Izitsha zobumba ze-Silicon nitride (Si₃N₄), njengezitsha zobumba ezithuthukisiwe, zinezinto ezinhle kakhulu ezifana nokumelana nezinga lokushisa eliphezulu, amandla aphezulu, ukuqina okuphezulu, ukuqina okuphezulu, ukumelana nokukhasa, ukumelana ne-oxidation, nokumelana nokugqokwa. Ukwengeza, banikeza ukumelana nokushaqeka okuhle kwe-thermal, izakhiwo ze-dielectric, izinga eliphezulu le-thermal conductivity, kanye nokusebenza okuhle kakhulu kwe-high-frequency electromagnetic wave transmission. Lezi zakhiwo eziphelele ezivelele zizenza zisetshenziswe kabanzi ezingxenyeni zesakhiwo esiyinkimbinkimbi, ikakhulukazi ku-aerospace kanye nezinye izinkambu zobuchwepheshe obuphezulu.

Kodwa-ke, i-Si₃N₄, iyinhlanganisela enamabhondi aqinile, inesakhiwo esizinzile esenza ukuminyana kube nzima ngokusatshalaliswa kwesimo esiqinile kuphela. Ukuze kuphromothwe i-sintering, izinsiza ze-sintering, ezifana nama-metal oxides (MgO, CaO, Al₂O₃) nama-earth oxides angavamile (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), ayangezwa ukuze kube lula ukuminyana ngendlela ye-liquid-sintering mechanism.

Njengamanje, ubuchwepheshe bedivaysi ye-semiconductor yomhlaba wonke buthuthukela kuma-voltage aphezulu, ama-currents amakhulu, kanye nokuminyana kwamandla okukhulu. Ucwaningo lwezindlela zokwenza i-Si₃N₄ ceramics lubanzi. Lesi sihloko sethula izinqubo ze-sintering ezithuthukisa ngempumelelo ukuminyana kanye nezakhiwo zemishini ezibanzi ze-silicon nitride ceramics.

Izindlela Zokubumba Ezivamile Ze-Si₃N₄ Ceramics

Ukuqhathaniswa kokusebenza kwe-Si₃N₄ Ceramics Kulungiselelwe Izindlela Ezihlukile Zokuhlanganisa

1. I-Reactive Sintering (RS):I-reactive sintering kwaba indlela yokuqala eyasetshenziswa ukulungisa ngokwezimboni izitsha zobumba ze-Si₃N₄. Ilula, ingabizi, futhi iyakwazi ukwenza izimo eziyinkimbinkimbi. Nokho, inomjikelezo omude wokukhiqiza, ongahambisani nokukhiqizwa kwezimboni.

2. I-Pressureless Sintering (PLS):Lena inqubo eyisisekelo kakhulu futhi elula sintering. Kodwa-ke, idinga izinto zokusetshenziswa zekhwalithi ephezulu ze-Si₃N₄ futhi ngokuvamile iholela kuma-ceramics anokuminyana okuphansi, ukuncipha okukhulu, nokuthambekela kokuqhekeka noma ukonakala.

3. I-Hot-Press Sintering (HP):Ukusetshenziswa kwe-uniaxial mechanical pressure kwandisa amandla okushayela e-sintering, okuvumela izitsha zobumba eziminyene ukuthi zikhiqizwe emazingeni okushisa angu-100-200°C ngaphansi kunalawo asetshenziswa ekushiseni okungenasici. Le ndlela ivamise ukusetshenziselwa ukwenza izitsha zobumba ezilula ezimise okwebhulokhi kodwa kunzima ukuhlangabezana nezimfuneko zokujiya nokuma kwezinto ze-substrate.

