Uhlolojikelele Lwenqubo Ye-Semiconductor

Inqubo ye-semiconductor ngokuyinhloko ihilela ukusebenzisa ubuchwepheshe be-microfabrication kanye nefilimu ukuze kuxhunywe ngokugcwele ama-chips nezinye izici ngaphakathi kwezifunda ezihlukahlukene, njengama-substrates namafreyimu. Lokhu kusiza ukukhishwa kwamatheminali omthofu kanye nokuhlanganisa nge-plastic insulating medium ukuze kwakheke konke okuhlanganisiwe, okwethulwa njengesakhiwo esinezinhlangothi ezintathu, ekugcineni kuphothule inqubo yokupakisha ye-semiconductor. Umqondo wenqubo ye-semiconductor nawo uphathelene nencazelo ewumngcingo yokupakishwa kwe-semiconductor chip. Ngokombono obanzi, ibhekisela kubunjiniyela bokupakisha, okubandakanya ukuxhuma nokulungisa ku-substrate, ukulungisa okokusebenza kwe-elekthronikhi okuhambisanayo, nokwakha uhlelo oluphelele olunokusebenza okuqinile okubanzi.

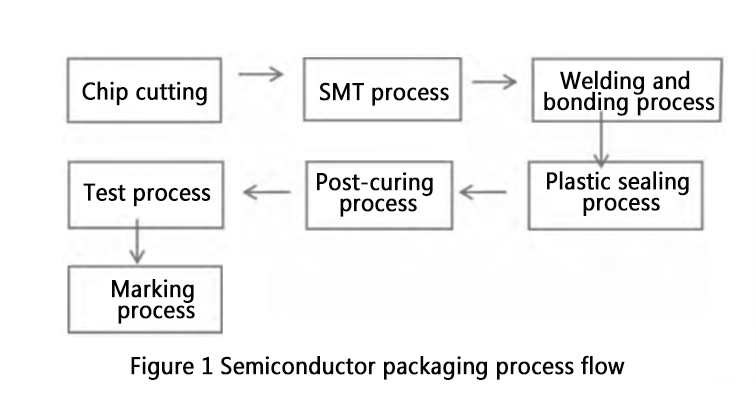

I-Semiconductor Packaging Process Flow

Inqubo yokupakisha ye-semiconductor ihlanganisa imisebenzi eminingi, njengoba kuboniswe kuMfanekiso 1. Inqubo ngayinye inezidingo ezithile kanye nokugeleza komsebenzi okuhlobene eduze, okudinga ukuhlaziywa okuningiliziwe ngesikhathi sesigaba esisebenzayo. Okuqukethwe okuqondile kungokulandelayo:

1. I-Chip Cutting

Enqubweni yokupakisha ye-semiconductor, ukusika kwe-chip kuhilela ukusika ama-wafers e-silicon abe ama-chips ngamanye kanye nokususa udoti we-silicon ukuvimbela izithiyo emsebenzini olandelayo nokulawulwa kwekhwalithi.

2. I-Chip Mounting

Inqubo yokukhweza i-chip igxile ekugwemeni umonakalo wokujikeleza ngesikhathi sokugaya i-wafer ngokusebenzisa isendlalelo sefilimu esivikelayo, ngokuqhubekayo igcizelela ubuqotho besifunda.

3. Wire Bonding Process

Ukulawula ikhwalithi yenqubo yokuhlanganisa izintambo kuhilela ukusebenzisa izinhlobo ezahlukene zezintambo zegolide ukuze kuxhunywe amaphedi okubopha we-chip namaphedi ozimele, ukuqinisekisa ukuthi i-chip ingakwazi ukuxhuma kumasekhethi angaphandle nokugcina ubuqotho benqubo iyonke. Ngokuvamile, kusetshenziswa izintambo zegolide ezigoqiwe kanye nezintambo zegolide ezihlanganisiwe.

Izintambo Zegolide Ezihlanganisiwe: Izinhlobo zifaka i-GS, i-GW, ne-TS, ilungele i-arc ephezulu (GS: >250 μm), i-arc ephakeme emaphakathi (GW: 200-300 μm), kanye ne-arc ephansi emaphakathi (TS: 100-200 μm) ukuhlanganisa ngokulandelana.

Izintambo Zegolide Ezihlanganisiwe: Izinhlobo zifaka i-AG2 ne-AG3, ifanele i-low-arc bonding (70-100 μm).

Izinketho zobubanzi zalezi zintambo zisuka ku-0.013 mm ziye ku-0.070 mm. Ukukhetha uhlobo olufanele nobubanzi obusekelwe ezidingweni zokusebenza namazinga kubalulekile ekulawuleni ikhwalithi.

4. Inqubo yokubumba

I-circuitry eyinhloko ezintweni zokubumba ihlanganisa i-encapsulation. Ukulawula ikhwalithi yenqubo yokubumba kuvikela izingxenye, ikakhulukazi emandleni angaphandle abangela amazinga ahlukene omonakalo. Lokhu kuhilela ukuhlaziywa okuphelele kwezinto ezibonakalayo zezingxenye.

