1. Isingeniso

Inqubo yokunamathisela izinto (izinto zokusetshenziswa) ebusweni bezinto ezingaphansi kwe-substrate ngezindlela ezingokwenyama noma zamakhemikhali ibizwa ngokuthi ukukhula kwefilimu encane.

Ngokwemigomo yokusebenza ehlukene, ukufakwa kwefilimu emincane yesekethe ehlanganisiwe kungahlukaniswa kube:

-I-Physical Vapor Deposition (PVD);

-Chemical Vapor Deposition (CVD);

-Isandiso.

2. Inqubo Yokukhula Kwefilimu Encane

2.1 Ukufakwa komhwamuko obonakalayo kanye nenqubo yokufafaza

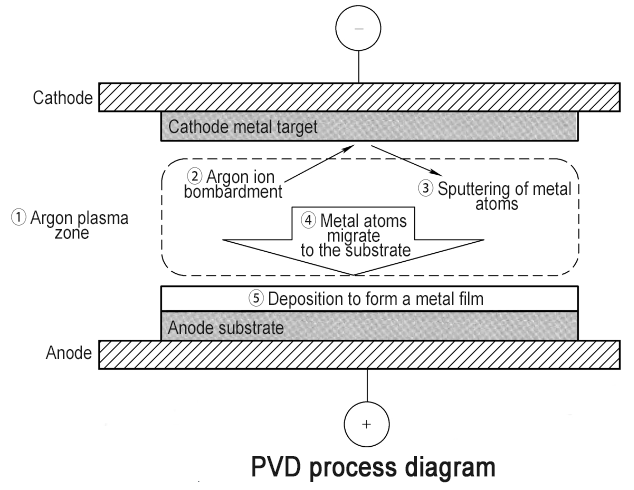

Inqubo ye-physical vapor deposition (PVD) ibhekisela ekusetshenzisweni kwezindlela ezibonakalayo ezifana nokuhwamuka kwe-vacuum, ukufafaza, ukunamathela ku-plasma kanye ne-epitaxy ye-molecular beam ukuze kwakhe ifilimu elincanyana phezu kwe-wafer.

Embonini ye-VLSI, ubuchwepheshe be-PVD obusetshenziswa kakhulu yi-sputtering, esetshenziselwa ikakhulukazi ama-electrode nokuxhuma kwensimbi kwamasekethe ahlanganisiwe. I-Sputtering inqubo lapho amagesi angavamile [njenge-argon (Ar)] enziwa i-ion ibe ama-ion (afana ne-Ar+) ngaphansi kwesenzo senkambu kagesi yangaphandle ngaphansi kwezimo ze-vacuum ephezulu, futhi aqhume ngebhomu umthombo wezinto ezibonakalayo ngaphansi kwendawo yamandla kagesi aphezulu, ukukhipha ama-athomu noma ama-molecule wento eqondiwe, bese ifika ngaphezulu kwe-wafer ukwenza ifilimu elincanyana ngemva kwenqubo yendiza engashayisani. I-Ar inezindawo zamakhemikhali ezizinzile, futhi ama-ion ayo ngeke asabele ngamakhemikhali ngento ehlosiwe kanye nefilimu. Njengoba ama-chips esekethe ahlanganisiwe angena enkathini ye-copper interconnect engu-0.13μm, isendlalelo sezinto ezivimbela ithusi sisebenzisa ifilimu ye-titanium nitride (TiN) noma i-tantalum nitride (TaN). Isidingo sobuchwepheshe bezimboni sigqugquzele ucwaningo nokuthuthukiswa kobuchwepheshe be-chemical reaction sputtering, okungukuthi, ekamelweni lokufafaza, ngaphezu kwe-Ar, kukhona negesi ye-nitrogen esebenzayo (N2), ukuze i-Ti noma i-Ta iqhume impahla okuqondiwe kuyo i-Ti noma i-Ta ihlangana ne-N2 ukuze ikhiqize ifilimu edingekayo ye-TiN noma ye-TaN.

Kunezindlela ezintathu ezisetshenziswa kakhulu zokuphalaza, okuyi-DC sputtering, i-RF sputtering kanye ne-magnetron sputtering. Njengoba ukuhlanganiswa kwamasekethe ahlanganisiwe kuqhubeka kwanda, inani lezendlalelo zezintambo zensimbi ezinezingqimba eziningi liyanda, futhi ukusetshenziswa kobuchwepheshe be-PVD kukhula kakhulu. Izinto ze-PVD zifaka i-Al-Si, i-Al-Cu, i-Al-Si-Cu, i-Ti, i-Ta, i-Co, i-TiN, i-TaN, i-Ni, i-WSi2, njll.

Izinqubo ze-PVD kanye ne-sputtering ngokuvamile ziqedwa ekamelweni lokuphendula elivalwe kakhulu nge-vacuum degree ye-1 × 10-7 kuya ku-9 × 10-9 Torr, engaqinisekisa ukuhlanzeka kwegesi ngesikhathi sokusabela; ngesikhathi esifanayo, i-voltage ephezulu yangaphandle iyadingeka ukuze kufakwe i-ionize igesi engavamile ukuze kukhiqizwe amandla kagesi aphezulu ngokwanele ukuze kuqhume okuhlosiwe. Imingcele eyinhloko yokuhlola izinqubo ze-PVD ne-sputtering ihlanganisa inani lothuli, kanye nenani lokumelana, ukufana, ukushuba kokubonakala kanye nokucindezeleka kwefilimu eyenziwe.

2.2 I-Chemical Vapor Deposition kanye nenqubo yokufafaza

I-Chemical vapor deposition (CVD) ibhekisela kubuchwepheshe benqubo lapho izinhlobonhlobo zama-reactants gaseous anengcindezi eyingxenye ehlukene zisabela ngamakhemikhali ezingeni elithile lokushisa nokucindezela, futhi izinto eziqinile ezikhiqiziwe zifakwa phezu kwe-substrate material ukuze kutholwe okuncanyana okufunayo. ifilimu. Enqubweni yokukhiqiza yesekethe edidiyelwe yendabuko, izinto zefilimu ezacile ezitholiwe ngokuvamile ziyinhlanganisela efana nama-oxides, nitrides, carbides, noma izinto ezifana ne-polycrystalline silicon ne-amorphous silicon. Ukukhula kwe-epitaxial okukhethiwe, okuvame ukusetshenziswa kakhulu ngemva kwenodi engu-45nm, njengomthombo kanye nokukhipha amanzi e-SiGe noma i-Si selective epitaxial growth, nakho kuwubuchwepheshe be-CVD.

Lobu buchwepheshe bungaqhubeka nokwakha izinto ze-crystal eyodwa zohlobo olufanayo noma ezifana ne-lattice yasekuqaleni endaweni eyodwa ye-crystal substrate ye-silicon noma ezinye izinto ezihambisana ne-lattice yasekuqaleni. I-CVD isetshenziswa kakhulu ekukhuleni kwamafilimu e-dielectric (afana ne-SiO2, i-Si3N4 ne-SiON, njll.) namafilimu ensimbi (afana ne-tungsten, njll.).

Ngokujwayelekile, ngokwesigaba sokucindezela, i-CVD ingahlukaniswa ibe yingcindezi yomoya yamakhemikhali e-chemical vapor deposition (APCVD), i-sub-atmosphere pressure chemical vapor deposition (SAPCVD) kanye ne-low pressure chemical vapor deposition (LPCVD).

