Kuzo zonke izinqubo ezihilelekile ekudaleni i-chip, isiphetho sokugcina se-isilucwecwanaizosikwa ibe yifa ngalinye bese ipakishwa emabhokisini amancane, avalelwe aveze izikhonkwane ezimbalwa kuphela. I-chip izohlolwa ngokusekelwe embundwini, ukumelana, amanani amanje, kanye ne-voltage, kodwa akekho ozocabangela ukubukeka kwayo. Phakathi nenqubo yokukhiqiza, sipholisha ngokuphindaphindiwe i-wafer ukuze sifinyelele i-planarization edingekayo, ikakhulukazi isinyathelo ngasinye se-photolithography. Iisilucwecwanaindawo kufanele ibe sicaba ngokwedlulele ngoba, njengoba inqubo yokukhiqiza amashiphu incipha, ilensi yomshini we-photolithography idinga ukuzuza ukulungiswa kwesikali se-nanometer ngokwandisa indawo yokuvula izinombolo (NA) yelensi. Nokho, lokhu kanyekanye kunciphisa ukujula kokugxila (DoF). Ukujula kokugxila kubhekisela ekujuleni lapho isistimu yokubona ingagcina igxilile. Ukuqinisekisa ukuthi isithombe se-photolithography sihlala sicacile futhi sigxilile, ukuhlukahluka kwendawoisilucwecwanakufanele iwele ekujuleni kokugxila.

Ngamagama alula, umshini we-photolithography udela ikhono lokugxila lokuthuthukisa ukunemba kwesithombe. Isibonelo, imishini yesizukulwane esisha ye-EUV photolithography inembobo yenombolo engu-0.55, kodwa ukujula kokugxila okuqondile kungama-nanometer angu-45 kuphela, okunobubanzi obuncane kakhulu bokuthatha izithombe ngesikhathi sokuthwebula izithombe. Uma iisilucwecwanaayiphansi, inokuqina okungalingani, noma ukuguquguquka kwendawo, izodala izinkinga ngesikhathi se-photolithography ezindaweni eziphakeme neziphansi.

I-Photolithography akuyona ukuphela kwenqubo edinga ukushelelaisilucwecwanaphezulu. Ezinye izinqubo eziningi zokukhiqiza ama-chip nazo zidinga ukupholishwa kwe-wafer. Isibonelo, ngemva kokucwiliswa okumanzi, ukupholishwa kuyadingeka ukuze bushelelezi indawo emagebhugebhu ukuze kuhlanganiswe nokumiswa okulandelayo. Ngemuva kokuhlukaniswa kwe-trench engajulile (STI), ukupholishwa kuyadingeka ukuze bushelelezi i-silicon dioxide eyeqile futhi uqedele ukugcwaliswa komsele. Ngemva kokufakwa kwensimbi, ukupholishwa kuyadingeka ukuze kukhishwe izendlalelo zensimbi ezeqile futhi kuvinjwe amasekhethi amafushane edivayisi.

