1. Isingeniso

Ukufakwa kwe-ion kungenye yezinqubo eziyinhloko ekukhiqizeni isekethe edidiyelwe. Isho inqubo yokusheshisa i-ion beam kumandla athile (imvamisa ebangeni le-keV ukuya ku-MeV) bese ijova endaweni eqinile yento eqinile ukuze kushintshwe izici ezibonakalayo zobuso bento. Enqubweni ehlanganisiwe yesifunda, izinto eziqinile ngokuvamile ziyi-silicon, futhi ama-ion angcolile afakwe ngokuvamile ama-boron ions, ions phosphorus, ion arsenic, ion indium, ion germanium, njll. impahla noma yakha ukuhlangana kwe-PN. Lapho usayizi wesici wamasekhethi ahlanganisiwe wehliselwa enkathini ye-sub-micron, inqubo yokufakelwa kwe-ion yasetshenziswa kabanzi.

Enkambweni yokukhiqiza isekethe edidiyelwe, ukufakwa kwe-ion kuvame ukusetshenziselwa izendlalelo ezijule ezigqitshiwe, imithombo ehlehlisiwe, ukulungiswa kwe-voltage embundwini, ukufakelwa kwesandiso somthombo nokukhipha amanzi, ukufakwa komthombo nokukhipha amanzi, ukudotshwa kwesango le-polysilicon, ukwakha ukuhlangana kwe-PN nama-resistors/capacitors, njll. Enqubweni yokulungisa izinto ze-silicon substrate kuma-insulators, ungqimba lwe-oxide olungcwatshwe ikakhulukazi lwakhiwe ngokufakwa kwe-ion ion ye-oxygen ephezulu, noma ehlakaniphile. ukusika kufezwa ngokufakwa kwe-hydrogen ion ion ephezulu yokugxila.

Ukufakwa kwe-ion kwenziwa i-ion implanter, futhi imingcele yayo yenqubo ebaluleke kakhulu umthamo namandla: umthamo unquma ukugxila kokugcina, futhi amandla anquma ububanzi (okungukuthi, ukujula) kwama-ion. Ngokuya ngezidingo ezihlukene zedizayini yedivayisi, izimo zokufakelwa zihlukaniswe ngedosi ephezulu yamandla, umthamo omaphakathi wamandla, umthamo omaphakathi wamandla, noma umthamo ophansi wamandla. Ukuze kutholwe umphumela ofanele wokufakelwa, izifakeli ezihlukene kufanele zihlonyiselwe izidingo zenqubo ehlukene.

Ngemva kokufakwa kwe-ion, ngokuvamile kuyadingeka ukuba kwenziwe inqubo yokudonsa izinga lokushisa eliphezulu ukuze kulungiswe umonakalo we-lattice odalwe ukufakwa kwe-ion kanye nokwenza kusebenze ama-ion angcolile. Ezinqubweni zesifunda ezididiyelwe zendabuko, nakuba izinga lokushisa le-annealing linethonya elikhulu ku-doping, izinga lokushisa lenqubo yokufakelwa kwe-ion ngokwayo ayibalulekile. Kumanodi obuchwepheshe angaphansi kuka-14nm, izinqubo ezithile zokufakelwa kwe-ion zidinga ukwenziwa endaweni yokushisa ephansi noma ephezulu ukuze kuguqulwe imiphumela yokulimala kwe-lattice, njll.

2. inqubo yokufakwa kwe-ion

2.1 Izimiso Eziyisisekelo

Ukufakwa kwe-ion kuyinqubo yokudotshwa kwezidakamizwa eyasungulwa ngeminyaka yawo-1960s ehamba phambili kumasu endabuko okusabalalisa ezicini eziningi.

