1.Mayelana Neziyingi Ezihlanganisiwe

1.1 Umqondo nokuzalwa kwamasekethe adidiyelwe

I-Integrated Circuit (IC): ibhekisela kudivayisi ehlanganisa amadivayisi asebenzayo njengama-transistors nama-diode anezingxenye ze-passive ezifana neziphikisayo nama-capacitor ngochungechunge lwamasu athile okucubungula.

Isekhethi noma isistimu "ehlanganisiwe" ku-semiconductor (njenge-silicon noma izinhlanganisela ezifana ne-gallium arsenide) iwafa ngokuya ngoxhumano oluthile lwesekethe bese ihlanganiswa kugobolondo ukuze yenze imisebenzi ethile.

Ngo-1958, uJack Kilby, owayebhekele ukwenziwa kancane kwemishini kagesi eTexas Instruments (TI), uhlongoze umbono wamasekethe ahlanganisiwe:

“Njengoba zonke izingxenye ezinjengama-capacitor, resistors, transistors, njll. zingenziwa ngento eyodwa, ngicabange ukuthi kungenzeka ukuzenza ocezwini lwe-semiconductor material bese uzixhumanisa ukuze zenze isekethe ephelele.”

NgoSepthemba 12 noSepthemba 19, 1958, uKilby waqeda ukwakhiwa nokuboniswa kwe-oscillator ne-trigger ye-phase-shift, ngokulandelana, okumaka ukuzalwa kwesekethe ehlanganisiwe.

Ngo-2000, uKilby waklonyeliswa ngeNobel Prize in Physics. IKomidi Lomklomelo KaNobel lake laphawula ukuthi uKilby “wabeka isisekelo sobuchwepheshe besimanje bolwazi.”

Isithombe esingezansi sibonisa u-Kilby kanye ne-patent yakhe ehlanganisiwe yesifunda:

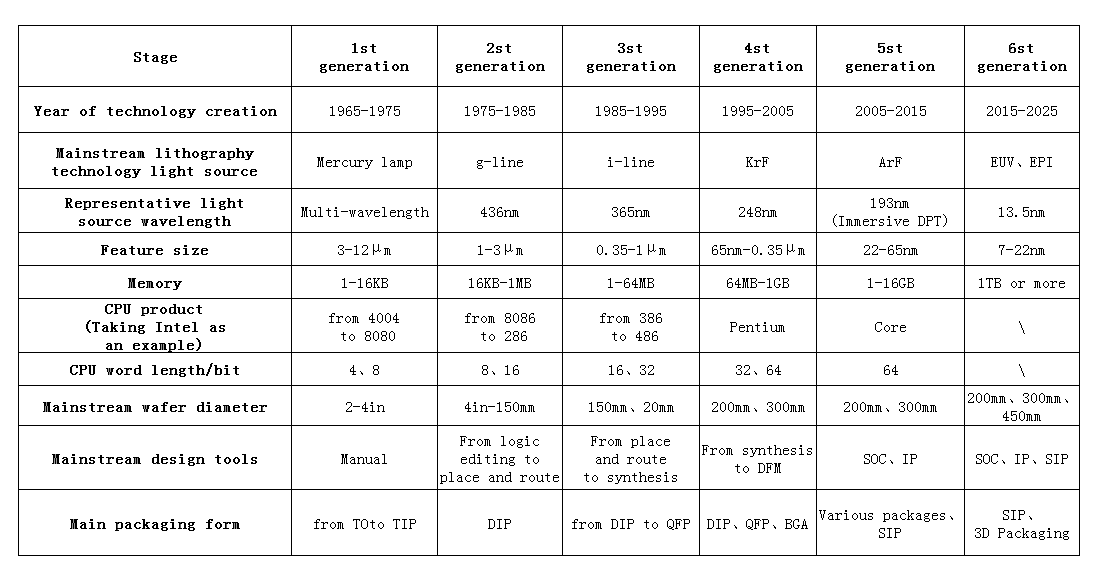

1.2 Ukuthuthukiswa kobuchwepheshe bokukhiqiza i-semiconductor

Isibalo esilandelayo sibonisa izigaba zokuthuthukiswa kobuchwepheshe bokukhiqiza i-semiconductor:

