Ukukhula Okusheshayo Kwe-SiC Single Crystal UkusebenzisaI-CVD-SiC UbuningiUmthombo nge-Sublimation Method

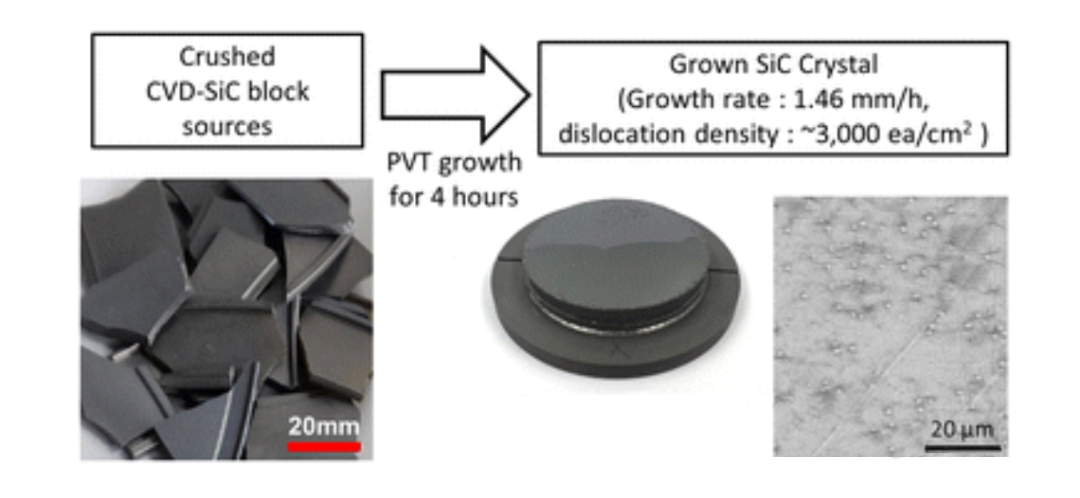

Ngokusebenzisa okugaywe kabushaAmabhulokhi we-CVD-SiCnjengomthombo we-SiC, amakristalu e-SiC akhule ngempumelelo ngesilinganiso se-1.46 mm / h ngokusebenzisa indlela ye-PVT. I-micropipe ye-crystal ekhulile kanye nokuminyana kokuhlukana kubonisa ukuthi naphezu kwezinga lokukhula eliphezulu, ikhwalithi yekristalu yinhle kakhulu.

I-Silicon carbide (SiC)iyi-wide-bandgap semiconductor enezakhiwo ezinhle kakhulu zokusetshenziswa ku-voltage ephezulu, amandla aphezulu, kanye nemvamisa ephezulu. Isidingo sayo sikhule ngokushesha eminyakeni yamuva, ikakhulukazi emkhakheni we-semiconductor yamandla. Kuzinhlelo zokusebenza ze-semiconductor yamandla, amakristalu e-SiC single akhuliswa ngokukhipha umthombo we-SiC we-high-purity ku-2100-2500 ° C, bese ephinda acwebezela kukristalu lwembewu kusetshenziswa indlela yokuthutha umhwamuko obonakalayo (PVT), okulandelwa ukucutshungulwa ukuze kutholwe ama-crystal substrates ama-wafers. . Ngokwesiko,Amakristalu e-SiCzikhuliswa kusetshenziswa indlela ye-PVT ngesilinganiso sokukhula esingu-0.3 kuya ku-0.8 mm/h ukuze kulawuleke ukucwebezela, okuhamba kancane uma kuqhathaniswa nezinye izinto zekristalu eyodwa ezisetshenziswa ezinhlelweni ze-semiconductor. Lapho amakristalu e-SiC ekhulile emazingeni aphezulu okukhula kusetshenziswa indlela ye-PVT, ukuwohloka kwekhwalithi okuhlanganisa ukufakwa kwekhabhoni, ukuhlanzeka okuncishisiwe, ukukhula kwe-polycrystalline, ukwakheka komngcele wokusanhlamvu, kanye nokuchithwa kanye nokukhubazeka kwe-porosity akuzange kukhishwe. Ngakho-ke, ukukhula okusheshayo kwe-SiC akuzange kuthuthukiswe, futhi izinga lokukhula kancane kwe-SiC libe yisithiyo esikhulu ekukhiqizeni ama-substrates e-SiC.