Umehluko omkhulu phakathi kwe-doping yokufakelwa kwe-ion kanye ne-doping yendabuko yokusabalalisa imi kanje:

(1) Ukusatshalaliswa kokugxilisa ukungcola endaweni ene-doped kuhlukile. Isilinganiso esiphakeme sokungcola kokufakelwa kwe-ion sitholakala ngaphakathi kwekristalu, kuyilapho ukugxiliswa kokungcola okuphezulu kokusabalalisa kutholakala ebusweni bekristalu. (2) Ukufakwa kwe-ion kuyinqubo eyenziwa ekamelweni lokushisa noma ngisho namazinga okushisa aphansi, futhi isikhathi sokukhiqiza sifushane. I-Diffusion doping idinga ukwelashwa okude kwezinga lokushisa eliphezulu. (3) Ukufakwa kwe-ion kuvumela ukukhetha okuguquguqukayo nokunembe kwezinto ezitshaliwe. (4) Njengoba ukungcola kuthintwa ukusabalalisa okushisayo, i-waveform eyakhiwe ngokufakwa kwe-ion kukristalu ingcono kune-waveform eyakhiwe ngokusakazwa kukristalu. (5) Ukufakwa kwe-ion ngokuvamile kusebenzisa i-photoresist kuphela njengemaski, kodwa i-diffusion doping idinga ukukhula noma ukubekwa kwefilimu enogqinsi oluthile njengesifihla-buso. (6) Ukufakwa kwe-ion ngokuyisisekelo kuthathe indawo yokusabalalisa futhi kwaba inqubo eyinhloko ye-doping ekwenzeni amasekhethi ahlanganisiwe namuhla.

Uma i-ion beam yesigameko enamandla athile iqhumisa ithagethi eqinile (imvamisa i-wafer), ama-ion nama-athomu endaweni okuqondiwe kuyobhekana nokusebenzelana okunhlobonhlobo, futhi idlulisele amandla kuma-athomu aqondiwe ngendlela ethile ukuze ajabule noma afake ionini. bona. Ama-ion angaphinda alahlekelwe inani elithile lamandla ngokudluliswa komfutho, futhi ekugcineni ahlakazwe ama-athomu aqondiwe noma ame kokubalulekile okuqondiwe. Uma ama-ion ajovwe esinda, ama-ion amaningi azojovwa kuthagethi eqinile. Ngokuphambene, uma ama-ion ajovwe elula, ama-ion amaningi ajovwe azogxuma asuke endaweni okuhlosiwe. Ngokuyisisekelo, la ma-ion anamandla aphezulu ajovwe kokuhlosiwe azongqubuzana nama-athomu e-lattice nama-electron kuthagethi eqinile ukuya kumazinga ahlukahlukene. Phakathi kwazo, ukungqubuzana phakathi kwama-ion nama-athomu okuqondiwe aqinile kungabhekwa njengokungqubuzana okunwebekayo ngoba asondelene ngobuningi.

2.2 Imingcele eyinhloko yokufakelwa kwe-ion

Ukufakwa kwe-ion kuyinqubo evumelana nezimo okufanele ihlangabezane nezidingo eziqinile zokuklanywa kwe-chip kanye nezidingo zokukhiqiza. Imingcele ebalulekile yokufakelwa kwe-ion yilezi: umthamo, ububanzi.

Umthamo (D) ubhekisela enanini lama-ion ajovwe ngeyunithi ngayinye yendawo ye-silicon wafer, kuma-athomu ngesentimitha lesikwele (noma ama-ion ngesentimitha lesikwele). D ingabalwa ngefomula elandelayo:

Lapho u-D kuwumthamo wokufakelwa (inani lama-ion/iyunithi yendawo); t isikhathi sokufakelwa; Mina ngingumsinga womlilo; q inkokhiso ethwalwa yi-ion (inkokhelo eyodwa ngu-1.6×1019C[1]); futhi u-S uyindawo yokufakelwa.

Esinye sezizathu eziyinhloko zokuthi kungani ukufakwa kwe-ion kube ubuchwepheshe obubalulekile ekukhiqizeni i-silicon wafer ukuthi kungafaka ngokuphindaphindiwe umthamo ofanayo wokungcola kuma-silicon wafers. I-implanter ifinyelela lo mgomo ngosizo lokukhokhiswa okuhle kwama-ion. Uma ama-ion ahlanzekile enza i-ion beam, izinga lokugeleza kwawo libizwa ngokuthi i-ion beam current, elinganiswa nge-mA. Ububanzi bemisinga ephakathi nendawo naphansi bungu-0.1 kuye ku-10 mA, kanti ububanzi bemisinga ephezulu yi-10 kuya ku-25 mA.

