Okokuqala, isakhiwo kanye izakhiwo SiC crystal.

I-SiC iyinhlanganisela kanambambili eyakhiwe i-Si element ne-C ngesilinganiso esingu-1:1, okungukuthi, 50% we-silicon (Si) no-50% wekhabhoni (C), futhi iyunithi yayo yesakhiwo eyisisekelo yi-SI-C tetrahedron.

Umdwebo we-Schematic wesakhiwo se-silicon carbide tetrahedron

Isibonelo, ama-athomu ama-Si makhulu ngobubanzi, alingana ne-apula, kanti ama-athomu angu-C mancane ububanzi, alingana newolintshi, futhi inani elilinganayo lamawolintshi nama-apula kunqwabelaniswa ndawonye ukuze akhe ikristalu ye-SiC.

I-SiC iyinhlanganisela kanambambili, lapho ukuhlukaniswa kwe-athomu yebhondi ye-Si-Si kungu-3.89 A, ukusiqonda kanjani lesi sikhala? Njengamanje, umshini omuhle kakhulu we-lithography emakethe unokunemba kwe-lithography ye-3nm, okuyibanga elingu-30A, nokunemba kwe-lithography izikhathi ezingu-8 kunebanga le-athomu.

Amandla ebhondi ye-Si-Si angama-310 kJ/mol, ngakho-ke ungaqonda ukuthi amandla ebhondi angamandla adonsa lawa ma-athomu amabili ahlukene, futhi lapho amandla ebhondi emakhulu, amandla amakhulu owadingayo ukuze uwahlukanise.

Isibonelo, ama-athomu ama-Si makhulu ngobubanzi, alingana ne-apula, kanti ama-athomu angu-C mancane ububanzi, alingana newolintshi, futhi inani elilinganayo lamawolintshi nama-apula kunqwabelaniswa ndawonye ukuze akhe ikristalu ye-SiC.

I-SiC iyinhlanganisela kanambambili, lapho ukuhlukaniswa kwe-athomu yebhondi ye-Si-Si kungu-3.89 A, ukusiqonda kanjani lesi sikhala? Njengamanje, umshini omuhle kakhulu we-lithography emakethe unokunemba kwe-lithography ye-3nm, okuyibanga elingu-30A, nokunemba kwe-lithography izikhathi ezingu-8 kunebanga le-athomu.

Amandla ebhondi ye-Si-Si angama-310 kJ/mol, ngakho-ke ungaqonda ukuthi amandla ebhondi angamandla adonsa lawa ma-athomu amabili ahlukene, futhi lapho amandla ebhondi emakhulu, amandla amakhulu owadingayo ukuze uwahlukanise.

Umdwebo we-Schematic wesakhiwo se-silicon carbide tetrahedron

Isibonelo, ama-athomu ama-Si makhulu ngobubanzi, alingana ne-apula, kanti ama-athomu angu-C mancane ububanzi, alingana newolintshi, futhi inani elilinganayo lamawolintshi nama-apula kunqwabelaniswa ndawonye ukuze akhe ikristalu ye-SiC.

I-SiC iyinhlanganisela kanambambili, lapho ukuhlukaniswa kwe-athomu yebhondi ye-Si-Si kungu-3.89 A, ukusiqonda kanjani lesi sikhala? Njengamanje, umshini omuhle kakhulu we-lithography emakethe unokunemba kwe-lithography ye-3nm, okuyibanga elingu-30A, nokunemba kwe-lithography izikhathi ezingu-8 kunebanga le-athomu.

Amandla ebhondi ye-Si-Si angama-310 kJ/mol, ngakho-ke ungaqonda ukuthi amandla ebhondi angamandla adonsa lawa ma-athomu amabili ahlukene, futhi lapho amandla ebhondi emakhulu, amandla amakhulu owadingayo ukuze uwahlukanise.

Isibonelo, ama-athomu ama-Si makhulu ngobubanzi, alingana ne-apula, kanti ama-athomu angu-C mancane ububanzi, alingana newolintshi, futhi inani elilinganayo lamawolintshi nama-apula kunqwabelaniswa ndawonye ukuze akhe ikristalu ye-SiC.

I-SiC iyinhlanganisela kanambambili, lapho ukuhlukaniswa kwe-athomu yebhondi ye-Si-Si kungu-3.89 A, ukusiqonda kanjani lesi sikhala? Njengamanje, umshini omuhle kakhulu we-lithography emakethe unokunemba kwe-lithography ye-3nm, okuyibanga elingu-30A, nokunemba kwe-lithography izikhathi ezingu-8 kunebanga le-athomu.

