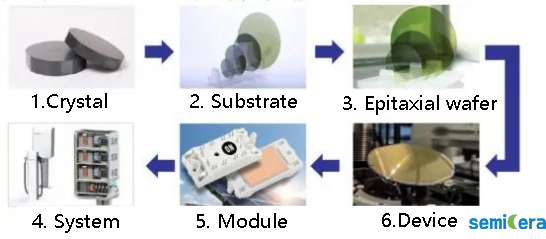

I-Epitaxial layer ifilimu ethize yekristalu eyodwa ekhule ku-wafer ngenqubo ye-ep ·itaxial, futhi i-substrate wafer nefilimu ye-epitaxial kuthiwa yi-epitaxial wafer. Ngokukhulisa ungqimba lwe-silicon carbide epitaxial ku-conductive silicon carbide substrate, i-silicon carbide homogeneous epitaxial wafer ingabuye ilungiswe ibe yi-Schottky diodes, MOSFETs, IGBTs namanye amadivaysi kagesi, phakathi kwawo i-4H-SiC substrate isetshenziswa kakhulu.

Ngenxa yenqubo ehlukene yokukhiqiza ye-silicon carbide idivayisi yamandla kanye nedivayisi yamandla ye-silicon yendabuko, ayikwazi ukwakhiwa ngokuqondile ku-silicon carbide single crystal material. Izinto ezengeziwe zekhwalithi ephezulu ze-epitaxial kufanele zikhuliswe ku-conductive single crystal substrate, futhi amadivaysi ahlukahlukene kufanele enziwe kungqimba lwe-epitaxial. Ngakho-ke, ikhwalithi ye-epitaxial layer inethonya elikhulu ekusebenzeni kwedivayisi. Ukuthuthukiswa kokusebenza kwemishini yamandla ehlukene futhi kubeka phambili izidingo eziphakeme zogqinsi lwe-epitaxial layer, ukugxiliswa kwe-doping kanye nokukhubazeka.

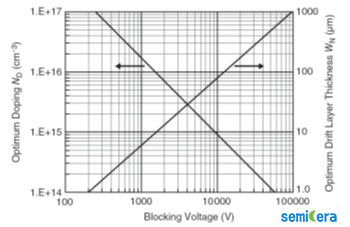

I-FIG. 1. Ubudlelwano phakathi kokugxila kwe-doping kanye nogqinsi lwe-epitaxial yedivayisi ye-unipolar kanye ne-voltage evimbayo

Izindlela zokulungiselela ze-SIC epitaxial layer ikakhulukazi zifaka indlela yokukhula yokuhwamuka, ukukhula kwe-epitaxial yesigaba se-liquid (LPE), ukukhula kwe-molecular beam epitaxial growth (MBE) kanye ne-chemical vapor deposition (CVD). Njengamanje, i-chemical vapor deposition (CVD) iyindlela eyinhloko esetshenziselwa ukukhiqizwa okukhulu ezimbonini.

| Indlela yokulungiselela | Izinzuzo zenqubo | Ukungalungi kwenqubo |

|

I-Liquid Phase Epitaxial Growth

(LPE)

|

Izidingo ezilula zemishini kanye nezindlela zokukhula ezingabizi kakhulu. |

Kunzima ukulawula i-morphology engaphezulu ye-epitaxial layer. Izinto zokusebenza azikwazi ukwenza i-epitaxialize ama-wafer amaningi ngesikhathi esisodwa, okukhawulela ukukhiqizwa okukhulu. |

|

Ukukhula kwe-Molecular Beam Epitaxial (MBE)

|

Izendlalelo ezihlukile ze-SiC crystal epitaxial zingatshalwa emazingeni okushisa aphansi okukhula |

Izidingo ze-vacuum yezisetshenziswa ziphezulu futhi zibiza. Izinga lokukhula elinensayo le-epitaxial layer |

|

I-Chemical Vapor Deposition (CVD) |

Indlela ebaluleke kakhulu yokukhiqiza ngobuningi ezimbonini. Izinga lokukhula lingalawulwa ngokunembile lapho kukhula izendlalelo ze-epitaxial eziwugqinsi. |

Izendlalelo ze-SiC epitaxial zisenokukhubazeka okuhlukahlukene okuthinta izici zedivayisi, ngakho-ke inqubo yokukhula kwe-epitaxial ye-SiC idinga ukuthuthukiswa ngokuqhubekayo.(I-TaCokudingekayo, bheka i-SemiceraUmkhiqizo we-TaC) |

|

Indlela yokukhula yokuhwamuka

|

Ukusebenzisa okokusebenza okufanayo nokudonsa kwe-SiC crystal, inqubo ihluke kancane ekudonseni ikristalu. Imishini evuthiwe, izindleko eziphansi |

Ukuhwamuka okungalingani kwe-SiC kwenza kube nzima ukusebenzisa ukuhwamuka kwayo ukuze kukhule izingqimba ze-epitaxial zekhwalithi ephezulu |

I-FIG. 2. Ukuqhathaniswa kwezindlela zokulungiselela eziyinhloko ze-epitaxial layer