4. I-Spark Plasma Sintering (SPS):I-SPS ibonakala ngokushibilika ngokushesha, ukucolisiswa okusanhlamvu, kanye nokuncipha kwamazinga okushisa e-sintering. Kodwa-ke, i-SPS idinga ukutshalwa kwezimali okubalulekile kumishini, futhi ukulungiswa kwe-thermal conductivity ephezulu ye-Si₃N₄ ceramics nge-SPS kusesesigabeni sokuhlola futhi akukakathuthukiswa.

5. I-Gas-Pressure Sintering (GPS):Ngokusebenzisa ukucindezela kwegesi, le ndlela ivimbela ukubola kwe-ceramic nokulahlekelwa isisindo emazingeni okushisa aphezulu. Kulula ukukhiqiza izitsha zobumba ezinobukhulu obukhulu futhi zenza ukukhiqizwa kwenqwaba. Kodwa-ke, inqubo ye-gas-pressure sintering yesinyathelo esisodwa idonsa kanzima ukukhiqiza izingxenye zesakhiwo ezinombala ofanayo wangaphakathi nangaphandle kanye nesakhiwo. Ukusebenzisa inqubo ye-sintering enezinyathelo ezimbili noma enezinyathelo eziningi kunganciphisa kakhulu okuqukethwe kwe-oksijini ye-intergranular, kuthuthukise ukuqhutshwa kwe-thermal, futhi kuthuthukise izici eziphelele.

Kodwa-ke, izinga lokushisa eliphezulu le-sintering lezinyathelo ezimbili ze-gas-pressure sintering liholele ekutheni ucwaningo lwangaphambilini lugxile ikakhulukazi ekulungiseni ama-substrates e-ceramic e-Si₃N₄ ane-thermal conductivity ephezulu namandla okugoba ezinga lokushisa legumbi. Ucwaningo nge-ceramics ye-Si₃N₄ enezici zemishini ezibanzi kanye nezakhiwo zemishini yezinga eliphezulu lokushisa kulinganiselwe.

I-Gas-Pressure Two-Pressure Sintering Method ye-Si₃N₄

U-Yang Zhou kanye nozakwabo base-Chongqing University of Technology basebenzise isistimu yosizo ye-sintering engu-5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ ukuze balungiselele izitsha zobumba ze-Si₃N₄ zisebenzisa kokubili isinyathelo esisodwa kanye nezinyathelo ezimbili izinqubo zokucwilisa igesi yokucindezela ku-1800°C. I-Ceramics ye-Si₃N₄ ekhiqizwe inqubo ye-sintering enezinyathelo ezimbili ibe nokuminyana okuphezulu kanye nezakhiwo zemishini ezihlanganisa kangcono. Okulandelayo kufinyeza imiphumela yesinyathelo esisodwa kanye nezinyathelo ezimbili zezinqubo zokucindezela igesi ku-microstructure kanye nezakhiwo zemishini zezingxenye ze-ceramic ze-Si₃N₄.

