Ama-wafers ayizinto zokusetshenziswa eziphambili zokukhiqizwa kwamasekethe ahlanganisiwe, amadivaysi e-semiconductor ahlukene kanye namadivayisi kagesi. Ngaphezu kuka-90% wamasekethe ahlanganisiwe enziwa ngamawafa asezingeni eliphezulu, asezingeni eliphezulu.

Imishini yokulungiselela i-wafer isho inqubo yokwenza izinto ezimsulwa ze-polycrystalline silicon zibe izinto ze-silicon eyodwa ye-crystal rod enobubanzi nobude obuthile, bese ibeka izinto ze-silicon single crystal rod ochungechungeni lokucutshungulwa kwemishini, ukwelashwa kwamakhemikhali nezinye izinqubo.

Izinto ezikhiqiza ama-silicon wafers noma ama-epitaxial silicon wafers ahlangabezana nokunemba okuthile kwejiyomethri kanye nezidingo zekhwalithi engaphezulu futhi ahlinzeke nge-silicon substrate edingekayo yokukhiqiza ama-chip.

Ukugeleza kwenqubo ejwayelekile yokulungiselela ama-wafers e-silicon anobubanzi obungaphansi kwama-200 mm yile:

Ukukhula kwekristalu eyodwa → ukunqanyulwa → ukugoqeka kobubanzi obungaphandle → ukusika → ukuthandeka → ukugaya → ukuhlanganisa → ukupholisha → ukupholisha → ukuhlanza → i-epitaxy → ukupakisha, njll.

Ukugeleza kwenqubo eyinhloko yokulungiselela ama-wafers e-silicon enobubanzi obungama-300 mm imi kanje:

Ukukhula kwekristalu eyodwa → ukunqanyulwa → ukugoqa kwedayamitha yangaphandle → ukusika → ukucwebezela → ukugaya kwendawo → ukuchopha → ukupholisha emaphethelweni → ukupholisha okunezinhlangothi ezimbili → ukupholisha okuhlangene → ukuhlanzwa kokugcina → i-epitaxy/i-annealing → ukupakisha, njll.

1.Izinto ze-silicon

I-Silicon iyimpahla ye-semiconductor ngoba inama-electron angu-4 e-valence futhi iseqenjini le-IVA lethebula le-periodic kanye nezinye izakhi.

Inombolo yama-electron e-valence ku-silicon iyibeka phakathi komqhubi omuhle (i-electron engu-1 ye-valence) kanye nesivikeli (ama-electron angu-8).

I-silicon ehlanzekile ayitholakali emvelweni futhi kufanele ikhishwe futhi ihlanzwe ukuze ihlanzeke ngokwanele ukukhiqiza. Ivame ukutholakala ku-silica (i-silicon oxide noma i-SiO2) namanye ama-silicates.

Ezinye izinhlobo ze-SiO2 zifaka ingilazi, ikristalu engenambala, i-quartz, i-agate neso lekati.

Izinto zokuqala ezazisetshenziswa njenge-semiconductor kwakuyi-germanium ngeminyaka yawo-1940 nasekuqaleni kwawo-1950, kodwa yathathelwa indawo ngokushesha i-silicon.

I-silicon yakhethwa njengento eyinhloko ye-semiconductor ngezizathu ezine eziyinhloko:

Ubuningi bezinto zeSilicon: I-silicon iyisici sesibili esitholakala ngobuningi eMhlabeni, ibalwa ku-25% woqweqwe lomhlaba.

Iphuzu eliphakeme lokuncibilika lezinto ze-silicon livumela ukubekezelelana okubanzi kwenqubo: indawo yokuncibilika ye-silicon ku-1412°C iphakeme kakhulu kunephuzu lokuncibilika le-germanium ku-937°C. Iphuzu lokuncibilika eliphakeme livumela i-silicon ukuthi imelane nezinqubo zokushisa okuphezulu.

Izinto ze-silicon zinebanga lokushisa elibanzi lokusebenza;

Ukukhula kwemvelo kwe-silicon oxide (SiO2): I-SiO2 iyikhwalithi ephezulu, into eqinile yokuvikela ugesi futhi isebenza njengesithiyo samakhemikhali esihle kakhulu sokuvikela i-silicon ekungcoleni kwangaphandle. Ukuzinza kukagesi kubalulekile ukuze kugwenywe ukuvuza phakathi kwamakhondaktha aseduze kumasekethe ahlanganisiwe. Amandla okukhulisa izingqimba ezincane ezizinzile zezinto ze-SiO2 abalulekile ekwenziweni kwamadivayisi asebenza kahle kakhulu e-metal-oxide semiconductor (MOS-FET). I-SiO2 inezici zomshini ezifanayo ne-silicon, evumela ukucutshungulwa kwezinga lokushisa eliphezulu ngaphandle kwe-silicon wafer warping eyeqile.