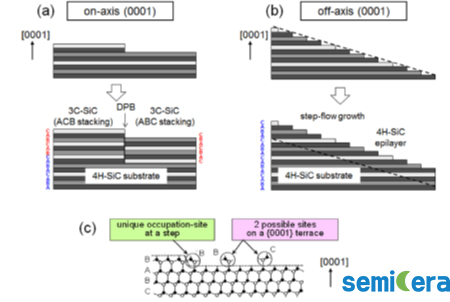

Ku-off-axis {0001} ene-engeli ethize etshekile, njengoba kukhonjisiwe kuMfanekiso 2(b), ukuminyana kwendawo yesinyathelo kukhudlwana, futhi usayizi wendawo yesinyathelo mncane, futhi i-crystal nucleation akulula ukuyenza. zenzeka endaweni yesinyathelo, kodwa kaningi kwenzeka endaweni yokuhlangana yesinyathelo. Kulokhu, kunokhiye owodwa kuphela we-nucleating. Ngakho-ke, ungqimba lwe-epitaxial lungaphindaphinda kahle ukuhleleka kokunqwabelanisa kwe-substrate, ngaleyo ndlela kususe inkinga yokuhlalisana kwezinhlobo eziningi.

I-FIG. 3. Umdwebo wenqubo ebonakalayo ye-4H-SiC yokulawula isinyathelo se-epitaxy indlela

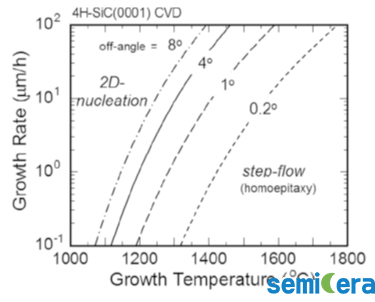

I-FIG. 4. Izimo ezibucayi zokukhula kwe-CVD nge-4H-SiC indlela ye-epitaxy elawulwa isinyathelo

I-FIG. 5. Ukuqhathaniswa kwamazinga okukhula ngaphansi kwemithombo ehlukene ye-silicon ku-4H-SiC epitaxy

Njengamanje, ubuchwepheshe be-silicon carbide epitaxy sebuvuthiwe kuma-voltage aphansi naphakathi (njengamadivayisi angu-1200 volt). Ukufana kogqinsi, ukugxilwa kwe-doping ukufana nokusabalaliswa kwesici kongqimba lwe-epitaxial kungafinyelela ezingeni elihle uma kuqhathaniswa, elingahlangabezana nezidingo ze-voltage ephakathi nendawo nephansi ye-SBD (Schottky diode), i-MOS (i-metal oxide semiconductor field effect transistor), i-JBS ( i-junction diode) namanye amadivaysi.

Kodwa-ke, emkhakheni wengcindezi ephezulu, ama-epitaxial wafers asadinga ukunqoba izinselelo eziningi. Isibonelo, kumadivayisi adinga ukumelana nama-volts angu-10,000, ukujiya kongqimba lwe-epitaxial kumele kube ngu-100μm. Uma kuqhathaniswa namadivayisi ane-voltage ephansi, ukujiya kwesendlalelo se-epitaxial kanye nokufana kokugxiliswa kwe-doping kuhluke kakhulu, ikakhulukazi ukufana kokuhlushwa kwe-doping. Ngesikhathi esifanayo, iphutha likanxantathu kungqimba lwe-epitaxial lizophinde libhubhise ukusebenza okuphelele kwedivayisi. Kuzinhlelo zokusebenza ezinamandla amakhulu, izinhlobo zedivayisi zivamise ukusebenzisa amadivaysi e-bipolar, adinga impilo encane ephezulu kungqimba lwe-epitaxial, ngakho-ke inqubo idinga ukuthuthukiswa ukuze kuthuthukiswe impilo yabantu abambalwa.

Njengamanje, i-epitaxy yasekhaya ngokuyinhloko ingamayintshi angu-4 no-6 amayintshi, futhi ingxenye ye-silicon carbide epitaxy yosayizi omkhulu iyanda unyaka nonyaka. Usayizi weshidi le-silicon carbide epitaxial ikakhulukazi unqunyelwe usayizi we-silicon carbide substrate. Njengamanje, i-6-inch silicon carbide substrate isidayiswe, ngakho-ke i-silicon carbide epitaxial ishintsha kancane kancane isuka kuma-intshi angu-4 kuya ku-6 amayintshi. Ngokuthuthuka okuqhubekayo kobuchwepheshe bokulungiselela i-silicon carbide substrate kanye nokwanda komthamo, intengo ye-silicon carbide substrate iyehla kancane kancane. Ekwakhiweni kwentengo yeshidi le-epitaxial, i-substrate ilandisa ngaphezu kuka-50% wezindleko, ngakho-ke ngokuncipha kwenani le-substrate, intengo ye-silicon carbide epitaxial sheet nayo kulindeleke ukuthi yehle.

Isikhathi sokuthumela: Jun-03-2024