Ubukhulu be-ion beam current buyinguquko ebalulekile ekuchazeni umthamo. Uma ukwanda kwamanje, inani lama-athomu okungcola afakwe ngesikhathi seyunithi nalo liyakhuphuka. Amandla aphezulu asiza ekwandiseni isivuno se-silicon wafer (ukujova ama-ion engeziwe ngesikhathi sokukhiqiza seyunithi), kodwa futhi kubangela izinkinga zokufana.

3. Imishini yokufaka i-ion

3.1 Isakhiwo Esiyisisekelo

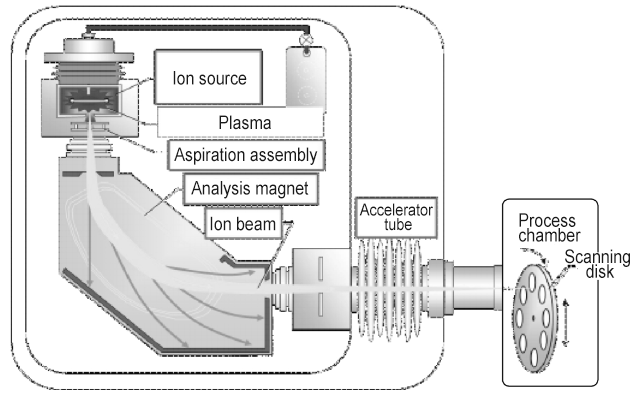

Imishini yokufakelwa kwe-ion ihlanganisa amamojula ayi-7 ayisisekelo:

① umthombo we-ion kanye nesibambisi;

② i-mass analyzer (okungukuthi uzibuthe wokuhlaziya);

③ ishubhu ye-accelerator;

④ ukuskena idiski;

⑤ uhlelo lwe-electrostatic neutralization;

⑥ igumbi lenqubo;

⑦ uhlelo lokulawula umthamo.

All amamojula asendaweni ye-vacuum esungulwe uhlelo lwe-vacuum. Umdwebo oyisisekelo wesakhiwo sokufakelwa kwe-ion uboniswa esithombeni esingezansi.

(1)Umthombo we-ion:

Ngokuvamile kugumbi le-vacuum efanayo ne-electrode yokumunca. Ukungcola okulinde ukujovwa kufanele kube khona esimweni se-ion ukuze kulawulwe futhi kusheshiswe inkambu kagesi. Okuvame ukusetshenziswa kakhulu B+, P+, As+, njll. kutholakala ngama-athomu e-ionizing noma ama-molecule.

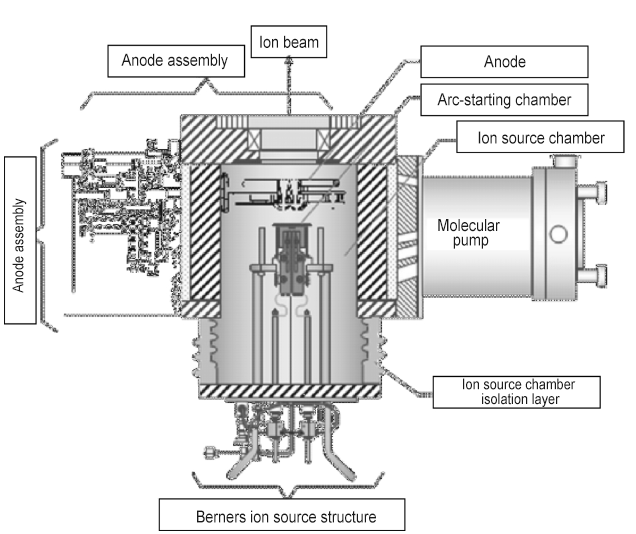

Imithombo yokungcola esetshenzisiwe yi-BF3, PH3 kanye ne-ASH3, njll., futhi izakhiwo zayo ziboniswa esithombeni esingezansi. Ama-electron akhishwa umcu ashayisana nama-athomu egesi ukuze akhiqize ama-ion. Ama-electron ngokuvamile akhiqizwa umthombo oshisayo we-tungsten filament. Isibonelo, umthombo we-ion Berners, i-cathode filament ifakwe ekamelweni le-arc eline-inlet yegesi. Udonga lwangaphakathi lwegumbi le-arc yi-anode.