Ngakolunye uhlangothi, imibiko yakamuva yokukhula ngokushesha kwe-SiC ibisebenzisa izindlela zokubeka umhwamuko wamakhemikhali okushisa aphezulu (HTCVD) kunendlela ye-PVT. Indlela ye-HTCVD isebenzisa umhwamuko oqukethe u-Si no-C njengomthombo we-SiC kureactor. I-HTCVD ayikasetshenziselwa ukukhiqizwa okukhulu kwe-SiC futhi idinga ucwaningo olwengeziwe nokuthuthukiswa ukuze kwenziwe ukuhweba. Kuyathakazelisa ukuthi ngisho nangesilinganiso sokukhula esiphezulu esingu-~3 mm/h, amakristalu e-SiC eyodwa angatshalwa ngekhwalithi enhle yekristalu kusetshenziswa indlela ye-HTCVD. Ngaleso sikhathi, izingxenye ze-SiC zisetshenziswe ezinqubweni ze-semiconductor ngaphansi kwezindawo ezinonya ezidinga ukulawulwa kwenqubo yokuhlanzeka okuphezulu kakhulu. Kuzicelo zenqubo ye-semiconductor, ~99.9999% (∼6N) izingxenye ze-SiC zokuhlanzeka zivame ukulungiswa yinqubo ye-CVD kusuka ku-methyltrichlorosilane (CH3Cl3Si, MTS). Kodwa-ke, naphezu kokuhlanzeka okuphezulu kwezingxenye ze-CVD-SiC, zilahliwe ngemuva kokusetshenziswa. Muva nje, izingxenye ze-CVD-SiC ezilahliwe zibhekwa njengemithombo ye-SiC yokukhula kwekristalu, nakuba ezinye izinqubo zokubuyisela ezihlanganisa ukuchotshozwa nokuhlanzwa zisadingeka ukuze kuhlangatshezwane nezidingo eziphezulu zomthombo wokukhula kwekristalu. Kulolu cwaningo, sisebenzise amabhulokhi e-CVD-SiC alahliwe ukuze sisebenzise izinto kabusha njengomthombo wokukhulisa amakristalu e-SiC. Amabhulokhi e-CVD-SiC okukhula kwekristalu eyodwa alungiswa njengamabhulokhi achotshoziwe alawulwa usayizi, ahluke kakhulu ngokuma nosayizi uma kuqhathaniswa ne-SiC powder yezohwebo evame ukusetshenziswa kwinqubo ye-PVT, ngakho-ke ukuziphatha kwe-SiC single crystal ukukhula kwakulindeleke ukuba kube kakhulu. ezahlukene. Ngaphambi kokwenza ukuhlolwa kokukhula kwekristalu eyodwa ye-SiC, ukulingisa kwekhompiyutha kwenziwa ukuze kuzuzwe amazinga aphezulu okukhula, futhi indawo eshisayo yalungiselelwa ngokufanele ukukhula kwekristalu eyodwa. Ngemva kokukhula kwekristalu, amakristalu asekhulile ahlolwe nge-tomography ehlukanisa izingxenye, i-micro-Raman spectroscopy, i-X-ray diffraction enesinqumo esiphezulu, kanye ne-synchrotron white beam X-ray topography.

