I-Silicon carbide (SiC)impahla inezinzuzo ze-bandgap ebanzi, ukuguquguquka okushisayo okuphezulu, amandla ensimu yokuqhekeka okubucayi okuphezulu, kanye nesivinini esigcwele kakhulu se-electron drift, okuyenza ithembise kakhulu emkhakheni wokukhiqiza i-semiconductor. Amakristalu e-SiC single ngokuvamile akhiqizwa ngendlela yokuthutha umhwamuko obonakalayo (PVT). Izinyathelo ezithile zale ndlela zihlanganisa ukubeka i-SiC powder phansi kwe-graphite crucible nokubeka i-crystal yembewu ye-SiC phezulu kwe-crucible. I-graphitecrucibleIshiselwa ekushiseni kwe-sublimation ye-SiC, okwenza i-SiC powder ibole ibe yizinto zesigaba somhwamuko ezifana ne-Si vapor, i-Si2C, ne-SiC2. Ngaphansi kwethonya le-axial temperature gradient, lezi zinto ezihwamuke zikhuphukela phezulu ku-crucible futhi zijiyane phezu kwekristalu yembewu ye-SiC, icwebezela ibe yikristalu eyodwa ye-SiC.

Njengamanje, ububanzi be-crystal imbewu esetshenziswa kuyoUkukhula kwekristalu eyodwa ye-SiCidinga ukufanisa ububanzi bekristalu eqondiwe. Ngesikhathi sokukhula, i-crystal yembewu igxiliwe kumnikazi wembewu phezulu kwe-crucible isebenzisa i-adhesive. Kodwa-ke, le ndlela yokulungisa ikristalu yembewu ingaholela ezindabeni ezinjengama-voids ongqimbeni olunamathelayo ngenxa yezici ezifana nokunemba kwendawo yomnikazi wembewu kanye nokufana kwe-adhesive coating, okungase kubangele ukukhubazeka kwe-hexagonal void. Lokhu kufaka phakathi ukuthuthukisa ukucaba kwepuleti le-graphite, ukukhulisa ukufana kogqinsi lwesendlalelo sokunamathisela, kanye nokwengeza isendlalelo sebhafa esishintshashintshayo. Naphezu kwale mizamo, kusenezinkinga ngokuminyana kwesendlalelo sokunamathisela, futhi kunengozi yokuhlukaniswa kwe-crystal imbewu. Ngokusebenzisa indlela yokuhlanganisa i-isilucwecwanakuya ephepheni le-graphite futhi lidlulele phezulu kwe-crucible, ukuminyana kwesendlalelo sokunamathisela kungathuthukiswa, futhi ukuhlukaniswa kwe-wafer kungavinjelwa.

1. Uhlelo Lokuhlola:

Ama-wafers asetshenziswe ekuhloleni ayatholakala ngokuthengisa6-intshi N-uhlobo lwe-SiC wafers. I-Photoresist isetshenziswa kusetshenziswa i-spin coater. Ukunamathela kufinyelelwa kusetshenziswa isithando somlilo esizithuthukisayo sembewu.

1.1 I-Seed Crystal Fixation Scheme:

Njengamanje, ama-SiC seed crystal adhesion schemes angahlukaniswa ngezigaba ezimbili: uhlobo lokunamathela kanye nohlobo lokumiswa.