Lapho umthombo wegesi wethulwa, i-current enkulu idlula i-filament, futhi i-voltage engu-100 V isetshenziswa phakathi kwama-electrode amahle namabi, azokhiqiza ama-electron anamandla amakhulu azungeze umcu. Ama-ion amahle akhiqizwa ngemva kokuba ama-electron anamandla amakhulu eshayisana nama-molecule egesi yomthombo.

Uzibuthe wangaphandle usebenzisa insimu kazibuthe ehambisana nentambo ukuze kwandiswe i-ionization futhi kuqiniswe i-plasma. Ekamelweni le-arc, ngakolunye uhlangothi oluhlobene ne-filament, kukhona i-reflector ekhokhiswa kabi ekhombisa ama-electron emuva ukuze kuthuthukiswe ukukhiqizwa nokusebenza kahle kwama-electron.

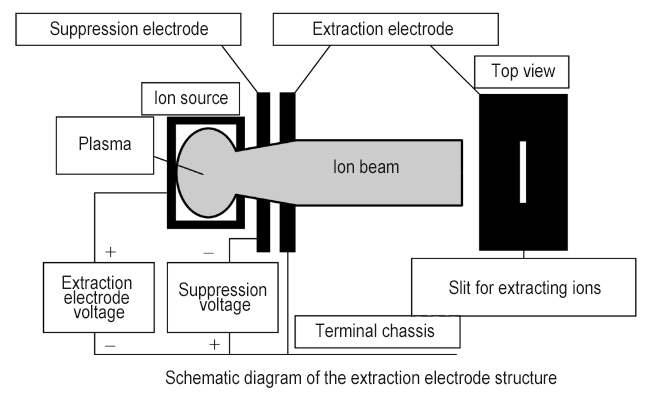

(2)Ukumuncwa:

Isetshenziselwa ukuqoqa ama-ion aqondile akhiqizwe egumbini le-arc lomthombo we-ion futhi awakhe abe yi-ion beam. Njengoba i-arc chamber iyi-anode futhi i-cathode icindezelwa kabi ku-electrode yokumunca, inkambu kagesi ekhiqiziwe ilawula ama-ion aqondile, okuwenza adlulele ku-electrode yokumunca futhi akhishwe osikweni lwe-ion, njengoba kuboniswe esithombeni esingezansi. . Uma amandla enkundla kagesi emakhulu, amandla e-kinetic azuza ama-ion ngemva kokusheshisa. Kukhona futhi i-sppression voltage ku-electrode yokumunca ukuvimbela ukuphazamiseka kwama-electron ku-plasma. Ngesikhathi esifanayo, i-electrode yokucindezela ingenza ama-ion abe yi-ion beam futhi iwagxilise emfuleni we-ion beam stream ukuze idlule ku-implanter.

(3)I-mass analyzer:

Kungase kube nezinhlobo eziningi zama-ion akhiqizwa emthonjeni we-ion. Ngaphansi kokusheshisa kwe-voltage ye-anode, ama-ion ahamba ngesivinini esikhulu. Ama-ion ahlukene anamayunithi esisindo se-athomu ahlukene kanye nezilinganiso ezihlukene ze-mass to-charge.

(4)Ishubhu ye-Accelerator:

Ukuze uthole isivinini esiphezulu, amandla aphezulu ayadingeka. Ngaphandle kwenkambu kagesi ehlinzekwe yi-anode ne-mass analyzer, inkambu kagesi enikezwe kushubhu ye-accelerator nayo iyadingeka ukuze kusheshiswe. Ishubhu le-accelerator liqukethe uchungechunge lwama-electrode ahlukaniswe i-dielectric, futhi i-voltage engalungile kuma-electrode iyanda ngokulandelana ngoxhumano lochungechunge. Lapho isamba se-voltage siphezulu, sikhulu isivinini esitholwe ama-ion, okungukuthi, amandla amakhulu aphathwayo. Amandla aphezulu angavumela ama-ion angcolile ukuthi afakwe ekujuleni kwe-silicon wafer ukuze akhe ukuhlangana okujulile, kuyilapho amandla aphansi angasetshenziswa ukwenza ukuhlangana okungajulile.

