Okukodwa Uhlolojikelele

Enkambweni yokukhiqiza isekethe ehlanganisiwe, i-photolithography iyinqubo eyinhloko enquma izinga lokuhlanganisa lamasekethe ahlanganisiwe. Umsebenzi wale nqubo ukudlulisa ngokwethembeka nokudlulisa imininingwane yesithombe sesifunda kusuka kumaski (ebuye ibizwe ngokuthi imaski) kuya ku-substrate yezinto ze-semiconductor.

Umgomo oyisisekelo wenqubo ye-photolithography ukusebenzisa ukusabela kwe-photochemical kwe-photoresist embozwe ngaphezulu kwe-substrate ukurekhoda iphethini yesifunda kumaski, ngaleyo ndlela kufezwe injongo yokudlulisa iphethini yesekethe ehlanganisiwe isuka eklanyweni iye endaweni engaphansi.

Inqubo eyisisekelo ye-photolithography

Okokuqala, i-photoresist isetshenziswa endaweni engaphansi kwe-substrate kusetshenziswa umshini wokumboza;

Khona-ke, umshini we-photolithography usetshenziselwa ukudalula i-substrate ehlanganiswe ne-photoresist, futhi indlela yokusabela ye-photochemical isetshenziselwa ukurekhoda ulwazi lwephethini yemaski ehanjiswa umshini we-photolithography, ukugcwalisa ukudluliselwa kokwethembeka, ukudlulisa nokuphindaphinda kwephethini yemaski ku-substrate;

Okokugcina, unjiniyela usetshenziselwa ukuthuthukisa i-substrate eveziwe ukuze asuse (noma agcine) i-photoresist ebhekana nokusabela kwe-photochemical ngemva kokuchayeka.

Inqubo yesibili ye-photolithography

Ukuze udlulisele iphethini yesekethe eklanyelwe kumaski ku-wafer ye-silicon, ukudluliswa kufanele kuqala kufinyelelwe ngenqubo yokuchayeka, bese iphethini ye-silicon kufanele itholwe ngenqubo yokunamathisela.

Njengoba ukukhanya kwendawo yenqubo ye-photolithography kusebenzisa umthombo wokukhanya ophuzi lapho izinto ze-photosensitive zingazweli, kubizwa nangokuthi indawo yokukhanya okuphuzi.

I-Photolithography yaqala ukusetshenziswa embonini yokunyathelisa futhi yayiwubuchwepheshe obuyinhloko bokukhiqiza i-PCB yokuqala. Kusukela ngawo-1950, i-photolithography kancane kancane ibe ubuchwepheshe obujwayelekile bokudlulisa iphethini ekukhiqizeni kwe-IC.

Izinkomba ezibalulekile zenqubo ye-lithography zihlanganisa ukulungiswa, ukuzwela, ukunemba kwembondela, izinga lokukhubazeka, njll.

Into ebaluleke kakhulu enqubweni ye-photolithography yi-photoresist, okuyingxenye ye-photosensitive. Njengoba ukuzwela kwe-photoresist kuncike kubude begagasi bomthombo wokukhanya, izinto ezihlukile ze-photoresist ziyadingeka ezinqubweni ze-photolithography ezifana nomugqa we-g/i, 248nm KrF, kanye ne-193nm ArF.

Inqubo eyinhloko yenqubo ye-photolithography evamile ihlanganisa izinyathelo ezinhlanu

:

-Base ukulungiselela ifilimu;

-Faka i-photoresist kanye nokubhaka okuthambile;

-Ukuqondanisa, ukuchayeka kanye nokubhaka ngemuva kokuchayeka;

- Yakha ifilimu eqinile;

-Ukutholwa kokuthuthukiswa.

(1)Ukulungiswa kwefilimu okuyisisekelo: ikakhulukazi ukuhlanza nokuphelelwa amanzi emzimbeni. Ngenxa yokuthi noma yikuphi ukungcola kuzonciphisa ukunamathela phakathi kwe-photoresist ne-wafer, ukuhlanzeka okuphelele kungathuthukisa ukunamathela phakathi kwe-wafer ne-photoresist.

(2)I-Photoresist enamathela: Lokhu kufinyelelwa ngokuzungezisa i-silicon wafer. Ama-photoresist ahlukene adinga amapharamitha enqubo yokuhlanganisa ahlukene, okuhlanganisa isivinini sokuzungezisa, ukujiya kwe-photoresist, nezinga lokushisa.

