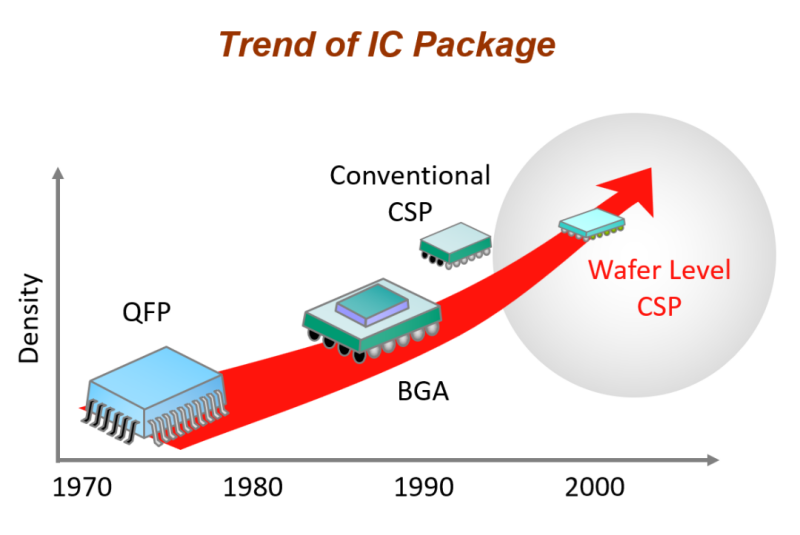

Ubuchwepheshe bokupakisha bungenye yezinqubo ezibaluleke kakhulu embonini ye-semiconductor. Ngokwesimo sephakheji, ingahlukaniswa ngephakheji yesokhethi, iphakheji ye-surface Mount, iphakheji ye-BGA, iphakheji yesayizi ye-chip (CSP), iphakheji yemojula ye-chip eyodwa (SCM, igebe phakathi kwezintambo ebhodini lesifunda eliphrintiwe (PCB) kanye nomentshisi wephedi lebhodi elididiyelwe (IC), iphakethe lemojula ye-multi-chip (MCM, engahlanganisa ama-chips ahlukahlukene), iphakheji yezinga le-wafer (WLP, okuhlanganisa iphakheji yeleveli ye-wafer-out (FOWLP), i-micro surface mount izingxenye (microSMD), njll.), iphakheji ye-three-dimensional (iphakheji yokuxhuma i-micro bump, iphakheji ye-TSV interconnect, njll.), iphakheji yesistimu (SIP), isistimu ye-chip (SOC).

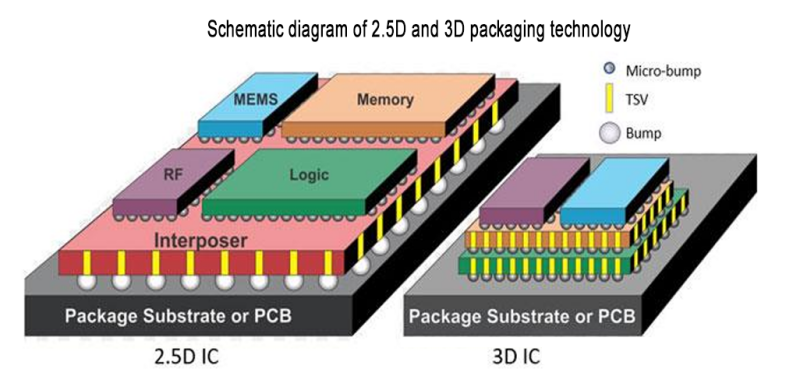

Izinhlobo zokupakishwa kwe-3D zihlukaniswa ngokuyinhloko zibe izigaba ezintathu: uhlobo olungcwatshiwe (ukungcwaba idivayisi kuzintambo ezinezingqimba eziningi noma ukungcwatshwa ku-substrate), uhlobo lwe-substrate esebenzayo (ukuhlanganiswa kwe-silicon wafer: okokuqala hlanganisa izingxenye kanye ne-wafer substrate ukuze wenze i-substrate esebenzayo. ; bese uhlela imigqa yokuxhuma enezingqimba eziningi, bese uhlanganisa amanye ama-chips noma izingxenye kungqimba olungaphezulu) kanye nohlobo olustakiwe (amawafa e-silicon apakishwe ngamawafa e-silicon, ama-chips). epakishwe ngeziqephu ze-silicon, nama-chips apakishwe ngama-chips).

Izindlela zokuxhumanisa i-3D zifaka i-wire bonding (WB), i-flip chip (FC), nge-silicon nge-(TSV), umqhubi wefilimu, njll.

I-TSV ibona ukuxhumana okuqondile phakathi kwama-chips. Njengoba ulayini wokuxhuma ome mpo unebanga elifushane namandla angaphezulu, kulula ukubona i-miniaturization, ukuminyana okuphezulu, ukusebenza okuphezulu, kanye nokupakishwa kwesakhiwo se-heterogeneous multifunctional. Ngesikhathi esifanayo, ingakwazi futhi ukuxhuma ama-chips ezinto ezahlukene;

okwamanje, kunezinhlobo ezimbili zobuchwepheshe bokukhiqiza ama-microelectronics kusetshenziswa inqubo ye-TSV: ukupakishwa kwesekethe enezinhlangothi ezintathu (ukuhlanganiswa kwe-3D IC) kanye nokupakishwa kwe-silicon enezinhlangothi ezintathu (ukuhlanganiswa kwe-3D Si).

Umehluko phakathi kwamafomu amabili ukuthi:

(1) Ukupakishwa kwesekethe ye-3D kudinga ukuthi ama-electrode e-chip alungiswe abe amaqhubu, futhi amaqhubu axhunywe (ahlanganiswe yi-bonding, fusion, welding, njll.), kuyilapho ukupakishwa kwe-silicon ye-3D kuwukuxhumana okuqondile phakathi kwama-chips (ukubopha phakathi kwama-oxide ne-Cu -Cu ukuhlanganisa).

(2) Ubuchwepheshe bokuhlanganiswa kwesekethe ye-3D bungafinyelelwa ngokubopha phakathi kwama-wafers (ukupakishwa kwesekethe ye-3D, ukupakishwa kwe-silicon ye-3D), kuyilapho i-chip-to-chip bonding kanye ne-chip-to-wafer bonding ingafinyelelwa kuphela ngokupakishwa kwesekethe ye-3D.

