Kusukelacrucibleisetshenziswa njengesiqukathi futhi kukhona i-convection ngaphakathi, njengoba usayizi wekristalu eyodwa okhiqizwayo ukhula, ukuhanjiswa kokushisa kanye nokufana kwezinga lokushisa kuba nzima kakhulu ukulawula. Ngokungeza inkambu kazibuthe ukuze wenze ukuncibilika okuguquguqukayo kusebenze ngamandla e-Lorentz, i-convection ingancishiswa noma isuswe ukuze kukhiqizwe i-silicon eyodwa yekristalu eyodwa.

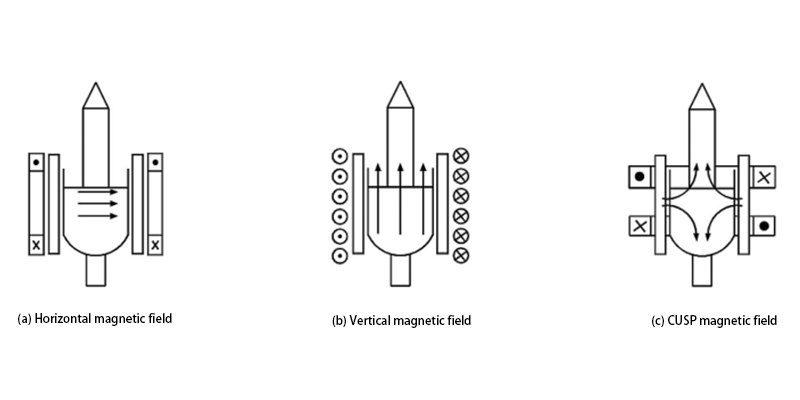

Ngokohlobo lwensimu kazibuthe, ingahlukaniswa ibe yinkundla kazibuthe enezingqimba, indawo kazibuthe eqondile kanye ne-CUSP yamagnetic field:

Inkundla kazibuthe emile ayikwazi ukuqeda i-convection eyinhloko ngenxa yezizathu zesakhiwo futhi ayivamile ukusetshenziswa.

Isiqondiso sengxenye yensimu kazibuthe yenkundla kazibuthe evundlile incike endaweni yokushisa enkulu kanye nokuguquguquka okuphoqelekile ngokwengxenye kodonga oluhlabayo, olunganqanda ngempumelelo ukunyakaza, kugcine ukucaba kwesixhumi esibonakalayo sokukhula, nokunciphisa imigqa yokukhula.

Inkundla kazibuthe ye-CUSP inokugeleza okufanayo okufana nokudluliswa kokushisa kokuncibilika ngenxa yokulinganisa kwayo, ngakho ucwaningo lwezindawo kazibuthe ezimile kanye ne-CUSP belulokhu luhambisana.

E-China, i-Xi'an University of Technology ibone ukukhiqizwa kanye nokuhlolwa kokudonsa kwekristalu kwekristalu eyodwa ye-silicon isebenzisa izizibuthe ngaphambili. Imikhiqizo yayo eyinhloko yizinhlobo ezidumile ezingu-6-8in, ezihloselwe emakethe ye-silicon wafer yamaseli e-solar photovoltaic. Emazweni angaphandle, njenge-KAYEX e-United States kanye ne-CGS eJalimane, imikhiqizo yabo eyinhloko i-8-16in, elungele izinduku ze-crystal crystal eyodwa ezingeni lamasekethe ahlanganisiwe we-ultra-escale kanye nama-semiconductors. Banoyedwa oyedwa emkhakheni wezibuthe ukuze kukhule amakristalu awodwa wekhwalithi ephezulu enobubanzi obukhulu futhi yiwo amele kakhulu.