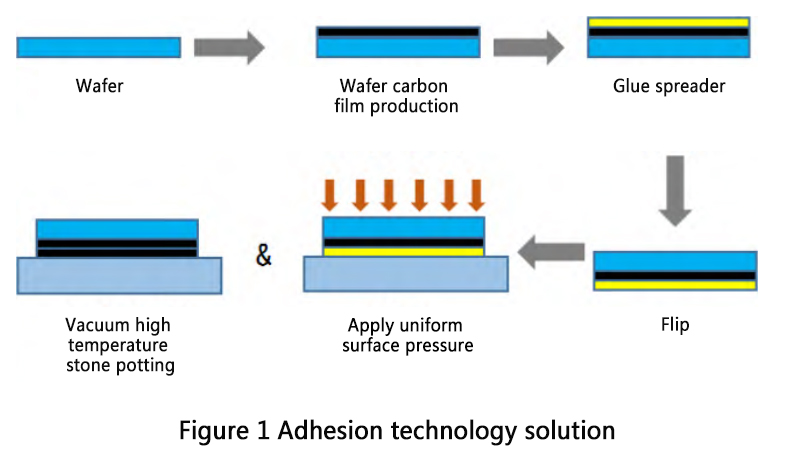

I-Adhesive Type Scheme (Umfanekiso 1): Lokhu kuhilela ukuhlanganisa i-Isicwecwana se-SiCku-graphite plate enongqimba lwephepha le-graphite njengesendlalelo se-buffer ukuqeda izikhala phakathi kwe-Isicwecwana se-SiCkanye ne-graphite plate. Ekukhiqizeni kwangempela, amandla okubopha phakathi kwephepha le-graphite nepuleti ye-graphite abuthakathaka, okuholela esikhumbeni se-crystal sembewu njalo ngesikhathi senqubo yokukhula kwezinga lokushisa eliphezulu, okuholela ekuhlulekeni kokukhula.

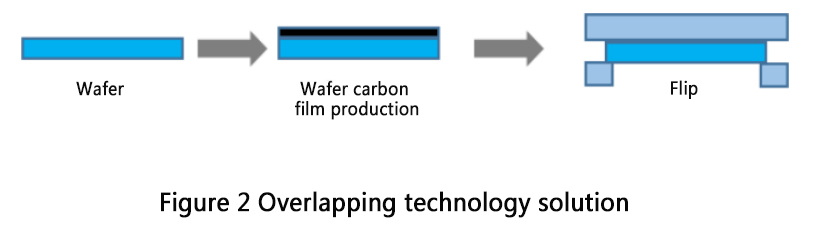

I-Suspension Type Scheme (Umfanekiso wesi-2): Ngokuvamile, ifilimu ye-carbon eminyene idalwe endaweni yokubopha ye-SiC wafer isebenzisa i-glue carbonization noma izindlela zokugqoka. IIsicwecwana se-SiCibe isiboshelwa phakathi kwamapuleti amabili e-graphite futhi ibekwe phezulu kwe-graphite crucible, iqinisekisa ukuzinza kuyilapho ifilimu yekhabhoni ivikela i-wafer. Kodwa-ke, ukudala ifilimu ye-carbon ngokusebenzisa ukugqoka kuyabiza futhi akufanelekile ukukhiqizwa kwezimboni. Indlela ye-glue carbonization ikhiqiza ikhwalithi yefilimu ye-carbon engahambisani, okwenza kube nzima ukuthola ifilimu ye-carbon eminyene ngokuphelele ngokunamathela okuqinile. Ukwengeza, ukubopha amapuleti e-graphite kunciphisa indawo yokukhula ephumelelayo ye-wafer ngokuvimbela ingxenye yobuso bayo.

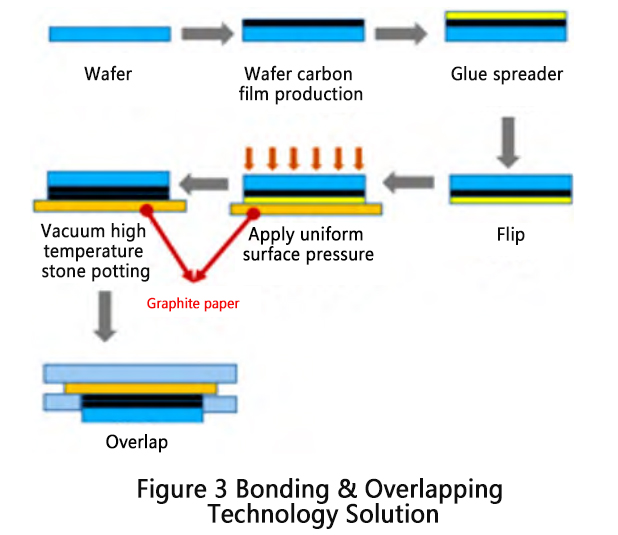

Ngokusekelwe kulezi zinhlelo ezimbili ezingenhla, kuhlongozwa uhlelo olusha lokunamathisela nokugqagqana (Umfanekiso 3):

Ifilimu yekhabhoni eminyene ngokuqhathaniswa yenziwa endaweni ebophayo ye-SiC wafer kusetshenziswa indlela yeglue carbonization, iqinisekisa ukuthi akukho ukuvuza okukhulu kokukhanya ngaphansi kokukhanyisa.

I-wafer ye-SiC embozwe ngefilimu yekhabhoni iboshelwa ephepheni le-graphite, indawo yokubopha iyingxenye yefilimu ye-carbon. Isendlalelo sokunamathisela kufanele sibonakale simnyama ngokulinganayo ngaphansi kokukhanya.