Ukubhaka okuthambile: Ukubhaka kungathuthukisa ukunamathela phakathi kwe-photoresist ne-silicon wafer, kanye nokufana kogqinsi lwe-photoresist, okuzuzisa ukulawula okunembile kobukhulu bejometri benqubo yokunamathisela elandelayo.

(3)Ukuqondanisa nokuchayeka: Ukuqondanisa nokuchayeka yizinyathelo ezibaluleke kakhulu kunqubo ye-photolithography. Babhekisela ekuqondaniseni iphethini yemaski nephethini ekhona ku-wafer (noma iphethini yongqimba yangaphambili), bese bayikhanyisela ngokukhanya okuthile. Amandla okukhanya enza kusebenze izingxenye ze-photoresist ku-photoresist, ngaleyo ndlela adlulisele iphethini yemaski kumthwebuli wezithombe.

Imishini esetshenziselwa ukuqondanisa nokuchayeka ingumshini we-photolithography, okuwucezu olulodwa olubiza kakhulu lwemishini yenqubo kuyo yonke inqubo yokukhiqiza isekethe edidiyelwe. Izinga lobuchwepheshe lomshini we-photolithography limelela izinga lokuthuthuka kwawo wonke umugqa wokukhiqiza.

Ukubhaka kwangemuva kokuchayeka: kubhekisela kunqubo yokubhaka emfushane ngemva kokuchayeka, enomthelela ohlukile kunama-photoresists e-ultraviolet ajulile kanye nama-photoresists we-i-line avamile.

Ku-photoresist ye-ultraviolet ejulile, ukubhaka ngemuva kokuchayeka kususa izingxenye zokuzivikela ku-photoresist, okuvumela i-photoresist ukuthi incibilike kumthuthukisi, ngakho-ke ukubhaka ngemuva kokuchayeka kuyadingeka;

Kuma-photoresists we-i-line evamile, ukubhaka ngemuva kokuchayeka kungathuthukisa ukunamathela kwe-photoresist futhi kunciphise amagagasi amile (amagagasi amile azoba nomthelela omubi ku-morphology enqenqemeni ye-photoresist).

(4)Ukuthuthukisa ifilimu eqinile: usebenzisa unjiniyela ukuncibilikisa ingxenye encibilikayo ye-photoresist (i-photoresist positive) ngemva kokuchayeka, futhi ibonise ngokunembile iphethini yemaski ngephethini ye-photoresist.

Amapharamitha angukhiye wenqubo yokuthuthukisa ahlanganisa izinga lokushisa lokuthuthukiswa nesikhathi, umthamo wonjiniyela kanye nokugxilisa ingqondo, ukuhlanza, njll. Ngokulungisa amapharamitha afanelekile ekuthuthukisweni, umehluko wezinga lokuchithwa phakathi kwezingxenye eziveziwe nezingaveziwe ze-photoresist ungakhuphuka, ngalokho. ukuthola umphumela wokuthuthukisa owufunayo.

Ukuqina kwaziwa nangokuthi ukubhaka ukuqina, okuyinqubo yokususa i-solvent esele, umthuthukisi, amanzi nezinye izingxenye ezisele ezingadingekile ku-photoresist ethuthukisiwe ngokuyifudumeza futhi ihwamuke, ukuze kuthuthukiswe ukunamathela kwe-photoresist ku-silicon substrate futhi ukumelana ne-etching of photoresist.

Izinga lokushisa lenqubo yokuqina liyahlukahluka kuye ngokuthi ama-photoresist ahlukene kanye nezindlela zokuqina. Isisekelo siwukuthi iphethini ye-photoresist ayiwohloki futhi i-photoresist kufanele yenziwe ibe nzima ngokwanele.

(5)Ukuhlolwa kwentuthuko: Lokhu okokuhlola ukukhubazeka kuphethini ye-photoresist ngemva kokuthuthukiswa. Ngokuvamile, ubuchwepheshe bokubona isithombe busetshenziselwa ukuskena ngokuzenzakalelayo iphethini ye-chip ngemva kokuthuthukiswa futhi uyiqhathanise nephethini evamile engenasici egcinwe ngaphambilini. Uma kukhona umehluko otholakalayo, uthathwa njengonesici.

Uma inani lokukhubazeka lidlula inani elithile, i-silicon wafer ibhekwa njengehlulekile ukuhlolwa kokuthuthukiswa futhi ingase ichithwe noma isetshenzwe kabusha njengoba kufanele.

Enqubweni ehlanganisiwe yokukhiqiza isifunda, izinqubo eziningi azikwazi ukuhlehliswa, futhi i-photolithography ingenye yezinqubo ezimbalwa kakhulu ezingase zisetshenzwe kabusha.