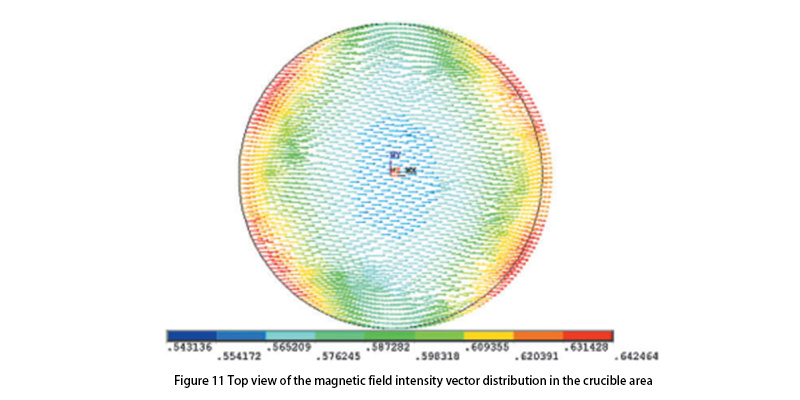

Ukusatshalaliswa kwensimu kazibuthe endaweni ebethelekayo yesistimu yokukhula kwekristalu eyodwa yingxenye ebaluleke kakhulu kazibuthe, okuhlanganisa amandla kanye nokufana kwenkundla kazibuthe emaphethelweni e-crucible, isikhungo se-crucible, kanye nendawo efanele. ibanga elingaphansi kwendawo ewuketshezi. Inkundla kazibuthe evundlile neyunifomu efanayo, imigqa yamandla kazibuthe incike ku-axis yokukhula kwekristalu. Ngokomphumela kazibuthe kanye nomthetho we-Ampere, ikhoyili iseduze kakhulu nonqenqema lwe-crucible futhi amandla enkundla makhulu kakhulu. Njengoba ibanga likhula, ukumelana namagnetic emoyeni kuyanda, amandla ensimu ayancipha kancane kancane, futhi yiwona mncane phakathi nendawo.

Indima ye-superconducting field magnetic

Ukuvimbela i-thermal convection: Uma ingekho insimu yamagnetic yangaphandle, i-silicon encibilikisiwe izokhiqiza i-convection yemvelo ngesikhathi sokushisa, okungase kuholele ekusabalaliseni ukungcola okungalingani kanye nokwakhiwa kwamaphutha e-crystal. Inkambu kazibuthe yangaphandle ingacindezela le convection, yenze ukusatshalaliswa kwezinga lokushisa ngaphakathi kwencibilika ibe yinto efanayo futhi kunciphise ukusatshalaliswa kokungcola okungalingani.

Ukulawula izinga lokukhula kwekristalu: Inkambu kazibuthe ingathinta izinga nesiqondiso sokukhula kwekristalu. Ngokulawula ngokunembile amandla nokusatshalaliswa kwendawo kazibuthe, inqubo yokukhula kwekristalu ingathuthukiswa futhi ubuqotho nokufana kwekristalu kungathuthukiswa. Ngesikhathi sokukhula kwe-silicon eyodwa ye-crystal, i-oksijini ingena ku-silicon iyancibilika ikakhulukazi ngokunyakaza okuhlobene kokuncibilika kanye ne-crucible. Inkambu kazibuthe inciphisa ithuba lokuxhumana komoyampilo ne-silicon encibilikayo ngokunciphisa ukuguquguquka kokuncibilika, ngaleyo ndlela yehlise ukuhlakazeka komoyampilo. Kwezinye izimo, inkambu kazibuthe yangaphandle ingashintsha izimo ze-thermodynamic zokuncibilika, njengokushintsha ukushuba kwendawo kokuncibilika, okungase kusize ukuguquguquka komoyampilo, ngaleyo ndlela kunciphise okuqukethwe komoyampilo ekuncibilikeni.

Yehlisa ukuncibilika komoyampilo nokunye ukungcola: I-oksijeni ingenye yezinto ezingcolile ezivamile ekukhuleni kwamakristalu e-silicon, okuzokwenza izinga le-crystal liwohloke. Inkambu kazibuthe inganciphisa okuqukethwe komoyampilo ekuncibilikeni, ngaleyo ndlela yehlise ukuhlakazeka komoyampilo kukristalu futhi ithuthukise ubumsulwa bekristalu.

Thuthukisa ukwakheka kwangaphakathi kwekristalu: Inkambu kazibuthe ingathinta isakhiwo esinesici ngaphakathi kwekristalu, njengokuhlakazeka kanye nemingcele yokusanhlamvu. Ngokunciphisa inani lalezi ziphambeko futhi kuthinte ukusatshalaliswa kwazo, ikhwalithi iyonke ye-crystal ingathuthukiswa.

Ukuthuthukisa izici zikagesi zamakristalu: Njengoba izizinda kazibuthe zinomthelela omkhulu ku-microstructure ngesikhathi sokukhula kwekristalu, zingathuthukisa izici zikagesi zamakristalu, njenge-resistivity kanye nesikhathi sempilo yenkampani yenethiwekhi, ezibalulekile ekukhiqizeni amadivaysi e-semiconductor asebenza kahle kakhulu.

Yamukela noma yimaphi amakhasimende avela emhlabeni wonke ukuthi asivakashele ukuze uthole enye ingxoxo!

https://www.semi-cera.com/

https://www.semi-cera.com/tac-coating-monocrystal-growth-parts/

https://www.semi-cera.com/cvd-coating/

Isikhathi sokuthumela: Jul-24-2024