Ngokwezigaba zokushisa, i-CVD ingahlukaniswa ngokushisa okuphezulu/izinga lokushisa eliphansi lefilimu ye-oxide i-chemical vapor deposition (HTO/LTO CVD) kanye nokufakwa komhwamuko wamakhemikhali ashisayo (Rapid Thermal CVD, RTCVD);

Ngokomthombo wokusabela, i-CVD ingahlukaniswa ibe i-CVD esekwe ku-silane, i-polyester-based CVD (i-TEOS-based CVD) kanye ne-metal organic chemical vapor deposition (MOCVD);

Ngokuya ngezigaba zamandla, i-CVD ingahlukaniswa ibe yi-thermal chemical vapor deposition (Thermal CVD), i-plasma ethuthukisiwe umhwamuko wamakhemikhali (i-Plasma Enhanced CVD, PECVD) kanye ne-high density plasma chemical vapor deposition (High Density Plasma CVD, HDPCVD). Muva nje, i-flowable chemical vapor deposition (i-Flowable CVD, FCVD) enekhono elihle kakhulu lokugcwalisa igebe nayo iye yathuthukiswa.

Amafilimu ahlukene akhule nge-CVD anezakhiwo ezahlukene (njengokwakheka kwamakhemikhali, i-dielectric constant, tension, stress and breakdown voltage) futhi angasetshenziswa ngokuhlukana ngokwezidingo zenqubo ehlukene (njengokushisa, ukumbozwa kwesinyathelo, izidingo zokugcwalisa, njll.).

2.3 Inqubo yokubeka isendlalelo se-athomu

I-Atomic layer Deposition (ALD) ibhekisela ekubekweni kwesendlalelo se-athomu ngokwesendlalelo kokubalulekile kwe-substrate ngokukhulisa ungqimba olulodwa lwefilimu ye-athomu ngokwesendlalelo. I-ALD evamile isebenzisa indlela yokufaka izandulela zegesi ku-reactor ngendlela eshintshashintshayo ye-pulsed.

Isibonelo, okokuqala, i-reaction precursor 1 yethulwa endaweni engaphansi kwe-substrate, futhi ngemva kokukhangisa kwamakhemikhali, ungqimba olulodwa lwe-athomu lwakhiwe phezu kwe-substrate; khona-ke i-precursor 1 esele endaweni engaphansi kwe-substrate futhi ekamelweni lokusabela likhishwa ngepompo yomoya; bese i-reaction precursor 2 yethulwa endaweni engaphansi, futhi isabela ngamakhemikhali nesandulela 1 esikhangisiwe endaweni engaphansi kwe-substrate ukuze kukhiqizwe impahla yefilimu emincane ehambisanayo kanye nemikhiqizo ehambisanayo endaweni engaphansi; lapho i-precursor 1 isabela ngokuphelele, ukusabela kuzophela ngokuzenzakalelayo, okuyisici esizibekela umkhawulo se-ALD, bese kuthi ama-reactants asele kanye nemikhiqizo ekhiqizwe ikhishwe ukuze kulungiselelwe isigaba esilandelayo sokukhula; ngokuphindaphinda le nqubo engenhla ngokuqhubekayo, ukubekwa kwezinto zefilimu ezincanyana ezikhule ungqimba nge-athomu eyodwa kungafinyelelwa.

Kokubili i-ALD ne-CVD izindlela zokwethula umthombo wamakhemikhali wegesi ukuze usabele ngamakhemikhali endaweni engaphansi, kodwa umehluko ukuthi umthombo wokusabela kwegesi we-CVD awunaso isici sokukhula okuzibekela umkhawulo. Kungabonakala ukuthi ukhiye wokuthuthukisa ubuchwepheshe be-ALD ukuthola izandulela ezinezakhiwo zokusabela ezizibekela umkhawulo.

2.4 Inqubo ye-Epitaxial

Inqubo ye-Epitaxial ibhekisela enqubweni yokukhulisa ungqimba olulodwa lwekristalu olu-ode ngokuphelele ku-substrate. Ngokuvamile, inqubo ye-epitaxial iwukukhulisa ungqimba lwekristalu olune-lattice orientation efanayo ne-substrate yasekuqaleni ku-crystal substrate eyodwa. Inqubo ye-Epitaxial isetshenziswa kabanzi ekukhiqizeni ama-semiconductor, njengama-epitaxial silicon wafers embonini yesifunda ehlanganisiwe, umthombo oshumekiwe kanye nokukhipha ukukhula kwe-epitaxial kwama-MOS transistors, ukukhula kwe-epitaxial kuma-substrates e-LED, njll.

Ngokwezimo zezigaba ezihlukene zomthombo wokukhula, izindlela zokukhula kwe-epitaxial zingahlukaniswa zibe i-epitaxy yesigaba esiqinile, i-epitaxy yesigaba soketshezi, kanye ne-vapor phase epitaxy. Ekwenziweni kwesekethe edidiyelwe, izindlela ezivame ukusetshenziswa ze-epitaxial ziyi-epitaxy yesigaba esiqinile kanye ne-vapor phase epitaxy.

I-epitaxy yesigaba esiqinile: ibhekisela ekukhuleni kongqimba olulodwa lwekristalu ku-substrate kusetshenziswa umthombo oqinile. Isibonelo, ukufakwa okushisayo ngemva kokufakwa kwe-ion empeleni kuyinqubo yesigaba esiqinile se-epitaxy. Ngesikhathi sokufakelwa kwe-ion, ama-athomu e-silicon esilucwecwana se-silicon ahlaselwa ama-ion afakwe amandla aphezulu, ashiye izindawo zawo zokuqala ze-lattice futhi abe amorphous, akhe ungqimba lwe-silicon olungaphezulu. Ngemuva kokushisa okushisayo okuphezulu, ama-athomu a-amorphous abuyela ezindaweni zawo ze-lattice futhi ahlale ehambisana nokuma kwekristalu ye-athomu ngaphakathi kwe-substrate.

Izindlela zokukhula ze-vapor phase epitaxy zihlanganisa i-chemical vapor phase epitaxy, i-molecular beam epitaxy, i-atomic layer epitaxy, njll. Ekwenziweni kwesekethe ehlanganisiwe, i-chemical vapor phase epitaxy iyona esetshenziswa kakhulu. Isimiso se-epitaxy yesigaba somhwamuko wamakhemikhali siyafana naso sokubeka umhwamuko wamakhemikhali. Zombili ziyizinqubo ezifaka amafilimu amancanyana ngokusabela ngokwekhemikhali phezu kwamawafa ngemva kokuxutshwa kwegesi.

Umehluko wukuthi ngenxa yokuthi i-epitaxy yesigaba somhwamuko wamakhemikhali ikhulisa ungqimba olulodwa lwekristalu, inezidingo eziphakeme zokuqukethwe ukungcola emishinini kanye nokuhlanzeka kwendawo eyisicwecwana. Inqubo yokuqala ye-chemical vapor phase epitaxial silicon idinga ukwenziwa ngaphansi kwezimo zokushisa eziphezulu (ezingaphezu kuka-1000°C). Ngokuthuthukiswa kwemishini yenqubo, ikakhulukazi ukwamukelwa kobuchwepheshe begumbi lokushintshisana nge-vacuum, ukuhlanzeka kwendawo yokusebenza kanye nobuso be-silicon wafer kuye kwaba ngcono kakhulu, futhi i-silicon epitaxy ingenziwa ekushiseni okuphansi (600-700 °). C). Inqubo ye-epitaxial silicon wafer ukukhulisa ungqimba lwe-silicon eyodwa yekristalu ebusweni be-silicon wafer.