2.Ukulungiswa kwe-wafer

Ama-wafers we-semiconductor asikwa ezintweni eziningi ze-semiconductor. Le nto ye-semiconductor ibizwa ngokuthi i-crystal rod, ekhuliswa kusukela kubhulokhi enkulu ye-polycrystalline kanye nezinto zangaphakathi ezingavuliwe.

Ukuguqula ibhulokhi ye-polycrystalline ibe yikristalu eyodwa enkulu futhi uyinikeze umumo ofanele wekristalu kanye nenani elifanele le-N-type noma i-P-doping ibizwa ngokuthi ukukhula kwekristalu.

Ubuchwepheshe obuvame kakhulu bokukhiqiza ingots ye-crystal silicon eyodwa yokulungiselela i-silicon wafer indlela ye-Czochralski kanye nendlela yokuncibilika kwendawo.

2.1 Indlela ye-Czochralski kanye ne-Czochralski single crystal furnace

Indlela ye-Czochralski (CZ), eyaziwa nangokuthi indlela ye-Czochralski (CZ), isho inqubo yokuguqula uketshezi lwe-silicon encibilikisiwe lube yizingothi ze-silicon eziqinile ezinekristalu eyodwa enomumo olungile wekristalu futhi ifakwe kuhlobo lwe-N noma i-P- uhlobo.

Njengamanje, ngaphezu kwe-85% ye-silicon eyodwa ye-crystal ikhule kusetshenziswa indlela ye-Czochralski.

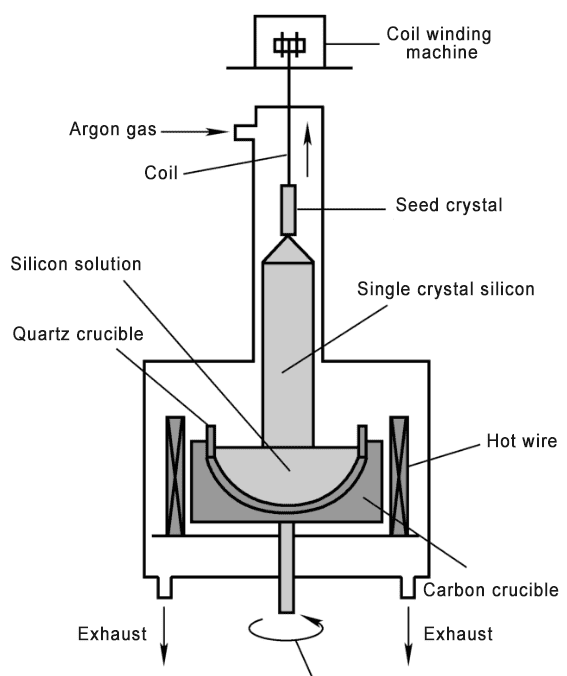

I-Czochralski single crystal furnace ibhekisela kumshini wenqubo oncibilikisa izinto ze-polysilicon ezihlanzeke kakhulu zibe uketshezi ngokufudumeza endaweni evalekile ephakeme noma igesi engavamile (noma igesi engasebenzi), bese iphinda izihlanganisela ukwenza izinto ze-silicon eyodwa ezinezinto ezithile zangaphandle. izilinganiso.

Umgomo wokusebenza wesithando somlilo sekristalu eyodwa inqubo engokomzimba ye-polycrystalline silicon impahla ephinda ikristale ibe yinto eyodwa ye-silicon esesimweni esiwuketshezi.

Isithando somlilo sekristalu esisodwa se-CZ singahlukaniswa sibe izingxenye ezine: umzimba wesithando somlilo, uhlelo lokudlulisa ngomshini, uhlelo lokulawula ukushisa nokushisa, kanye nohlelo lokudlulisa igesi.

Umzimba wesithando somlilo uhlanganisa imbobo yesithando somlilo, i-axis yekristalu yembewu, i-quartz crucible, isipuni se-doping, isembozo sekristalu yembewu, kanye newindi lokubuka.