Ama-photomasks amathathu nezinto zokwakha ze-photoresist

3.1 Imaski yesithombe

I-photomask, eyaziwa nangokuthi imaski ye-photolithography, iyingcweti esetshenziswa enqubweni ye-photolithography yokukhiqiza iwafa yesifunda ehlanganisiwe.

Inqubo yokukhiqiza i-photomask iwukuguqula idatha yesakhiwo sangempela esidingekayo ekukhiqizweni kwe-wafer eklanywe onjiniyela abaklami besifunda abahlanganisiwe ibe ifomethi yedatha engabonwa abakhiqizi bephethini ye-laser noma imishini yokuvezwa kwe-electron beam ngokucubungula idatha yemaski, ukuze ivezwe izinto zokusebenza ezingenhla ku-substrate ye-photomask ehlanganiswe ngezinto ezithinta izithombe; bese icutshungulwa ngochungechunge lwezinqubo ezifana nokuthuthukiswa nokunamathisela ukuze kulungiswe iphethini kokubalulekile kwe-substrate; ekugcineni, ihlolwe, ilungiswe, ihlanzwe, futhi ifakwe ifilimu ukuze yakhe umkhiqizo we-mask futhi ihanjiswe kumkhiqizi wesifunda ohlanganisiwe ukuze asetshenziswe.

3.2 Umthwebuli wezithombe

I-Photoresist, eyaziwa nangokuthi i-photoresist, i-photoresist material. Izingxenye ze-photosensitive ezikuyo zizobhekana nezinguquko zamakhemikhali ngaphansi kwemisebe yokukhanya, ngaleyo ndlela kubangele izinguquko kuzinga lokuncibilika. Umsebenzi wayo oyinhloko ukudlulisa iphethini kumaski ku-substrate efana ne-wafer.

Umgomo wokusebenza we-photoresist: Okokuqala, i-photoresist imbozwa ku-substrate futhi ibhakwe ngaphambili ukuze isuse isincibilikizi;

Okwesibili, imaski ivezwa ekukhanyeni, okwenza izingxenye ze-photosensitive engxenyeni eveziwe zibhekane nokusabela kwamakhemikhali;

Bese, ukubhaka ngemuva kokuchayeka kwenziwa;

Okokugcina, i-photoresist incibilika kancane ngokuthuthukiswa (ku-photoresist enhle, indawo eveziwe iyancibilika; ku-photoresist engalungile, indawo engaveziwe iyancibilika), ngaleyo ndlela ibona ukudluliswa kwephethini yesekethe ehlanganisiwe isuka kumaski iye ku-substrate.

Izingxenye ze-photoresist ikakhulukazi zifaka i-resin eyenza ifilimu, ingxenye ye-photosensitive, trace additives kanye ne-solvent.

Phakathi kwabo, i-resin eyenza ifilimu isetshenziselwa ukuhlinzeka ngezakhiwo zemishini kanye nokumelana nokufaka; ingxenye ye-photosensitive ibhekana nezinguquko zamakhemikhali ngaphansi kokukhanya, okubangela izinguquko kuzinga lokuchithwa;

Izengezo zokulandelela zihlanganisa odayi, izithuthukisi ze-viscosity, njll., ezisetshenziselwa ukuthuthukisa ukusebenza kwe-photoresist; ama-solvents asetshenziselwa ukuhlakaza izingxenye futhi azixube ngokulinganayo.

Ama-photoresists asetshenziswa kabanzi njengamanje angahlukaniswa abe ama-photoresists endabuko kanye nama-photoresists akhuliswe ngamakhemikhali ngokuya nge-photochemical reaction mechanism, futhi angahlukaniswa abe yi-ultraviolet, i-ultraviolet ejulile, i-ultraviolet ngokweqile, i-electron beam, i-ion beam kanye ne-X-ray photoresists ngokusho kwe i-photosensitivity wavelength.

Imishini ye-photolithography emine

Ubuchwepheshe be-Photolithography buye badlula enqubweni yokuthuthukisa ye-contact/proximity lithography, i-optical projection lithography, i-lithography yesinyathelo nokuphindaphinda, i-lithography yokuskena, i-immersion lithography, kanye ne-EUV lithography.