(3) Kukhona izikhala phakathi kwama-chips ahlanganiswe yinqubo yokupakisha yesifunda se-3D, futhi izinto ze-dielectric zidinga ukugcwaliswa ukuze kulungiswe i-thermal conductivity kanye ne-thermal yokwandisa i-coefficient yesistimu ukuze kuqinisekiswe ukuzinza kwezakhiwo zemishini nekagesi yesistimu; azikho izikhala phakathi kwama-chips ahlanganiswe yinqubo yokupakisha ye-silicon ye-3D, futhi ukusetshenziswa kwamandla, ivolumu, nesisindo se-chip kuncane, nokusebenza kukagesi kuhle kakhulu.

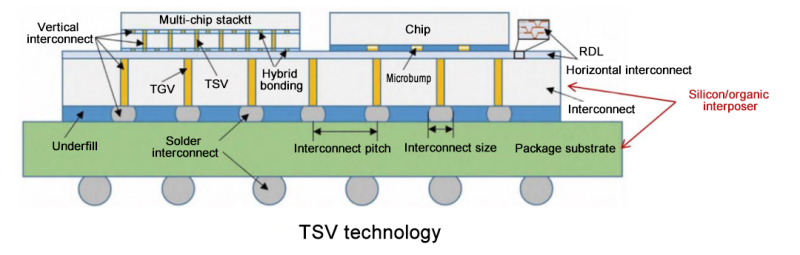

Inqubo ye-TSV ingakha indlela yesignali eqondile phakathi kwe-substrate futhi ixhume i-RDL phezulu nangaphansi kwe-substrate ukuze yakhe indlela yekhondatha enezinhlangothi ezintathu. Ngakho-ke, inqubo ye-TSV ingelinye lamatshe ekhona abalulekile okwakhiwa kwesakhiwo sedivayisi engenzi lutho enezinhlangothi ezintathu.

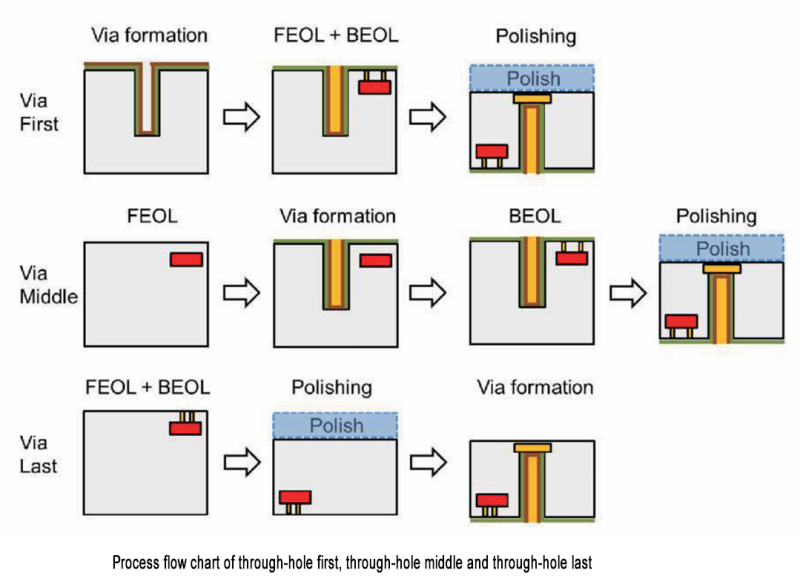

Ngokohlelo phakathi komugqa ongaphambili womugqa (FEOL) kanye nokuphela komugqa (BEOL), inqubo ye-TSV ingahlukaniswa ngezinqubo ezintathu ezijwayelekile zokukhiqiza, okungukuthi, ngeyokuqala (i-ViaFirst), idlule phakathi (Via Middle) kanye ngenqubo yokugcina (Ngedlule), njengoba kukhonjisiwe emfanekisweni.

1. Ngenqubo yokubhala

Inqubo nge-etching iwukhiye wokwenza isakhiwo se-TSV. Ukukhetha inqubo yokubhala efanelekile kungathuthukisa ngempumelelo amandla emishini kanye nezakhiwo zikagesi ze-TSV, futhi kuhlobene nakakhulu nokuthembeka kukonke kwedivayisi ye-TSV enezinhlangothi ezintathu.

Njengamanje, kune-TSV eyinhloko emine esebenzisa izinqubo zokuhlanganisa: I-Deep Reactive Ion Etching (DRIE), i-wet etching, i-photo-assisted electrochemical etching (PAECE) kanye ne-laser drilling.

(1) I-Deep Reactive Ion Etching (DRIE)