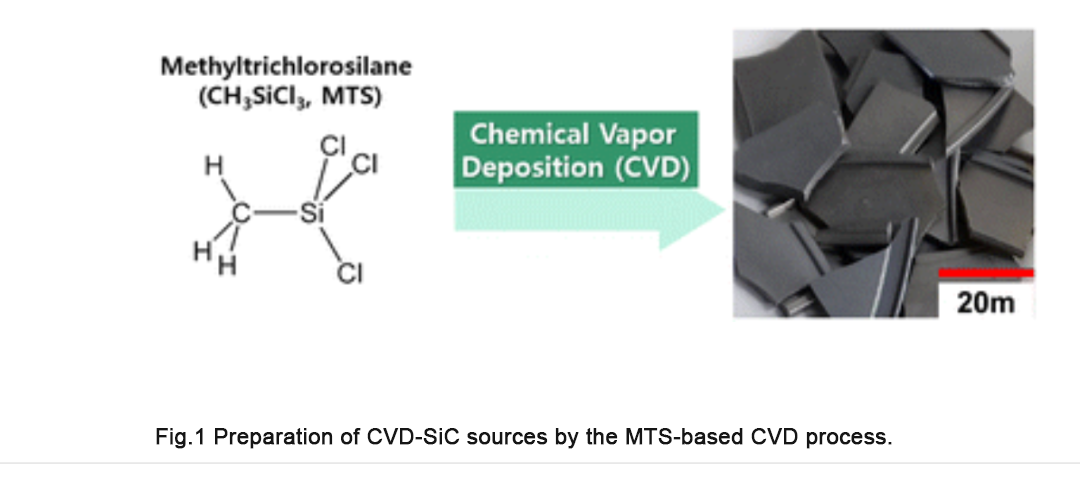

Umfanekiso 1 ubonisa umthombo we-CVD-SiC osetshenziselwa ukukhula kwe-PVT yamakristalu e-SiC kulolu cwaningo. Njengoba kuchazwe esingenisweni, izingxenye ze-CVD-SiC zahlanganiswa kusuka ku-MTS ngenqubo ye-CVD futhi zalolongwa ukusetshenziswa kwe-semiconductor ngokucubungula ngomshini. I-N yafakwa ohlelweni lwe-CVD ukuze kuzuzwe ukuqhutshwa kwezicelo zenqubo ye-semiconductor. Ngemva kokusetshenziswa ezinqubweni ze-semiconductor, izingxenye ze-CVD-SiC zachotshozwa ukuze kulungiswe umthombo wokukhula kwekristalu, njengoba kuboniswe kuMfanekiso 1. Umthombo we-CVD-SiC walungiswa njengamapuleti anobukhulu obuyisilinganiso ~ ~ 0.5 mm kanye nesilinganiso sobukhulu bezinhlayiyana. 49.75 mm.

Umfanekiso 1: Umthombo we-CVD-SiC olungiselelwe inqubo ye-CVD esekwe ku-MTS.

Umfanekiso 1: Umthombo we-CVD-SiC olungiselelwe inqubo ye-CVD esekwe ku-MTS.