Umgodi wesithando somlilo uwukuqinisekisa ukuthi izinga lokushisa esithandweni lisakazwa ngokulinganayo futhi lingakhipha ukushisa kahle; i-seed crystal shaft isetshenziselwa ukushayela ikristalu yembewu ukuze ihambe phezulu naphansi futhi ijikeleze; ukungcola okudingeka kufakwe ku-doping spoon spoon;

Isembozo sekristalu sembewu ukuvikela ikristalu lembewu ekungcoleni. Uhlelo lokudlulisa ngomshini lusetshenziswa kakhulu ukulawula ukunyakaza kwekristalu lembewu kanye ne-crucible.

Ukuze kuqinisekiswe ukuthi isisombululo se-silicon asifakwanga i-oxidized, i-vacuum degree esithandweni iyadingeka ukuba ibe phezulu kakhulu, ngokuvamile ibe ngaphansi kwe-5 Torr, futhi ukuhlanzeka kwegesi ye-inert eyengeziwe kufanele ibe ngaphezu kuka-99.9999%.

Ucezu lwe-silicon eyodwa yekristalu enomumo wekristalu oyifunayo isetshenziswa njengekristalu yembewu ukuze kukhule ingot ye-silicon, futhi i-silicon ingot ekhulile ifana ne-replica yekristalu lembewu.

Izimo ekuxhumaneni phakathi kwe-silicon encibilikisiwe kanye nekristalu eyodwa ye-crystal silicon imbewu zidinga ukulawulwa ngokunembile. Lezi zimo ziqinisekisa ukuthi ungqimba oluncane lwe-silicon lungaphindaphinda ngokunembile ukwakheka kwekristalu yembewu futhi ekugcineni lukhule lube ingot enkulu ye-crystal silicon eyodwa.

2.2 Indlela Yokuncibilikisa Indawo kanye Nesithando Somlilo Esiyikristalu Esisodwa

Indlela ye-float zone (FZ) ikhiqiza ama-ingots e-crystal crystal eyodwa anokuqukethwe komoyampilo okuphansi kakhulu. Indlela ye-float zone yathuthukiswa ngeminyaka yawo-1950s futhi ingakhiqiza i-crystal silicon eyodwa emsulwa kuze kube manje.

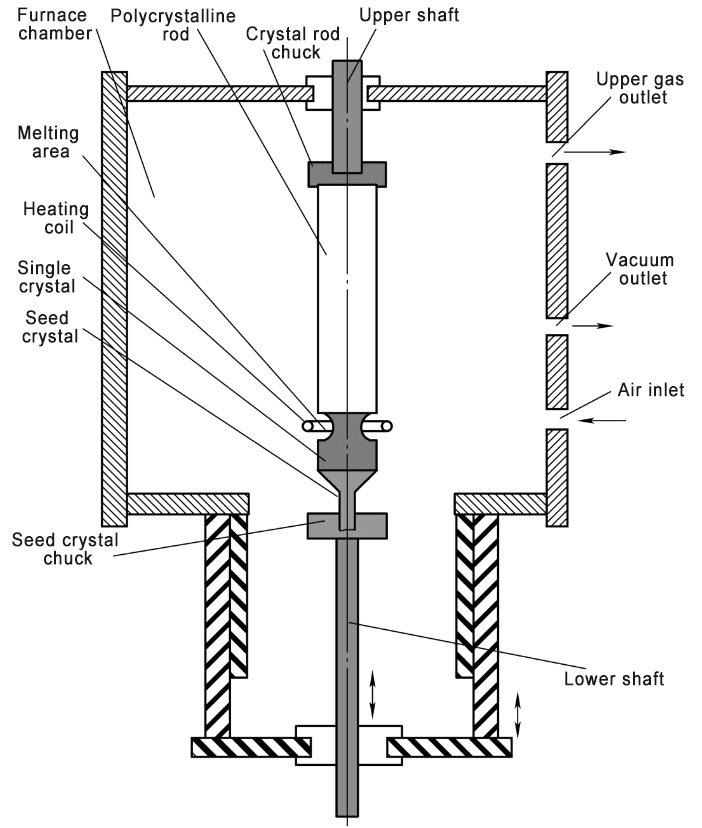

Indawo encibilikisa isithando somlilo sekristalu eyodwa isho isithando somlilo esisebenzisa umgomo wokuncibilika kwendawo ukuze kukhiqizwe indawo encane yokuncibilika entongeni ye-polycrystalline endaweni evalekile enezinga lokushisa eliphezulu ewumngcingo womzimba wesithando somlilo we-polycrystalline endaweni engenalutho noma igesi eyithubhu ye-quartz eyivelakancane. indawo yokuvikela.

