I-Silicon carbide iwuhlobo olusha lwe-ceramics olusebenza ngezindleko eziphakeme kanye nezakhiwo ezinhle kakhulu zezinto ezibonakalayo. Ngenxa yezici ezinjengamandla aphezulu nobulukhuni, ukumelana nokushisa okuphezulu, ukuguquguquka okukhulu kokushisa kanye nokumelana nokubola kwamakhemikhali, i-Silicon Carbide icishe imelane nayo yonke into yamakhemikhali. Ngakho-ke, i-SiC isetshenziswa kakhulu ezimayini zikawoyela, amakhemikhali, imishini kanye ne-airspace, ngisho namandla enuzi kanye nezempi banezidingo zabo ezikhethekile ku-SIC. Olunye uhlelo olujwayelekile esingalunikeza izindandatho zophawu lwepompo, i-valve nezikhali zokuzivikela njll.

Siyakwazi ukuklama nokwenza ngokuvumelana nobukhulu bakho obuthile ngekhwalithi enhle nesikhathi sokuletha esinengqondo.

I-non-pressure sintered silicon carbide roller, i-atmospheric pressure sintered silicon carbide ceramic products, ukusetshenziswa kwe-high purity ultra-fine silicon carbide powder, efakwe ku-2450℃ izinga lokushisa eliphezulu, okuqukethwe kwe-silicon carbide okungaphezu kuka-99.1%, ukuminyana komkhiqizo ≥3.10g/ cm3, akukho ukungcola kwensimbi okufana ne-silicon yensimbi.

► Okuqukethwe kwe-silicon carbide --≥99%;

► Ukumelana nokushisa okuphezulu - ukusetshenziswa okujwayelekile ku-1800 ℃;

► High conductivity ezishisayo - kuqhathaniswa conductivity ezishisayo of graphite materials;

► Ukuqina okuphezulu - ubulukhuni okwesibili kuphela kwedayimane, i-cubic boron nitride;

► Ukumelana nokugqwala - i-asidi eqinile ne-alkali ayinakho ukugqwala, ukumelana nokugqwala kungcono kune-tungsten carbide ne-alumina;

► Isisindo esilula - ukuminyana 3.10g/cm3, eduze ne-aluminium;

► Akukho ukuguqulwa - i-coefficient encane kakhulu yokwandisa ukushisa;

► Ukumelana nokushaqeka kwe-thermal - impahla ingamelana nezinguquko zokushisa ezisheshayo, ukumelana nokushisa okushisayo, ukumelana nokubanda nokushisa, ukusebenza okuzinzile.

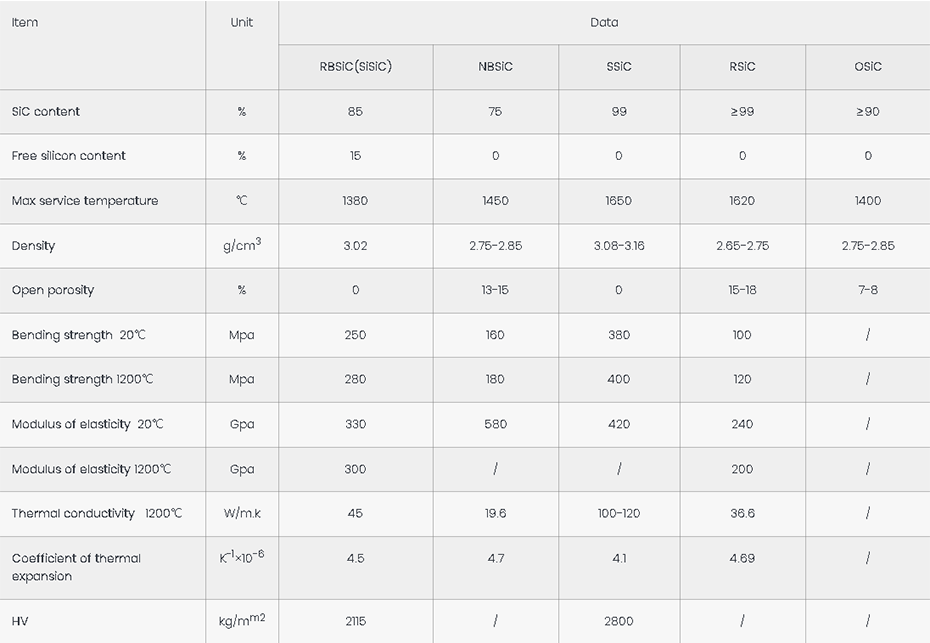

Amapharamitha wobuchwepheshe:

-

Ukuhlanzeka okuphezulu kwe-CVD Silicon Carbide impahla eluhlaza

-

I-silico ukumelana nokugqwala kanye nezinga lokushisa eliphezulu...

-

I-Silicon Carbide Pump Shafts

-

Izindandatho zeSilicon Carbide Mechanical Seal

-

Izinga lokushisa eliphezulu le-Silicon ye-Pressureless Sintered ...

-

I-Silicon Carbide Gas Sealing Rings