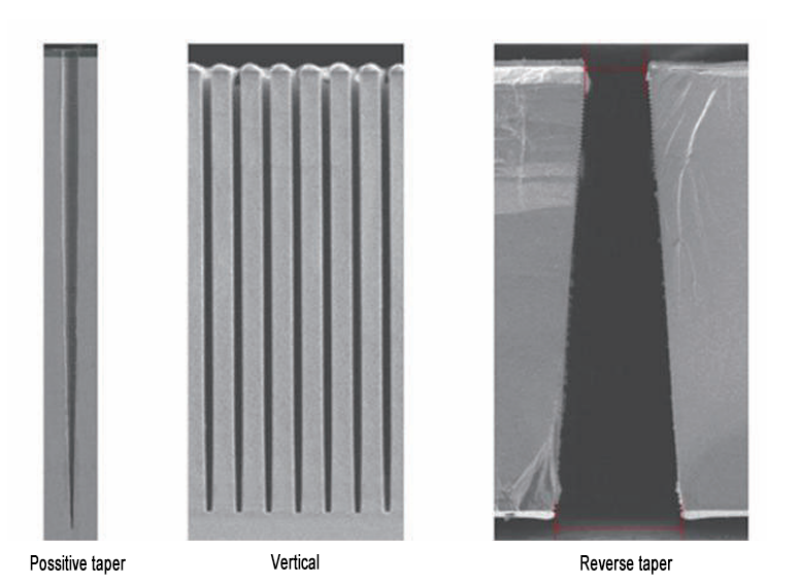

I-Deep reactive ion etching, eyaziwa nangokuthi inqubo ye-DRIE, inqubo yokuqopha evame ukusetshenziswa kakhulu ye-TSV, esetshenziswa kakhulu ukubona i-TSV ngezakhiwo ezine-aspect ratio ephezulu. Izinqubo zosiko zokuqopha i-plasma ngokuvamile zingafinyelela kuphela ukujula kokujula kwama-microns ambalwa, ngezinga eliphansi lokukhipha kanye nokuntuleka kokukhetha kwemaski etching. I-Bosch yenze intuthuko yenqubo ehambisanayo ngalesi sisekelo. Ngokusebenzisa i-SF6 njengegesi esebenzayo kanye nokukhipha igesi ye-C4F8 phakathi nenqubo yokuhlanganisa njengesivikelo sokudlula sezindonga ezisemaceleni, inqubo ye-DRIE ethuthukisiwe ifaneleka ukufaka isici sesilinganiso esiphezulu. Ngakho-ke, ibizwa nangokuthi inqubo ye-Bosch ngemuva komsunguli wayo.

Isithombe esingezansi siyisithombe se-aspect ratio ephezulu esakhiwe ngokubhala inqubo ye-DRIE.

Nakuba inqubo ye-DRIE isetshenziswa kakhulu kunqubo ye-TSV ngenxa yokulawula kwayo okuhle, okubi kwayo ukuthi ukucaba kwe-sidewall kubi futhi kuzokwakheka izici zokushwabana ezimise okwe-scallop. Lesi sici sibaluleke kakhulu uma ufaka i-aspect ratio nge-aspect ratio.

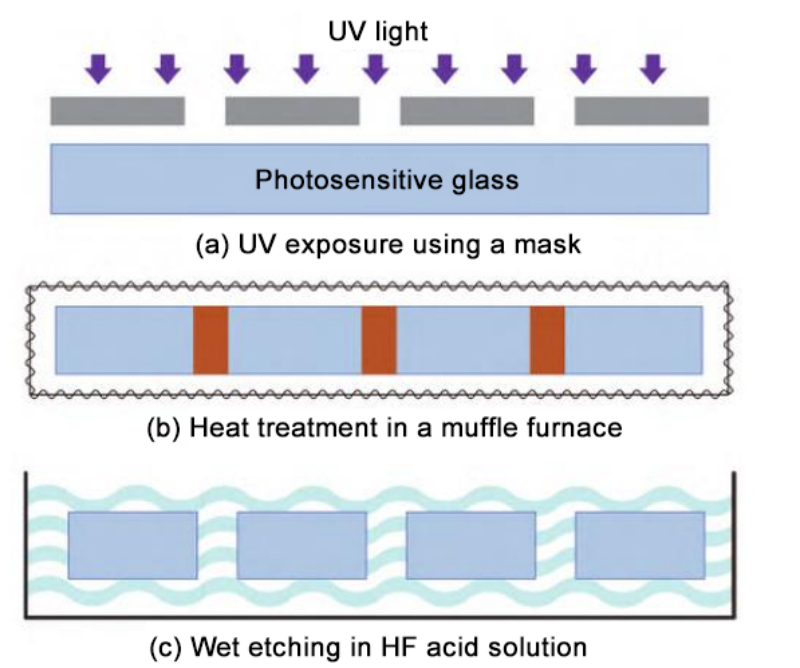

(2) Ukubhebhana okumanzi

I-Wet etching isebenzisa inhlanganisela yemaski kanye ne-chemical etching ukuze ingene emigodini. Isixazululo se-etching esisetshenziswa kakhulu yi-KOH, esingafaka izikhundla ku-silicon substrate ezingavikelwe imaski, ngaleyo ndlela yakhe isakhiwo esifiselekayo sembobo. I-Wet etching iyinqubo yokuqala yokuqopha imbobo ethuthukisiwe. Njengoba izinyathelo zayo zenqubo kanye nemishini edingekayo ilula, ifanele ukukhiqizwa ngobuningi be-TSV ngezindleko eziphansi. Kodwa-ke, indlela yayo yokuhlanganisa amakhemikhali inquma ukuthi imbobo edabula ngale ndlela izothinteka ngokuma kwekristalu kwesinkwa esisicwecwana se-silicon, okwenza imbobo eboshiwe ingabi mpo kodwa ibonise into ecacile yengaphezulu elibanzi nephansi eliwumngcingo. Lesi sici sikhawulela ukusetshenziswa kwe-etching emanzi ekukhiqizeni kwe-TSV.

(3) Ukufakwa kwe-electrochemical (PAECE) okusizwa isithombe

Umgomo oyisisekelo we-photo-assisted electrochemical etching (PAECE) ukusebenzisa ukukhanya kwe-ultraviolet ukusheshisa ukukhiqizwa kwamapheya e-electron-hole, ngaleyo ndlela kusheshiswe inqubo yokuhlanganisa i-electrochemical. Uma kuqhathaniswa nenqubo ye-DRIE esetshenziswa kabanzi, inqubo ye-PAECE ifaneleka kakhulu ukuhlanganisa izakhiwo ze-ultra-large aspect ratio ngokusebenzisa imbobo enkulu kuno-100:1, kodwa okubi kwayo ukuthi ukulawulwa kokujula kokushumeka kubuthakathaka kune-DRIE, futhi ubuchwepheshe bayo zidinga ucwaningo olwengeziwe kanye nokuthuthukiswa kwenqubo.