Ithuluzi lenqubo elihambisa i-polycrystalline rod noma umzimba wokushisisa isithando somlilo ukuze uhambise indawo encibilikayo futhi kancane kancane uyikristale ibe yintonga eyodwa yekristalu.

Isici sokulungiselela izinduku ze-crystal eyodwa ngendlela yokuncibilika kwendawo ukuthi ukuhlanzeka kwezinduku ze-polycrystalline kungathuthukiswa ngenqubo ye-crystallization ibe yizinduku ze-crystal eyodwa, futhi ukukhula kwe-doping yezinto zenduku kufana kakhulu.

Izinhlobo zezoni zokuncibilika komlilo owodwa wekristalu zingahlukaniswa zibe izinhlobo ezimbili: indawo entantayo encibilikisa okomlilo wekristalu eyodwa encike ekucindezelekeni kwendawo kanye nezindawo ezivundlile ezincibilikisa amaziko ekristalu eyodwa. Ezisetshenziswa ezingokoqobo, izindawo zomlilo ezincibilika zekristalu eyodwa ngokuvamile zisebenzisa ukuncibilika kwendawo entantayo.

Indawo encibilika isithando somlilo sekristalu esisodwa singalungisa i-silicon eyodwa yekristalu ehlanzekile ephansi kakhulu ngaphandle kwesidingo se-crucible. Isetshenziselwa kakhulu ukulungisa ukumelana okuphezulu (>20kΩ·cm) i-silicon eyodwa yekristalu nokuhlanza indawo encibilika i-silicon. Le mikhiqizo isetshenziswa kakhulu ekwenzeni amadivaysi kagesi ahlukene.

Isithando somlilo sekristalu esisodwa esincibilika sinegumbi lesithando somlilo, umgodi ongaphezulu kanye ne-shaft ephansi (ingxenye yokudlulisela ngomshini), i-crystal rod chuck, i-seed crystal chuck, i-coil yokufudumeza (i-high frequency generator), amachweba wegesi (imbobo ye-vacuum, indawo yokungenisa igesi, indawo yokukhipha igesi ephezulu), njll.

Esakhiweni segumbi lesithando somlilo, ukujikeleza kwamanzi okupholisa kuhlelwa. Umkhawulo ongezansi we-shaft engenhla yesithando somlilo se-crystal eyodwa i-crystal rod chuck, esetshenziselwa ukubopha induku ye-polycrystalline; umkhawulo ophezulu we-shaft engezansi yi-seed crystal chuck, esetshenziselwa ukubopha ikristalu yembewu.

Ukunikezwa kwamandla okuvama okuphezulu kunikezwa kukhoyili yokushisisa, futhi indawo encane yokuncibilika iyakhiwa entweni ye-polycrystalline kusukela ekugcineni okuphansi. Ngesikhathi esifanayo, izimbazo ezingenhla neziphansi ziyazungeza futhi zehle, ukuze indawo encibilikayo igqanyiswe ibe yikristalu eyodwa.

Izinzuzo ze-zone melting single crystal furnace yukuthi ayikwazi nje ukuthuthukisa ukuhlanzeka kwekristalu eyodwa elungiselelwe, kodwa futhi yenza ukukhula kwe-doping yenduku kube okufanayo, futhi induku eyodwa ye-crystal ingahlanzwa ngezinqubo eziningi.

Okubi kwesithando somlilo esincibilikisa i-zone esisodwa yizindleko zenqubo ephezulu kanye nobubanzi obuncane bekristalu eyodwa elungisiwe. Njengamanje, ububanzi obukhulu bekristalu elilodwa elingalungiselelwa ngu-200mm.

Ukuphakama sekukonke kwemishini yesithando somlilo sekristalu eyodwa kuphezulu uma kuqhathaniswa, futhi ukushaywa kwezimbazo ezingenhla neziphansi kude kakhulu, ngakho-ke kungakhuliswa izinduku zekristalu eyodwa ezinde.

3. I-wafer processing kanye nemishini

I-crystal rod idinga ukudlula ochungechungeni lwezinqubo ukuze yakhe i-silicon substrate ehlangabezana nezidingo zokwenziwa kwe-semiconductor, okuyi-wafer. Inqubo eyisisekelo yokucubungula yile:

Ukugingqika, ukusika, ukusika, i-wafer annealing, i-chamfering, ukugaya, ukupholisha, ukuhlanza nokupakisha, njll.