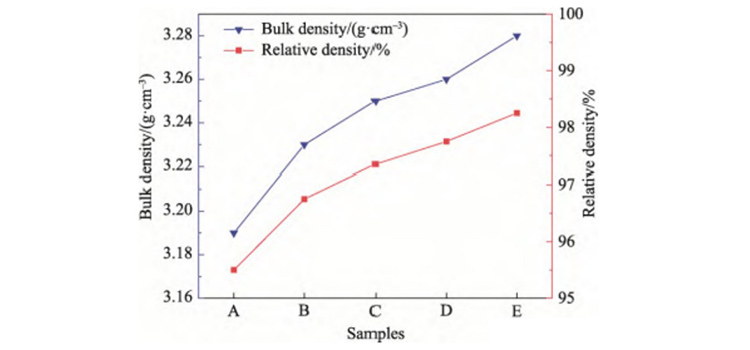

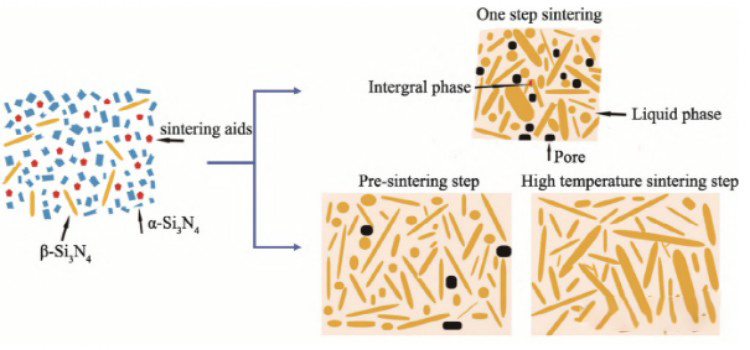

Ukuminyana Inqubo yokuhlanganisa ye-Si₃N₄ ngokuvamile ibandakanya izigaba ezintathu, nokugqagqana phakathi kwezigaba. Isigaba sokuqala, ukuhlelwa kabusha kwezinhlayiyana, kanye nesigaba sesibili, ukuhlakazeka-imvula, yizigaba ezibucayi kakhulu zokuminyana. Isikhathi esanele sokusabela kulezi zigaba sithuthukisa kakhulu ukuminyana kwesampula. Lapho izinga lokushisa langaphambi kwe-sintering lenqubo ye-sintering yezinyathelo ezimbili isethelwe ku-1600°C, izinhlamvu ze-β-Si₃N₄ zakha uhlaka futhi zenze izimbotshana ezivaliwe. Ngemuva kwe-sintering yangaphambili, ukushisa okuqhubekayo ngaphansi kwezinga lokushisa eliphezulu kanye nengcindezi ye-nitrogen kukhuthaza ukugeleza kwesigaba se-liquid kanye nokugcwalisa, okusiza ukuqeda ama-pores avaliwe, kuthuthukise ngokwengeziwe ukuminyana kwe-ceramics ye-Si₃N₄. Ngakho-ke, amasampula akhiqizwe inqubo ye-sintering enezinyathelo ezimbili abonisa ukuminyana okuphezulu nokuminyana okuhlobene kunalawo akhiqizwa i-sintering yesinyathelo esisodwa.

Isigaba kanye ne-Microstructure Ngesikhathi se-sintering yesinyathelo esisodwa, isikhathi esitholakalayo sokuhlelwa kabusha kwezinhlayiyana kanye nokusabalalisa komngcele wokusanhlamvu sinqunyelwe. Enqubweni ye-sintering yezinyathelo ezimbili, isinyathelo sokuqala senziwa ekushiseni okuphansi kanye nokucindezela kwegesi okuphansi, okwandisa isikhathi sokuhlelwa kabusha kwezinhlayiyana futhi kubangele okusanhlamvu okukhulu. Izinga lokushisa libe selikhushulelwa esigabeni sokushisa okuphezulu, lapho okusanhlamvu kuqhubeka khona ukukhula ngenqubo yokuvuthwa kwe-Ostwald, kuthela amaceramics e-Si₃N₄ aphezulu.