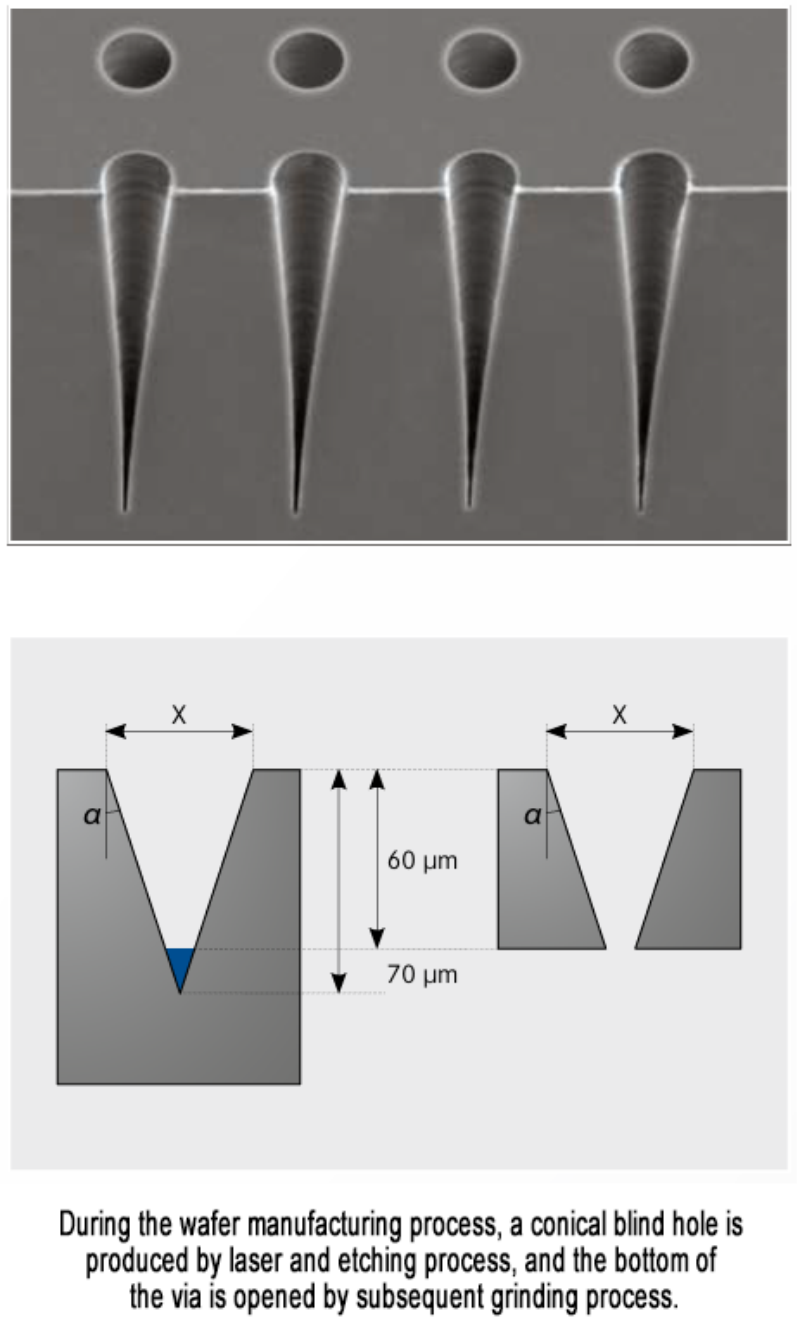

(4) Ukubhoboza i-laser

Ihlukile kulezi zindlela ezintathu ezingenhla. Indlela yokumba i-laser iyindlela engokomzimba kuphela. Ikakhulukazi isebenzisa imisebe yelaser enamandla amakhulu ukuncibilikisa nokuhwamulisa i-substrate material endaweni eshiwo ukuze ibone ngokoqobo ukwakhiwa kwembobo ye-TSV.

Imbobo yokubhoboza eyenziwe nge-laser ine-aspect ratio ephezulu futhi i-sidewall imile ngokuyisisekelo. Kodwa-ke, njengoba i-laser drilling empeleni isebenzisa ukushisisa kwasendaweni ukwenza imbobo ephumela, udonga lwembobo lwe-TSV luzothinteka kabi ngokulimala okushisayo futhi lunciphise ukuthembeka.

2. Inqubo yokubeka isendlalelo selayini

Obunye ubuchwepheshe obubalulekile bokukhiqiza i-TSV inqubo yokubeka isendlalelo se-liner.

Inqubo yokubeka ungqimba lwe-liner yenziwa ngemva kokuqoshwa kwembobo yokudlula. Isendlalelo se-liner esifakiwe ngokuvamile siyi-oxide efana ne-SiO2. Isendlalelo se-liner sitholakala phakathi kwe-conductor yangaphakathi ye-TSV kanye ne-substrate, futhi idlala ikakhulukazi indima yokuhlukanisa ukuvuza kwamanje kwe-DC. Ngaphezu kokufaka i-oxide, izingqimba nezingqimba zembewu nazo ziyadingeka ukuze kugcwaliswe umqhubi ohlelweni olulandelayo.

Isendlalelo se-liner esakhiwe kufanele sihlangabezane nezidingo ezimbili eziyisisekelo ezilandelayo:

(1) i-voltage ehlukanayo yongqimba lwe-insulating kufanele ihlangabezane nezidingo zangempela zokusebenza ze-TSV;

(2) izingqimba ezifakiwe ziyahambisana kakhulu futhi zinokunamathela okuhle komunye nomunye.

Isibalo esilandelayo sibonisa isithombe sesendlalelo se-liner esifakwe i-plasma enhanced chemical vapor deposition (PECVD).

Inqubo yokubeka idinga ukulungiswa ngokufanele ngezinqubo ezahlukene zokukhiqiza ze-TSV. Ngenqubo ye-front through-hole, inqubo yokubeka izinga lokushisa eliphezulu ingasetshenziswa ukuthuthukisa ikhwalithi yongqimba lwe-oxide.

Ukufakwa okujwayelekile kwezinga lokushisa eliphezulu kungase kusekelwe ku-tetraethyl orthosilicate (TEOS) ehlanganiswe nenqubo ye-oxidation eshisayo ukuze kwakheke ungqimba oluvikelayo lwekhwalithi ephezulu ye-SiO2. Ngenqubo ephakathi nendawo nembobo yokubuyela emuva, njengoba inqubo ye-BEOL isiqediwe ngesikhathi sokubekwa, indlela yezinga lokushisa eliphansi iyadingeka ukuze kuqinisekiswe ukuhambisana nezinto ze-BEOL.

Ngaphansi kwalesi simo, izinga lokushisa lokubeka kufanele likhawulelwe ku-450°, okuhlanganisa ukusetshenziswa kwe-PECVD ukuze ufake i-SiO2 noma i-SiNx njengesendlalelo sokuvikela.

Enye indlela evamile ukusebenzisa i-atomic layer deposition (ALD) ukufaka i-Al2O3 ukuze uthole ungqimba oluminyene lwe-insulating.

3. Inqubo yokugcwalisa insimbi

Inqubo yokugcwalisa ye-TSV yenziwa ngokushesha ngemva kwenqubo yokubeka i-liner, okungobunye ubuchwepheshe obubalulekile obunquma ikhwalithi ye-TSV.