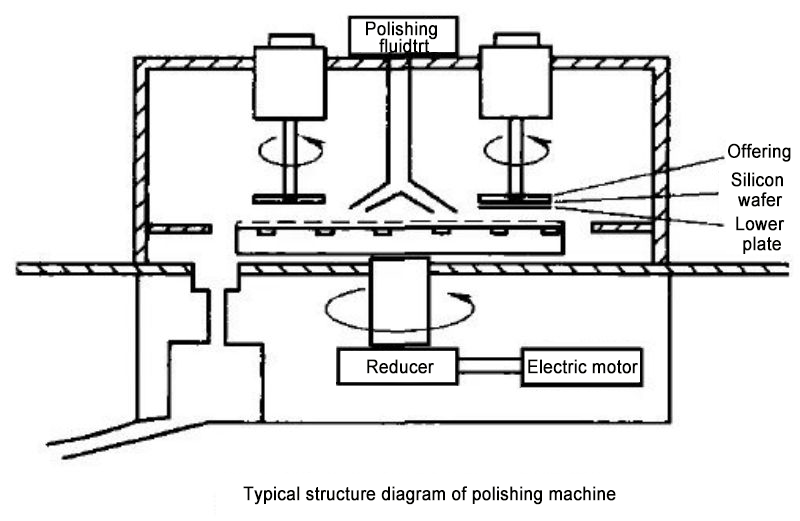

Ngakho-ke, ukuzalwa kwe-chip kuhilela izinyathelo eziningi zokupholisha ukuze kuncishiswe ama-wafer ama-wafer kanye nokwehluka kwendawo kanye nokususa izinto ezingaphezulu. Ukwengeza, ukukhubazeka okungaphezulu okubangelwa izinkinga ezihlukahlukene zenqubo ku-wafer ngokuvamile kubonakala kuphela ngemva kwesinyathelo ngasinye sokupholisha. Ngakho-ke, onjiniyela abanomthwalo wemfanelo wokupholisha banomthwalo wemfanelo omkhulu. Bayizibalo ezimaphakathi ohlelweni lokukhiqiza ama-chip futhi bavame ukuthwala icala emihlanganweni yokukhiqiza. Kumelwe babe nekhono kukho kokubili ukushumeka okumanzi kanye nokukhiphayo ngokomzimba, njengezindlela eziyinhloko zokupholisha ekukhiqizeni ama-chip.

Yiziphi izindlela zokupholisha ama-wafer?

Izinqubo zokupholisha zingahlukaniswa zibe izigaba ezintathu ezinkulu ngokusekelwe ezimisweni zokusebenzisana phakathi koketshezi lokupholisha nendawo ecwecwana ye-silicon:

1. Indlela Yokupholisha Ngomshini:

Ukupholisha ngomshini kususa ama-protrusions wendawo epholishiwe ngokusikwa kanye nokuguqulwa kwepulasitiki ukuze kufinyelele indawo ebushelelezi. Amathuluzi avamile ahlanganisa amatshe kawoyela, amasondo oboya, nephepha lesandpaper, elisetshenziswa ngokuyinhloko ngesandla. Izingxenye ezikhethekile, njengezindawo ezizungezayo zemizimba, zingasebenzisa ama-turntable namanye amathuluzi asizayo. Ezindaweni ezinezidingo zekhwalithi ephezulu, izindlela zokupholisha ezinhle kakhulu zingasetshenziswa. Ukupholisha okuhle kakhulu kusebenzisa amathuluzi abrasive enziwe ngokukhethekile, okuthi, oketshezini lokupholisha olunogwayi, acindezelwe ngokuqinile ebusweni bomsebenzi futhi ajikeleziswa ngesivinini esikhulu. Le nqubo ingafinyelela ubulukhuni obuphezulu be-Ra0.008μm, obuphakeme kakhulu kuzo zonke izindlela zokupholisha. Le ndlela ivame ukusetshenziselwa isikhunta se-optical lens.

2. Indlela Yokupholisha Amakhemikhali:

Ukupholisha ngamakhemikhali kuhilela ukuchithwa okukhethekile kwama-micro-protrusions endaweni ebonakalayo endaweni yamakhemikhali, okuholela endaweni ebushelelezi. Izinzuzo eziyinhloko zale ndlela ukuntuleka kwesidingo semishini eyinkimbinkimbi, ikhono lokupholisha ama-workpieces amise okuyinkimbinkimbi, kanye nekhono lokupholisha izingcezu zokusebenza eziningi ngesikhathi esisodwa ngendlela esebenza kahle kakhulu. Inkinga eyinhloko yokupholisha amakhemikhali ukwakhiwa koketshezi olupholisha. Ubulukhuni obungaphezulu obutholakala ngokupholisha ngamakhemikhali ngokuvamile buba amashumi amaningana ama-micrometer.