(5)Iskena idiski

I-ion beam egxilile ngokuvamile incane kakhulu ngobubanzi. Ububanzi bendawo ye-beam yokufakelwa kwamanje kwe-medium bungaba ngu-1 cm, kanti lokho okufakelwayo kwamanje kwe-beam kucishe kube ngu-3 cm. I-wafer yonke ye-silicon kufanele imbozwe ngokuskena. Ukuphindaphinda kokufakwa komthamo kunqunywa ngokuskena. Ngokuvamile, kunezinhlobo ezine zezinhlelo zokuskena ze-implanter:

① ukuskena kwe-electrostatic;

② ukuskena ngomshini;

③ ukuskena okuxubile;

④ ukuskena okuhambisanayo.

(6)Isistimu yokunciphisa ugesi omile:

Ngesikhathi senqubo yokufakelwa, i-ion beam ishaya isicwecwana se-silicon futhi ibangele ukuthi ukushaja kunqwabelane endaweni yemaski. Ukunqwabelana kweshaja okuwumphumela kushintsha ibhalansi yeshaji ku-ion, kwenze indawo ye-beam ibe nkulu futhi nokusabalalisa umthamo kungalingani. Ingase igqekeze ungqimba lwe-oxide engaphezulu futhi ibangele ukwehluleka kwedivayisi. Manje, i-silicon wafer kanye ne-ion beam kuvame ukubekwa endaweni ezinzile ye-plasma ephezulu-density ebizwa ngokuthi i-plasma electron shower system, engalawula ukushajwa kwewafa ye-silicon. Le ndlela ikhipha ama-electron ku-plasma (imvamisa i-argon noma i-xenon) ekamelweni le-arc elitholakala kumzila we-ion beam eduze ne-silicon wafer. I-plasma iyahlungwa futhi ama-electron esibili kuphela angafinyelela phezulu kwe-silicon wafer ukuze anciphise ukushaja okuhle.

(7)Inqubo ye-cavity:

Umjovo wemishayo ye-ion ku-silicon wafers kwenzeka ekamelweni lenqubo. Igumbi lenqubo liyingxenye ebalulekile yokufakelwa, okuhlanganisa isistimu yokuskena, isiteshi setheminali esinokhiye we-vacuum wokulayisha nokukhipha ama-silicon wafers, isistimu yokudlulisa i-silicon wafer, kanye nesistimu yokulawula ikhompuyutha. Ngaphezu kwalokho, kunamanye amadivaysi okuqapha imithamo nokulawula imiphumela yesiteshi. Uma kusetshenziswa ukuskena ngomshini, isiteshi setheminali sizoba sikhulu uma kuqhathaniswa. I-vacuum yegumbi lenqubo impontshelwa ekucindezelweni okuphansi okudingwa inqubo yiphampu yomshini yezigaba eziningi, iphampu ye-turbomolecular, kanye nephampu yokufingqa, ngokuvamile ecishe ibe ngu-1×10-6Torr noma ngaphansi.

(8)Uhlelo lokulawula umthamo:

Ukuqapha umthamo wesikhathi sangempela kusifakeli se-ion kufezwa ngokukala ugongolo lwe-ion olufinyelela ku-silicon wafer. I-ion beam current ikalwa kusetshenziswa inzwa ebizwa nge-Faraday cup. Kuhlelo olulula lwe-Faraday, kunenzwa yamanje kumzila we-ion beam okala amandla amanje. Kodwa-ke, lokhu kuveza inkinga, njengoba i-ion beam iphendulana nenzwa futhi ikhiqize ama-electron esibili azoholela ekufundweni kwamanje okuyiphutha. Isistimu ye-Faraday ingacindezela ama-electron esibili isebenzisa izinkundla zikagesi noma kazibuthe ukuze ithole ukufundwa kwamanje kwe-beam. Okwamanje okukalwa ngohlelo lwe-Faraday kufakwa kusilawuli somthamo we-elekthronikhi, esisebenza njenge-accumulator yamanje (eqoqa ngokuqhubekayo umthamo wamanje we-beam). Isilawuli sisetshenziselwa ukuhlobanisa inani lamanje nesikhathi esihambelanayo sokufakelwa nokubala isikhathi esidingekayo kumthamo othile.