Izinto ezingagcwaliswa zihlanganisa i-polysilicon ene-doped, i-tungsten, i-carbon nanotubes, njll. kuye ngenqubo esetshenzisiwe, kodwa okujwayelekile kakhulu kuseyithusi elenziwe nge-electroplated, ngoba inqubo yalo ivuthiwe futhi ukuqhutshwa kwayo kukagesi nokushisayo kuphakeme ngokuqhathaniswa.

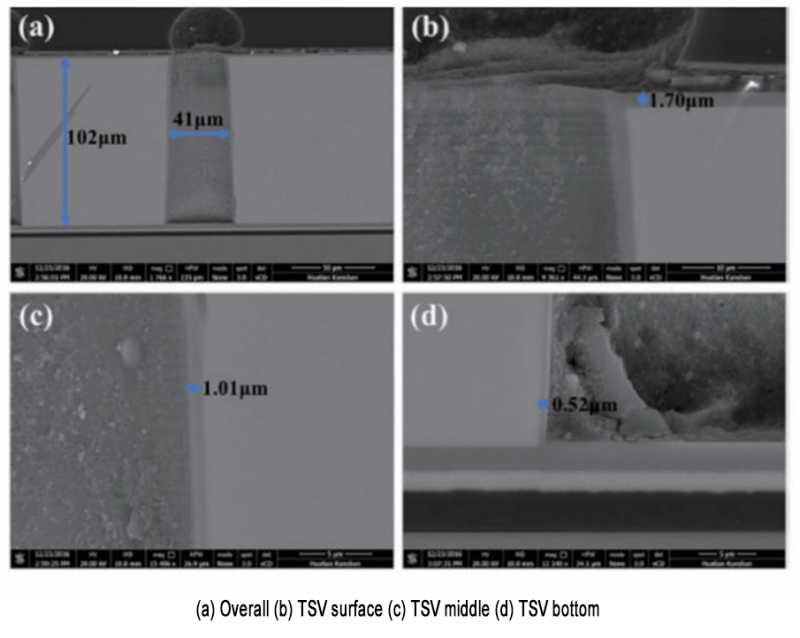

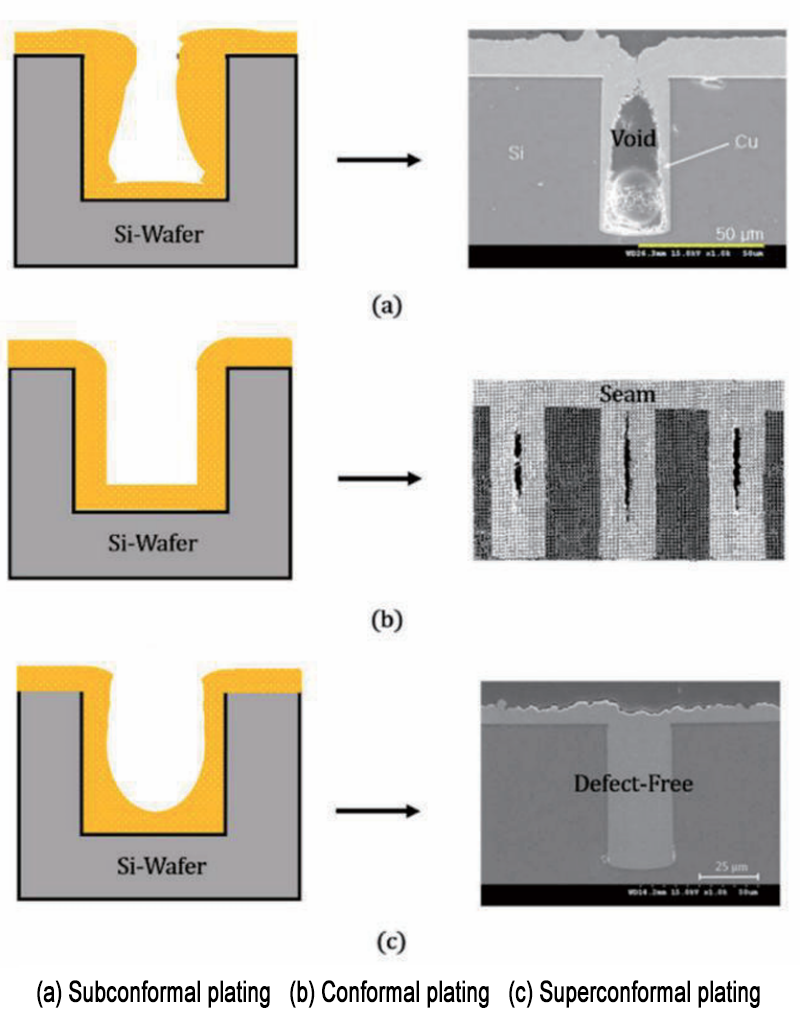

Ngokomehluko wokusabalalisa wezinga layo le-electroplating embotsheni edlulayo, ingahlukaniswa ngokuyinhloko ibe izindlela ze-electroplating ezingaphansi, ezivumelanayo, eziphakeme kakhulu neziphansi phezulu, njengoba kuboniswe emfanekisweni.

I-subconformal electroplating yayisetshenziswa kakhulu esigabeni sokuqala socwaningo lwe-TSV. Njengoba kuboniswe kuMfanekiso (a), ama-Cu ions ahlinzekwa yi-electrolysis agxilwe phezulu, kuyilapho okuphansi kungeziwe ngokungenele, okubangela izinga le-electroplating phezulu kwembobo yokudlula ibe phezulu kunaleyo engezansi phezulu. Ngakho-ke, i-top hole-hole izovalwa kusengaphambili ngaphambi kokuba igcwaliswe ngokuphelele, futhi kuzokwakhiwa isikhala esikhulu ngaphakathi.

Umdwebo wohlelo nesithombe sendlela ye-conformal electroplating kukhonjisiwe kuMfanekiso (b). Ngokuqinisekisa ukwengezwa okufanayo kwama-Cu ions, izinga le-electroplating endaweni ngayinye embobeni ngokuyisisekelo liyafana, ngakho-ke kuzosala kuphela umthungo ngaphakathi, futhi ivolumu engenalutho incane kakhulu kunaleyo yendlela ye-electroplating engaphansi. isetshenziswa kabanzi.

