa okuphansi kanye nekhwalithi ephezulu ye-4H-SiC substrate wafer processing.

Isivivinyo

Ukuhlolwa kusebenzisa i-ingot engu-4-inch N-type 4H-SiC ekhuliswe indlela yokuthutha umhwamuko, ecutshungulwa ngokusikwa kwentambo, ukugaywa, ukugaywa okuqinile, ukugaywa kahle nokupholishwa, futhi irekhoda ukujiya kokususwa kwendawo engu-C nendawo engu-Si. kanye nogqinsi lwe-wafer yokugcina enqubweni ngayinye.

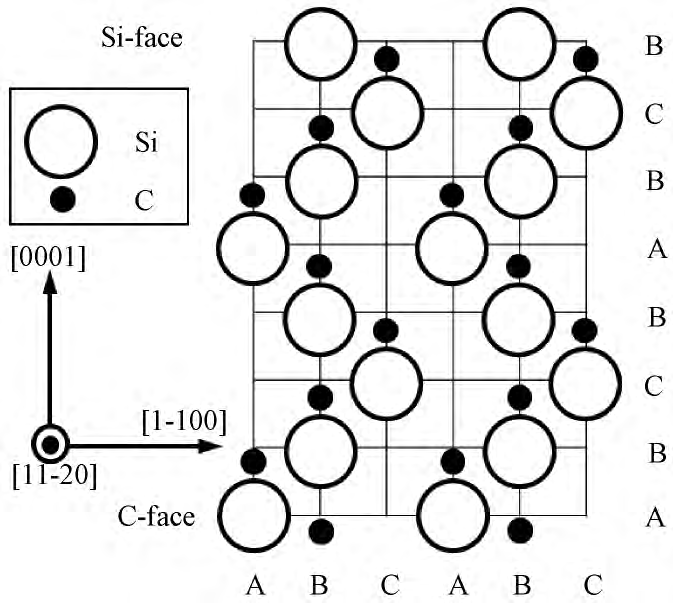

Umfanekiso we-1 Umdwebo we-Schematic we-4H-SiC isakhiwo se-crystal

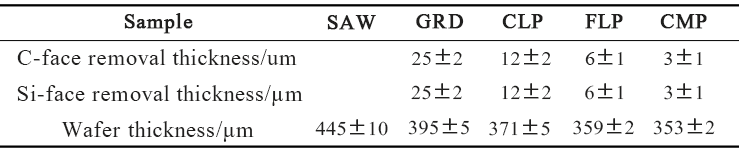

Umfanekiso 2 Ukuqina kususiwe ku-C-side kanye ne-Si-side ye-4H-Isicwecwana se-SiCngemva kwezinyathelo ezihlukene zokucubungula nokuqina kwe-wafer ngemva kokucubungula

Ugqinsi, i-surface morphology, ubuhhadlahhadla kanye nezakhiwo zemishini zesiluli zazibonakala ngokugcwele ngesihloli sepharamitha eyilucwecwana yejiyomethri, isibonakhulu esiphazamisayo esihlukanisayo, isibonakhulu samandla e-athomu, ithuluzi lokulinganisa ukugwedla kanye ne-nanoindenter. Ngaphezu kwalokho, i-X-ray diffractometer yokulungiswa okuphezulu yasetshenziswa ukuze kuhlolwe ikhwalithi yekristalu yesinkwa esilucwecwana.

Lezi zinyathelo zokuhlola nezindlela zokuhlola zihlinzeka ngosekelo oluningiliziwe lwezobuchwepheshe lokufunda izinga lokususwa kwezinto kanye nekhwalithi yendawo ngesikhathi sokucutshungulwa kwe-4H-Ama-wafers e-SiC.

Ngokuhlola, abacwaningi bahlaziye izinguquko kuzinga lokususwa kwezinto (MRR), i-surface morphology kanye nokuqina, kanye nezakhiwo zemishini kanye nekhwalithi yekristalu ye-4H-Ama-wafers e-SiCngezinyathelo ezihlukene zokucubungula (ukusika ucingo, ukugaya, ukugaya okungalungile, ukugaya kahle, ukupholisha).