Amandla ebhondi ye-Si-Si angama-310 kJ/mol, ngakho-ke ungaqonda ukuthi amandla ebhondi angamandla adonsa lawa ma-athomu amabili ahlukene, futhi lapho amandla ebhondi emakhulu, amandla amakhulu owadingayo ukuze uwahlukanise.

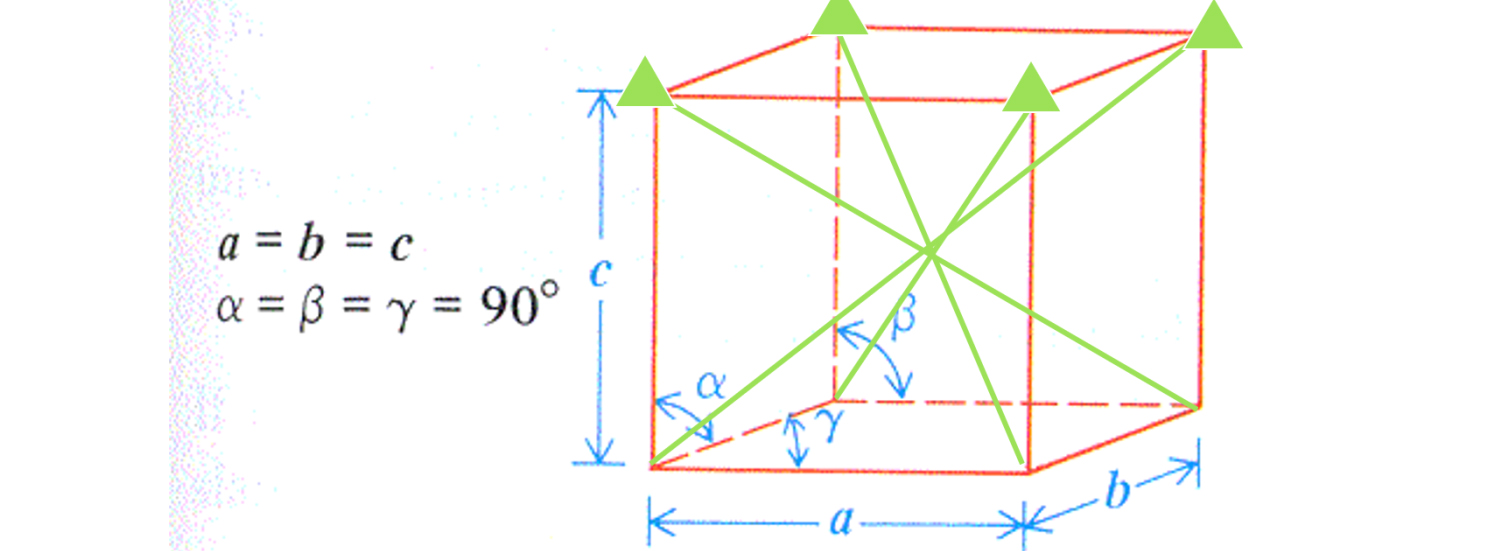

Siyazi ukuthi yonke into yenziwe ngama-athomu, futhi ukwakheka kwekristalu kuwuhlelo olujwayelekile lwama-athomu, okubizwa ngokuthi i-oda lebanga elide, njengalokhu okulandelayo. Iyunithi yekristalu encane kunazo zonke ibizwa ngokuthi iseli, uma iseli liyisakhiwo se-cubic, libizwa ngokuthi i-cubic egcwele, futhi iseli liyisakhiwo esinezinhlangothi ezine, sibizwa ngokuthi i-close-packed hexagonal.