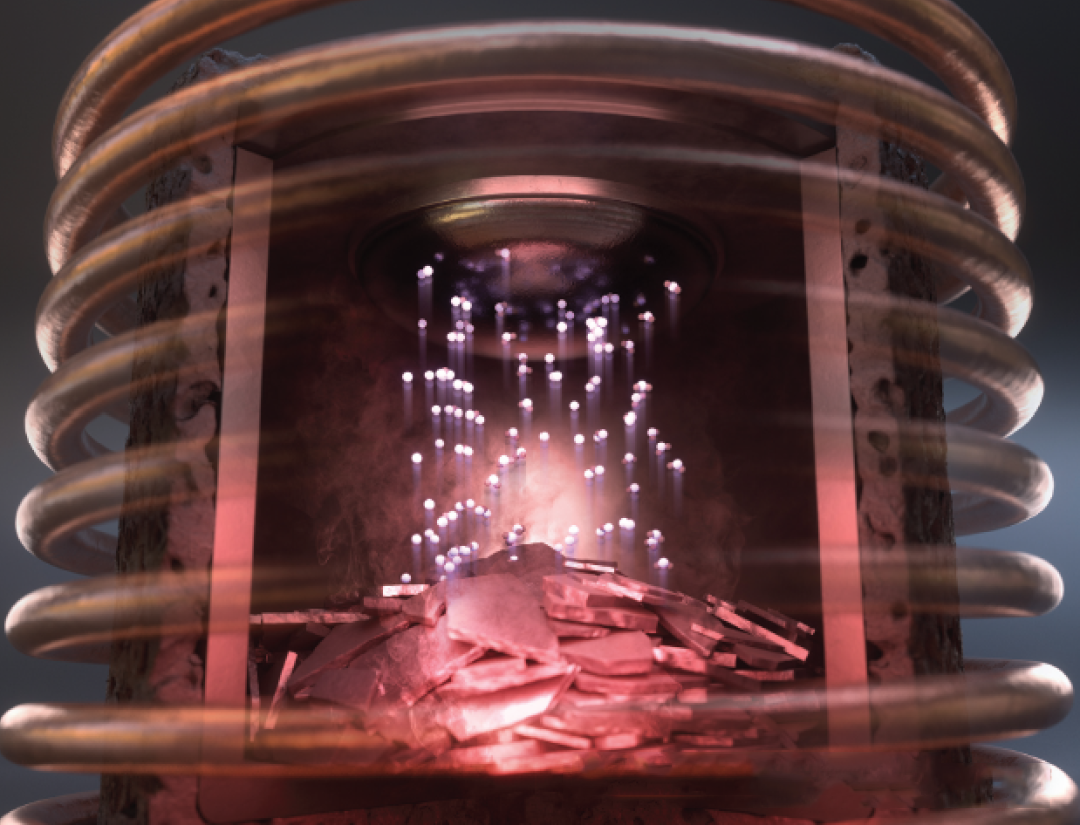

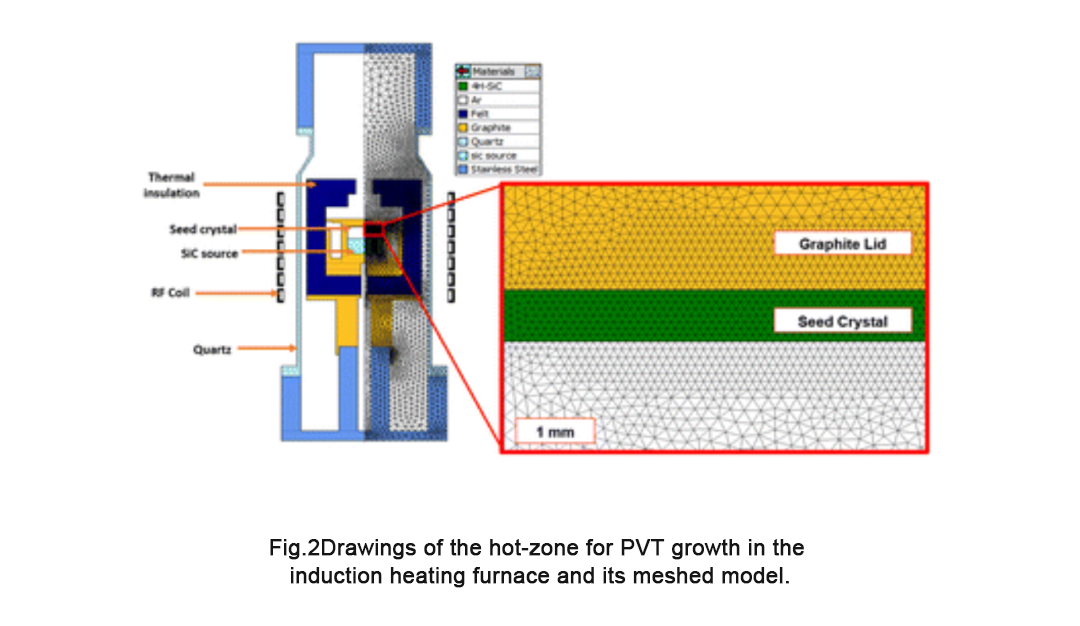

Kusetshenziswa umthombo we-CVD-SiC oboniswe ku-Figure 1, amakristalu e-SiC akhuliswe ngendlela ye-PVT esithandweni sokushisa sokungeniswa. Ukuze uhlole ukusatshalaliswa kwezinga lokushisa endaweni eshisayo, ikhodi yokulingisa yezentengiso i-VR-PVT 8.2 (STR, Republic of Serbia) isetshenzisiwe. I-reactor enendawo eshisayo imodelwe njengemodeli ye-axisymmetric engu-2D, njengoba kuboniswe kuMfanekiso 2, ngemodeli yayo yemeshi. Zonke izinto ezisetshenziswa ekufanisweni zikhonjiswe kuMfanekiso 2, futhi izakhiwo zazo zibhalwe kuThebula 1. Ngokusekelwe emiphumeleni yokulingisa, amakristalu e-SiC akhuliswa kusetshenziswa indlela ye-PVT ebangeni lokushisa lika-2250-2350 ° C endaweni ye-Ar at. 35 Bhaka amahora angu-4. I-wafer engu-4° off-axis 4H-SiC isetshenziswe njengembewu ye-SiC. Amakristalu asekhulile ahlolwe i-micro-Raman spectroscopy (Witec, UHTS 300, Germany) kanye ne-XRD enokulungiswa okuphezulu (HRXRD, X'Pert-PROMED, PANalytical, Netherlands). Ukugxila kokungcola kumakristalu e-SiC asekhulile kwahlolwa kusetshenziswa i-ion mass spectrometry eguqukayo yesibili (SIMS, Cameca IMS-6f, France). Ukuminyana kokususwa kwamakristalu akhulile kwahlolwa kusetshenziswa i-synchrotron white beam X-ray topography eMthonjeni Wokukhanya we-Pohang.

Umfanekiso 2: Umdwebo wendawo eshisayo kanye nemodeli yemeshi yokukhula kwe-PVT esithandweni sokushisa esingeniswayo.

Umfanekiso 2: Umdwebo wendawo eshisayo kanye nemodeli yemeshi yokukhula kwe-PVT esithandweni sokushisa esingeniswayo.