Uma kuqhathaniswa ne-silicon substrate yasekuqaleni, ungqimba lwe-silicon ye-epitaxial lunokuhlanzeka okuphezulu kanye nokukhubazeka okumbalwa kwe-lattice, ngaleyo ndlela kuthuthukise isivuno sokukhiqizwa kwe-semiconductor. Ngaphezu kwalokho, ukushuba kokukhula nokugxiliswa kwe-doping kongqimba lwe-silicon ye-epitaxial ekhule ku-wafer ye-silicon kungaklanywa ngendlela eguquguqukayo, okuletha ukuguquguquka kwesakhiwo sedivayisi , njengokunciphisa ukumelana ne-substrate kanye nokuthuthukisa ukuhlukaniswa kwe-substrate. Inqubo eshumekiwe ye-source-drain epitaxial iwubuchwepheshe obusetshenziswa kakhulu kumanodi obuchwepheshe be-logic ethuthukisiwe.

Isho inqubo yokukhula kwe-epitaxially doped germanium sililikoni noma i-silicon ezindaweni eziwumthombo nezikhipha amanzi zama-transistors e-MOS. Izinzuzo eziyinhloko zokwethula inqubo ye-epitaxial yomthombo oshumekiwe ihlanganisa: ukukhulisa isendlalelo se-pseudocrystalline esiqukethe ukucindezeleka ngenxa yokulungiswa kwe-lattice, ukuthuthukisa ukuhamba kwenkampani yenethiwekhi; i-in-situ doping yomthombo kanye ne-drain inganciphisa ukumelana ne-parasitic of the source-drain junction futhi inciphise ukukhubazeka kokufakwa kwe-ion enamandla amakhulu.

3. Imishini yokukhulisa ifilimu emincane

3.1 Imishini yokuhwamuka kwevacuum

I-vacuum evaporation iyindlela yokwemboza eshisisa izinto eziqinile egumbini le-vacuum ukuze zihwamuke, zihwamuke noma zibe ngaphansi kwe-sublimate, bese zijiya futhi zibeke phezu kwe-substrate impahla ezingeni lokushisa elithile.

Ngokuvamile iqukethe izingxenye ezintathu, okungukuthi i-vacuum system, i-evaporation system kanye nesistimu yokushisa. Uhlelo lwe-vacuum luqukethe amapayipi e-vacuum namaphampu e-vacuum, futhi umsebenzi walo oyinhloko ukuhlinzeka ngendawo ye-vacuum efanelekayo yokuhwamuka. Uhlelo lokuhwamuka luqukethe itafula lokuhwamuka, ingxenye yokushisa kanye nengxenye yokulinganisa izinga lokushisa.

Izinto eziqondiwe ezizohwamuka (ezifana ne-Ag, Al, njll.) zibekwe etafuleni lokuhwamuka; ingxenye yokulinganisa ukushisa nokushisa iwuhlelo oluvaliwe olusetshenziswa ukulawula izinga lokushisa lokuhwamuka ukuze kuqinisekiswe ukuhwamuka okubushelelezi. Isistimu yokushisisa iqukethe isiteji se-wafer kanye nengxenye yokushisa. Isiteji se-wafer sisetshenziselwa ukubeka i-substrate lapho ifilimu elincanyana lidinga ukuhwamuka, futhi ingxenye yokufudumeza isetshenziselwa ukuqaphela ukushisisa kwe-substrate nokulawula impendulo yokulinganisa izinga lokushisa.

Imvelo ye-vacuum yisimo esibaluleke kakhulu enqubweni yokuhwamuka kwe-vacuum, ehlobene nezinga lokuhwamuka kanye nekhwalithi yefilimu. Uma i-vacuum degree ingahlangabezani nezidingo, ama-athomu noma ama-molecule ahwamukile azoshayisana njalo nama-molecule egesi asele, enze indlela yawo yamahhala ibe mncane, futhi ama-athomu noma ama-molecule azohlakazeka kakhulu, ngaleyo ndlela aguqule indlela yokuhamba futhi ehlise ifilimu. izinga lokwakheka.

Ngaphezu kwalokho, ngenxa yokuba khona kwamangqamuzana egesi angcolile asele, ifilimu efakiwe ingcoliswe kakhulu futhi isezingeni eliphansi, ikakhulukazi lapho izinga lokukhuphuka kokucindezela kwegumbi lingahlangabezani nezinga elijwayelekile futhi kukhona ukuvuza, umoya uzovuza egumbini le-vacuum. , okuzoba nomthelela omkhulu kwikhwalithi yefilimu.

Izici zesakhiwo sempahla yokuhwamuka kwevacuum zinquma ukuthi ukufana kwe-coating kuma-substrates anosayizi omkhulu kubi. Ukuze kuthuthukiswe ukufana kwayo, indlela yokwandisa ibanga lomthombo-substrate kanye nokuzungezisa i-substrate ngokuvamile iyamukelwa, kodwa ukukhulisa ibanga lomthombo-substrate kuzodela izinga lokukhula nokuhlanzeka kwefilimu. Ngesikhathi esifanayo, ngenxa yokwanda kwesikhala se-vacuum, izinga lokusebenzisa impahla ehwamukile liyancishiswa.

3.2 Imishini yokufaka umhwamuko we-DC

I-Direct current physical vapor deposition (DCPVD) yaziwa nangokuthi i-cathode sputtering noma i-vacuum DC yezigaba ezimbili. Izinto ezihlosiwe ze-vacuum DC sputtering zisetshenziswa njenge-cathode futhi i-substrate isetshenziswa njenge-anode. I-vacuum sputtering ukwakha i-plasma ngokwenza i-ionizing igesi yenqubo.

Izinhlayiya ezikhokhisiwe ku-plasma ziyasheshiswa ensimini kagesi ukuze zithole inani elithile lamandla. Izinhlayiya ezinamandla anele zibhoboza ingaphezulu lento eqondiwe, ukuze ama-athomu okuqondiwe ahlakazeke ngaphandle; ama-athomu anamanzi anamandla athile e-kinetic aya endaweni engaphansi ukuze akhe ifilimu elincanyana ebusweni be-substrate. Igesi esetshenziselwa ukuphafaza ngokuvamile iyigesi engavamile, njenge-argon (Ar), ngakho ifilimu elakhiwe ngokufafaza ngeke lingcoliswe; ngaphezu kwalokho, irediyasi ye-athomu ye-argon ifaneleka kakhulu ukuphalaza.

Ubukhulu bezinhlayiya ezifafazayo kufanele busondele kusayizi wama-athomu okuhlosiwe okufanele ahlakazwe. Uma izinhlayiya zinkulu kakhulu noma zizincane kakhulu, ukuphalaza okuphumelelayo akukwazi ukwakhiwa. Ngaphezu kobukhulu besici se-athomu, i-mass factor ye-athomu izophinde ithinte ikhwalithi yokufafaza. Uma umthombo wezinhlayiyana zokufafaza ulula kakhulu, ama-athomu okuhlosiwe ngeke ahlakazwe; uma izinhlayiya zokufafaza zisinda kakhulu, okuhlosiwe kuzobe "kugobile" futhi okuhlosiwe ngeke kuhlulwe.