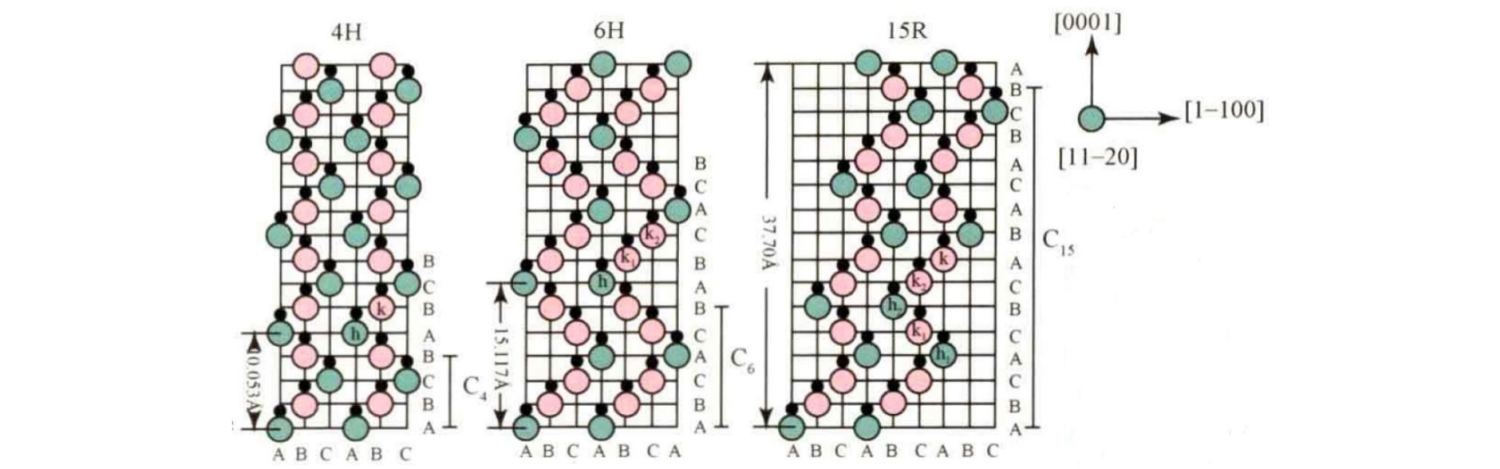

Izinhlobo zekristalu ezivamile ze-SiC zifaka i-3C-SiC, i-4H-SiC, i-6H-SiC, i-15R-SiC, njll. Ukulandelana kwabo kokupakisha ku-c isiqondiso se-axis kuboniswa esithombeni.

Phakathi kwazo, ukulandelana okuyisisekelo kwe-stacking kwe-4H-SiC yi-ABCB...; Ukulandelana kokunqwabelanisa okuyisisekelo kwe-6H-SiC yi-ABCACB... ; Ukulandelana kokunqwabelanisa okuyisisekelo kwe-15R-SiC ithi ABCACBCABACABCB... .

Lokhu kungabonakala njengesitini sokwakha indlu, ezinye izitini zendlu zinezindlela ezintathu zokuzibeka, ezinye zinezindlela ezine zokuzibeka, ezinye zinezindlela eziyisithupha.

Amapharamitha amaseli ayisisekelo alezi zinhlobo zekristalu ye-SiC abonisiwe kuthebula:

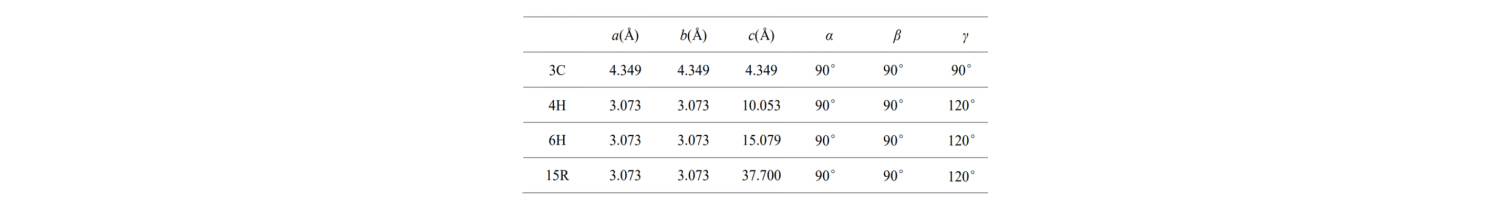

Usho ukuthini u-a, b, c nama-engeli? Isakhiwo seyunithi yeyunithi encane kunazo zonke ku-SiC semiconductor ichazwa kanje:

Endabeni yeseli efanayo, ukwakheka kwekristalu nakho kuzohluka, lokhu kufana nokuthi sithenga ilotho, inombolo ewinile ngu-1, 2, 3, uthenge 1, 2, 3 izinombolo ezintathu, kepha uma inombolo ihlungiwe. ngokuhlukile, inani lokuwina lihlukile, ngakho-ke inombolo nokuhleleka kwekristalu efanayo, kungabizwa ngokuthi i-crystal efanayo.