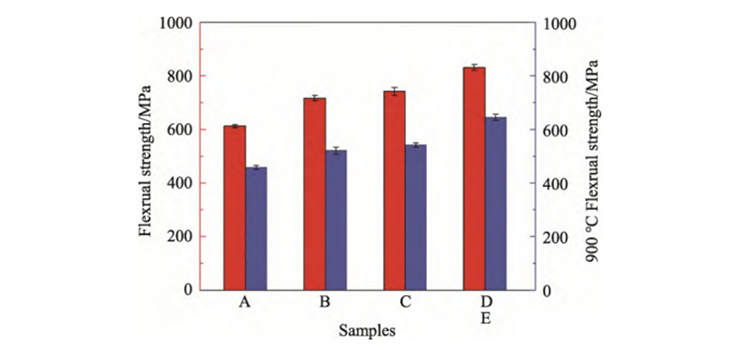

Izakhiwo Zemishini Ukuthambisa kwesigaba se-intergranular emazingeni okushisa aphezulu kuyisizathu esiyinhloko sokunciphisa amandla. Ekushiseni ngesinyathelo esisodwa, ukukhula okusanhlamvu okungavamile kudala izimbotshana ezincane phakathi kwezinhlamvu, okuvimbela ukuthuthukiswa okuphawulekayo kumandla aphezulu okushisa. Kodwa-ke, enqubweni yezinyathelo ezimbili ze-sintering, isigaba sengilazi, esatshalaliswa ngokulinganayo emingceleni yokusanhlamvu, kanye nezinhlamvu ezinosayizi ofanayo zithuthukisa amandla e-intergranular, okuholela ekuqineni okuphezulu kwezinga lokushisa eliphezulu.

Sengiphetha, ukubamba isikhathi eside ngesikhathi se-sintering yesinyathelo esisodwa kunganciphisa ngempumelelo i-porosity yangaphakathi futhi kuzuze umbala wangaphakathi ofanayo kanye nesakhiwo kodwa kungase kuholele ekukhuleni okungavamile okusanhlamvu, okuthunaza izici ezithile zomshini. Ngokusebenzisa inqubo ye-sintering enezinyathelo ezimbili—ukusebenzisa i-pre-sintering esezingeni eliphansi lokushisa ukuze kwandiswe isikhathi sokuhlela kabusha izinhlayiyana nokubamba izinga lokushisa eliphezulu ukuze kuthuthukiswe ukukhula okusanhlamvu okufanayo—i-ceramic ye-Si₃N₄ enobukhulu obuhlobene obungu-98.25%, i-microstructure efanayo, kanye nezakhiwo ezinhle kakhulu zemishini ezibanzi. ingalungiswa ngempumelelo.

| Igama | I-substrate | Ukwakhiwa kwesendlalelo se-Epitaxial | Inqubo ye-Epitaxial | I-Epitaxial medium |

| I-silicon homoepitaxial | Si | Si | I-Vapor Phase Epitaxy (VPE) | I-SiCl4+H2 |

| I-silicon heteroepitaxial | Isafire noma i-spinel | Si | I-Vapor Phase Epitaxy (VPE) | SiH₄+H₂ |

| I-GaAs i-homoepitaxial | I-GaAs | I-GaAs I-GaAs | I-Vapor Phase Epitaxy (VPE) | I-AsCl₃+Ga+H₂ (Ar) |

| I-GaAs | I-GaAs I-GaAs | I-Molecular Beam Epitaxy (MBE) | I-Ga+As | |

| I-GaA i-heteroepitaxial | I-GaAs I-GaAs | I-GaAlAs/GaAs/GaAlAs | I-Liquid Phase Epitaxy (LPE) Isigaba se-Vapor (VPE) | I-Ga+Al+CaAs+ H2 I-Ga+AsH3+PH3+CHl+H2 |

| I-GaP homoepitaxial | I-GaP | I-GaP(GaP;N) | I-Liquid Phase Epitaxy (LPE) I-Liquid Phase Epitaxy (LPE) | I-Ga+GaP+H2+(NH3) I-Ga+Gas+GaP+NH3 |

| I-Superlattice | I-GaAs | I-GaAlAs/GaAs (umjikelezo) | I-Molecular Beam Epitaxy (MBE) I-MOCVD | Ca, As, Al I-GaR₃+AlR3+AsH3+H2 |

| I-InP homoepitaxial | I-InP | I-InP | I-Vapor Phase Epitaxy (VPE) I-Liquid Phase Epitaxy (LPE) | PCl3+In+H2 Ku+InAs+Gas+InP+H₂ |

| Si/GaAs Epitaxy | Si | I-GaAs | I-Molecular Beam Epitaxy (MBE) I-MOGVD | Ga, As I-GaR₃+AsH₃+H₂ |

Isikhathi sokuthumela: Dec-24-2024