Iphepha le-graphite liboshwe ngamapuleti e-graphite futhi limiswe ngaphezu kwe-graphite crucible yokukhula kwekristalu.

1.2 Okunamathelayo:

I-viscosity ye-photoresist ithinta kakhulu ukufana kwefilimu. Ngejubane elifanayo le-spin, i-viscosity ephansi iphumela kumafilimu anamathelayo amancane futhi afanayo. Ngakho-ke, i-photoresist ye-viscosity ephansi ikhethwa ngaphakathi kwezidingo zohlelo lokusebenza.

Ngesikhathi sokuhlolwa, kwatholakala ukuthi i-viscosity ye-adhesive carbonizing ithinta amandla okubopha phakathi kwefilimu ye-carbon kanye ne-wafer. I-viscosity ephezulu yenza kube nzima ukusebenzisa ngendlela efanayo usebenzisa i-spin coater, kuyilapho i-viscosity ephansi ibangela amandla okubopha abuthakathaka, okuholela ekuqhekekeni kwefilimu ye-carbon ngesikhathi sezinqubo zokubopha ezilandelayo ngenxa yokugeleza kokunamathela nokucindezela kwangaphandle. Ngocwaningo lokuhlola, i-viscosity ye-adhesive carbonizing yanqunywa ukuthi ibe ngu-100 mPa·s, futhi i-viscosity enamathelayo enamathelayo isethelwe ku-25 mPa·s.

1.3 I-Vacuum Yokusebenza:

Inqubo yokudala ifilimu ye-carbon ku-wafer ye-SiC ihilela ukufakwa kwe-carbonizing ungqimba olunamathelayo endaweni eyisicwecwana se-SiC, okufanele yenziwe endaweni engenalutho noma evikelwe nge-argon. Imiphumela yokuhlola ibonisa ukuthi indawo evikelwe nge-argon ivumela kakhulu ekudalweni kwefilimu yekhabhoni kunendawo yevacuum ephezulu. Uma kusetshenziswa indawo ye-vacuum, izinga le-vacuum kufanele libe ngu-≤1 Pa.

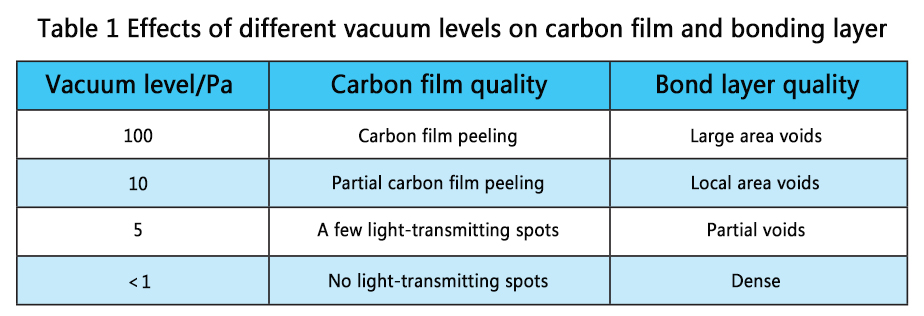

Inqubo yokuhlanganisa ikristalu yembewu ye-SiC ihilela ukuhlanganisa i-wafer ye-SiC ne-graphite plate/graphite paper. Uma kucatshangelwa umphumela wokuguguleka we-oxygen ezintweni ze-graphite emazingeni okushisa aphezulu, le nqubo idinga ukuqhutshwa ngaphansi kwezimo ze-vacuum. Umthelela wamazinga ahlukene we-vacuum ongqimbeni olunamathelayo wacwaningwa. Imiphumela yokuhlola iboniswa kuThebula 1. Kungabonakala ukuthi ngaphansi kwezimo eziphansi ze-vacuum, ama-molecule e-oksijini emoyeni awasuswa ngokuphelele, okuholela ezingqimbeni zokunamathela ezingaphelele. Lapho izinga le-vacuum lingaphansi kwe-10 Pa, umphumela wokuguguleka wama-molecule e-oksijini ongqimbeni lokunamathisela wehla kakhulu. Lapho izinga le-vacuum lingaphansi kwe-1 Pa, umphumela wokuguguleka ususwa ngokuphelele.

Isikhathi sokuthumela: Jun-11-2024