Isibalo esilandelayo sibonisa izindlela ezimbili ezijwayelekile zokupakisha, umehluko kuphela kumodi yokupakisha yama-athomu aphezulu, isakhiwo sekristalu sihlukile.

Isakhiwo sekristalu esakhiwe yi-SiC sihlobene kakhulu nezinga lokushisa. Ngaphansi kwesenzo sokushisa okuphezulu okungu-1900 ~ 2000 ℃, i-3C-SiC izoshintsha kancane kancane ibe yi-polyform ye-SiC ene-hexagonal efana ne-6H-SiC ngenxa yokungaqini kahle kwesakhiwo sayo. Kuhle ngenxa yokuhlobana okuqinile phakathi kwamathuba okwakhiwa kwama-polymorphs e-SiC kanye nezinga lokushisa, kanye nokungazinzi kwe-3C-SiC ngokwayo, izinga lokukhula kwe-3C-SiC linzima ukuthuthukisa, futhi ukulungiswa kunzima. Uhlelo lwe-4H-SiC ne-6H-SiC olunezinhlangothi ezine yizona ezivame kakhulu futhi kulula ukuzilungiselela, futhi zifundwa kabanzi ngenxa yezimpawu zazo.

Ubude bebhondi yebhondi ye-SI-C ku-SiC crystal buyi-1.89A kuphela, kodwa amandla okubopha aphakeme njengo-4.53eV. Ngakho-ke, igebe lezinga lamandla phakathi kombuso wokubopha kanye nezwe eliphikisana nesibopho likhulu kakhulu, futhi igebe lebhande elibanzi lingakhiwa, eliphindwe izikhathi eziningana kune-Si ne-GaAs. Ububanzi begebe lebhendi ephakeme busho ukuthi ukwakheka kwekristalu enezinga eliphezulu lokushisa kuzinzile. Ama-electronics ahlobene angakwazi ukubona izici zokusebenza okuzinzile emazingeni okushisa aphezulu kanye nesakhiwo esilula sokulahla ukushisa.

Ukubopha okuqinile kwebhondi ye-Si-C kwenza i-lattice ibe nemvamisa yokudlidliza ephezulu, okungukuthi, i-phonon yamandla aphezulu, okusho ukuthi ikristalu ye-SiC inokuhamba okugcwele kwe-electron egcwele kanye ne-thermal conductivity, kanye namandla ahlobene namadivayisi kagesi ane- isivinini sokushintsha esiphezulu nokuthembeka, okunciphisa ingcuphe yokwehluleka kwezinga lokushisa elingaphezu kwamandla edivayisi. Ngaphezu kwalokho, amandla enkambu yokwehlukaniswa okuphezulu kwe-SiC ayivumela ukuthi ifinyelele ukugxila okuphezulu kwe-doping futhi ibe nokumelana okuphansi.

Okwesibili, umlando wokuthuthukiswa kwe-crystal ye-SiC

Ngo-1905, uDkt. Henri Moissan wathola ikristalu ye-SiC yemvelo emgodini, ayithola ifana nedayimane futhi wayiqamba ngokuthi idayimane likaMose.

Eqinisweni, kusukela ngo-1885, u-Acheson wathola i-SiC ngokuxuba i-coke ne-silica futhi ayishise esithandweni sikagesi. Ngaleso sikhathi, abantu babecabanga ukuthi ingxube yedayimane futhi bayibiza ngokuthi i-emery.

Ngo-1892, u-Acheson wathuthukisa inqubo yokuhlanganisa, waxuba isihlabathi se-quartz, i-coke, inani elincane lama-chips enkuni kanye ne-NaCl, futhi wayishisisa esithandweni sikagesi se-arc kuya ku-2700 ℃, futhi wathola ngempumelelo amakristalu e-scaly SiC. Le ndlela yokwenza amakristalu e-SiC yaziwa ngokuthi indlela ye-Acheson futhi iseyindlela evamile yokukhiqiza ama-abrasive e-SiC embonini. Ngenxa yokuhlanzeka okuphansi kwezinto zokwenziwa zokwenziwa kanye nenqubo yokuhlanganisa ama-rough synthesis, indlela ye-Acheson ikhiqiza ukungcola okwengeziwe kwe-SiC, ubuqotho bekristalu obumpofu kanye nobubanzi bekristalu elincane, okunzima ukuhlangabezana nezidingo zemboni ye-semiconductor yobukhulu obukhulu, ubumsulwa obuphezulu kanye nokuphakama okuphezulu. -amakristalu ekhwalithi, futhi angeke asetshenziselwe ukwenza izinto zikagesi.

