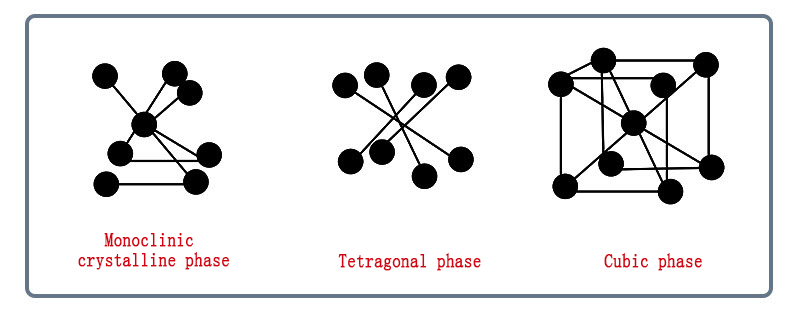

I-Zirconia Ceramicszimhlophe, ziphuzi noma zimpunga uma ziqukethe ukungcola, futhi ngokuvamile ziqukethe i-HfO2, okungelula ukuyihlukanisa. Kunezimo ezintathu zekristalu ze-ZrO2 ehlanzekile ngaphansi kwengcindezi evamile.

■Izinga lokushisa eliphansi le-monoclinic (m-ZrO2)■I-tetragonal yezinga lokushisa elimaphakathi (t-ZrO2)■I-cubic yokushisa ephezulu (c-ZrO2)

Izinhlobo ezintathu ezingenhla zekristalu zikhona kumazinga okushisa ahlukene, futhi kukhona ubudlelwano obulandelayo bokuguqula okulinganayo:

Izici ze-zirconia ceramics

Hi-igh-melting-point

Iphuzu elincibilikayo le-Zirconia lithi: 2715 ℃, lingasetshenziswa njengezinto ezivimbela ukushisa okuphezulu

Ukuqina okuphezulu, ukumelana okuhle kokugqoka

Ngokusho kobunzima be-Mohs: isafire >I-Zirconia Ceramics> I-Corning Glass > I-Aluminium magnesium alloy > Ingilazi eqinile > i-polycarbonate

Amandla aphezulu kanye nokuqina

Amandla e-zirconia angafinyelela: 1500MPa

I-conductivity ephansi ye-thermal kanye ne-coefficient yokwandisa

Phakathi kwezinto ezivamile ze-ceramic, i-thermal conductivity yayo iphansi kakhulu (1.6-2.03W/(mk)), futhi i-coefficient yokwanda okushisayo iseduze naleyo yensimbi.

Ukusebenza kahle kukagesi

I-dielectric constant ye-zirconia iphindwe izikhathi ezingu-3 kunesafire, futhi isignali izwela kakhulu.

Ukusetshenziswa kwe-zirconia ceramics

I-Zirconia Ceramicszisetshenziswa kabanzi ku-3C electronics, ukuxhumana optical, smart wear, biomedical, jewelry, ukuphila kwansuku zonke, refractory materials kanye neminye imikhakha.

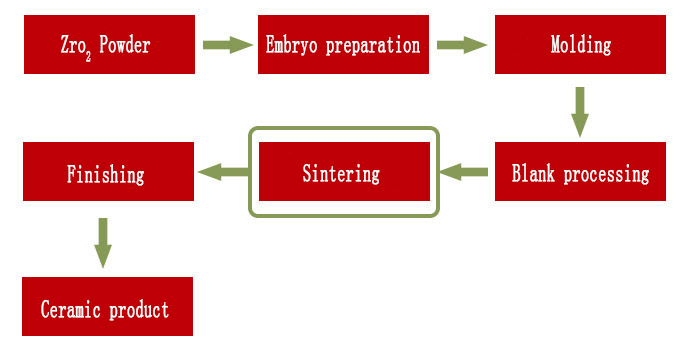

Ubuchwepheshe bokulungiselela umkhiqizo we-Zirconia ceramic

I-Sintering iyinqubo ebaluleke kakhulu ekulungiselelenii-zirconia ceramics, ikhwalithi ye-sintering izothinta ngokuqondile ukucubungula kwe-ceramic, kuphela izinga lokushisa le-sintering elilungiswa kahle, umzimba walo wombungu uzoba uphelele. I-pressureless sintering iyindlela evame ukusetshenziswa kakhulu ye-sintering.

Ngenxa yokuthi izinto ze-ceramic ezihlanzekile ngezinye izikhathi kunzima ukucwiliswa, ngaphansi kwezimo zokusebenza, ezinye izithasiselo ze-sintering zivame ukwethulwa ukuze zenze indawo encibilikayo eyingxenye yesisombululo esiqinile, isigaba sengilazi noma esinye isigaba se-liquid, ukukhuthaza ukuhlelwa kabusha kwezinhlayiya nokugeleza kwe-viscous. , ukuze uthole umkhiqizo ominyene, kodwa futhi unciphise izinga lokushisa le-sintering.

Ukunciphisa usayizi we-powder ngangokunokwenzeka futhi kungenye yezinyathelo ezibalulekile zokukhuthaza i-sintering. Ngoba lapho impushana icwebezela, amandla angaphezulu aphezulu, kuba lula ukucwilisa. Ngezinto ze-ceramic kanye nemikhiqizo enezidingo zokusebenza ezivamile, i-non-pressure sintering iyindlela elula kakhulu futhi eyongayo ye-sintering.

Isikhathi sokuthumela: Jul-24-2023