3.2 Ukulungisa umonakalo

Ukufakwa kwe-ion kuzokhipha ama-athomu esakhiweni se-lattice futhi kulimaze i-silicon wafer lattice. Uma umthamo otshaliwe mkhulu, isendlalelo esifakiwe sizoba yi-amorphous. Ngaphezu kwalokho, ama-ion atshaliwe ngokuyisisekelo awathathi amaphuzu e-lattice e-silicon, kodwa ahlale ezindaweni zegebe le-lattice. Lokhu kungcola kwe-interstitial kungenziwa kusebenze kuphela ngemva kwenqubo yokushisa ephezulu yokushisa.

I-annealing ingashisisa isicwecwana se-silicon esitshaliwe ukuze silungise ukukhubazeka kwe-lattice; ingakwazi futhi ukuhambisa ama-athomu okungcola iye ezindaweni ze-lattice futhi iwasebenze. Izinga lokushisa elidingekayo ukuze kulungiswe amaphutha e-lattice licishe libe ngu-500°C, futhi izinga lokushisa elidingekayo ukuze kusebenze ama-athomu angcolile licishe libe ngu-950°C. Ukwenza kusebenze ukungcola kuhlobene nesikhathi nezinga lokushisa: isikhathi eside futhi izinga lokushisa liphakeme, ukungcola kuyasebenza ngokugcwele. Kunezindlela ezimbili eziyisisekelo zokunamathisela ama-silicon wafers:

① ukufakwa kwesithando sokushisa okuphezulu;

② i-annealing eshisayo esheshayo (RTA).

Ukushisa okuphezulu kokushisa kwesithando somlilo: Ukushisa okuphezulu kwesithando somlilo kuyindlela evamile yokuthungatha izifutho, esebenzisa isithando somlilo esishisayo ukushisa iwafa ye-silicon ibe ngu-800-1000℃ futhi uyigcine imizuzu engama-30. Kuleli zinga lokushisa, ama-athomu e-silicon abuyela endaweni ye-lattice, futhi ama-athomu okungcola angangena esikhundleni sama-athomu e-silicon futhi angene ku-lattice. Kodwa-ke, ukwelashwa ngokushisa ngalelo zinga lokushisa kanye nesikhathi kuzoholela ekusakazweni kokungcola, okuyinto imboni yesimanje yokukhiqiza i-IC engafuni ukuyibona.

I-Rapid Thermal Annealing: I-Rapid thermal annealing (RTA) iphatha amawafa e-silicon ngokukhuphuka kwezinga lokushisa okushesha kakhulu kanye nesikhathi esifushane kuzinga lokushisa eliqondisiwe (ngokuvamile lingu-1000°C). Ukufakwa kwe-silicon wafers afakwe ngokuvamile kwenziwa kuphrosesa eshisayo esheshayo ene-Ar noma i-N2. Inqubo yokukhuphuka kwezinga lokushisa ngokushesha kanye nobude besikhathi esifushane bungakwazi ukulungisa kahle ukonakala kwe-lattice, ukwenziwa kusebenze ukungcola kanye nokuvinjwa kokusabalalisa ukungcola. I-RTA futhi inganciphisa ukusakazeka okuthuthukisiwe kwesikhashana futhi iyindlela engcono kakhulu yokulawula ukujula kwenhlonhlo ekufakweni kwe-junction okungajulile.

————————————————————————————————————————————————— ————————————-

I-Semicera ingahlinzekaizingxenye zegraphite, ukuzwakala okuthambile/okuqinile, izingxenye ze-silicon carbide, Izingxenye ze-CVD silicon carbide, futhiIzingxenye ezihlanganisiwe ze-SiC/TaCngezinsuku ezingama-30.

Uma unentshisekelo kule mikhiqizo engenhla ye-semiconductor,sicela ungangabazi ukusithinta okokuqala.

Ucingo: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Isikhathi sokuthumela: Aug-31-2024