Into eqondiwe esetshenziswa ku-DCPVD kumele kube umqhubi. Lokhu kungenxa yokuthi lapho ama-argon ion enkambisweni yegesi eqhuma okokusebenza okuqondiwe, azophinde ahlangane nama-electron ebusweni bento eqondiwe. Lapho into eqondiwe kuyi-conductor efana nensimbi, ama-electron asetshenziswa yilokhu kuhlanganiswa kabusha agcwaliseka kalula ngokuphakelwa kwamandla kanye nama-electron amahhala kwezinye izingxenye zento eqondiwe ngokuqhutshwa kukagesi, ukuze ingaphezulu lento eqondiwe ibe njenge yonke ihlala inecala elibi futhi i-sputtering iyagcinwa.

Ngokuphambene nalokho, uma into ehlosiwe iyisivikeli, ngemva kokuba ama-electron angaphezulu kwento ehlosiwe esephinde wahlanganiswa, ama-electron amahhala kwezinye izingxenye zento ehlosiwe awakwazi ukugcwaliswa ngokuqhutshwa kukagesi, ngisho nezindleko ezinhle zizonqwabelana kugesi. ingaphezulu lempahla eqondiwe, okubangela ukuthi amandla ezinto eziqondiwe akhuphuke, futhi ukushaja okungekuhle kwento eqondiwe yenziwa buthaka ize iphele, ekugcineni kuholele ekunqanyulweni kokufafaza.

Ngakho-ke, ukuze wenze izinto zokuvikela i-insulating nazo zisebenziseke ukuphafaza, kuyadingeka ukuthola enye indlela yokufaka ama-sputtering. I-Radio frequency sputtering iyindlela ye-sputtering elungele kokubili okuqondiwe okuqhutshwayo nokungaqhubeki.

Okunye okungalungile kwe-DCPVD ukuthi i-voltage yokushisa iphezulu futhi ibhomu ye-electron ku-substrate inamandla. Indlela ephumelelayo yokuxazulula le nkinga ukusebenzisa i-magnetron sputtering, ngakho-ke i-magnetron sputtering inenani elisebenzayo emkhakheni wamasekethe ahlanganisiwe.

3.3 I-RF Physical Vapor Deposition Equipment

I-Radio frequency physical vapor deposition (RFPVD) isebenzisa amandla efrikhwensi yomsakazo njengomthombo wokuvusa amadlingozi futhi iyindlela ye-PVD elungele izinhlobonhlobo zezinto zensimbi nezingezona ezensimbi.

Amafrikhwensi ajwayelekile okunikezwa kwamandla e-RF asetshenziswa ku-RFPVD ngu-13.56MHz, 20MHz, kanye no-60MHz. Imijikelezo emihle nengalungile yokuphakelwa kwamandla e-RF ivela ngokushintshana. Lapho i-PVD target is in the positive half cycle, ngenxa yokuthi indawo okuhloswe kuyo inamandla amahle, ama-electron asemoyeni wenqubo azogeleza aye endaweni eqondiwe ukuze anciphise ukushajwa okuhle okunqwabelene endaweni yayo, futhi aqhubeke nokuqongelela ama-electron, ukwenza ubuso bayo bucheme kabi; lapho i-sputtering target ikumjikelezo wesigamu esinegethivu, ama-ion aphozithivu azoya kulokho okuqondiwe futhi asuswe kancane endaweni eqondiwe.

Into ebaluleke kakhulu ukuthi isivinini sokunyakaza kwama-electron emkhakheni kagesi we-RF sishesha kakhulu kuneso sama-ion aqondile, kuyilapho isikhathi somjikelezo wesigamu esihle nesibi siyefana, ngakho-ke ngemva komjikelezo ophelele, indawo okuhlosiwe izoba "inetha" likhokhiswe kabi. Ngakho-ke, emijikelezweni embalwa yokuqala, ukukhokhiswa okungalungile kwendawo okuhlosiwe kubonisa ukuthambekela okwandayo; ngemva kwalokho, indawo okuhloswe ngayo ifinyelela emandleni azinzile angalungile; ngemva kwalokho, ngenxa yokuthi ukushajwa okungekuhle kwethagethi kunomphumela onyanyekayo kuma-electron, inani lezindleko ezinhle nezingezinhle ezitholwe i-electrode eqondiwe livame ukulingana, futhi okuqondiwe kuveza ukushaja okungekuhle okuzinzile.

Kusukela kule nqubo engenhla, kungabonakala ukuthi inqubo yokwakhiwa kwe-voltage engalungile ayihlangene nezakhiwo zezinto ezihlosiwe ngokwazo, ngakho-ke indlela ye-RFPVD ayikwazi nje ukuxazulula inkinga yokuqhuma kwezinhloso zokufaka i-insulating, kodwa futhi iyahambisana kahle. ngezinhloso ezijwayelekile zomqhubi wensimbi.

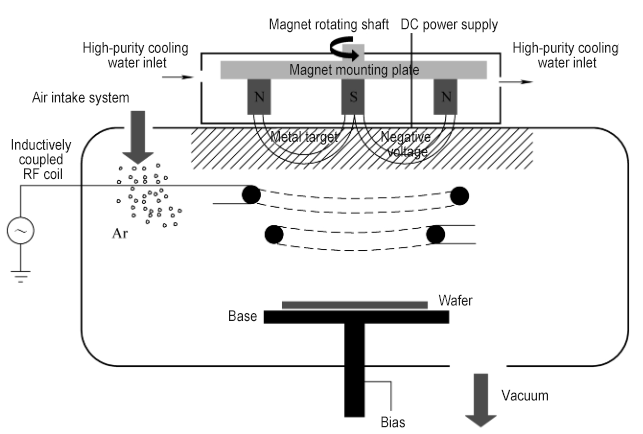

3.4 Imishini yokuphalaza iMagnetron

I-Magnetron sputtering iyindlela ye-PVD eyengeza omazibuthe ngemuva kwethagethi. Ozibuthe abangeziwe kanye nohlelo lukagesi lwe-DC (noma ugesi we-AC) lwakha umthombo we-magnetron sputtering. Umthombo we-sputtering usetshenziselwa ukwakha inkambu ye-electromagnetic esebenzisanayo ekamelweni, ukuthwebula nokukhawulela ububanzi bokunyakaza kwama-electron ku-plasma ngaphakathi kwegumbi, ukunweba indlela yokunyakaza kwama-electron, ngaleyo ndlela kwandise ukugxila kwe-plasma, futhi ekugcineni kuzuze okwengeziwe. ukubeka.

Ngaphezu kwalokho, ngenxa yokuthi ama-electron amaningi aboshwe eduze kwendawo ehlosiwe, ukuqhuma kwamabhomu kwe-substrate ngama-electron kuyancishiswa, futhi izinga lokushisa le-substrate liyancipha. Uma kuqhathaniswa nobuchwepheshe be-flat-plate DCPVD, esinye sezici ezisobala kakhulu ze-magnetron vapor deposition technology ukuthi i-voltage yokukhipha ukushisa iphansi futhi izinzile.