Ukuze kuqhutshekwe kuzuzwe umphumela wokugcwalisa ongenalutho, indlela ye-superconformal electroplating yahlongozwa ukuze kwandiswe indlela ye-conformal electroplating. Njengoba kuboniswe kuMfanekiso (c), ngokulawula ukunikezwa kwe-Cu ions, izinga lokugcwalisa elingezansi liphakeme kancane kunalelo kwezinye izikhundla, ngaleyo ndlela kuthuthukisa i-gradient yesinyathelo sezinga lokugcwalisa ukusuka phansi kuya phezulu ukuze kuqedwe ngokuphelele umthungo kwesokunxele. nge-conformal electroplating method, ukuze kuzuzwe ukugcwaliswa kwethusi kwensimbi okungenalutho ngokuphelele.

Indlela ye-electroplating engezansi-phezulu ingabhekwa njengecala elikhethekile lendlela ye-super-conformal. Kulesi simo, izinga le-electroplating ngaphandle kwephansi licindezelwa ku-zero, futhi i-electroplating kuphela eyenziwa kancane kancane kusukela phansi kuya phezulu. Ngaphezu kokusizakala kwe-void-free yendlela ye-conformal electroplating, le ndlela ingase futhi inciphise ngempumelelo isikhathi sisonke se-electroplating, ngakho iye yacwaningwa kabanzi eminyakeni yamuva.

4. Ubuchwepheshe benqubo ye-RDL

Inqubo ye-RDL iwubuchwepheshe obuyisisekelo obubalulekile enqubweni yokupakisha enezinhlangothi ezintathu. Ngale nqubo, ukuxhumana kwensimbi kungenziwa ezinhlangothini zombili ze-substrate ukuze kufezwe injongo yokwabiwa kabusha kwechweba noma ukuxhumana phakathi kwamaphakheji. Ngakho-ke, inqubo ye-RDL isetshenziswa kakhulu kuma-fan-in-fan-out noma amasistimu wokupakisha we-2.5D/3D.

Enqubweni yokwakha amadivayisi anezinhlangothi ezintathu, inqubo ye-RDL ivamise ukusetshenziselwa ukuxhuma i-TSV ukuze kuqashwe izinhlobonhlobo zezakhiwo zedivayisi ezinezinhlangothi ezintathu.

Njengamanje kunezinqubo ezimbili ezijwayelekile ze-RDL. Eyokuqala isekelwe kuma-polymers e-photosensitive futhi ihlanganiswe nezinqubo zethusi ze-electroplating ne-etching; enye isetshenziswa kusetshenziswa inqubo ye-Cu Damaseku ehlanganiswe ne-PECVD kanye nenqubo yokupholisha ngamakhemikhali (CMP).

Okulandelayo kuzokwethula izindlela zenqubo ezijwayelekile zalawa ma-RDL amabili ngokulandelana.

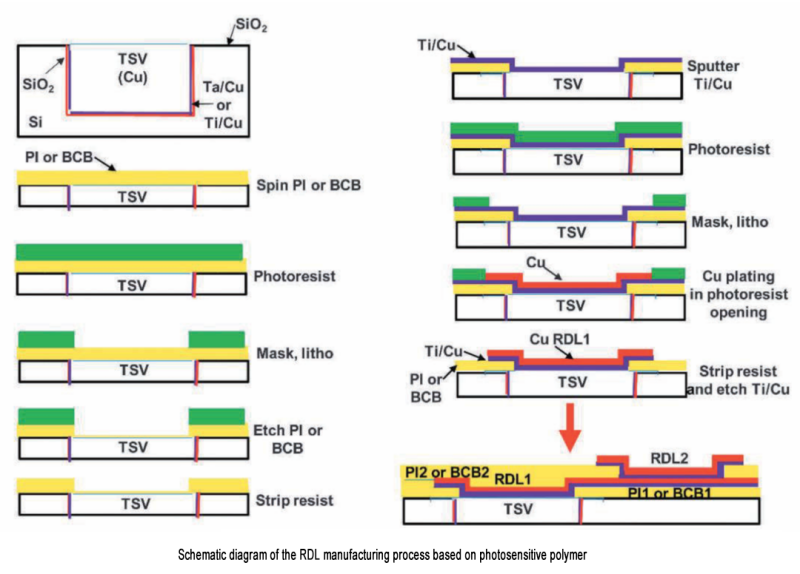

Inqubo ye-RDL esekelwe ku-polymer e-photosensitive ikhonjisiwe esithombeni esingenhla.

Okokuqala, ungqimba lwe-PI noma lwe-BCB glue lumbozwe phezu kwe-wafer ngokujikeleza, futhi ngemva kokushisa nokuphulukisa, inqubo ye-photolithography isetshenziselwa ukuvula izimbobo endaweni oyifunayo, bese u-etching yenziwa. Okulandelayo, ngemva kokukhipha i-photoresist, u-Ti no-Cu bafafazwa ku-wafer ngenqubo yokubeka umhwamuko obonakalayo (PVD) njengesendlalelo sokuvimbela kanye nongqimba lwembewu, ngokulandelana. Okulandelayo, ungqimba lokuqala lwe-RDL lukhiqizwa kusendlalelo se-Ti/Cu esiveziwe ngokuhlanganisa i-photolithography nezinqubo ze-electroplating Cu, bese kukhishwa i-photoresist bese kuqoshwa i-Ti ne-Cu engaphezulu. Phinda izinyathelo ezingenhla ukuze wakhe uhlaka lwe-RDL enezingqimba eziningi. Le ndlela okwamanje isetshenziswa kabanzi embonini.

Enye indlela yokukhiqiza i-RDL ngokuyinhloko isekelwe kwinqubo ye-Cu Damaseku, ehlanganisa izinqubo ze-PECVD ne-CMP.

Umehluko phakathi kwale ndlela kanye nenqubo ye-RDL esekelwe ku-polymer e-photosensitive ukuthi esinyathelweni sokuqala sokukhiqiza ungqimba ngalunye, i-PECVD isetshenziselwa ukufaka i-SiO2 noma i-Si3N4 njengongqimba oluvikelayo, bese kwakhiwa iwindi kungqimba oluvikelayo nge-photolithography kanye i-ion etching esebenzayo, kanye nongqimba lwe-Ti/Cu/ungqimba lwembewu kanye nekhopha yekhondatha kuphafazwa ngokulandelana, bese ungqimba lwekhondatha luncishiswa lube ukujiya okudingekayo Inqubo ye-CMP, okungukuthi, ungqimba lwe-RDL noma ungqimba lwembobo luyakhiwa.