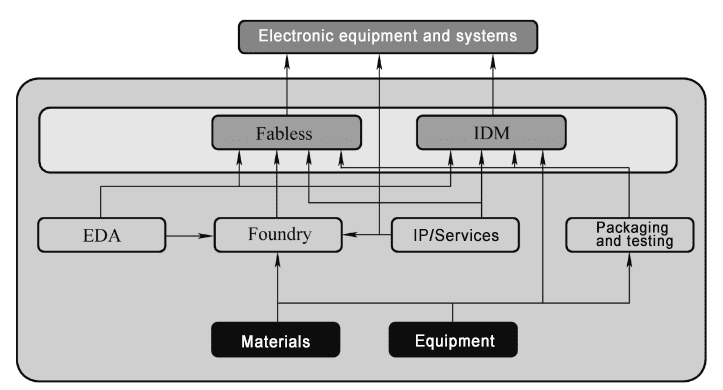

1.3 Uchungechunge Lwemboni Yesifunda Edidiyelwe

Ukwakheka kochungechunge lwemboni ye-semiconductor (ikakhulukazi amasekhethi ahlanganisiwe, okuhlanganisa namadivaysi ahlukene) kuboniswa esithombeni esingenhla:

- I-Fabless: Inkampani eklama imikhiqizo ngaphandle komugqa wokukhiqiza.

- I-IDM: Umkhiqizi Wedivayisi Ohlanganisiwe, umenzi wedivayisi ohlanganisiwe;

- IP: Umkhiqizi wemojula yesifunda;

- I-EDA: I-Electronic Design Automatic, i-electronic design automation, inkampani ikakhulukazi inikeza amathuluzi okuklama;

- Foundry; I-wafer foundry, ehlinzeka ngezinsizakalo zokukhiqiza ama-chip;

- Izinkampani zokupakisha nokuhlola: ikakhulukazi i-Fabless ne-IDM;

- Izinkampani zezinto zokwakha nemishini ekhethekile: ikakhulukazi zihlinzeka ngezinto ezidingekayo kanye nemishini yezinkampani ezikhiqiza ama-chip.

Imikhiqizo eyinhloko ekhiqizwa kusetshenziswa ubuchwepheshe be-semiconductor yiziyingi ezihlanganisiwe kanye namadivayisi ahlukene we-semiconductor.

Imikhiqizo eyinhloko yamasekhethi ahlanganisiwe ihlanganisa:

- Izingxenye Ezijwayelekile Zohlelo Lokusebenza (ASSP);

- Iyunithi ye-Microprocessor (MPU);

- Inkumbulo

- Isicelo Specific Integrated Circuit (ASIC);

- Isifunda se-analog;

- Isekethe ye-logic evamile (Isekhithi Enengqondo).

Imikhiqizo eyinhloko yamadivayisi we-semiconductor discrete ihlanganisa:

- Diode;

- Transistor;

- Idivayisi yamandla;

- Idivayisi ye-High-Voltge;

- Idivayisi ye-Microwave;

- Optoelectronics;

- Idivayisi yenzwa (Inzwa).

2. Inqubo Edidiyelwe Yokukhiqiza Isekethe

2.1 Ukwenziwa Kwe-chip

Amashumi noma amashumi ezinkulungwane zama-chips athile angenziwa kanyekanye ku-wafer ye-silicon. Inani lama-chips ku-wafer ye-silicon lincike ohlotsheni lomkhiqizo kanye nosayizi we-chip ngayinye.

Ama-wafers e-silicon ngokuvamile abizwa ngokuthi ama-substrates. Ububanzi bama-wafers e-silicon bebulokhu bukhuphuka eminyakeni edlule, busuka ngaphansi kweyintshi elingu-1 ekuqaleni ukuya kumayintshi avame ukusetshenziswa angu-12 (cishe u-300 mm) manje, futhi lushintshashintsha luye kumayintshi angu-14 noma amayintshi angu-15.