Umfanekiso 3 Izinga lokususwa kwezinto ezibonakalayo ze-C-face kanye ne-Si-face ye-4H-Isicwecwana se-SiCngezinyathelo ezahlukene zokucubungula

Ucwaningo lwathola ukuthi ngenxa ye-anisotropy yezakhiwo zemishini yobuso obuhlukile be-crystal ye-4H-SiC, kukhona umehluko ku-MRR phakathi kwe-C-face no-Si-face ngaphansi kwenqubo efanayo, futhi i-MRR ye-C-face iphakeme kakhulu ekaSi-face. Ngokuthuthuka kwezinyathelo zokucubungula, i-morphology yangaphezulu kanye nokuqina kwama-wafers we-4H-SiC kuthuthukiswa kancane kancane. Ngemuva kokupholishwa, i-Ra ye-C-face ingu-0.24nm, futhi i-Ra ye-Si-face ifinyelela ku-0.14nm, engahlangabezana nezidingo zokukhula kwe-epitaxial.

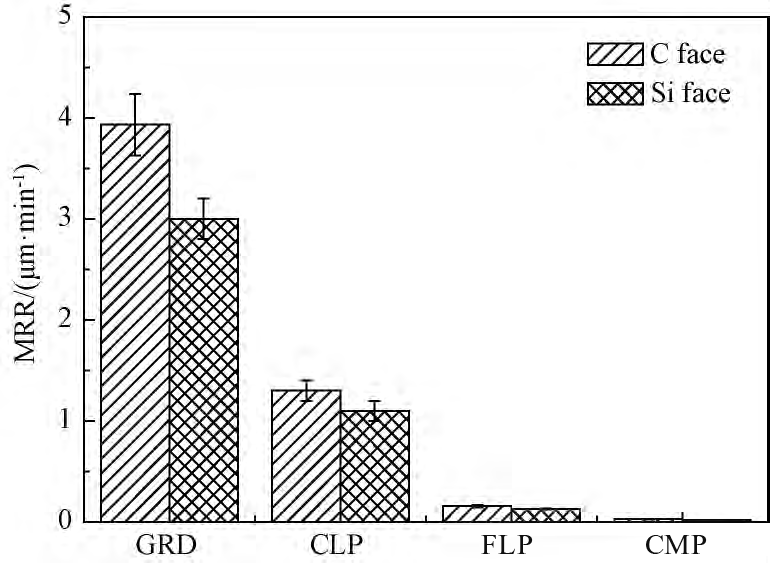

Umfanekiso 4 Izithombe zesibonakhulu esibonakalayo sendawo engu-C (a~e) ne-Si surface (f~j) ye-4H-SiC wafer ngemva kwezinyathelo ezihlukene zokucubungula.