4.1 Umshini Wokuthintana/I-Proximity Lithography

Ubuchwepheshe be-lithography bokuxhumana buvele ngeminyaka yawo-1960 futhi babusetshenziswa kakhulu ngeminyaka yawo-1970. Kwakuyindlela eyinhloko ye-lithography ngenkathi yamasekhethi amancane ahlanganisiwe futhi yayisetshenziselwa ikakhulukazi ukukhiqiza amasekhethi ahlanganisiwe anosayizi besici abakhulu kuno-5μm.

Emshinini we-lithography othintana naye/ubude, iwafa ivamise ukubekwa endaweni evundlile elawulwa mathupha kanye netafula lokusebenza elizungezayo. Umsebenzisi usebenzisa isibonakhulu senkambu ehlukene ukuze abone ngesikhathi esisodwa indawo yemaski newafa, futhi alawule mathupha indawo yetafula lokusebenza ukuze aqondanise imaski newafa. Ngemuva kokuthi i-wafer ne-mask ziqondaniswe, lezi ezimbili zizocindezelwa ndawonye ukuze imaski ixhumane ngqo ne-photoresist ebusweni be-wafer.

Ngemva kokukhipha inhloso yesibonakhulu, iwafa ecindezelwe kanye nemaski kuhanjiswa kuthebula lokuchayeka ukuze kucace. Ukukhanya okukhishwa isibani se-mercury kuyahlanganiswa futhi kuhambisane nemaski nge-lens. Njengoba imaski ixhumene ngqo nesendlalelo se-photoresist ku-wafer, iphethini yemaski idluliselwa kungqimba lwe-photoresist ngesilinganiso esingu-1:1 ngemuva kokuchayeka.

Imishini ye-contact lithography iyisisetshenziswa esilula futhi esonga kakhulu se-optical lithography, futhi ingafinyelela ukuvezwa kwezithombe zosayizi wesici se-sub-micron, ngakho isasetshenziswa ekukhiqizweni kwemikhiqizo emincane kanye nocwaningo lwaselabhorethri. Ekukhiqizweni kwesekethe edidiyelwe enkulu, ubuchwepheshe be-proximity lithography yethulwa ukuze kugwenywe ukwanda kwezindleko ze-lithography okubangelwa ukuthintana okuqondile phakathi kwe-mask ne-wafer.

I-Proximity lithography yayisetshenziswa kakhulu ngeminyaka yawo-1970s phakathi nenkathi yamasekethe ahlanganisiwe amancane kanye nenkathi yokuqala yamasekethe ahlanganisiwe asezingeni eliphakathi. Ngokungafani ne-contact lithography, imaskhi ku-proximity lithography ayixhumani ngqo ne-photoresist ku-wafer, kodwa igebe eligcwele i-nitrogen lishiywe. Imaski intanta phezu kwe-nitrogen, futhi ubukhulu begebe phakathi kwe-mask ne-wafer kunqunywa ukucindezela kwe-nitrogen.

Njengoba kungekho ukuxhumana okuqondile phakathi kwe-wafer kanye ne-mask ku-proximity lithography, amaphutha okwethulwa ngesikhathi senqubo ye-lithography ayancishiswa, ngaleyo ndlela kunciphisa ukulahleka kwe-mask futhi kuthuthukise isivuno se-wafer. Ku-proximity lithography, igebe phakathi kwe-wafer ne-mask ibeka i-wafer endaweni ye-Fresnel diffraction. Ukuba khona kwe-diffraction kunciphisa ukuthuthukiswa okuqhubekayo kokuxazululwa kwemishini ye-proximity lithography, ngakho-ke lobu buchwepheshe bufaneleka ngokuyinhloko ukukhiqizwa kwamasekhethi ahlanganisiwe anobukhulu besici obungaphezu kuka-3μm.

4.2 Isitepisi nesiphindaphindayo

I-stepper ingenye yemishini ebaluleke kakhulu emlandweni we-wafer lithography, ekhuthaze inqubo ye-sub-micron lithography ibe ukukhiqizwa ngobuningi. Isitebhisi sisebenzisa inkambu evamile yokuchayeka emile engu-22mm × 22mm kanye nelensi yokubona ebonakalayo enesilinganiso sokunciphisa esingu-5:1 noma 4:1 ukuze idlulisele iphethini kumaski ku-wafer.