Njengoba izindlela ze-HTCVD ne-PVT zikhula amakristalu ngaphansi kokulingana kwesigaba esiqinile segesi ngaphambili, ukukhula okuphumelelayo kwe-SiC ngendlela ye-HTCVD kwabangela inselele yokukhula ngokushesha kwe-SiC ngendlela ye-PVT kulolu cwaningo. Indlela ye-HTCVD isebenzisa umthombo wegesi olawulwa kalula, kuyilapho indlela ye-PVT isebenzisa umthombo oqinile ongalawuli ngokuqondile ukugeleza. Izinga lokugeleza elinikezwe ngaphambili lokukhula ngendlela ye-PVT lingalawulwa izinga lokuncishiswa kwe-sublimation lomthombo oqinile ngokulawulwa kokusabalalisa izinga lokushisa, kodwa ukulawula okunembile kokusatshalaliswa kwezinga lokushisa ezinhlelweni ezisebenzayo zokukhula akulula ukukufeza.

Ngokwandisa izinga lokushisa lomthombo ku-reactor ye-PVT, izinga lokukhula le-SiC lingakhushulwa ngokukhuphula izinga lokuncishiswa kwe-sublimation lomthombo. Ukufinyelela ukukhula kwekristalu okuzinzile, ukulawulwa kwezinga lokushisa ngaphambi kokukhula kubalulekile. Ukwandisa izinga lokukhula ngaphandle kokwenza ama-polycrystals, i-gradient yezinga eliphezulu lokushisa idinga ukufinyelelwa ngaphambili kokukhula, njengoba kuboniswa ukukhula kwe-SiC ngendlela ye-HTCVD. Ukushintshwa kokushisa okuqondile okunganele ngemuva kwekepisi kufanele kukhiphe ukushisa okunqwabelene ngaphambili ngemisebe eshisayo ukuya endaweni yokukhula, okuholela ekwakhekeni kwezindawo ezingaphezulu, okungukuthi, ukukhula kwe-polycrystalline.

Zombili izinqubo zokudluliswa kobuningi kanye ne-recrystallization endleleni ye-PVT zifana kakhulu nendlela ye-HTCVD, nakuba zihluke emthonjeni we-SiC. Lokhu kusho ukuthi ukukhula okusheshayo kwe-SiC nakho kuyafezeka uma izinga lokuncibilika komthombo we-SiC liphezulu ngokwanele. Kodwa-ke, ukuzuza amakristalu e-SiC asezingeni eliphakeme ngaphansi kwezimo zokukhula okuphezulu ngendlela ye-PVT kunezinselelo ezimbalwa. Izimpushana zezentengiso ngokuvamile ziqukethe ingxube yezinhlayiya ezincane nezinkulu. Ngenxa yomehluko wamandla angaphezulu, izinhlayiya ezincane zinezinga eliphezulu lokungcola futhi ziphansi ngaphambi kwezinhlayiya ezinkulu, okuholela ekugxilweni kokungcola okuphezulu ezigabeni zokuqala zokukhula kwekristalu. Ukwengeza, njengoba i-SiC eqinile ibola ibe yizinhlobo zomhwamuko ezifana no-C no-Si, i-SiC2 ne-Si2C emazingeni okushisa aphezulu, u-C oqinile wakha lapho umthombo we-SiC uncipha ngendlela ye-PVT. Uma i-C eqinile eyakhiwe incane futhi ilula ngokwanele, ngaphansi kwezimo zokukhula ngokushesha, izinhlayiya ezincane ze-C, ezaziwa ngokuthi "uthuli lwe-C," zingahanjiswa endaweni ye-crystal ngokudluliswa kwenqwaba eqinile, okuholela ekufakweni ku-crystal ekhulile. Ngakho-ke, ukuze kuncishiswe ukungcola kwensimbi nothuli C, usayizi wezinhlayiyana zomthombo we-SiC kufanele ngokuvamile ulawulwe ube ububanzi obungaphansi kuka-200 μm, futhi izinga lokukhula akufanele lidlule ~0.4 mm/h ukuze kugcinwe ukudluliswa kwesisindo okuhamba kancane futhi kungafaki ukuntanta. C uthuli. Ukungcola kwensimbi nothuli lwe-C kuholela ekulimazeni amakristalu e-SiC asekhulile, okuyizithiyo eziyinhloko ekukhuleni okusheshayo kwe-SiC ngendlela ye-PVT.

