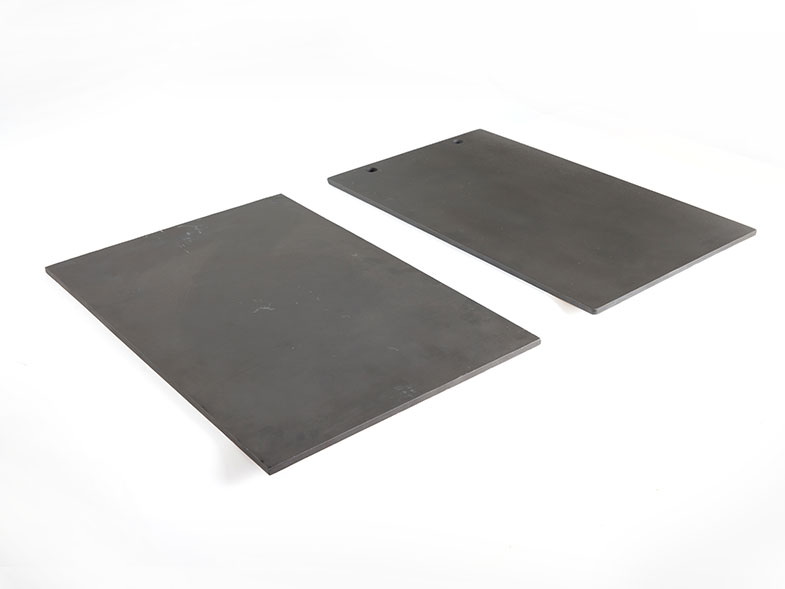

Isithando somlilo se-silicon carbideinezinzuzo zamandla aphezulu, ubulukhuni obuphezulu, ukumelana nokugqokwa okuhle, ukumelana nokushisa okuphezulu, ukumelana nokugqwala, ukumelana nokushaqeka okuhle kokushisa, ukuguquguquka okuphezulu kwe-thermal, ukumelana okuhle kwe-oxidation nokunye. Isetshenziswa kakhulu ekuphonsweni kwefrikhwensi ephakathi, isithando somlilo esihlukahlukene sokushisa, i-metallurgy, imboni yamakhemikhali, i-non-ferrous metal forging kanye neminye imisebenzi.Isithando somlilo se-silicon carbideisetshenziswa kabanzi esithandweni se-metallurgical sintering kanye nesithando sokushisa esiphakathi nendawo, futhi ubude baso bungenziwa ngokwezifiso ngokuya ngezidingo zangempela zesayithi.

Izici zeamashubhu omlilo we-silicon carbide

I-Silicon carbide furnace tube iwumkhiqizo omuhle kakhulu we-silicon carbide oshiswe ekushiseni okuphezulu nge-silicon carbide njengento eluhlaza. Inezinzuzo zokumelana nokushisa okuphezulu, ukumelana nokugqwala, ukuguquguquka kokushisa okusheshayo, amandla aphezulu, ubulukhuni obuphezulu, ukumelana nokugqokwa okuhle, ukumelana nokushaqeka okuhle kokushisa, ukuguquguquka okukhulu kwe-thermal, ukumelana okuhle kwe-oxidation nokunye. Zombili iziphetho zifakwe ama-bushings akhethekile okushisa aphezulu, ukugqwala kwesisombululo sensimbi ezintweni zokushisa zikagesi (okuhlanganisa induku ye-silicon carbide, intambo yesithando somlilo kagesi, njll.) kungagwenywa ngempumelelo, futhi izinkomba zingcono kunezinhlobo zonke zemikhiqizo ye-graphite. . I-silicon carbide furnace tube ine-thermal conductivity, ukumelana ne-oxidation, ukumelana nokushaqeka okushisayo, ukumelana nokushisa okuphezulu kokugqoka, ukuzinza okuhle kwamakhemikhali, ukumelana ne-asidi eqinile, akukho ukusabela ku-asidi eqinile ne-alkali.

Isithando somlilo se-silicon carbideubuchwepheshe bokukhiqiza: umkhiqizo oqediwe uthatha i-silicon carbide njengento yokuqala eluhlaza, futhi ingumkhiqizo omuhle kakhulu oqediwe we-silicon carbide oshiswe ubuchwepheshe obukhethekile ekushiseni okuphezulu. Izinga lobude lingenziwa ngokwezifiso ngokuya ngezidingo zangempela zamakhasimende. Ukusetshenziswa okuyinhloko kwe-silicon carbide furnace tube: esetshenziswa kabanzi ekuqeqesheni insimbi engeyona insimbi, uhlelo lokususa ugesi lwemikhiqizo ye-aluminium, imishini yokunyathelisa nokudaya, ukuqeqeshwa kwe-zinc ne-aluminium kanye nokucubungula umkhiqizo ophelile.

Ukuthuthukiswa kwezimboni ze-silicon carbide

I-Silicon carbide inezici ze-impedance ephezulu yokufaka, umsindo ophansi, ukuhambisana okuhle, njll., ingenye yezinsiza ezithuthuka ngokushesha ze-silicon carbide, futhi eyokuqala ukuzuza ukuhweba. Uma kuqhathaniswa nama-MOSFET, azikho izinkinga zokwethenjelwa ezibangelwa ukukhubazeka kwe-oxide yesango kanye nemikhawulo ephansi yokuhamba kwenkampani yenethiwekhi, futhi izici zayo zokusebenza ze-unipolar zigcina amandla amahle wokusebenza kwe-high-frequency. Ukwengeza, isakhiwo se-silicon carbide junction sinokuzinza nokuthembeka okungcono emazingeni okushisa aphezulu ukuze i-threshold voltage ibe yimbi, okungukuthi, idivayisi evame ukuvuleka, engalungile kakhulu ekusetshenzisweni kwamandla kagesi, futhi ayihambisani nezivamile zamanje. shayela isifunda. Ngokwethula ubuchwepheshe bedivayisi yomjovo we-groove, idivayisi ethuthukisiwe ngaphansi kwesimo sokungasebenzi esijwayelekile iyathuthukiswa. Kodwa-ke, izisetshenziswa ezithuthukisiwe zivame ukwakhiwa ngezindleko zezici ezithile ezinhle zokungazweli, ngakho-ke ngokuvamile ukuvuleka (uhlobo lokuncipha) kulula ukuzuza ukuminyana kwamandla aphezulu namandla amanje, futhi uhlobo lokuncipha lungafinyelelwa ngokuphuma ngokuvamile kusimo sokusebenza. Indlela ye-cascade isetshenziswa ngochungechunge lwama-MOSFET asuselwa ku-silicon-voltage aphansi. Isifunda se-cascade drive sihambisana ngokwemvelo nesekhethi ye-silicon device drive evamile. Lesi sakhiwo se-cascade sifaneleke kakhulu ukufaka esikhundleni se-silicon yasekuqaleni ngezikhathi zamandla kagesi aphezulu kanye namandla aphezulu, futhi sigwema ngokuqondile inkinga yokuhambisana yesekethe yedrayivu.

Isikhathi sokuthumela: Sep-25-2023