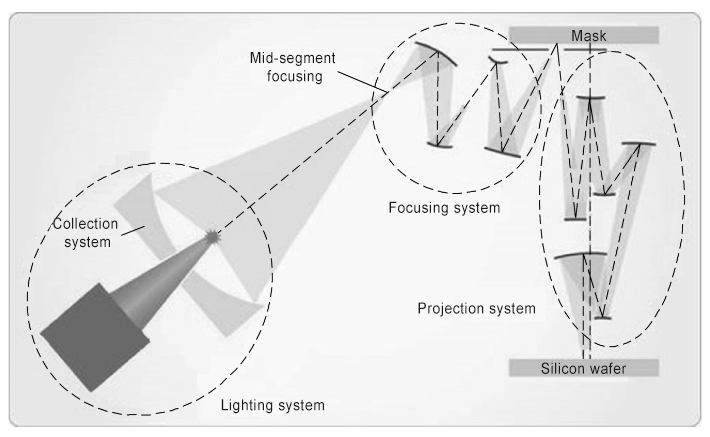

Umshini we-lithography wesinyathelo nophindayo uvamise ukwakhiwa ngesistimu engaphansi yokuchayeka, isistimu engaphansi yesiteji socezu lokusebenza, uhlelo olungaphansi lwesiteji semaski, uhlelo olungaphansi lokugxila/lokulinganisa, uhlelo oluncane lokuqondanisa, uhlelo olungaphansi lohlaka oluyinhloko, uhlelo olungaphansi lokudlulisa oluyilucwecwana, uhlelo olungaphansi lokudlulisa imaski. , isistimu engaphansi ye-elekthronikhi, kanye nesistimu engaphansi yesofthiwe.

Inqubo evamile yokusebenza yomshini we-lithography wesinyathelo-futhi-phindaphinda imi kanje:

Okokuqala, i-wafer ehlanganiswe ne-photoresist idluliselwa etafuleni le-workpiece ngokusebenzisa i-subsystem yokudlulisa i-wafer, futhi imaski ezovezwa idluliselwa etafuleni lemaski ngokusebenzisa uhlelo olungaphansi lokudlulisa imaski;

Bese, isistimu isebenzisa isistimu engaphansi yokugxila/yokunikeza ileveli ukwenza isilinganiso sobude bamaphuzu amaningi ku-wafer esesiteji sesiqephu sokusebenzela ukuze kutholwe ulwazi olufana nobude ne-engeli yokutsheka yobuso bewafa ukuze kuvezwe, ukuze indawo yokuchayeka iwafa ingahlala ilawulwa ngaphakathi kokujula kokugxilile kwenhloso yokuqagela phakathi nenqubo yokuchayeka;Ngokulandelayo, isistimu isebenzisa isistimu engaphansi yokuqondanisa ukuze iqondanise imaski ne-wafer ukuze ngesikhathi senqubo yokuchayeka ukunemba kwendawo yesithombe semaski nokudluliswa kwephethini ye-wafer kuhlale kungaphakathi kwezidingo zembondela.

Ekugcineni, isinyathelo sokuchayeka kanye nokuchayeka kwayo yonke indawo eyisicwecwana siqedwa ngokuya ngendlela enqunyiwe ukuze kuqashwe umsebenzi wokudlulisa iphethini.

Umshini olandelayo we-stepper kanye ne-scanner lithography usekelwe enqubweni yokusebenza eyisisekelo engenhla, ukuthuthukisa ukunyathela → ukuchayeka ekuskeneni → ukuchayeka, nokugxila/ukubeka izinga → ukuqondanisa → ukuchayeka kumodeli yezigaba ezimbili esilinganisweni (ukugxila/ukulinganisa → ukuqondanisa) nokuskena ukuchayeka ngokuhambisana.

Uma kuqhathaniswa nomshini we-lithography wesinyathelo nokuskena, umshini we-lithography wesinyathelo nokuphinda awudingi ukuzuza ukuskena okuhlanekezela okuhambisanayo kwemaski ne-wafer, futhi awudingi ithebula lemaski lokuskena kanye nesistimu yokulawula ukuskena okuvumelanayo. Ngakho-ke, isakhiwo silula, izindleko ziphansi, futhi ukusebenza kunokwethenjelwa.

Ngemuva kokuthi ubuchwepheshe be-IC bungene ku-0.25μm, ukusetshenziswa kwe-lithography yesinyathelo nokuphindaphinda kwaqala ukwehla ngenxa yezinzuzo ze-lithography yesinyathelo ne-scan ekuskeneni usayizi wensimu yokuchayeka kanye nokufana kokuchayeka. Okwamanje, i-lithography yakamuva yesinyathelo nokuphinda ehlinzekwe ngu-Nikon inomkhakha wokubuka omile omkhulu njengalowo we-lithography yesinyathelo nese-skeni, futhi ingacubungula ama-wafers angaphezu kwangu-200 ngehora, ngokusebenza kahle kokukhiqiza okuphezulu kakhulu. Lolu hlobo lomshini we-lithography okwamanje lusetshenziselwa ikakhulukazi ukwakhiwa kwezingqimba ze-IC ezingabalulekile.