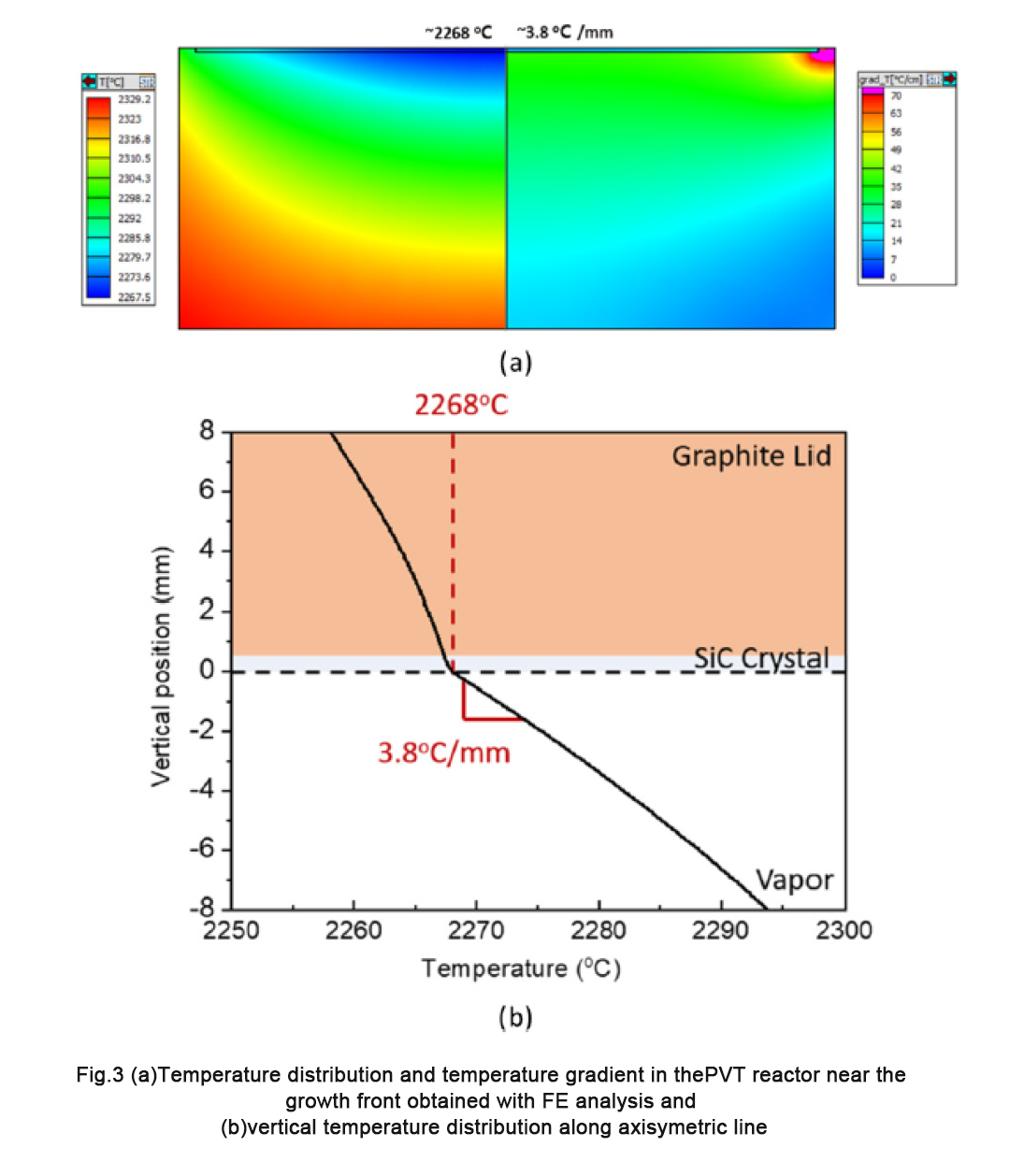

Kulolu cwaningo, imithombo echotshoziwe ye-CVD-SiC ngaphandle kwezinhlayiya ezincane isetshenzisiwe, iqeda uthuli oluntantayo lwe-C ngaphansi kokudluliswa kwenqwaba eqinile. Ngakho-ke, isakhiwo sendawo eshisayo saklanywa kusetshenziswa indlela ye-PVT esekwe ku-multiphysics ukuze kuzuzwe ukukhula okusheshayo kwe-SiC, futhi ukusabalalisa okufanisiwe kwezinga lokushisa kanye ne-gradient yokushisa kuboniswa kuMfanekiso 3a.

Umfanekiso 3: (a) Ukusatshalaliswa kwezinga lokushisa nezinga lokushisa eduze kwangaphambili kokukhula kwe-reactor ye-PVT etholwe ngokuhlaziywa kwesici esinomkhawulo, kanye (b) nokusatshalaliswa kwezinga lokushisa okuqondile ngomugqa we-axisymmetric.