3.1 I-Wafer Annealing

Enqubweni yokukhiqiza i-silicon ye-polycrystalline ne-Czochralski silicon, i-silicon eyodwa ye-crystal iqukethe umoya-mpilo. Ezingeni elithile lokushisa, umoya-mpilo ku-silicon eyodwa yekristalu uzonikela ngama-electron, futhi umoya-mpilo uzoguqulwa ube abanikeli komoyampilo. Lawa ma-electron azohlangana nokungcola ku-silicon wafer futhi athinte ukumelana kwe-silicon wafer.

I-Annealing furnace: ibhekisela esithandweni somlilo esiphakamisa izinga lokushisa esithandweni sibe ngu-1000-1200°C endaweni ye-hydrogen noma ye-argon. Ngokugcina ukufudumala nokupholisa, umoya-mpilo oseduze nendawo yesicwecwana se-silicon esiphucuziwe siyashintshashintsha futhi sisuswe endaweni yayo, okubangela ukuba umoya-mpilo uhle futhi ugqinsise.

Imishini yokucubungula encibilikisa amaphutha amancane ebusweni bama-silicon wafers, inciphisa inani lokungcola eduze nendawo yama-silicon wafers, inciphisa amaphutha, futhi yakha indawo ehlanzekile uma kuqhathaniswa ebusweni bamawafa e-silicon.

Isithando somlilo sibizwa nangokuthi isithando somlilo esishisa kakhulu ngenxa yokushisa kwaso okuphezulu. Imboni iphinde ibize inqubo ye-silicon wafer annealing gettering.

I-Silicon wafer annealing furnace ihlukaniswe yaba:

-Isithando somlilo esivundlile;

-Isithando somlilo esiqondile;

-Isithando somlilo esisheshayo.

Umehluko omkhulu phakathi kwesithando somlilo esivundlile kanye nesithando somlilo esime mpo isiqondiso sesakhiwo segumbi lokusabela.

Igumbi lokusabela lesithando somlilo esivundlile lakhiwe ngokuvundlile, futhi iqoqo lama-wafers e-silicon lingalayishwa ekamelweni lokusabela lesithando somlilo ukuze lifakwe ngesikhathi esifanayo. Isikhathi sokukhipha isisu ngokuvamile siyimizuzu engama-20 ukuya kwengama-30, kodwa igumbi lokusabela lidinga isikhathi eside sokushisa ukuze lifinyelele izinga lokushisa elidingwa inqubo yokuhoxisa.

Inqubo yesithando somlilo esime mpo futhi yamukela indlela yokulayisha kanyekanye inqwaba yamawafa e-silicon ekamelweni lokusabela lesithando somlilo ukuze kutholakale ukwelashwa. Igumbi lokusabela linesakhiwo sesakhiwo esime mpo, esivumela ama-wafer e-silicon ukuthi abekwe esikebheni se-quartz esimweni esivundlile.

Ngesikhathi esifanayo, njengoba isikebhe se-quartz singakwazi ukuzungeza sisonke ekamelweni lokusabela, izinga lokushisa le-annealing le-reaction chamber lifana, ukusabalalisa kwezinga lokushisa ku-wafer ye-silicon kufana, futhi inezici ezinhle kakhulu zokufana kwe-anneal. Kodwa-ke, izindleko zenqubo yesithando somlilo esime mpo ziphezulu kunalezo zesithando somlilo esivundlile.

Isithando somlilo esisheshayo sisebenzisa isibani se-halogen tungsten ukushisa ngokuqondile iwafa ye-silicon, engafinyelela ukushisisa ngokushesha noma ukupholisa ebangeni elibanzi elingu-1 kuye ku-250°C/s. Izinga lokushisisa noma lokupholisa liyashesha kunalelo lesithando somlilo esivamile. Kuthatha imizuzwana embalwa nje ukushisa izinga lokushisa legumbi lokusabela libe ngaphezu kuka-1100°C.

————————————————————————————————————————————————— —-

I-Semicera ingahlinzekaizingxenye zegraphite,ukuzwakala okuthambile/okuqinile,izingxenye ze-silicon carbide, Izingxenye ze-CVD silicon carbide, futhiIzingxenye ezihlanganisiwe ze-SiC/TaCngenqubo ephelele ye-semiconductor ezinsukwini ezingama-30.

Uma unentshisekelo kule mikhiqizo engenhla ye-semiconductor, sicela ungangabazi ukusithinta okokuqala.

Ucingo: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Isikhathi sokuthumela: Aug-26-2024