4.3 I-Stepper Scanner

Ukusetshenziswa kwe-lithography yesinyathelo-futhi-skeni kwaqala ngawo-1990. Ngokulungiselela imithombo yokukhanya yokuchayeka ehlukene, ubuchwepheshe besinyathelo kanye nokuskena bungasekela amanode obuchwepheshe bezinqubo, kusukela ku-365nm, 248nm, 193nm ukucwiliswa kuya ku-EUV lithography. Ngokungafani ne-lithography yezinyathelo neziphindaphindayo, ukuvezwa kwenkundla eyodwa ye-lithography yesinyathelo neseskena kusebenzisa ukuskena okuguquguqukayo, okungukuthi, ipuleti lemaski liqedela ukunyakaza kokuskena ngokuhambisana ne-wafer; ngemva kokuba ukuchayeka kwenkambu yamanje sekuqediwe, isicwecwana sithwalwa yisiteji se-workpiece bese sinyathela endaweni elandelayo yenkambu yokuskena, futhi ukuchayeka okuphindaphindiwe kuyaqhubeka; phinda ukuchayeka kwesinyathelo nokuskena izikhathi eziningi kuze kube yilapho zonke izinkambu zewafa zivezwa.

Ngokumisa izinhlobo ezahlukene zemithombo yokukhanya (efana ne-i-line, KrF, ArF), isithwebuli esinyathelayo singasekela cishe wonke amanodi zobuchwepheshe enqubo yokuphela kwe-semiconductor yangaphambili. Izinqubo ezijwayelekile ezisekelwe ku-silicon ezisekelwe ku-CMOS zamukele izikena ezinyathela ngobuningi kusukela endaweni engu-0.18μm; imishini ye-lithography ye-ultraviolet (EUV) eyedlulele esetshenziswa njengamanje kuma-process node angaphansi kuka-7nm nayo isebenzisa i-stepper-scanning. Ngemuva kokuguqulwa okuyingxenye okuguquguqukayo, isithwebuli se-stepper singase futhi sisekele ucwaningo nokuthuthukiswa nokukhiqizwa kwezinqubo eziningi ezingezona i-silicon njenge-MEMS, amadivayisi kagesi, namadivayisi e-RF.

Abakhiqizi abakhulu bemishini ye-lithography yesinyathelo ne-scan bahlanganisa i-ASML (Netherlands), i-Nikon (eJapane), i-Canon (eJapane) kanye ne-SMEE (China). I-ASML yethule uchungechunge lwe-TWINSCAN lwemishini ye-lithography yesinyathelo ne-scan ngo-2001. Yamukela ukwakheka kwesistimu yezigaba ezimbili, engathuthukisa ngokuphumelelayo izinga lokuphuma kwemishini futhi isibe umshini we-lithography osetshenziswa kakhulu kunazo zonke.

4.4 I-Immersion Lithography

Kungabonakala kufomula ye-Rayleigh ukuthi, lapho ubude beza beza bokuchayeka buhlala bungashintshile, indlela ephumelelayo yokuthuthukisa ukuxazulula kwesithombe ukukhulisa ukuvuleka kwezinombolo kwesistimu yokucabanga. Ukuze uthole izinqumo zokucabanga ezingaphansi kuka-45nm nangaphezulu, indlela yokuchayeka okomile ye-ArF ngeke isakwazi ukuhlangabezana nezidingo (ngoba isekela ukulungiswa kwesithombe okuphezulu okungu-65nm), ngakho-ke kuyadingeka ukwethula indlela yokucwiliswa kwe-lithography. Kubuchwepheshe be-lithography bendabuko, okuphakathi phakathi kwe-lens ne-photoresist kuwumoya, kuyilapho ubuchwepheshe be-lithography bokucwiliswa buthatha indawo ye-air medium ngoketshezi (imvamisa amanzi e-ultrapure anenkomba ye-refractive engu-1.44).