Uma kuqhathaniswa nezilungiselelo ezijwayelekile zendawo eshisayo zokukhulisa amakristalu e-SiC ngesilinganiso sokukhula esingu-0.3 kuye ku-0.8 mm/h ngaphansi kwezinga lokushisa elincane elingaphansi kuka-1 °C/mm, izilungiselelo zendawo eshisayo kulolu cwaningo zinezinga lokushisa elicishe libe ngu-∼ 3.8 °C/mm ekukhuleni kwezinga lokushisa elingu-∼2268°C. Inani le-gradient yezinga lokushisa kulolu cwaningo liqhathaniswa nokukhula okusheshayo kwe-SiC ngesilinganiso esingu-2.4 mm/h kusetshenziswa indlela ye-HTCVD, lapho i-gradient yezinga lokushisa isethelwe ku-∼14 °C/mm. Kusukela ekusakazweni kwezinga lokushisa eliqondile eliboniswe ku-Figure 3b, siqinisekisile ukuthi akukho gradient yokushisa ehlehlayo engakha i-polycrystals eyayikhona eduze kwendawo yokukhula, njengoba kuchazwe ezincwadini.

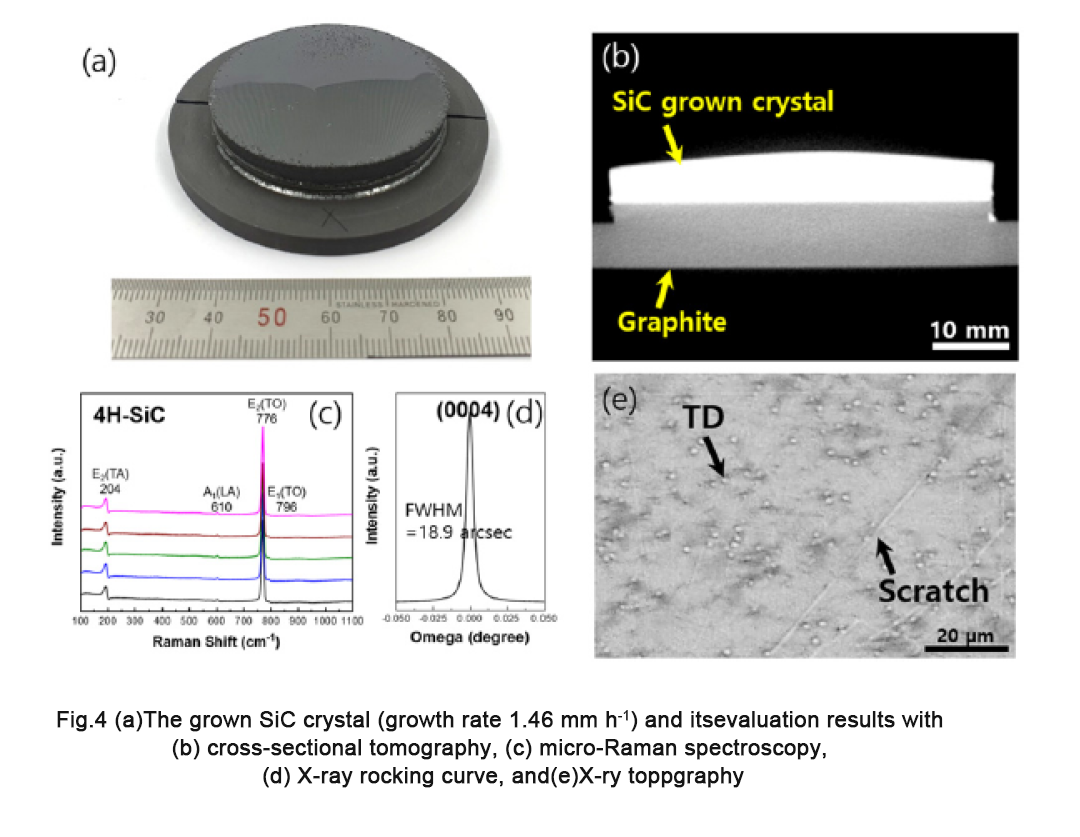

Ukusebenzisa uhlelo lwe-PVT, amakristalu e-SiC akhuliswa kusukela kumthombo we-CVD-SiC amahora angu-4, njengoba kuboniswe ku-Figure 2 no-3. Ummeleli we-SiC crystal ukukhula ovela ku-SiC ekhulile uboniswa ku-Figure 4a. Ubukhulu kanye nezinga lokukhula kwekristalu ye-SiC eboniswe kuMfanekiso 4a ngu-5.84 mm no-1.46 mm/h, ngokulandelanayo. Umthelela womthombo we-SiC kukhwalithi, i-polytype, i-morphology, nokuhlanzeka kwekristalu ye-SiC ekhulile ekhonjiswe ku-Figure 4a yaphenywa, njengoba kuboniswe ku-Figure 4b-e. Isithombe se-cross-sectional tomography ku-Figure 4b sibonisa ukuthi ukukhula kwekristalu bekumise okwe-convex ngenxa yezimo zokukhula ezingafanelekile. Nokho, i-micro-Raman spectroscopy ku-Figure 4c ikhombe ikristalu ekhulile njengesigaba esisodwa se-4H-SiC ngaphandle kokufakwa kwe-polytype. Inani le-FWHM lokuphakama (0004) elitholwe ekuhlaziyweni kwejika le-X-ray lalingu-18.9 arcseconds, futhi liqinisekisa ikhwalithi enhle yekristalu.