Izindlela ezintathu eziyinhloko ezisetshenziswayo njengamanje: ukupakisha nge-ceramic, ukupakisha kwepulasitiki, kanye nokupakishwa kwendabuko. Ukuphatha ingxenye yohlobo ngalunye lokupakisha kubalulekile ukuze kuhlangatshezwane nezidingo zokukhiqizwa kwama-chip emhlabeni wonke. Phakathi nenqubo, amakhono aphelele ayadingeka, njengokushisa kuqala i-chip kanye nohlaka lomthofu ngaphambi kokugqunywa nge-epoxy resin, ukubumba, kanye nokwelapha kwangemva kwesikhunta.

5. Inqubo Ngemva Kokwelapha

Ngemuva kwenqubo yokubumba, ukwelashwa kwe-post-curing kuyadingeka, kugxile ekususeni noma yiziphi izinto ezidlulele ezizungeze inqubo noma iphakheji. Ukulawulwa kwekhwalithi kubalulekile ukuze kugwenywe ukuthikameza ikhwalithi yenqubo yonke kanye nokubukeka.

6.Inqubo Yokuhlola

Uma izinqubo zangaphambilini seziqediwe, ikhwalithi iyonke yenqubo kufanele ihlolwe kusetshenziswa ubuchwepheshe bokuhlola obusezingeni eliphezulu nezinsiza. Lesi sinyathelo sibandakanya ukurekhodwa okuningiliziwe kwedatha, okugxile ekutheni i-chip isebenza ngokujwayelekile yini ngokusekelwe ezingeni layo lokusebenza. Uma kubhekwa izindleko eziphezulu zemishini yokuhlola, kubalulekile ukugcina ukulawulwa kwekhwalithi kuzo zonke izigaba zokukhiqiza, okuhlanganisa ukuhlola okubonakalayo nokuhlolwa kokusebenza kukagesi.

Ukuhlolwa Kokusebenza Kogesi: Lokhu kuhilela ukuhlola amasekhethi ahlanganisiwe kusetshenziswa okokusebenza kokuhlola okuzenzakalelayo kanye nokuqinisekisa ukuthi isekethe ngayinye ixhumeke kahle ukuze kuhlolwe ugesi.

Ukuhlola Okubonakalayo: Ochwepheshe basebenzisa izibonakhulu ukuze bahlole kahle ama-chips apakishiwe aqediwe ukuze baqinisekise ukuthi awanawo amaphutha futhi ahlangabezana nezindinganiso zekhwalithi yokupakishwa kwe-semiconductor.

7. Inqubo yokumaka

Inqubo yokumaka ihlanganisa ukudlulisa ama-chips ahloliwe endaweni yokugcina impahla ecishe iqedwe ukuze icutshungulwe okokugcina, ihlolwe ikhwalithi, ukupakishwa, nokuthunyelwa. Le nqubo ihlanganisa izinyathelo ezintathu eziyinhloko:

1) I-Electroplating: Ngemva kokwenza umkhondo, i-anti-corrosion material isetshenziswa ukuvimbela i-oxidation nokugqwala. Ubuchwepheshe be-Electroplating deposition buvame ukusetshenziswa njengoba imikhondo eminingi yenziwe nge-tin.

2)Ukugoba: Imikhondo ecutshunguliwe ibe isibunjwa, bese kuthi umucu wesekethe ohlanganisiwe ubekwe ethuluzini lokwakha umthofu, olawula umumo wokuhola (uhlobo luka-J noma u-L) kanye nokupakishwa okubekwe phezulu.

3) I-Laser Printing: Ekugcineni, imikhiqizo eyenziwe iphrintwa ngomklamo, osebenza njengophawu olukhethekile lwenqubo yokupakisha ye-semiconductor, njengoba kubonisiwe kuMfanekiso 3.

Izinselelo Nezincomo

Ucwaningo lwezinqubo zokupakisha ze-semiconductor luqala ngokubukezwa kobuchwepheshe be-semiconductor ukuqonda izimiso zabo. Okulandelayo, ukuhlola ukugeleza kwenqubo yokupakisha kuhlose ukuqinisekisa ukulawulwa ngokucophelela phakathi nokusebenza, kusetshenziswa ukuphathwa okucolisisiwe ukuze kugwenywe izinkinga ezivamile. Kumongo wentuthuko yesimanje, ukuhlonza izinselele ezinqubweni zokupakisha ze-semiconductor kubalulekile. Kunconywa ukuthi ugxile ezicini zokulawula ikhwalithi, ukwazi kahle amaphuzu abalulekile ukuze uthuthukise ngempumelelo ikhwalithi yenqubo.

Ukuhlaziya ngombono wokulawula ikhwalithi, kunezinselele ezibalulekile phakathi nokuqaliswa ngenxa yezinqubo eziningi ezinokuqukethwe okukhethekile nezimfuneko, ngayinye ithonya enye. Ukulawula okuqinile kuyadingeka ngesikhathi sokusebenza okungokoqobo. Ngokwamukela isimo sengqondo sokucophelela kanye nokusebenzisa ubuchwepheshe obuthuthukisiwe, ikhwalithi yenqubo yokupakisha ye-semiconductor kanye namazinga obuchwepheshe kungathuthukiswa, kuqinisekiswe ukusebenza kahle kwesicelo okuphelele futhi kuzuzwe izinzuzo ezinhle kakhulu zizonke.(njengoba kuboniswe kuMfanekiso 3).

Isikhathi sokuthumela: May-22-2024