Eqinisweni, ubuchwepheshe be-immersion lithography busebenzisa ukufinyezwa kobude begagasi bomthombo wokukhanya ngemva kokuba ukukhanya kudlule endaweni ewuketshezi ukuze kuthuthukiswe ukulungiswa, futhi isilinganiso esifushane siyinkomba ye-refractive ye-liquid medium. Nakuba umshini we-lithography wokucwiliswa uwuhlobo lomshini we-lithography wesinyathelo-futhi-scan, futhi isisombululo sawo sesistimu yemishini asikashintshi, kungukuguqulwa nokunwetshwa komshini we-ArF wesinyathelo-futhi-scan we-lithography ngenxa yokwethulwa kobuchwepheshe obubalulekile obuhlobene. ukucwiliswa.

Inzuzo yokucwiliswa kwe-lithography ukuthi, ngenxa yokwanda kokuvuleka kwenombolo yesistimu, ikhono lokuxazulula izithombe zomshini we-lithography we-stepper-scanner liyathuthukiswa, elingahlangabezana nezidingo zenqubo yokuxazulula izithombe ngaphansi kwe-45nm.

Njengoba umshini wokucwiliswa kwe-lithography usasebenzisa umthombo wokukhanya we-ArF, ukuqhubeka kwenqubo kuqinisekisiwe, konga izindleko ze-R&D zomthombo wokukhanya, okokusebenza kanye nenqubo. Ngalesi sisekelo, kuhlanganiswe nehluzo eziningi kanye nobuchwepheshe be-lithography bekhompiyutha, umshini wokucwilisa we-lithography ungasetshenziswa kuma-process nodes we-22nm nangaphansi. Ngaphambi kokuthi umshini we-EUV lithography ufakwe ngokusemthethweni ekukhiqizweni ngobuningi, umshini wokucwiliswa kwe-lithography wawusetshenziswe kabanzi futhi wawungahlangabezana nezidingo zenqubo ye-7nm node. Kodwa-ke, ngenxa yokwethulwa koketshezi lokucwiliswa, ubunzima bobunjiniyela bemishini ngokwayo bukhule kakhulu.

Ubuchwepheshe bayo obubalulekile buhlanganisa ukucwiliswa koketshezi nobuchwepheshe bokuthola kabusha, ubuchwepheshe bokucwiliswa kwe-lithography bokulungisa insimu, ukungcoliswa kwe-lithography yokucwiliswa kanye nobuchwepheshe bokulawula amaphutha, ukuthuthukiswa nokugcinwa kwamalensi okucwiliswa kokucwiliswa kwezinombolo ezinkulu kakhulu, kanye nobuchwepheshe bokubona ikhwalithi yokucabanga ngaphansi kwezimo zokucwiliswa.

Njengamanje, imishini yokuhweba ye-ArFi step-and-scan lithography ihlinzekwa ikakhulukazi izinkampani ezimbili, okuyi-ASML yaseNetherlands kanye ne-Nikon yase-Japan. Phakathi kwazo, intengo ye-ASML NXT1980 Di eyodwa icishe ibe yizigidi ezingama-80 zama-euro.

4.5 Umshini We-Ultraviolet Lithography Owedlulele

Ukuze kuthuthukiswe ukulungiswa kwe-photolithography, ubude beza beza bokuchayeka bufushaniswa futhi ngemva kokwamukelwa komthombo wokukhanya kwe-excimer, futhi ukukhanya kwe-ultraviolet okudlulele okunobude begagasi obungu-10 ukuya ku-14 nm kwethulwa njengomthombo wokukhanya wokuchayeka. Ubude begagasi bokukhanya kwe-ultraviolet okwedlulele bufushane ngokwedlulele, futhi isistimu yokubona ekhanyayo engasetshenziswa ngokuvamile yakhiwa izibonisi zefilimu ezinezendlalelo eziningi ezifana ne-Mo/Si noma i-Mo/Be.

Phakathi kwazo, ukuboniswa okuphezulu kwethiyori kwefilimu ye-Mo/Si ye-multilayer ebangeni le-wavelength elingu-13.0 kuya ku-13.5nm cishe kungama-70%, futhi ukubonakaliswa okuphezulu kwethiyori kwefilimu ye-Mo/Be ye-multilayer kubude obufushane obungu-11.1nm bucishe bube ngu-80%. Nakuba ukuboniswa kwezibonisi zefilimu ze-Mo/Be kuphezulu, i-Be inobuthi obukhulu, ngakho ucwaningo ngezinto ezinjalo luye lwayekwa lapho kuthuthukiswa ubuchwepheshe be-EUV lithography.Ubuchwepheshe bamanje be-EUV lithography busebenzisa ifilimu ye-Mo/Si enezingqimba eziningi, futhi ubude bayo bokuchayeka buphinde bunqunywe ukuthi bube ngu-13.5nm.