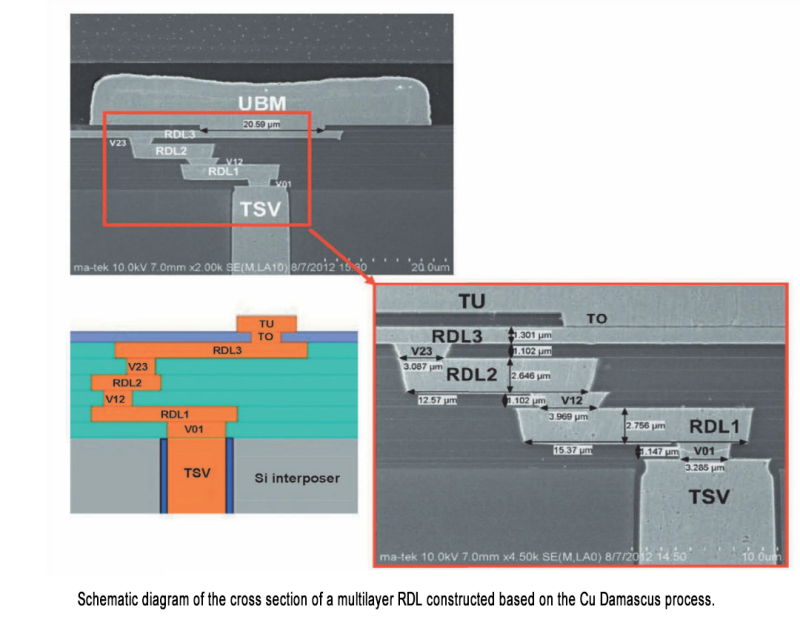

Isibalo esilandelayo siwumdwebo wohlelo nesithombe sesigaba esiphambanayo se-RDL enezingqimba eziningi esakhiwe ngokusekelwe kunqubo ye-Cu Damaseku. Kungaqashelwa ukuthi i-TSV iqala ngokuxhunywa kusendlalelo sembobo edlula i-V01, bese inqwabelaniswa ukusuka phansi kuye phezulu ngokulandelana kwe-RDL1, ungqimba lwe-hole V12, kanye ne-RDL2.

Ingqimba ngayinye ye-RDL noma i- through-hole layer yenziwa ngokulandelana ngendlela engenhla.Njengoba inqubo ye-RDL idinga ukusetshenziswa kwenqubo ye-CMP, izindleko zayo zokukhiqiza ziphakeme kunalezo zenqubo ye-RDL esekelwe ku-photosensitive polymer, ngakho-ke ukusetshenziswa kwayo kuphansi kakhulu.

5. Ubuchwepheshe benqubo ye-IPD

Ukuze kwenziwe amadivayisi anezinhlangothi ezintathu, ngaphezu kokuhlanganiswa okuqondile kwe-chip ku-MMIC, inqubo ye-IPD inikeza enye indlela yobuchwepheshe evumelana nezimo.

Imishini ehlanganisiwe ye-passive, eyaziwa nangokuthi inqubo ye-IPD, ihlanganisa noma iyiphi inhlanganisela yamadivayisi angenzi lutho okuhlanganisa ama-on-chip inductors, ama-capacitor, ama-resistors, iziguquli ze-balun, njll. endaweni engaphansi ehlukile ukuze akhe umtapo wolwazi wedivayisi engenzi lutho ngendlela yebhodi lokudlulisa elingakwazi kubizwe ngokuguquguqukayo ngokwezidingo zokuklama.

Njengoba enqubweni ye-IPD, izinto ezisetshenziswayo ziyakhiqizwa futhi zihlanganiswe ngokuqondile ebhodini lokudlulisa, ukugeleza kwenqubo yakho kulula futhi kungabizi kakhulu kunokuhlanganiswa kwe-on-chip kwama-ICs, futhi kungakhiqizwa ngobuningi kusenesikhathi njengomtapo wezincwadi wedivayisi ongenzi lutho.

Ngokukhiqizwa kwedivayisi ye-TSV enezinhlangothi ezintathu, i-IPD ingasusa ngempumelelo umthwalo wezindleko wezinqubo zokupakisha ezinezinhlangothi ezintathu ezihlanganisa i-TSV ne-RDL.