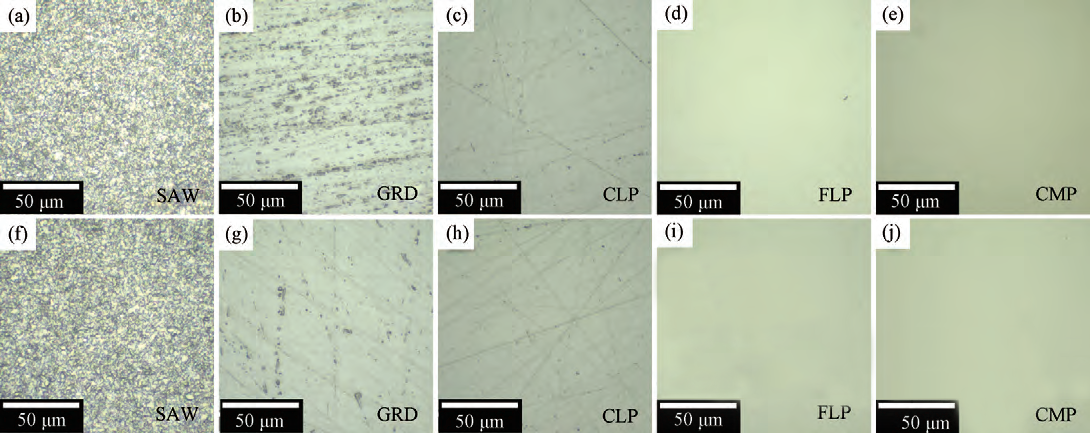

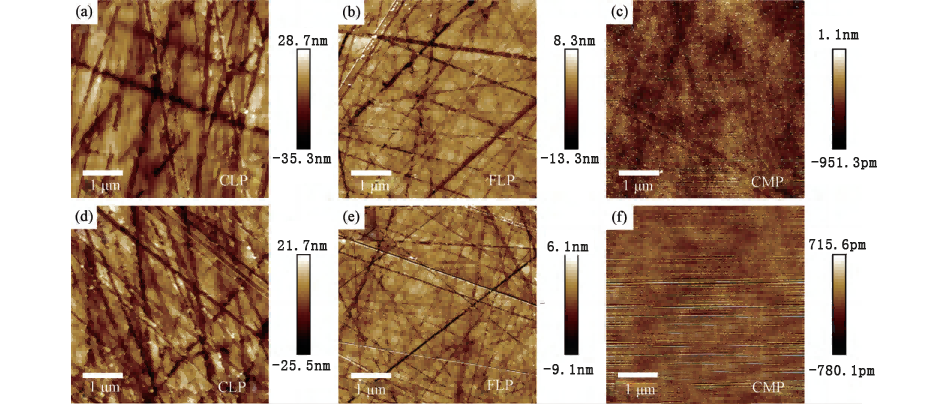

Umfanekiso 5 Izithombe zesibonakhulu se-Atomic force ye-C surface (a~c) kanye ne-Si surface (d~f) ye-4H-SiC wafer ngemva kwe-CLP, FLP kanye nezinyathelo zokucubungula ze-CMP

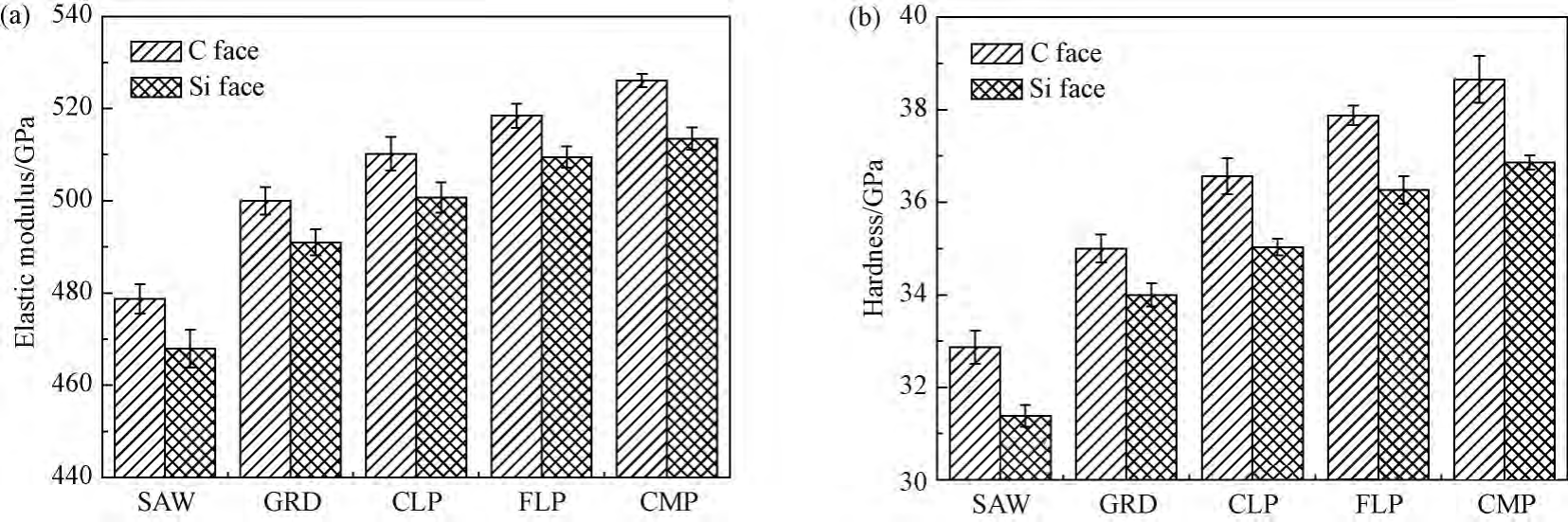

Umfanekiso wesi-6 (a) i-elastic modulus kanye (b) nokuqina kwe-C surface kanye ne-Si surface ye-4H-SiC wafer ngemva kwezinyathelo ezihlukene zokucubungula.