Ngenxa yokugcwala kwayo okuphezulu kwe-plasma kanye nesivuno esikhulu sokufafaza, ingakwazi ukufeza ukusebenza kahle okuhle kakhulu kokubeka, ukulawula ukushuba kwe-deposition ebangeni elikhulu losayizi, ukulawulwa kokwakheka okunembile kanye ne-voltage ephansi yokuthungela. Ngakho-ke, i-magnetron sputtering isendaweni evelele kufilimu yensimbi yamanje ye-PVD. Umklamo olula we-magnetron sputtering umthombo uwukubeka iqembu lezidonsa ngemuva kwethagethi eyisicaba (ngaphandle kwesistimu ye-vacuum) ukuze kukhiqizwe inkambu kazibuthe ehambisana nendawo okuqondiwe kuyo endaweni yendawo endaweni okuqondiwe kuyo.

Uma kubekwe uzibuthe ongunaphakade, inkambu yawo kazibuthe ishintshile ngokuqhathaniswa, okuholela ekusabalaliseni okulinganiselwe kwendawo kazibuthe endaweni eqondiwe ekamelweni. Izinto ezisetshenziswa ezindaweni ezithile ezihlosiwe kuphela eziphazanyiswe, izinga lokusetshenziswa okuhlosiwe liphansi, futhi ukufana kwefilimu elungisiwe kubi.

Kunethuba elithile lokuthi insimbi efafaziwe noma ezinye izinhlayiya zempahla zizofakwa emuva endaweni okuqondiswe kuyo, ngaleyo ndlela zihlangane zibe yizinhlayiya futhi zenze ukungcola. Ngakho-ke, imithombo ye-magnetron sputtering yezentengiselwano ngokuvamile isebenzisa umklamo ozibuthe ozungezayo ukuze kuthuthukiswe ukufana kwefilimu, izinga lokusetshenziswa okuhlosiwe, kanye nokugawula okuhlosiwe okugcwele.

Kubalulekile ukulinganisa lezi zici ezintathu. Uma ibhalansi ingaphathwa kahle, ingase iphumele ekufaneni kwefilimu okuhle kuyilapho kunciphisa kakhulu izinga lokusetshenziswa okuhlosiwe (kufinyeza ukuphila okuhlosiwe), noma yehluleke ukuzuza ukushaya okuhlosiwe okuhlosiwe noma ukugqwala okuphelele okuqondiwe, okuzodala izinkinga zezinhlayiya ngesikhathi sokufafaza. inqubo.

Kubuchwepheshe be-magnetron PVD, kuyadingeka ukucabangela umshini wokunyakaza kazibuthe ojikelezayo, ukuma okuhlosiwe, isistimu yokupholisa okuhlosiwe kanye nomthombo we-magnetron sputtering, kanye nokucushwa okusebenzayo kwesisekelo esiphethe i-wafer, njenge-wafer adsorption nokulawula izinga lokushisa. Enqubweni ye-PVD, izinga lokushisa le-wafer lilawulwa ukuze kutholwe isakhiwo se-crystal esidingekayo, usayizi wokusanhlamvu kanye nokuma, kanye nokuzinza kokusebenza.

Njengoba ukuqhutshwa kokushisa phakathi kwengemuva le-wafer kanye nobuso besisekelo kudinga ingcindezi ethile, ngokuvamile ngokulandelana kwe-Torr eminingana, futhi ukucindezela kokusebenza kwekamelo kuvame ukuhleleka kwama-mTorr amaningana, ingcindezi engemuva. yewafer inkulu kakhulu kunokucindezela endaweni engaphezulu yewafa, ngakho-ke i-chuck yomshini noma i-electrostatic chuck iyadingeka ukuze kumiswe futhi kukhawulelwe iwafa.

I-chuck engumshini incike esisindweni sayo kanye nonqenqema lwe-wafer ukufeza lo msebenzi. Nakuba inezinzuzo zesakhiwo esilula nokungazweli ezintweni ze-wafer, umphumela onqenqemeni we-wafer uyabonakala, ongahambisani nokulawula okuqinile kwezinhlayiya. Ngakho-ke, kancane kancane ithathelwe indawo yi-electrostatic chuck enqubweni yokukhiqiza ye-IC.

Ezinqubweni ezingazweli kakhulu izinga lokushisa, indlela yokubeka amasheluvu engeyona i-adsorption, engekho onqenqemeni (awukho umehluko wengcindezi phakathi kwendawo engaphezulu nephansi yewafa) nayo ingasetshenziswa. Phakathi nenqubo ye-PVD, uhlaka lwegumbi kanye nobuso bezingxenye ezixhumene ne-plasma kuzofakwa futhi kuhlanganiswe. Lapho ubukhulu befilimu obufakiwe budlula umkhawulo, ifilimu izoqhekeka futhi ixebuke, ibangele izinkinga zezinhlayiyana.

Ngakho-ke, ukwelashwa okungaphezulu kwezingxenye ezifana nolwelwesi kuyisihluthulelo sokwelula lo mkhawulo. I-surface sandblasting kanye nokufafaza kwe-aluminium yizindlela ezimbili ezivame ukusetshenziswa, inhloso yakho okuwukwandisa ubulukhuni bobuso ukuze kuqiniswe ukuhlangana phakathi kwefilimu nolwelwesi.

3.5 I-ionization Physical Vapor Deposition Equipment

Ngokuthuthuka okuqhubekayo kobuchwepheshe be-microelectronics, osayizi besici baba bancane futhi babancane. Njengoba ubuchwepheshe be-PVD bungakwazi ukulawula indlela yokubeka izinhlayiya, ikhono le-PVD lokungena ngezimbobo neziteshi ezincane ezinezilinganiso eziphakeme zesici lilinganiselwe, okwenza ukusetshenziswa okwandisiwe kobuchwepheshe be-PVD bendabuko kube inselele. Enqubweni ye-PVD, njengoba i-aspect ratio ye-pore groove ikhula, ukumbozwa phansi kuncipha, kwakheka isakhiwo esilenga phezulu esifana ne-eaves ekhoneni eliphezulu, futhi kwakheka ukumbozwa okubuthakathaka kakhulu ekhoneni elingezansi.

Ubuchwepheshe bokufakwa kwe-ionized physical vapor bathuthukiswa ukuze kuxazululwe le nkinga. Iqala i-plasmatize ama-athomu ensimbi ahlakazeke kusuka kulokho okuhlosiwe ngezindlela ezahlukene, bese ilungisa i-voltage yokuchema elayishwe ku-wafer ukuze ilawule indlela kanye namandla ama-ion ensimbi ukuze kutholwe ukugeleza kwe-ion yensimbi okuzinzile ukuze kulungiswe ifilimu elincanyana, ngaleyo ndlela kube ngcono. ukumbozwa phansi kwezinyathelo ze-aspect ratio ephezulu ngokusebenzisa izimbobo neziteshi ezincane.

