Kudingeka amakhulu ezinqubo ukuze kuphendulwe aisilucwecwanaku-semiconductor. Enye yezinqubo ezibaluleke kakhuluetching- okungukuthi, ukuqopha amaphethini wesifunda esihleisilucwecwana. Impumelelo yeetchinginqubo incike ekulawuleni okuguquguqukayo okuhlukahlukene ngaphakathi kwebanga elimisiwe lokusabalalisa, futhi isisetshenziswa sokufaka ngasinye kufanele silungiselelwe ukusebenza ngaphansi kwezimo ezifanele. Onjiniyela bethu bezinqubo ze-etching basebenzisa ubuchwepheshe bokukhiqiza obusezingeni eliphezulu ukuqedela le nqubo enemininingwane.

I-SK Hynix News Center ixoxisane namalungu e-Icheon DRAM Front Etch, Middle Etch, kanye namaqembu ezobuchwepheshe e-End Etch ukuze afunde kabanzi ngomsebenzi wawo.

Etch: Uhambo Lokuthuthukisa Ukukhiqiza

Ekwenziweni kwe-semiconductor, i-etching ibhekisela emaphethini okubaza kumafilimu amancane. Amaphethini afuthwa kusetshenziswa i-plasma ukwenza uhlaka lokugcina lwesinyathelo ngasinye senqubo. Inhloso yayo eyinhloko ukwethula ngokuphelele amaphethini anembe ngokusho kwesakhiwo nokugcina imiphumela efanayo ngaphansi kwazo zonke izimo.

Uma izinkinga zenzeka ekufakweni noma kunqubo ye-photolithography, zingaxazululwa ngobuchwepheshe be-etching (Etch) obukhethiwe. Kodwa-ke, uma kukhona okungahambi kahle ngesikhathi sokuqopha, isimo asikwazi ukuhlehliswa. Lokhu kungenxa yokuthi into efanayo ayikwazi ukugcwaliswa endaweni eqoshiwe. Ngakho-ke, enqubweni yokukhiqiza i-semiconductor, i-etching ibalulekile ukuze kutholakale isivuno esiphelele kanye nekhwalithi yomkhiqizo.

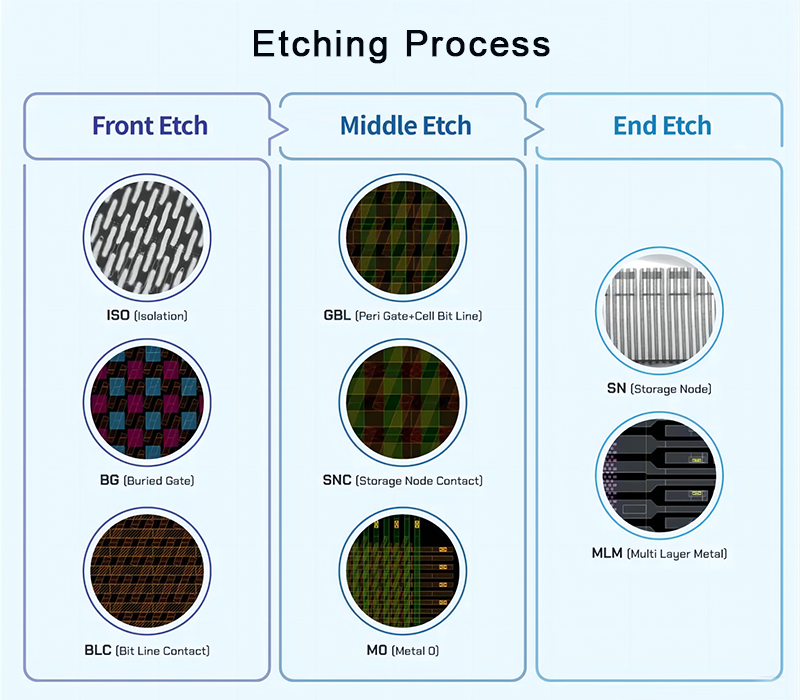

Inqubo yokufaka ihlanganisa izinyathelo eziyisishiyagalombili: ISO, BG, BLC, GBL, SNC, M0, SN kanye neMLM.

Okokuqala, i-ISO (Isolation) stage etches (Etch) silicon (Si) ku-wafer ukudala indawo yeseli esebenzayo. Isiteji se-BG (Isango Elingcwatshiwe) sakha umugqa wekheli lomugqa (Umugqa Wegama) 1 kanye nesango lokudala isiteshi se-elekthronikhi. Okulandelayo, isigaba se-BLC (Bit Line Contact) sidala ukuxhumana phakathi kwe-ISO nolayini wekheli lekholomu (Bit Line) 2 endaweni yeseli. Isiteji se-GBL (i-Peri Gate+Cell Bit Line) sizodala kanyekanye ulayini wekheli wekholomu yeseli kanye nesango ku-periphery 3.