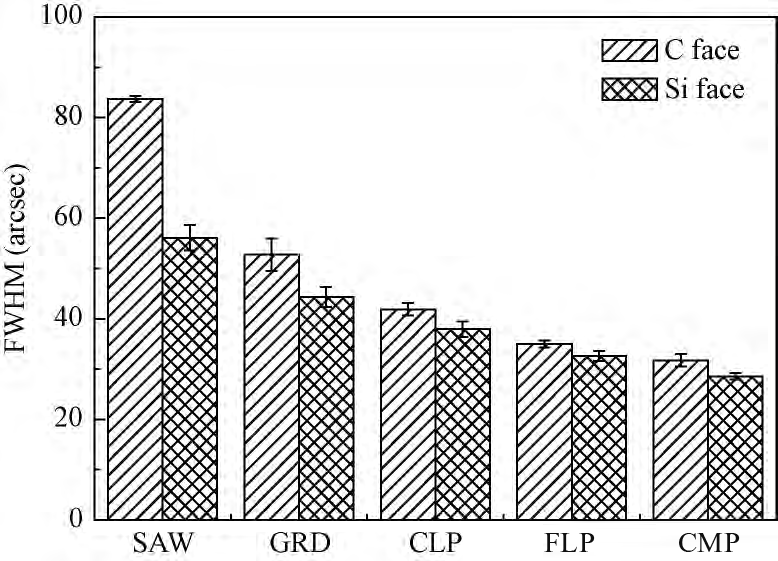

Ukuhlolwa kwesakhiwo semishini kubonisa ukuthi indawo engu-C yewafa inokuqina okubi kakhudlwana kunento engaphezulu ye-Si, izinga elikhulu lokuphuka okuphukayo ngesikhathi sokucutshungulwa, ukususwa kwempahla ngokushesha, kanye nokubukeka komhlaba okungekuhle nokumahhadla. Ukukhipha isendlalelo esilimele endaweni ecutshunguliwe kuyisihluthulelo sokuthuthukisa ikhwalithi yangaphezulu ye-wafer. Ububanzi obuyingxenye yobude bejika elinyakazisayo le-4H-SiC (0004) bungasetshenziselwa ukuveza ngokunembile nangokunembile uhlaka lomonakalo ongaphezulu we-wafer.

Umfanekiso 7 (0004) ijika elinyakazayo eliyingxenye yobubanzi bobuso be-C kanye ne-Si-face ye-4H-SiC wafer ngemva kwezinyathelo ezihlukene zokucubungula.

Imiphumela yocwaningo ikhombisa ukuthi ungqimba lomonakalo ongaphezulu we-wafer lungasuswa kancane kancane ngemuva kokucutshungulwa kwe-wafer ye-4H-SiC, okuthuthukisa ngempumelelo ikhwalithi engaphezulu ye-wafer futhi inikeze ireferensi yobuchwepheshe yokusebenza kahle okuphezulu, ukulahleka okuphansi kanye nokucubungula okuphezulu. ye-4H-SiC substrate wafers.

Abacwaningi bacubungule ama-wafers e-4H-SiC ngezinyathelo ezihlukene zokucubungula ezifana nokusika izintambo, ukugaya, ukugaya okungalungile, ukugaya kahle nokupholishwa, futhi bafunde imiphumela yalezi zinqubo kwikhwalithi engaphezulu ye-wafer.

Imiphumela ibonisa ukuthi ngokuthuthuka kwezinyathelo zokucubungula, i-morphology ye-surface kanye nokuqina kwe-wafer kuthuthukiswa kancane kancane. Ngemva kokupholishwa, ukuhwalala kwe-C-face kanye ne-Si-face kufinyelela ku-0.24nm no-0.14nm ngokulandelanayo, okuhlangabezana nezidingo zokukhula kwe-epitaxial. I-C-face ye-wafer inokuqina okumpofu kunento ye-Si-face, futhi ijwayele ukuphuka kancane ngesikhathi sokucutshungulwa, okuholela ekumeni kwesimo esingesihle kanye nokuba mahhadladla. Ukususa ungqimba lomonakalo ongaphezulu kwendawo ecutshunguliwe kuyisihluthulelo sokuthuthukisa ikhwalithi yangaphezulu ye-wafer. Ububanzi obuyingxenye ye-4H-SiC (0004) ijika elinyakazayo bungabonakalisa ngokunembile nangokunembile ungqimba lomonakalo ongaphezulu we-wafer.

Ucwaningo lubonisa ukuthi ungqimba olulimele olungaphezulu kwama-wafers we-4H-SiC lungasuswa kancane kancane ngokucubungula i-wafer ye-4H-SiC, ngokuthuthukisa ngempumelelo ikhwalithi engaphezulu ye-wafer, inikeze ireferensi yezobuchwepheshe yokusebenza kahle kakhulu, ukulahlekelwa okuphansi, kanye nokuphezulu- ukucutshungulwa kwekhwalithi ye-4H-SiC substrate wafers.

Isikhathi sokuthumela: Jul-08-2024