Isici esivamile sobuchwepheshe be-ionized metal plasma ukungezwa kwekhoyili yefrikhwensi yomsakazo ekamelweni. Phakathi nenqubo, ukucindezela kokusebenza kwekamelo kugcinwa endaweni ephakeme kakhulu (izikhathi ezi-5 kuya kwezingu-10 zokucindezela okujwayelekile kokusebenza). Ngesikhathi se-PVD, ikhoyili yefrikhwensi yomsakazo isetshenziselwa ukukhiqiza indawo yesibili ye-plasma, lapho ukugxila kwe-argon plasma kukhuphuka ngokwanda kwamandla efrikhwensi yomsakazo kanye nomfutho wegesi. Lapho ama-athomu ensimbi asakazeka endaweni okuhlosiwe edlula kulesi sifunda, asebenzisana ne-high density argon plasma ukuze akhe ama-ion ensimbi.

Ukusebenzisa umthombo we-RF kusithwali se-wafer (njenge-electrostatic chuck) kungakhuphula ukuchema okungekuhle ku-wafer ukuze kuhehe ama-ion ensimbi phansi kwembotshana. Lokhu kugeleza kwe-ion yensimbi eqonde ngqo endaweni eyi-wafer kuthuthukisa ukumbozwa kwesinyathelo esingezansi kwe-aspect ratio ephezulu yama-pores namashaneli amancane.

Ukuchema okungalungile okusetshenziswe ku-wafer kubangela futhi ama-ion ukuthi aqhume i-wafer surface (i-reverse sputtering), okwenza buthaka isakhiwo esilengayo somlomo we-pore groove futhi ikhiphe ifilimu efakwe ngaphansi ezindongeni eziseceleni emakhoneni angaphansi kwembotshana. i-groove, ngaleyo ndlela ithuthukisa ukumbozwa kwesinyathelo emakhoneni.

3.6 I-Atmospheric Pressure Chemical Vapor Deposition Equipment

Isisetshenziswa se-Atmospheric chemical chemical vapor deposition (APCVD) sisho isisetshenziswa esifafaza umthombo wokusabela kwegesi ngesivinini esingaguquki endaweni eshisayo eqinile ngaphansi kwendawo enengcindezi esondelene nomfutho womoya, okubangela ukuthi umthombo wokusabela usabele ngamakhemikhali i-substrate surface, futhi umkhiqizo wokusabela ufakwa endaweni engaphansi ukuze wenze ifilimu elincanyana.

Imishini ye-APCVD iyimishini yokuqala ye-CVD futhi isasetshenziswa kabanzi ekukhiqizweni kwezimboni nocwaningo lwesayensi. Imishini ye-APCVD ingasetshenziswa ukulungisa amafilimu amancane afana ne-crystal silicon eyodwa, i-polycrystalline silicon, i-silicon dioxide, i-zinc oxide, i-titanium dioxide, ingilazi ye-phosphosilicate, nengilazi ye-borophosphosilicate.

3.7 Izisetshenziswa Zokumisa I-Chemical Vapor Deposition

Isisetshenziswa se-low-pressure chemical vapor deposition (LPCVD) sisho okokusebenza ekusebenzisa izinto zokusetshenziswa ezinegesi ukuze zisabele ngamakhemikhali endaweni engaphansi eqinile ngaphansi kwendawo eshisayo (350-1100°C) kanye nengcindezi ephansi (10-100mTorr), futhi ama-reactants afakwa endaweni engaphansi ukuze enze ifilimu elincanyana. Imishini ye-LPCVD ithuthukiswa ngesisekelo se-APCVD ukuze kuthuthukiswe ikhwalithi yamafilimu amancanyana, kuthuthukiswe ukufana kokusabalalisa kwezimpawu ezinjengokuqina kwefilimu kanye nokumelana nokumelana, nokwenza ngcono ukusebenza kahle kokukhiqiza.

Isici sawo esiyinhloko ukuthi endaweni yensimu eshisayo enengcindezi ephansi, igesi yenqubo isabela ngamakhemikhali ebusweni be-wafer substrate, futhi imikhiqizo yokusabela ifakwe endaweni engaphansi ukuze yakhe ifilimu encane. Imishini ye-LPCVD inezinzuzo ekulungiseleleni amafilimu amancane amancane futhi ingasetshenziswa ukulungisa amafilimu amancane njenge-silicon oxide, i-silicon nitride, i-polysilicon, i-silicon carbide, i-gallium nitride ne-graphene.

Uma kuqhathaniswa ne-APCVD, indawo yokusabela kwengcindezi ephansi yemishini ye-LPCVD inyusa indlela yamahhala kanye ne-coefficient yokusabalalisa yegesi egumbini lokusabela.

I-reaction gas kanye ne-carrier gas molecules ekamelweni lokuphendula ingasatshalaliswa ngokulinganayo ngesikhathi esifushane, ngaleyo ndlela ithuthukise kakhulu ukufana kwefilimu ukushuba, ukufana kwe-resistant kanye nesinyathelo sokuhlanganisa ifilimu, kanye nokusetshenziswa kwegesi yokusabela nakho kuncane. Ngaphezu kwalokho, indawo enengcindezi ephansi ibuye isheshise isivinini sokudluliselwa kwezinto zegesi. Ukungcola kanye nemikhiqizo yokusabela esakazwa ku-substrate ingakhishwa ngokushesha endaweni yokusabela ngokusebenzisa ungqimba lomngcele, futhi igesi yokusabela idlula ngokushesha ungqimba lomngcele ukuze ifinyelele indawo engaphansi ukuze iphendule, ngaleyo ndlela icindezele ngempumelelo i-self-doping, ilungiselele. amafilimu ekhwalithi ephezulu anezindawo eziguquguqukayo eziwumqansa, aphinde athuthukise ukusebenza kahle kokukhiqiza.

3.8 Isisetshenziswa Se-Plasma Esithuthukisiwe Sokumisa Umhwamuko Wekhemikhali

I-Plasma enhanced chemical vapor deposition (PECVD) iyi-t esetshenziswa kakhuluubuchwepheshe bokubekwa kwefilimu ye-hin. Phakathi nenqubo ye-plasma, i-gaseous precursor i-ionized ngaphansi kwesenzo se-plasma ukuze yakhe amaqembu asebenzayo ajabule, asakazekela endaweni engaphansi bese ebhekana nokusabela kwamakhemikhali ukuze aqedele ukukhula kwefilimu.

Ngokwemvamisa yokukhiqizwa kwe-plasma, i-plasma esetshenziswe ku-PECVD ingahlukaniswa ibe izinhlobo ezimbili: i-radio frequency plasma (RF plasma) ne-microwave plasma (i-Microwave plasma). Njengamanje, imvamisa yomsakazo esetshenziswa embonini imvamisa ingu-13.56MHz.

Ukwethulwa kwe-plasma yefrikhwensi yomsakazo kuvame ukuhlukaniswa ngezinhlobo ezimbili: i-capacitive coupling (CCP) kanye ne-inductive coupling (ICP). Indlela ye-capacitive coupling ngokuvamile iyindlela eqondile yokusabela kwe-plasma; kuyilapho indlela yokuhlanganisa i-inductive ingaba indlela eqondile ye-plasma noma indlela ye-plasma ekude.