Isiteji se-SNC (I-Storage Node Contract) siyaqhubeka nokudala ukuxhumana phakathi kwendawo esebenzayo kanye ne-node yokugcina 4. Kamuva, isiteji se-M0 (Metal0) sakha amaphuzu okuxhumana e-peripheral S/D (I-Storage Node) 5 kanye nezindawo zokuxhuma. phakathi komugqa wekheli wekholomu kanye nendawo yokugcina. Isiteji se-SN (I-Storage Node) siqinisekisa umthamo weyunithi, futhi isigaba esilandelayo se-MLM (Multi Layer Metal) sidala ukunikezwa kwamandla kwangaphandle kanye nezintambo zangaphakathi, futhi yonke inqubo yobunjiniyela be-etching (Etch) iyaqedwa.

Njengoba kunikezwe ukuthi ochwepheshe be-etching (Etch) banesibopho ngokuyinhloko ekwenzeni ama-semiconductors, umnyango we-DRAM uhlukaniswe ngamaqembu amathathu: I-Front Etch (ISO, BG, BLC); I-Middle Etch (GBL, SNC, M0); I-End Etch (SN, MLM). Lawa maqembu aphinde ahlukaniswe ngokwezikhundla zokukhiqiza kanye nezindawo zemishini.

Izikhundla zokukhiqiza zinesibopho sokuphatha nokwenza ngcono izinqubo zokukhiqiza amayunithi. Izikhundla zokukhiqiza zidlala indima ebaluleke kakhulu ekuthuthukiseni isivuno nekhwalithi yomkhiqizo ngokulawula okuguquguqukayo nezinye izinyathelo zokuthuthukisa ukukhiqiza.

Izikhundla zezisetshenziswa zinomthwalo wemfanelo wokuphatha nokuqinisa imishini yokukhiqiza ukuze kugwenywe izinkinga ezingase zenzeke ngesikhathi sokuqopha. Isibopho esiyinhloko sezikhundla zemishini ukuqinisekisa ukusebenza kahle kwemishini.

Nakuba izibopho zicacile, wonke amaqembu asebenzela emgomweni ofanayo - okungukuthi, ukuphatha nokuthuthukisa izinqubo zokukhiqiza kanye nemishini ehlobene ukuze kuthuthukiswe umkhiqizo. Kuze kube manje, iqembu ngalinye labelana ngezimpumelelo zalo kanye nezindawo okufanele lithuthukiswe, futhi liyasebenzisana ukuze lithuthukise ukusebenza kwebhizinisi.

Ungabhekana kanjani nezinselelo zobuchwepheshe be-miniaturization

I-SK Hynix iqale ukukhiqizwa ngobuningi kwemikhiqizo ye-8Gb LPDDR4 DRAM yenqubo yekilasi le-10nm (1a) ngoJulayi 2021.

Amaphethini wesekethe yenkumbulo ye-semiconductor angenile enkathini ye-10nm, futhi ngemva kokuthuthukiswa, i-DRAM eyodwa ingamukela cishe amaseli angu-10,000. Ngakho-ke, ngisho nasenqubweni yokuqopha, umkhawulo wenqubo ayanele.

Uma imbobo eyenziwe (Imbobo) 6 incane kakhulu, ingase ibonakale "ingavuliwe" futhi ivimbe ingxenye engezansi ye-chip. Ngaphezu kwalokho, uma imbobo eyenziwe inkulu kakhulu, "ibhuloho" lingenzeka. Uma igebe phakathi kwezimbobo ezimbili linganele, “ukuvala ibhuloho” kwenzeka, okuholela ezinkingeni zokunamathelana ezinyathelweni ezilandelayo. Njengoba ama-semiconductors aya ngokuya ecwengwa, uhla lwamanani osayizi wembobo luncipha kancane kancane, futhi lezi zingozi zizoqedwa kancane kancane.

Ukuze kuxazululwe izinkinga ezingenhla, ochwepheshe bezobuchwepheshe be-etching bayaqhubeka nokuthuthukisa inqubo, okuhlanganisa ukulungisa iresiphi yenqubo kanye ne-algorithm ye-APC7, kanye nokwethula ubuchwepheshe obusha bokuhlanganisa obufana ne-ADCC8 ne-LSR9.

Njengoba izidingo zamakhasimende zihlukahluka kakhulu, kuye kwavela enye inselele - umkhuba wokukhiqizwa kwemikhiqizo eminingi. Ukuze kuhlangatshezwane nezidingo zekhasimende ezinjalo, izimo zenqubo elungiselelwe yomkhiqizo ngamunye zidinga ukusethwa ngokwehlukana. Lena inselele ekhetheke kakhulu konjiniyela ngoba badinga ukwenza ubuchwepheshe bokukhiqiza ngobuningi buhlangabezane nezidingo zazo zombili izimo ezimisiwe nezimo ezihlukene.

Kuze kube manje, onjiniyela be-Etch bethule ubuchwepheshe be-“APC offset”10 ukuze balawule okuphuma kokunye okusekelwe emikhiqizweni ewumongo (Core Products), futhi basungula futhi basebenzisa “uhlelo lwe-T-index” ukuze baphathe ngokuphelele imikhiqizo ehlukahlukene. Ngale mizamo, uhlelo luye lwathuthukiswa ngokuqhubekayo ukuze luhlangabezane nezidingo zokukhiqizwa kwemikhiqizo eminingi.

Isikhathi sokuthumela: Jul-16-2024