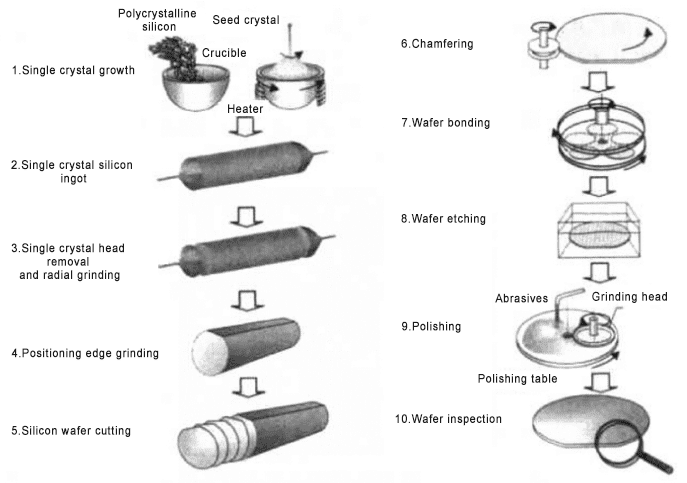

Ukukhiqizwa kwe-chip ngokuvamile kuhlukaniswe izigaba ezinhlanu: ukulungiswa kwe-silicon wafer, ukukhiqizwa kwe-silicon wafer, ukuhlolwa / ukukha ama-chip, ukuhlanganisa nokupakisha, nokuhlolwa kokugcina.

(1)

Ukulungiswa kwe-Silicon wafer:

Ukwenza izinto ezingavuthiwe, i-silicon ikhishwa esihlabathini futhi ihlanzwe. Inqubo ekhethekile ikhiqiza ingots ye-silicon yobubanzi obufanele. Ama-ingots abe esesikwa abe ama-silicon wafers amancane okwenza ama-microchips.

Ama-wafer alungiselelwa ukucaciswa okuthile, okufana nezidingo zonqenqema lokubhalisa namazinga okungcola.

(2)Ukukhiqiza i-silicone wafer:

Okwaziwa nangokuthi ukukhiqiza ama-chip, i-silicon wafer engenalutho ifika embonini yokukhiqiza i-silicon wafer bese idlula ekuhlanzeni okuhlukahlukene, ukwakheka kwefilimu, i-photolithography, i-etching kanye nezinyathelo zokudopha. I-silicon wafer ecutshunguliwe inesethi ephelele yamasekethe ahlanganisiwe amiswe unomphela ku-silicon wafer.

(3)Ukuhlolwa nokukhethwa kwama-wafers e-silicon:

Ngemuva kokuthi ukukhiqizwa kwe-silicon wafer kuqediwe, amawafa e-silicon athunyelwa endaweni yokuhlola/yokuhlunga, lapho ama-chips ngamanye ephenywa futhi ahlolwe ngogesi. Ama-chips amukelekayo nangamukeleki abe esehlungwa, bese kumakwa ama-chips anesici.

(4)Ukuhlanganisa nokupakishwa:

Ngemva kokuhlolwa kwewafa/ukuhlunga, amawafa angena esinyathelweni sokuhlanganisa nesokupakisha ukuze aphake ama-chips ngamanye kuphakheji yeshubhu yokuvikela. Uhlangothi olungemuva lwe-wafer luphansi ukuze kuncishiswe ubukhulu be-substrate.

Ifilimu yepulasitiki ewugqinsi inanyathiselwa ngemuva kwesinkwa esilucwecwana ngasinye, bese kusetshenziswa isaha esinenca yedayimane ukuze kuhlukaniswe ama-chips kuwawa ngamunye eduze kwemigqa yombhali ohlangothini olungaphambili.

Ifilimu yepulasitiki engemuva kwe-silicon wafer igcina i-silicon chip ingawi. Embonini yokuhlanganisa, ama-chips amahle ayacindezelwa noma akhishwe ukuze enze iphakheji yokuhlanganisa. Kamuva, i-chip ivalwa ngegobolondo lepulasitiki noma le-ceramic.

(5)Ukuhlolwa kokugcina:

Ukuqinisekisa ukusebenza kwe-chip, isekethe ngayinye ehlanganisiwe ehlanganisiwe ihlolwa ukuze kuhlangatshezwane nezidingo zepharamitha yomakhi kagesi neyemvelo. Ngemva kokuhlolwa kokugcina, i-chip ithunyelwa ekhasimendeni ukuze ihlanganiswe endaweni enikelwe.