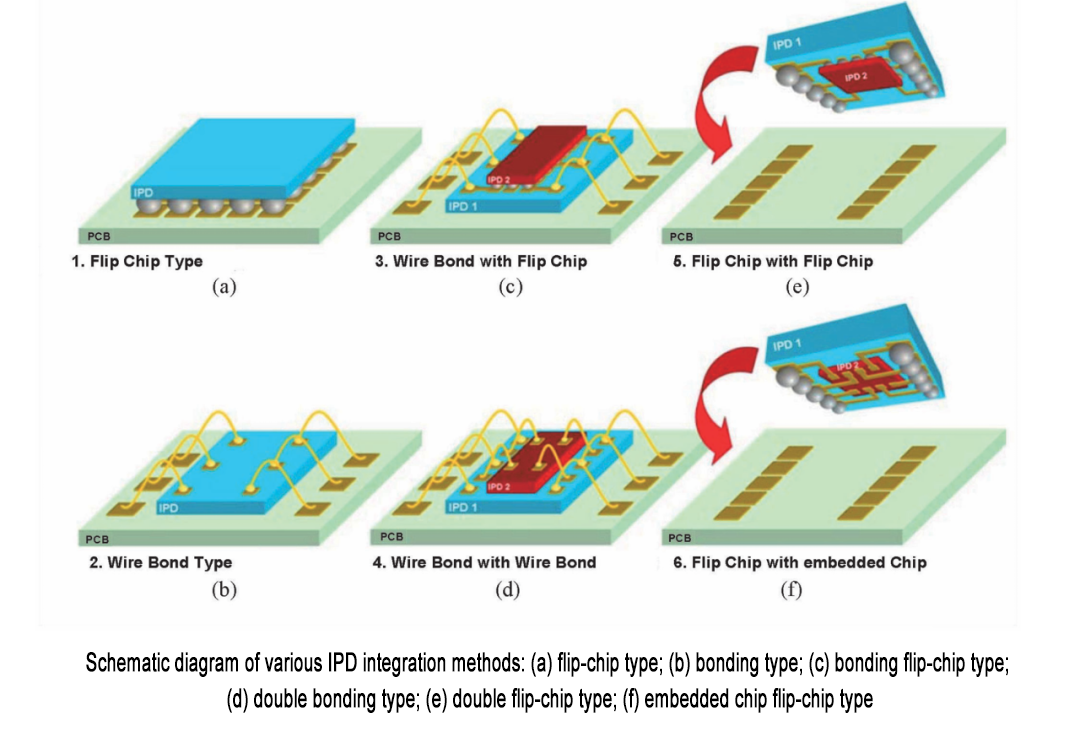

Ngaphezu kwezinzuzo zezindleko, enye inzuzo ye-IPD ukuguquguquka kwayo okuphezulu. Okukodwa kokuguquguquka kwe-IPD kubonakala ezindleleni ezihlukene zokuhlanganisa, njengoba kuboniswe esithombeni esingezansi. Ukwengeza ezindleleni ezimbili eziyisisekelo zokuhlanganisa ngokuqondile i-IPD ku-substrate yephakheji ngokusebenzisa inqubo ye-flip-chip njengoba kuboniswe kuMfanekiso (a) noma inqubo yokuhlanganisa njengoba kuboniswe kuMfanekiso (b), olunye ungqimba lwe-IPD lungahlanganiswa kusendlalelo esisodwa. ye-IPD njengoba kukhonjisiwe ku-Figure (c)-(e) ukuze kuzuzwe uhla olubanzi lwenhlanganisela yedivayisi ye-passive.

Ngesikhathi esifanayo, njengoba kukhonjisiwe kuMfanekiso (f), i-IPD ingasetshenziswa futhi njengebhodi ye-adaptha ukuze kungcwatshwe ngokuqondile i-chip ehlanganisiwe kuyo ukuze kwakhiwe ngokuqondile uhlelo lokupakisha olunokuminyana okuphezulu.

Uma usebenzisa i-IPD ukwakha amadivaysi e-passive anezinhlangothi ezintathu, inqubo ye-TSV kanye nenqubo ye-RDL nayo ingasetshenziswa. Ukugeleza kwenqubo ngokuyisisekelo kuyafana nendlela yokucubungula ukuhlanganiswa kwe-chip eshiwo ngenhla, futhi ngeke kuphindwe; umehluko wukuthi njengoba into yokuhlanganiswa ishintshiwe kusukela ku-chip kuya ebhodini le-adaptha, asikho isidingo sokucabangela umthelela wenqubo yokupakisha ye-three-dimensional endaweni esebenzayo kanye nesendlalelo sokuxhuma. Lokhu kuqhubekela phambili kuholela kokunye ukuguquguquka okubalulekile kwe-IPD: izinto ezahlukahlukene ze-substrate zingakhethwa ngokuguquguqukayo ngokuya ngezidingo zokuklama zemishini yokwenziwa.

Izinto ze-substrate ezitholakalayo ze-IPD azizona nje izinto ezivamile ze-semiconductor substrate ezifana ne-Si ne-GaN, kodwa futhi izitsha zobumba ze-Al2O3, izitsha zobumba ezibaselwe ngokuhlanganyela izinga lokushisa eliphansi/lokushisa okuphezulu, ama-glass substrates, njll. Lesi sici sinweba ngempumelelo ukuguquguquka kwedizayini kokungenzi lutho. amadivayisi ahlanganiswe IPD.

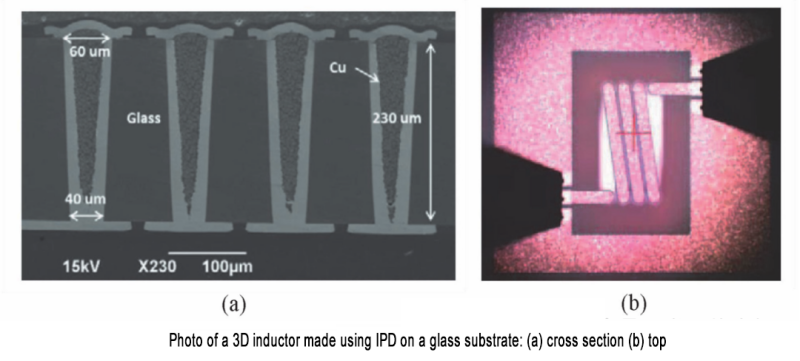

Isibonelo, isakhiwo se-inductor esinezinhlangothi ezintathu esingaguquki esihlanganiswe yi-IPD singasebenzisa i-substrate yengilazi ukuze kuthuthukiswe ngempumelelo ukusebenza kwe-inductor. Ngokuphambene nomqondo we-TSV, izimbobo ezenziwe ku-substrate yengilazi nazo zibizwa ngokuthi i- through-glass vias (TGV). Isithombe se-inductor enezinhlangothi ezintathu esakhiwe ngokusekelwe kuzinqubo ze-IPD ne-TGV siboniswa esithombeni esingezansi. Njengoba ukumelana kwe-substrate yengilazi kuphakeme kakhulu kunokwezinto ezivamile ze-semiconductor ezifana ne-Si, i-TGV i-inductor enezinhlangothi ezintathu inezinto ezingcono zokuhlanganisa, futhi ukulahlekelwa kokufakwa okubangelwa umphumela we-substrate parasitic kumafrikhwensi aphezulu kuncane kakhulu kunalokho i-inductor evamile ye-TSV enezinhlangothi ezintathu.

Ngakolunye uhlangothi, ama-capacitor e-metal-insulator-metal (MIM) nawo angakhiqizwa ku-IPD yengilazi engaphansi ngenqubo yokubeka ifilimu elincanyana, futhi axhunywe ne-TGV i-inductor enezinhlangothi ezintathu ukuze kwakhe uhlaka lwesihlungi esinezinhlangothi ezintathu. Ngakho-ke, inqubo ye-IPD inamandla abanzi wokusebenzisa ukuthuthukiswa kwemishini emisha enezinhlangothi ezintathu.

Isikhathi sokuthumela: Nov-12-2024