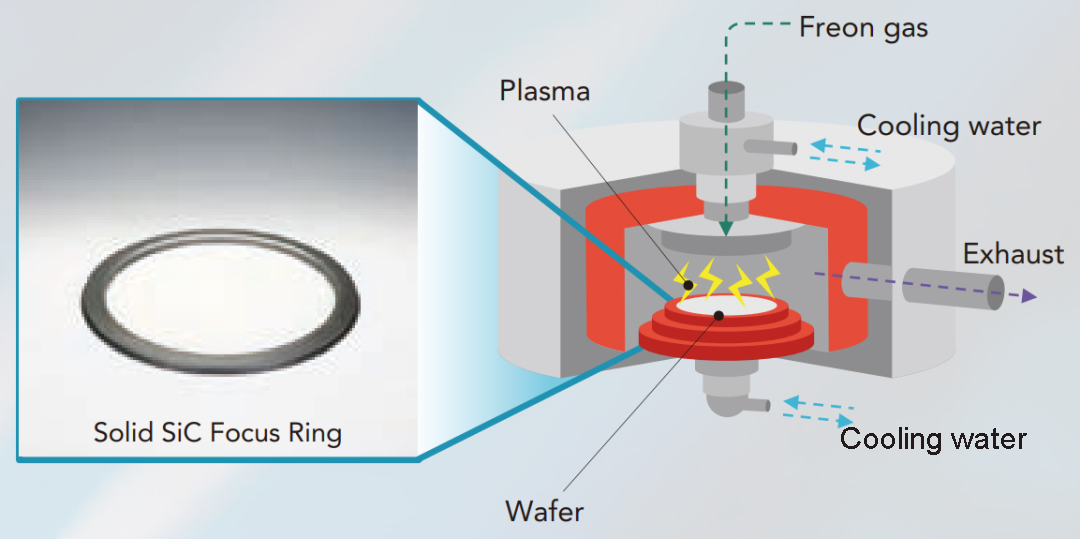

Emishinini yokufaka i-plasma, izingxenye ze-ceramic zidlala indima ebalulekile, kufaka phakathiindandatho yokugxila.I indandatho yokugxila, ibekwe eduze kwe-wafer futhi ithintane nayo ngokuqondile, ibalulekile ekugxiliseni i-plasma ku-wafer ngokusebenzisa i-voltage eringini. Lokhu kuthuthukisa ukufana kwenqubo yokufaka.

Ukusetshenziswa Kwezindandatho Ze-SiC Focus Emashini E-Etching

Izingxenye ze-SiC CVDemishinini yokufaka, njengeizindandatho zokugxila, i-gas showerheads, ama-platens, namasongo onqenqema, athandwa ngenxa yokusebenza kabusha okuphansi kwe-SiC ngamagesi e-chlorine ne-fluorine etching esekelwe kanye nokusebenza kwawo, okuyenza ibe into efanelekile yemishini yokufaka i-plasma.

Izinzuzo ze-SiC njenge-Focus Ring Material

Ngenxa yokuchayeka okuqondile ku-plasma egunjini le-vacuum reaction, izindandatho zokugxila zidinga ukwenziwa ngezinto ezimelana ne-plasma. Izindandatho zokugxila kwendabuko, ezenziwe nge-silicon noma i-quartz, zinenkinga yokumelana ne-etching ephansi kuma-plasma asekelwe ku-fluorine, okuholela ekugqwaleni okusheshayo nokuncipha kokusebenza kahle.

Ukuqhathaniswa Phakathi Kwezindandatho Zokugxila kwe-Si ne-CVD:

1. Ukuminyana Okuphezulu:Yehlisa ivolumu yokuqopha.

2. I-Bandgap ebanzi: Inikeza insulation enhle kakhulu.

3. High Thermal Conductivity & Low Expansion Coefficient: Imelana nokushaqeka okushisayo.

4. I-Elasticity ephezulu:Ukumelana kahle nomthelela wemishini.

5. Ukuqina Okuphakeme: Ingagugi futhi imelana nokugqwala.

I-SiC yabelana ngokusebenza kukagesi kwe-silicon ngenkathi inikezela ukumelana okuphezulu ne-ionic etching. Njengoba i-miniaturization yesekethe edidiyelwe iqhubeka, isidingo sezinqubo zokucupha ezisebenza kahle siyakhula. Imishini yokufaka i-Plasma, ikakhulukazi lezo ezisebenzisa i-capacitive coupled plasma (CCP), zidinga amandla aphezulu e-plasma,I-SiC focus ringsngokuya ukuthandwa.