Umthombo wokukhanya we-ultraviolet ngokwedlulele usebenzisa ubuchwepheshe be-laser-produced plasma (LPP), obusebenzisa amalaser anamandla kakhulu ukujabulisa i-hot-melt Sn plasma ukuze ikhiphe ukukhanya. Isikhathi eside, amandla nokutholakala komthombo wokukhanya kube yizingqinamba ezivimbela ukusebenza kahle kwemishini ye-EUV lithography. Nge-master oscillator power amplifier, ubuchwepheshe be-predictive plasma (PP) kanye nobuchwepheshe bokuhlanza isibuko sokuqoqwa kwe-in-situ, amandla nokuzinza kwemithombo yokukhanya ye-EUV kuthuthukiswe kakhulu.

Umshini we-EUV lithography wakhiwe ikakhulukazi amasistimu angaphansi afana nomthombo wokukhanya, ukukhanyisa, ilensi ephokophelwe, isiteji socezu lokusebenza, isigaba semaski, ukuqondanisa kwe-wafer, ukugxila/ukulinganisa, ukudluliswa kwemaski, ukudluliswa kwe-wafer, nohlaka lwe-vacuum. Ngemva kokudlula ohlelweni lokukhanyisa olwakhiwe ngezibonisi ezinezingqimba eziningi ezinamekwe, ukukhanya kwe-ultraviolet okwedlulele kukhanyiswa kumaski ekhanyayo. Ukukhanya okuvezwa imaski kungena ohlelweni lwe-optical total reflection imaging olwakhiwe uchungechunge lwezibonisi, futhi ekugcineni isithombe esiveziwe semaski sivezwa ebusweni bewafa endaweni engenalutho.

Inkambu yokuchayeka kanye nenkambu yokuthatha izithombe yomshini we-EUV we-lithography kokubili kumise okwe-arc, futhi indlela yokuskena yesinyathelo nesinyathelo isetshenziswa ukuze kuzuzwe ukuchayeka okugcwele kwe-wafer ukuze kuthuthukiswe izinga lokuphumayo. Umshini we-ASML othuthuke kakhulu we-NXE we-EUV lithography usebenzisa umthombo wokukhanya wokuchayeka onobude begagasi obungu-13.5nm, imaski ekhanyayo (isenzakalo esitshekile esingu-6°), isistimu yenhloso yokubonisa yokunciphisa i-4x enesakhiwo se-6-mirror (NA=0.33), a inkambu yokuskena yokubuka engu-26mm × 33mm, kanye nendawo yokuchayeka ku-vacuum.

Uma kuqhathaniswa nemishini yokucwiliswa kwe-lithography, ukulungiswa kokuvezwa okukodwa kwemishini ye-EUV ye-lithography esebenzisa imithombo yokukhanya kwe-ultraviolet okwedlulele kuye kwathuthukiswa kakhulu, okungagwema ngempumelelo inqubo eyinkimbinkimbi edingekayo ukuze i-photolithography yakhe ihluzo ezinokulungiswa okuphezulu. Njengamanje, ukulungiswa kokuvezwa okukodwa komshini we-lithography we-NXE 3400B nge-aperture yezinombolo ze-0.33 kufinyelela ku-13nm, futhi izinga lokukhipha lifinyelela izingcezu ezingu-125 / h.

Ukuze kuhlangatshezwane nezidingo zokunwetshwa okwengeziwe koMthetho ka-Moore, ngokuzayo, imishini ye-EUV ye-lithography enembobo yenombolo engu-0.5 izosebenzisa isistimu yenhloso yokuqagela enokuvimbela ukukhanya okumaphakathi, isebenzisa ukukhuliswa kwe-asymmetric izikhathi ezingu-0.25/0.125, kanye indawo yokubuka yokuskena izoncishiswa isuka ku-26m × 33mm iye ku-26mm × 16.5mm, futhi ukulungiswa kokuchayeka okukodwa kungafinyelela ngaphansi kuka-8nm.

————————————————————————————————————————————————— ————————————

I-Semicera ingahlinzekaizingxenye zegraphite, ukuzwakala okuthambile/okuqinile, izingxenye ze-silicon carbide, Izingxenye ze-CVD silicon carbide, futhiIzingxenye ezihlanganisiwe ze-SiC/TaCngenqubo ephelele ye-semiconductor ezinsukwini ezingama-30.

Uma unentshisekelo kule mikhiqizo engenhla ye-semiconductor,sicela ungangabazi ukusithinta okokuqala.

Ucingo: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Isikhathi sokuthumela: Aug-31-2024