Umfanekiso 4: (a) Ikristalu ye-SiC ekhulile (izinga lokukhula elingu-1.46 mm/h) kanye nemiphumela yokuhlolwa kwayo (b) ne-cross-sectional tomography, (c) i-micro-Raman spectroscopy, (d) i-X-ray rocking curve, kanye ( e) I-X-ray topography.

Umfanekiso 4e ubonisa indawo ye-X-ray ye-white beam ehlonza imihuzuko kanye nokugudluzwa kwentambo ku-wafer epholishiwe yekristalu ekhulile. Ukuminyana kokususwa kwekristalu ekhulile kukalwe kwaba ngu-∼3000 ea/cm², ephakeme kancane kunokuminyana kokugudluka kwekristalu yembewu, okwakungu-∼2000 ea/cm². Ikristalu ekhulile yaqinisekiswa ukuthi inomthamo ophansi wokugudluka, uma kuqhathaniswa nekhwalithi yekristalu yamawafa okuhweba. Kuyathakazelisa ukuthi ukukhula okusheshayo kwamakristalu e-SiC kwafinyelelwa kusetshenziswa indlela ye-PVT enomthombo ochotshoziwe we-CVD-SiC ngaphansi kwe-gradient enkulu yokushisa. Ukugxiliswa kuka-B, Al, kanye no-N kukristalu esikhulile kube ngu-2.18 × 10¹⁶, 7.61 × 10¹⁵, kanye no-1.98 × 10¹⁹ atoms/cm³, ngokulandelana. Ukugxila kuka-P kukristalu esikhulile bekungaphansi komkhawulo wokutholwa (<1.0 × 10¹⁴ ama-athomu/cm³). Ukugxiliswa kokungcola bekuphansi ngokwanele kubathwali abakhokhisayo, ngaphandle kwe-N, ekhishwe ngamabomu phakathi nenqubo ye-CVD.

Nakuba ukukhula kwekristalu kulolu cwaningo kwakuyizinto ezincane ezicatshangelwa ngemikhiqizo yezohwebo, ukuboniswa okuphumelelayo kokukhula okusheshayo kwe-SiC ngekhwalithi enhle ye-crystal usebenzisa umthombo we-CVD-SiC ngokusebenzisa indlela ye-PVT kunemiphumela ebalulekile. Njengoba imithombo ye-CVD-SiC, naphezu kwezakhiwo zayo ezinhle kakhulu, incintisana ngezindleko ngokuphinda isetshenziswe izinto ezilahliwe, silindele ukusetshenziswa kwayo okubanzi njengomthombo othembisayo we-SiC ozothatha indawo yemithombo ye-SiC powder. Ukusebenzisa imithombo ye-CVD-SiC ukuze ikhule ngokushesha kwe-SiC, ukuthuthukiswa kokusatshalaliswa kwezinga lokushisa ohlelweni lwe-PVT kuyadingeka, kubangele imibuzo eyengeziwe yocwaningo oluzayo.

Isiphetho

Kulolu cwaningo, ukuboniswa okuphumelelayo kokukhula kwe-crystal ye-SiC okusheshayo usebenzisa amabhulokhi e-CVD-SiC echotshoziwe ngaphansi kwezimo ze-gradient ephezulu yokushisa ngokusebenzisa indlela ye-PVT kufinyelelwe. Kuyathakazelisa ukuthi ukukhula okusheshayo kwamakristalu e-SiC kwabonakala ngokushintsha umthombo we-SiC ngendlela ye-PVT. Le ndlela kulindeleke ukuthi ikhulise kakhulu ukusebenza kahle kokukhiqiza okukhulu kwekristalu eyodwa ye-SiC, ekugcineni inciphise izindleko zeyunithi yama-substrates e-SiC futhi ikhuthaze ukusetshenziswa okubanzi kwemishini yamandla asebenza kahle kakhulu.

Isikhathi sokuthumela: Jul-19-2024