2.2 Isigaba Senqubo

Izinqubo zokukhiqiza isekethe ehlanganisiwe ngokuvamile zihlukaniswa zibe:

Ngaphambili: Inqubo ye-front-end ngokuvamile ibhekisela kunqubo yokukhiqiza yamadivayisi afana nama-transistors, ikakhulukazi ahlanganisa izinqubo zokwakheka kokuzihlukanisa, ukwakheka kwesango, umthombo nokukhipha amanzi, izimbobo zokuthintana, njll.

Emuva ekupheleni: Inqubo ye-back-end ikakhulukazi ibhekisela ekwakhekeni kwemigqa yokuxhuma engadlulisela amasignali kagesi kumadivayisi ahlukahlukene ku-chip, ikakhulukazi okuhlanganisa izinqubo ezifana ne-dielectric deposition phakathi kwemigqa yokuxhuma, ukwakheka kolayini wensimbi, nokwakheka kwephedi lomthofu.

Phakathi nesiteji: Ukuze kuthuthukiswe ukusebenza kwama-transistors, ama-node obuchwepheshe obuthuthukisiwe ngemva kwe-45nm/28nm asebenzisa ama-dielectrics wesango eliphezulu-k kanye nezinqubo zesango lensimbi, futhi wengeze izinqubo zesango lokungena esikhundleni nezinqubo zokuxhumanisa zendawo ngemva kokulungiswa komthombo we-transistor kanye nesakhiwo sokukhipha amanzi. Lezi zinqubo ziphakathi kwenqubo ye-front-end kanye ne-back-end inqubo, futhi azisetshenziswa ezinqubweni zendabuko, ngakho zibizwa ngokuthi izinqubo ze-mid-stage.

Ngokuvamile, inqubo yokulungisa imbobo yokuxhumana ingumugqa ohlukanisayo phakathi kwenqubo yangaphambili kanye nenqubo yokubuyela emuva.

Imbobo yokuxhumana: imbobo ejulwe yabheka phezulu kusiluli sesilicon ukuze kuxhunywe ulayini wokuxhuma wensimbi wesendlalelo sokuqala kanye nedivayisi ye-substrate. Igcwele insimbi efana ne-tungsten futhi isetshenziselwa ukuholela i-electrode yedivayisi isendlalelo sokuxhumanisa insimbi.

NgeHole: Kuyindlela yokuxhuma phakathi kwezingqimba ezimbili eziseduze zemigqa yokuxhuma yensimbi, etholakala kungqimba lwe-dielectric phakathi kwezingqimba ezimbili zensimbi, futhi ngokuvamile igcwaliswa ngezinsimbi ezifana nethusi.

Ngomqondo obanzi:

Inqubo yangaphambili: Ngomqondo obanzi, ukukhiqizwa kwesekethe ehlanganisiwe kufanele futhi kubandakanye ukuhlolwa, ukupakisha nezinye izinyathelo. Uma kuqhathaniswa nokuhlola nokupakishwa, ukukhiqizwa kwengxenye kanye ne-interconnect kuyingxenye yokuqala yokukhiqiza isekethe edidiyelwe, ngokuhlangene okubizwa ngokuthi izinqubo zangaphambili;

Inqubo yokubuyela emuva: Ukuhlola nokupakisha kubizwa ngokuthi izinqubo zokubuyela emuva.

3. Isithasiselo

I-SMIF:I-Standard Mechanical Interface

I-AMHS: Uhlelo Lokunikezela Ngezinto Ezizenzakalelayo

OHT: Ukudluliswa kwe-Overhead Hoist

I-FOUP: I-Front Opening Pod Unified, Exclusive to 12 inch (300mm) ama-wafers

Okubaluleke nakakhulu,I-Semicera ingahlinzekaizingxenye zegraphite, uthambile/uqinile,izingxenye ze-silicon carbide, Izingxenye ze-CVD silicon carbide, futhiIzingxenye ezihlanganisiwe ze-SiC/TaCngenqubo ephelele ye-semiconductor ezinsukwini ezingama-30.Sibheke ngabomvu ukuba uzakwethu wesikhathi eside e-China.

Isikhathi sokuthumela: Aug-15-2024