Ezinqubweni zokukhiqiza ze-semiconductor, i-PECVD ivame ukusetshenziselwa ukukhulisa amafilimu amancane kuma-substrates aqukethe izinsimbi noma ezinye izakhiwo ezizwela ukushisa. Isibonelo, emkhakheni we-back-end metal interconnection of circuits edidiyelwe, njengoba umthombo, isango kanye nezakhiwo zokukhipha idivayisi zenziwe ngenqubo yokuphela, ukukhula kwamafilimu amancane emkhakheni wokuxhuma kwensimbi kungaphansi. kuya emingceleni yesabelomali esishisayo esiqinile, ngakho-ke ngokuvamile iqedwa ngosizo lwe-plasma. Ngokulungisa imingcele yenqubo ye-plasma, ukuminyana, ukwakheka kwamakhemikhali, okuqukethwe okungcolile, ukuqina kwemishini kanye nemingcele yokucindezeleka yefilimu encane ekhuliswe yi-PECVD ingalungiswa futhi ithuthukiswe ngaphakathi kwebanga elithile.

3.9 Izisetshenziswa Zokumisa Ungqimba Lwe-athomu

I-Atomic layer Deposition (ALD) ubuchwepheshe bokubekwa kwefilimu obuncane obukhula ngezikhathi ezithile ngendlela yongqimba lwe-quasi-monoatomic. Isici sayo siwukuthi ukushuba kwefilimu efakiwe kungalungiswa ngokunembile ngokulawula inani lemijikelezo yokukhula. Ngokungafani nenqubo ye-chemical vapor deposition (CVD), izandulela ezimbili (noma ngaphezulu) zenqubo ye-ALD zishintshana zidlule endaweni engaphansi futhi zihlukaniswe ngokuphumelelayo ngokuhlanzwa kwegesi engavamile.

Izandulela ezimbili ngeke zihlangane futhi zihlangane esigabeni segesi ukuze zisabele ngamakhemikhali, kodwa zisabela kuphela nge-adsorption yamakhemikhali endaweni engaphansi. Emjikelezweni ngamunye we-ALD, inani le-precursor elikhangisiwe endaweni engaphansi kwe-substrate lihlobene nokuminyana kwamaqembu asebenzayo endaweni engaphansi. Lapho amaqembu asebenzayo endaweni engaphansi kwe-substrate ephelile, ngisho noma kwethulwa okwedlulele kwesandulela, ukukhangisa kwamakhemikhali ngeke kwenzeke endaweni engaphansi.

Le nqubo yokusabela ibizwa ngokuthi i-surface self-limiting reaction. Le nqubo yenqubo yenza ukushuba kwefilimu kukhule kumjikelezo ngamunye wenqubo ye-ALD kungashintshi, ngakho inqubo ye-ALD inezinzuzo zokulawula ukujiya okunembayo kanye nokufakwa okuhle kwesinyathelo sefilimu.

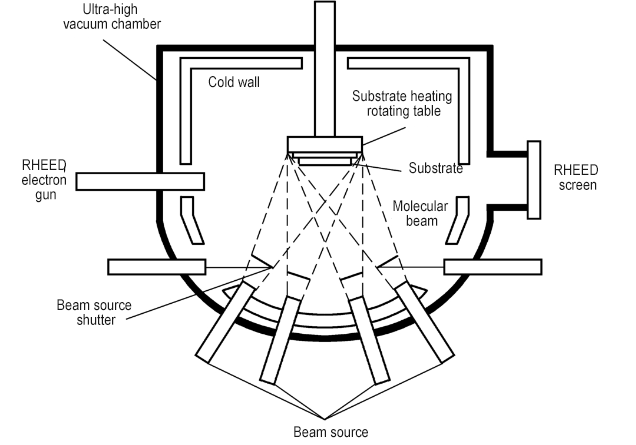

3.10 Isisetshenziswa se-Molecular Beam Epitaxy

Isistimu ye-Molecular Beam Epitaxy (MBE) ibhekisela kudivayisi ye-epitaxial esebenzisa imishayo ye-athomu yamandla ashisayo eyodwa noma ngaphezulu noma imishayo yengqamuzana ukuze ifafaze endaweni eshisayo ye-substrate ngesivinini esithile ngaphansi kwezimo ze-vacuum ephezulu kakhulu, futhi i-adsorb futhi ifuduke endaweni engaphansi. ukuze kukhule nge-epitaxially amafilimu amancane ekristalu eyodwa eduze kokuqondisa kwe-crystal axis ye-substrate material. Ngokuvamile, ngaphansi kwesimo sokushisisa ngesithando somlilo sejethi esinesivikelo sokushisa, umthombo wesigxobo wenza i-athomu ye-athomu noma i-molecule yamangqamuzana, futhi ifilimu ikhula ungqimba ngongqimba eduze kokuqondisa kwe-crystal axis yezinto ezingaphansi kwe-substrate.

Izici zayo izinga lokushisa eliphansi lokukhula kwe-epitaxial, futhi ukushuba, isikhombimsebenzisi, ukwakheka kwamakhemikhali nokugxilisa ukungcola kungalawulwa ngokunembile ezingeni le-athomu. Nakuba i-MBE yaqalwa ekulungiseni amafilimu ekristalu elilodwa le-semiconductor ultra-thin single, ukusetshenziswa kwayo manje sekunwetshwe ezinhlobonhlobo zezinhlelo zezinto ezibonakalayo njengezinsimbi nama-insulating dielectrics, futhi ingalungisa i-III-V, II-VI, i-silicon, i-silicon germanium (SiGe ), i-graphene, ama-oxides namafilimu e-organic.

Isistimu ye-molecular beam epitaxy (MBE) ikakhulukazi yakhiwe isistimu ye-vacuum ephezulu kakhulu, umthombo we-molecule ye-molecular, i-substrate fixing kanye nesistimu yokushisisa, isistimu yokudlulisa isampula, isistimu yokuqapha e-in-situ, isistimu yokulawula, kanye nokuhlola. uhlelo.

Isistimu ye-vacuum ihlanganisa amaphampu e-vacuum (amaphampu emishini, amaphampu amangqamuzana, amaphampu e-ion, namaphampu e-condensation, njll.) nama-valve ahlukahlukene, angakha indawo yokukhula kwe-vacuum ephezulu kakhulu. Idigri ye-vacuum ngokuvamile efinyelelekayo ngu-10-8 kuya ku-10-11 Torr. Isistimu ye-vacuum ikakhulukazi inamagumbi amathathu okusebenza e-vacuum, okuyigumbi lomjovo eliyisampula, igumbi lokwelapha kusengaphambili kanye negumbi lokuhlaziya indawo, kanye negumbi lokukhula.

Igumbi lomjovo wesampula lisetshenziselwa ukudlulisa amasampula emhlabeni wangaphandle ukuze kuqinisekiswe izimo eziphezulu ze-vacuum zamanye amagumbi; Igumbi lokwelapha kusengaphambili nelokuhlaziya indawo lixhuma isampula legumbi lomjovo kanye negumbi lokukhula, futhi umsebenzi walo oyinhloko uwukucubungula kusengaphambili isampula (ukukhipha umoya okushisa okuphezulu ukuze kuqinisekiswe ukuhlanzeka okuphelele kwendawo engaphansi) kanye nokwenza ukuhlaziya kokuqala kwendawo engaphansi. isampula ehlanzekile; Igumbi lokukhula liyingxenye eyinhloko yesistimu ye-MBE, ikakhulukazi eyakhiwe isithando somlilo somthombo kanye nokuhlanganiswa kwayo kwe-shutter ehambisanayo, isampula yokulawula ikhonsoli, isistimu yokupholisa, i-reflection high energy electron diffraction (RHEED), kanye nesistimu yokuqapha e-in-situ . Eminye imishini yokukhiqiza ye-MBE inokucushwa kwegumbi lokukhula okuningi. Umdwebo wohlelo lwesakhiwo semishini ye-MBE ukhonjiswe ngezansi:

I-MBE yezinto ze-silicon isebenzisa i-silicon ehlanzekile njengempahla eluhlaza, ikhula ngaphansi kwezimo ze-vacuum ephezulu kakhulu (10-10~10-11Torr), futhi izinga lokushisa lokukhula lingu-600℃900℃, ne-Ga (P-type) kanye ne-Sb ( N-uhlobo) njengemithombo ye-doping. Imithombo ye-doping esetshenziswa ngokujwayelekile efana no-P, As no-B ayivamisile ukusetshenziswa njengemithombo ye-beam ngoba kunzima ukuhwamuka.

