I-Rolling isho inqubo yokugaya ububanzi obungaphandle be-silicon single crystal rod ibe induku eyodwa yekristalu yobubanzi obudingekayo kusetshenziswa isondo lokugaya idayimane, futhi kugaywe indawo eyisithenjwa yonqenqema oluyisicaba noma umsele wokuma wenduku eyodwa yekristalu.

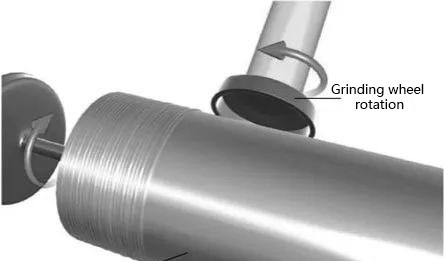

Ububanzi obungaphandle benduku eyodwa yekristalu elungiselelwe isithando somlilo sekristalu eyodwa ayibushelelezi futhi iyisicaba, futhi ububanzi bayo bukhulu kunobubanzi be-silicon wafer esetshenziswe ekusetshenzisweni kokugcina. I-diameter yenduku edingekayo ingatholakala ngokugoqa ububanzi obungaphandle.

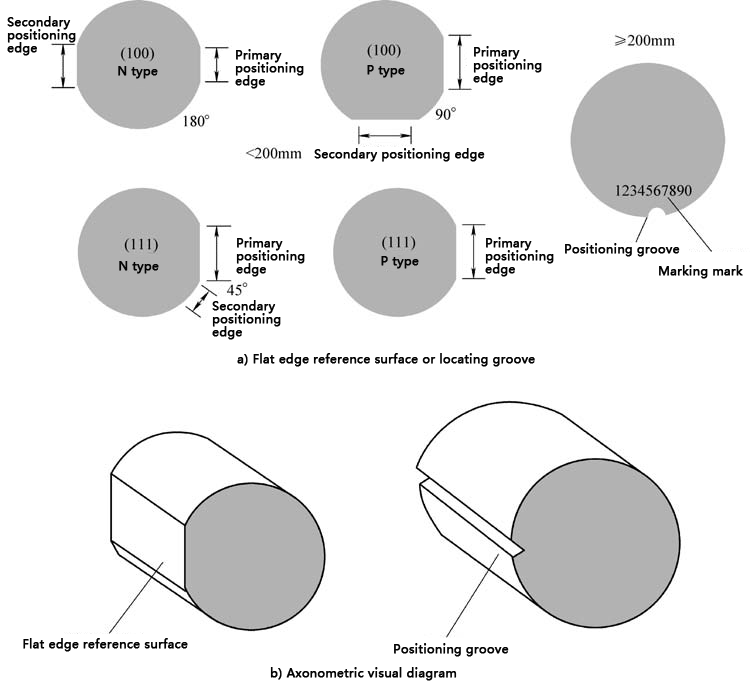

Umshini wokugaya unomsebenzi wokugaya indawo yereferensi yonqenqema oluyisicaba noma umsele wokumisa we-silicon single crystal rod, okungukuthi, ukwenza ukuhlola okuqondisayo entweni eyodwa yekristalu enobubanzi obudingekayo. Emshinini ofanayo wokugaya, indawo eyireferensi yonqenqema oluyisicaba noma umsele wokuma wenduku eyodwa yekristalu iphansi. Ngokuvamile, izinti zekristalu eyodwa ezinobubanzi obungaphansi kuka-200mm zisebenzisa izindawo eziyisithenjwa zonqenqema oluyisicaba, nezinduku zekristalu eyodwa ezinobubanzi obungu-200mm nangaphezulu zisebenzisa imisele yokubeka indawo. Izinduku zekristalu eyodwa ezinobubanzi obungu-200mm nazo zingenziwa zibe nereferensi yonqenqema oluyisicaba njengoba kudingeka. Inhloso yendawo yereferensi ye-crystal rod eyodwa ukuhlangabezana nezidingo zokusebenza kokuma okuzenzakalelayo kwemishini yenqubo ekukhiqizeni isekethe edidiyelwe; ukukhombisa i-crystal orientation kanye nohlobo lwe-conductivity ye-silicon wafer, njll., ukwenza lula ukuphathwa kokukhiqiza; unqenqema lokuma oluyinhloko noma i-groove yokuma i-perpendicular <110> isiqondiso. Ngesikhathi senqubo yokupakisha i-chip, inqubo yokudayela ingabangela ukuqhekeka kwemvelo kwe-wafer, futhi ukuma kungavimbela ukukhiqizwa kwezingcezu.

Izinjongo eziyinhloko zenqubo yokuqoqa zihlanganisa: Ukuthuthukisa ikhwalithi yendawo engaphezulu: Ukuzungeza kungasusa ama-burrs nokungalingani ebusweni bama-wafers e-silicon futhi kuthuthukise ukushelela kwangaphezulu kwama-silicon wafers, okubaluleke kakhulu kwizinqubo ezilandelayo ze-photolithography kanye ne-etching. Ukunciphisa ingcindezi: Ingcindezi ingadalwa ngesikhathi sokusikwa nokucubungula ama-wafers e-silicon. Ukuzungeza kungasiza ukukhulula lezi zingcindezi futhi kuvimbele ama-wafers e-silicon ukuthi angaphuki ezinqubweni ezilandelayo. Ukuthuthukisa amandla omshini wama-wafers e-silicon: Ngesikhathi senqubo yokuzungeza, imiphetho yama-wafers e-silicon izoba bushelelezi, okusiza ukuthuthukisa amandla omshini wama-silicon wafers nokunciphisa umonakalo ngesikhathi sokuhamba nokusetshenziswa. Ukuqinisekisa ukunemba kwe-dimensional: Ngokuzungezisa, ukunemba kwe-dimensional kwama-silicon wafers kungaqinisekiswa, okubalulekile ekwenzeni amadivaysi e-semiconductor. Ukuthuthukisa izakhiwo zikagesi zama-silicon wafers: Ukucutshungulwa konqenqema kwama-silicon wafers kunethonya elibalulekile ezintweni zabo zikagesi. Ukuzungeza kungathuthukisa izakhiwo zikagesi zamawafa e-silicon, njengokunciphisa ukuvuza kwamanje. I-Aesthetics: Amaphethelo ama-wafers e-silicon ashelelayo futhi mahle kakhulu ngemva kokugoqwa, okudingekayo futhi ezimweni ezithile zohlelo lokusebenza.

Isikhathi sokuthumela: Jul-30-2024