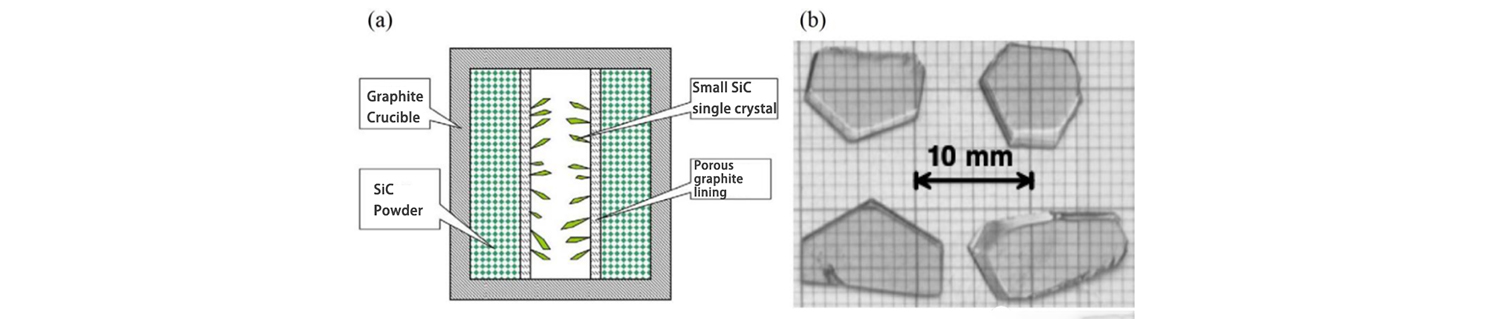

U-Lely we-Philips Laboratory uhlongoze indlela entsha yokukhulisa i-SiC single crystals ngo-1955. Kule ndlela, i-graphite crucible isetshenziswa njengesitsha sokukhula, i-SiC powder crystal isetshenziswa njengento eluhlaza ekukhuliseni i-SiC crystal, futhi i-graphite e-porous isetshenziselwa ukuhlukanisa. indawo engenalutho ukusuka phakathi nendawo yempahla eluhlaza ekhulayo. Lapho ikhula, i-graphite crucible ishiselwa ku-2500 ℃ ngaphansi komkhathi we-Ar noma i-H2, futhi i-peripheral SiC powder iyancishiswa futhi iboliswe ibe yizinto zesigaba somhwamuko we-Si no-C, futhi ikristalu ye-SiC ikhuliswa endaweni engenalutho emaphakathi ngemuva kwegesi. ukugeleza kudluliselwa nge-graphite enezimbotshana.

Okwesithathu, ubuchwepheshe bokukhula kwekristalu ye-SiC

Ukukhula kwekristalu eyodwa ye-SiC kunzima ngenxa yezimpawu zayo. Lokhu ikakhulukazi kungenxa yokuthi asikho isigaba soketshezi esinesilinganiso se-stoichiometric sika-Si: C = 1:1 ekucindezelweni komkhathi, futhi asikwazi ukukhuliswa ngezindlela zokukhula ezivuthiwe ezisetshenziswa inqubo yamanje yokukhula evamile ye-semiconductor. industry - cZ method, falling crucible method nezinye izindlela. Ngokusho kokubala kwethiyori, kuphela lapho ingcindezi ingaphezu kuka-10E5atm futhi izinga lokushisa lingaphezu kuka-3200℃, isilinganiso se-stoichiometric sikaSi: C = 1:1 singatholakala. Ukuze banqobe le nkinga, ososayensi baye benza imizamo engapheli yokuphakamisa izindlela ezihlukahlukene zokuthola izinga eliphezulu le-crystal, ubukhulu obukhulu kanye namakristalu e-SiC ashibhile. Njengamanje, izindlela eziyinhloko yindlela ye-PVT, indlela yesigaba se-liquid kanye nendlela yokubeka amakhemikhali okushisa aphezulu.

Isikhathi sokuthumela: Jan-24-2024