I-Si ne-CVD SiC Focus Ring Parameters:

| Ipharamitha | I-silicon (Si) | I-CVD Silicon Carbide (SiC) |

| Ukuminyana (g/cm³) | 2.33 | 3.21 |

| I-Band Gap (eV) | 1.12 | 2.3 |

| I-Thermal Conductivity (W/cm°C) | 1.5 | 5 |

| I-Thermal Expansion Coefficient (x10⁻⁶/°C) | 2.6 | 4 |

| I-Elastic Modulus (GPA) | 150 | 440 |

| Ukuqina | Phansi | Phezulu |

Inqubo Yokukhiqiza Yezindandatho Ze-SiC Focus

Emishinini ye-semiconductor, i-CVD (Chemical Vapor Deposition) ivame ukusetshenziselwa ukukhiqiza izingxenye ze-SiC. Amaringi okugxilisa ingqondo akhiqizwa ngokufaka i-SiC ekubunjweni okuthile ngokufakwa komhwamuko, okulandelwa ukucutshungulwa ngomshini ukuze kwakhe umkhiqizo wokugcina. Isilinganiso sezinto ezibonakalayo sokufakwa komhwamuko silungisiwe ngemva kokuhlolwa okubanzi, okwenza amapharamitha afana nokumelana nokungaguquguquki. Kodwa-ke, okokusebenza okuhlukile kwe-etching kungase kudinge izindandatho zokugxila ezinokumelana okuhlukahlukene, okudinga ukuhlolwa kwesilinganiso sezinto ezintsha esicacisweni ngasinye, okudla isikhathi futhi kubiza.

NgokukhethaI-SiC focus ringskusukaI-Semicera Semiconductor, amakhasimende angafinyelela izinzuzo zomjikelezo omude wokushintsha nokusebenza okuphakeme ngaphandle kokukhuphuka okukhulu kwezindleko.

Izingxenye Ze-Rapid Thermal Processing (RTP).

Izakhiwo ezishisayo ze-CVD SiC ziyenza ilungele izinhlelo zokusebenza ze-RTP. Izingxenye ze-RTP, okuhlanganisa izindandatho ezinqenqemeni namapuleti, zizuza ku-CVD SiC. Phakathi ne-RTP, amapulse okushisa aqinile asetshenziswa kumawafa angawodwana isikhathi esifushane, alandelwe ukupholisa ngokushesha. Amasongo e-CVD SiC onqenqemeni, abe mncane futhi anesisindo esincane esishisayo, awagcini ukushisa okuphawulekayo, okwenza angathinteki ngokushisa okusheshayo nokupholisa izinqubo.

Izingxenye ze-Plasma Etching

Ukumelana namakhemikhali okuphezulu kwe-CVD SiC kuyenza ifanelekele izinhlelo zokusebenza zokuqopha. Ama-etching chambers amaningi asebenzisa amapuleti okusabalalisa igesi e-CVD SiC ukuze asabalalise amagesi e-etching, aqukethe izinkulungwane zezimbobo ezincane zokuhlakazwa kwe-plasma. Uma kuqhathaniswa nezinye izinto, i-CVD SiC inokuphinda isebenze okuphansi nge-chlorine namagesi e-fluorine. Ku-etching eyomile, izingxenye ze-CVD SiC ezifana nezindandatho zokugxila, amapuleti e-ICP, izindandatho zomngcele, nama-showerheads zivame ukusetshenziswa.

Izindandatho zokugxila ze-SiC, ezine-voltage yazo esetshenzisiwe yokugxila ku-plasma, kufanele zibe nokuhamba okwanele. Ngokuvamile enziwe nge-silicon, izindandatho zokugxila zivezwa kumagesi asebenzayo aqukethe i-fluorine ne-chlorine, okuholela ekugqwaleni okungenakugwenywa. Izindandatho zokugxila ze-SiC, ezinokumelana nokugqwala kwazo okuphakeme, zinikeza isikhathi eside sokuphila uma kuqhathaniswa nezindandatho ze-silicon.

Ukuqhathaniswa kwe-Lifecycle:

· I-SiC Focus Rings:Ishintshwa njalo ezinsukwini eziyi-15 kuye kwezingama-20.

· Izindandatho zokugxila ze-Silicon:Ishintshwa njalo ezinsukwini eziyi-10 kuye kweziyi-12.

Naphezu kokuthi izindandatho ze-SiC zibiza izikhathi ezi-2 kuya kwezingu-3 kunezindandatho ze-silicon, umjikelezo owandisiwe wokushintsha unciphisa izindleko eziphelele zokushintshwa kwengxenye, njengoba zonke izingxenye zokugqoka ekamelweni zishintshwa ngesikhathi esisodwa lapho igumbi livulelwa ukushintshwa kwendandatho yokugxila.

I-Semicera Semiconductor's SiC Focus Rings

I-Semicera Semiconductor inikeza izindandatho zokugxila ze-SiC ngamanani asondelene nalawo amaringi e-silicon, nesikhathi sokuhola cishe esiyizinsuku ezingama-30. Ngokuhlanganisa izindandatho zokugxila ze-Semicera's SiC emishinini yokufaka i-plasma, ukusebenza kahle nokuphila isikhathi eside kuthuthukiswa kakhulu, kunciphisa izindleko zokunakekela zizonke kanye nokuthuthukisa ukusebenza kahle kokukhiqiza. Ukwengeza, i-Semicera ingenza ngokwezifiso ukumelana nezindandatho zokugxila ukuze kuhlangatshezwane nezidingo ezithile zamakhasimende.

Ngokukhetha izindandatho zokugxila ze-SiC ku-Semicera Semiconductor, amakhasimende angafinyelela izinzuzo zomjikelezo omude wokushintsha nokusebenza okuphakeme ngaphandle kokukhuphuka okukhulu kwezindleko.

Isikhathi sokuthumela: Jul-10-2024