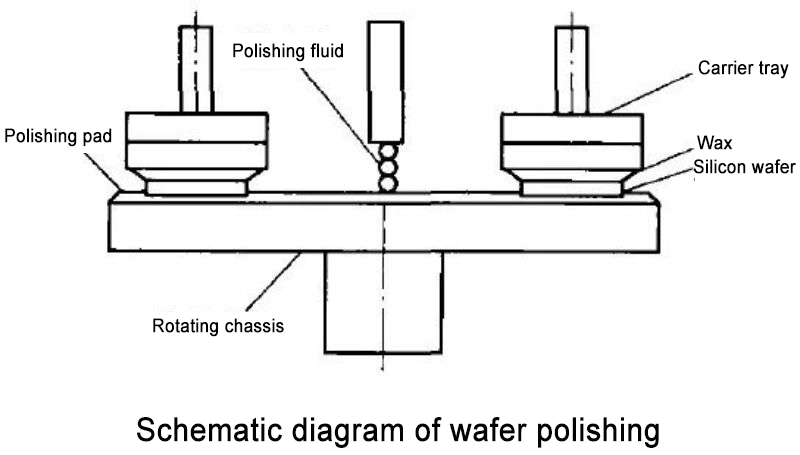

3. Indlela Yekhemikhali Yokupholisha (CMP):

Ngayinye yezindlela ezimbili zokuqala zokupholisha inezinzuzo zayo eziyingqayizivele. Ukuhlanganisa lezi zindlela ezimbili kungafinyelela imiphumela ehambisanayo kule nqubo. I-Chemical mechanical polishing ihlanganisa ukungqubuzana kwemishini kanye nezinqubo zokugqwala kwamakhemikhali. Ngesikhathi se-CMP, ama-reagents amakhemikhali oketshezi olucwebezelayo agcoba i-substrate epholile, yakhe ungqimba lwe-oxide oluthambile. Lesi sendlalelo se-oxide sibe sesikhishwa ngokungqubuzana komshini. Ukuphinda le nqubo ye-oxidation kanye nokususwa ngomshini kufeza ukupholisha okuphumelelayo.

Izinselelo Zamanje Nezinkinga Ekupholishani Kwemishini Yamakhemikhali (CMP):

I-CMP ibhekene nezinselelo nezinkinga ezimbalwa emkhakheni wezobuchwepheshe, ezomnotho, nokusimama kwemvelo:

1) Ukungaguquguquki Kwenqubo: Ukuthola ukuvumelana okuphezulu kunqubo ye-CMP kuhlala kuyinselele. Ngisho nangaphakathi komugqa ofanayo wokukhiqiza, ukuhluka okuncane kumapharamitha wenqubo phakathi kwamaqoqo ahlukene noma okokusebenza kungathinta ukuvumelana komkhiqizo wokugcina.

I-2) Ukuzivumelanisa Nezinto Ezintsha: Njengoba izinto ezintsha ziqhubeka nokuvela, ubuchwepheshe be-CMP kufanele buvumelane nezici zabo. Ezinye izinto ezithuthukisiwe zingase zingahambisani nezinqubo ze-CMP ezivamile, ezidinga ukuthuthukiswa koketshezi lokupholisha oluvumelana nezimo nama-abrasive.

3) Usayizi Wemiphumela: Njengoba ubukhulu bedivayisi ye-semiconductor buqhubeka nokuncipha, izinkinga ezibangelwa usayizi wemiphumela ziba zibaluleke kakhulu. Ubukhulu obuncane budinga ukuphakama okuphezulu kwendawo, okudinga izinqubo ze-CMP ezinembe kakhudlwana.

4) Ukulawulwa Kwezinga Lokususwa Kwezinto Ezibalulekile: Kwezinye izinhlelo zokusebenza, ukulawulwa okunembile kwezinga lokususwa kwezinto ezibonakalayo kubalulekile. Ukuqinisekisa amazinga okususwa angaguquki kuzo zonke izendlalelo ezahlukahlukene ngesikhathi se-CMP kubalulekile ekukhiqizeni amadivaysi asebenza kahle kakhulu.

5) Ubungane Bendawo: Uketshezi olucwebezelayo nama-abrasive asetshenziswa ku-CMP angase abe nezinto ezilimaza imvelo. Ucwaningo nokuthuthukiswa kwezinqubo nezinto zokwakha ze-CMP ezinobungani kakhulu nemvelo kuyizinselele ezibalulekile.

6) Intelligence and Automation: Nakuba izinga lobuhlakani nele-automation lezinhlelo ze-CMP liyathuthuka kancane kancane, kusafanele libhekane nezimo eziyinkimbinkimbi neziguquguqukayo zokukhiqiza. Ukuzuza amazinga aphezulu okuzenzakalela kanye nokuqapha okuhlakaniphile ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza kuyinselele okufanele ixazululwe.

I-7) Ukulawulwa Kwezindleko: I-CMP ihilela imishini ephezulu kanye nezindleko zempahla. Abakhiqizi badinga ukuthuthukisa ukusebenza kwenqubo kuyilapho belwela ukunciphisa izindleko zokukhiqiza ukuze kugcinwe ukuncintisana kwemakethe.

Isikhathi sokuthumela: Jun-05-2024