I-reaction chamber ye-MBE ine-vacuum ephezulu kakhulu, eyandisa indlela yamahhala yama-molecule futhi inciphisa ukungcoliswa kanye ne-oxidation ebusweni bezinto ezikhulayo. Impahla ye-epitaxial elungisiwe ine-morphology enhle yendawo kanye nokufana, futhi ingenziwa ibe isakhiwo se-multilayer esine-doping ehlukene noma izingxenye ezihlukene zezinto ezibonakalayo.

Ubuchwepheshe be-MBE bufinyelela ukukhula okuphindaphindiwe kwezendlalelo ze-epitaxial ezinogqinsi lwe-athomu eyodwa, futhi ukuxhumana phakathi kwezendlalelo ze-epitaxial kungumqansa. Ikhuthaza ukukhula kwama-semiconductors we-III-V nezinye izinto ezihlukene ezinezingxenye eziningi. Njengamanje, uhlelo lwe-MBE seluyithuluzi lenqubo elithuthukisiwe lokukhiqiza isizukulwane esisha samadivayisi we-microwave kanye namadivayisi we-optoelectronic. Ububi bobuchwepheshe be-MBE izinga lokukhula kwefilimu elihamba kancane, izidingo eziphezulu ze-vacuum, nezindleko eziphezulu zokusetshenziswa kwemishini nemishini.

3.11 I-Vapor Phase Epitaxy System

Isistimu ye-vapor phase epitaxy (VPE) ibhekisela kudivayisi yokukhula kwe-epitaxial ehambisa izinhlanganisela zegesi ku-substrate futhi ithole ungqimba olulodwa lwe-crystal material enokuhlelwa okufanayo kwe-lattice njenge-substrate ngokusebenzisa ukusabela kwamakhemikhali. I-epitaxial layer ingaba isendlalelo se-homoepitaxial (Si/Si) noma isendlalelo se-heteroepitaxial (SiGe/Si, SiC/Si, GaN/Al2O3, njll.). Njengamanje, ubuchwepheshe be-VPE busetshenziswe kabanzi emikhakheni yokulungiselela ama-nanomaterial, amadivaysi kagesi, amadivaysi e-semiconductor optoelectronic, ama-solar photovoltaics, namasekethe ahlanganisiwe.

I-VPE evamile ihlanganisa i-epitaxy yokucindezela komkhathi kanye ne-epitaxy yengcindezi encishisiwe, i-ultra-high vacuum chemical vapor deposition, i-metal organic chemical vapor deposition, njll. Amaphuzu abalulekile kubuchwepheshe be-VPE umklamo wegumbi lokusabela, imodi yokugeleza kwegesi nokufana, ukufana kwezinga lokushisa nokulawula ukunemba, ukulawula ingcindezi nokuzinza, ukulawulwa kwezinhlayiyana nokukhubazeka, njll.

Njengamanje, isiqondiso sokuthuthukiswa kwezinhlelo ze-VPE ezentengiselwano ezivamile ukulayishwa kwe-wafer enkulu, ukulawula okuzenzakalelayo ngokugcwele, nokuqapha ngesikhathi sangempela izinga lokushisa nenqubo yokukhula. Amasistimu we-VPE anezakhiwo ezintathu: mpo, ovundlile kanye ne-cylindrical. Izindlela zokushisisa zihlanganisa ukushisisa ukumelana, ukufudumeza kwe-high-frequency induction kanye nokushisa kwemisebe ye-infrared.

Njengamanje, izinhlelo ze-VPE zisebenzisa kakhulu izakhiwo ze-disc enezingqimba, ezinezici zokufana okuhle kokukhula kwefilimu ye-epitaxial kanye nokulayisha okukhulu kwe-wafer. Amasistimu we-VPE ngokuvamile aqukethe izingxenye ezine: i-reactor, isistimu yokufudumeza, isistimu yendlela yegesi kanye nesistimu yokulawula. Ngenxa yokuthi isikhathi sokukhula samafilimu e-GaAs kanye ne-GaN epitaxial side kakhulu, ukushisisa kokungeniswa nokushisa kokumelana kusetshenziswa kakhulu. Ku-silicon VPE, ukukhula kwefilimu ye-epitaxial ewugqinsi ngokuvamile kusebenzisa ukushisa kokungeniswa; ukukhula kwefilimu encane ye-epitaxial ngokuvamile kusebenzisa ukufudumeza kwe-infrared ukufeza inhloso yokukhuphuka/ukwehla kwezinga lokushisa ngokushesha.

3.12 I-Liquid Phase Epitaxy System

Uhlelo lwe-Liquid Phase Epitaxy (LPE) lubhekisela ezintweni ezisetshenziswayo zokukhulisa i-epitaxial ezincibilikisa izinto ezizokhula (ezifana no-Si, Ga, As, Al, njll.) kanye nama-dopants (afana no-Zn, Te, Sn, njll.) insimbi enephuzu elincibilikayo eliphansi (njenge-Ga, In, njll.), ukuze i-solute igcwale noma igcwale kakhulu ku-solvent, bese i-crystal substrate eyodwa ixhunywe nesixazululo, futhi i-solute idonswa kusuka ku-solvent ngokupholisa kancane kancane, futhi ungqimba lwe-crystal material enesakhiwo se-crystal kanye ne-lattice ehlala njalo efana ne-substrate ikhuliswa ebusweni be-substrate.

Indlela ye-LPE yahlongozwa nguNelson et al. ngo-1963. Isetshenziselwa ukukhulisa amafilimu ama-Si amancane kanye nezinto ze-crystal eyodwa, kanye nezinto ze-semiconductor ezifana namaqembu e-III-IV kanye ne-mercury cadmium telluride, futhi ingasetshenziswa ukwenza amadivaysi e-optoelectronic ahlukahlukene, amadivaysi e-microwave, amadivaysi e-semiconductor namaseli elanga. .

————————————————————————————————————————————————— ————————————-

I-Semicera ingahlinzekaizingxenye zegraphite, ukuzwakala okuthambile/okuqinile, izingxenye ze-silicon carbide, Izingxenye ze-CVD silicon carbide, futhiIzingxenye ezihlanganisiwe ze-SiC/TaCngezinsuku ezingama-30.

Uma unentshisekelo kule mikhiqizo engenhla ye-semiconductor,sicela ungangabazi ukusithinta okokuqala.

Ucingo: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Isikhathi sokuthumela: Aug-31-2024