I-Semicera Special Graphite - Ehola Ikusasa Lezinto Ezithuthukile

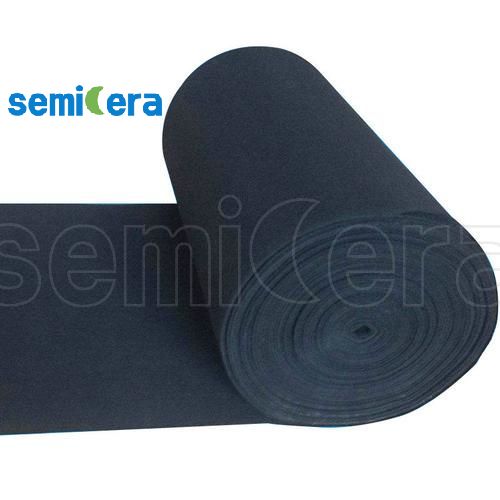

I-Semicera ingumholi womhlaba wonke ekukhiqizweni kwe-graphite ekhethekile, ezinikele ekuhlinzekeni imikhiqizo ye-graphite esebenza kahle kakhulu, enokwethenjelwa kakhulu kuzo zonke izimboni ezihlukahlukene. Eyethuisotropic graphiteubuchwepheshe, kanye nezakhiwo zabo ezivelele kanye nohlu olubanzi lwezinhlelo zokusebenza, buzuze ukuqashelwa kumakhasimende emhlabeni jikelele. Sinikeza izixazululo ezihambisanayo ukuhlangabezana nezidingo eziguqukayo zemakethe.

Izici ezihlukile ze-Special Graphite

Njengoba isidingo sezinto zekhabhoni ezinzile futhi ecolisisiwe sikhula, i-Semicera ibihamba phambili ekusunguleni izinto ezintsha, ithuthukisa i-isotropic graphite yekhwalithi ephezulu. UkusebenzisaI-Cold Isostatic Pressing (CIP)ubuchwepheshe, sicindezela izinhlayiya ezinosayizi we-micron zibe izakhiwo ze-graphite ezinembayo, okuholela ezintweni ezikhethekile ze-graphite ezisebenza kahle kakhulu. Imikhiqizo yethu ekhethekile ye-graphite isetshenziswa kabanzi ezimbonini zonkana, okuhlanganisa ama-semiconductors, amandla avumela imvelo, nokubumba okunembayo, okubonisa izinzuzo zayo ezingenakuqhathaniswa.

Izici Eziyinhloko:

▪Izakhiwo ezivelele ze-Isotropic

I-graphite ye-Isotropic ibonisa izici ezifanayo zomzimba namakhemikhali kuzo zonke izinhlangothi, okwenza kube lula ukuyiklama nokusebenzisa. Lesi sakhiwo sandisa ukusetshenziswa kwayo emikhakheni enembayo ephezulu.

▪Ukuthembeka okuphezulu

Isakhiwo sezinhlayiyana ezincane ze-graphite ye-isotropic senza sibe namandla kune-graphite evamile, ngokuhlukahluka okuncane kwempahla, ukuqinisekisa ukuzinza nokuthembeka ezindaweni ezidinga kakhulu.

▪Ukumelana Nokushisa Okuphezulu

Ezindaweni ezizungezile, i-graphite ye-isotropic ingasetshenziswa ngokuzinza emazingeni okushisa aphezulu kakhulu angaphezu kuka-2000℃. Ine-coefficient ephansi yokwandisa okushisayo kanye ne-conductivity ephezulu ye-thermal, ehlinzeka ngokumelana nokushaqeka okuhle kakhulu kwe-thermal kanye nezakhiwo zokusabalalisa ukushisa.

▪Kuhle Kakhulu Kagesi Conductivity

Ngenxa yokumelana nokushisa okuphezulu, i-graphite iyinto efanelekile yezinhlelo zokusebenza ezifana nezifudumezi zokushisa okuphezulu nezinye izinhlelo zokusebenza zikagesi ezinamandla amakhulu.

▪Ukuzinza Kwamakhemikhali

I-Isotropic graphite izinzile kumakhemikhali, imelana nokugqwala ezindaweni eziningi, ngaphandle kwamanye ama-oxidizing agents aqinile.

▪Ingasindi futhi Kulula Ukuwusebenzisa Umshini

Ngokuminyana kwenqwaba ephansi uma kuqhathaniswa nezinto zensimbi, i-graphite ivumela ukwakheka okungasindi. Iphinde ibe nokuhleleka okuhle kakhulu, yenza kube lula izinqubo zokubumba ezinembayo.

Izicelo Ze-Special Graphite

Imikhiqizo ekhethekile ye-graphite ye-Semicera isetshenziswa kabanzi ezimbonini ezahlukahlukene ezibalulekile empilweni yesimanje.

1. Imboni Yezemvelo Namandla:

▪Ukukhiqiza Amaseli eSolar kanye ne-Wafer: Embonini ye-photovoltaic, i-Semicera inikeza izinto eziphezulu zokusebenza ze-graphite ezisetshenziselwa inqubo yokukhiqiza amaseli elanga nama-wafers.

▪I-Fluorine ElectrolysisfuthiFuel Cells: Izinto zethu ze-graphite zisetshenziselwa i-electrolysis ephezulu yokushisa kanye nezicelo zamaseli kaphethiloli, zinikeza ukumelana nokushisa okuhle kakhulu nokumelana nokugqwala.

▪I-Polycrystalline kanye ne-Single Crystal Silicon Manufacturing: Embonini ye-semiconductor, imikhiqizo ye-graphite ye-Semicera isetshenziselwa ukukhiqizwa kwe-polycrystalline ephezulu yokuhlanzeka kanye ne-silicon eyodwa ye-crystal, iqinisekisa ukunemba kanye nekhwalithi ephezulu.

▪Ukwenziwa Kwe-LED Emhlophe: I-Graphite ye-thermal conductivity enhle kakhulu iyenza ibe yinto ekahle yokupakishwa kwe-LED nokukhipha ukushisa.

▪I-Precision Mold Processing: Izinto ze-graphite ze-Semicera zisetshenziswa kabanzi ekukhiqizeni isikhunta ngokunemba, ikakhulukazi ku-Electrical Discharge Machining (EDM), lapho ukunemba okuphezulu kubaluleke kakhulu.

▪Imboni Furnaces: Isetshenziswa ezindaweni ezinezinga lokushisa eliphezulu njengeziko lokusansimbi nokucutshungulwa kwezinto.

▪Ukusakaza Okuqhubekayo Kuyafa: Izinto zethu ze-graphite zisetshenziselwa ukukhishwa okuqhubekayo kokufa kwama-alloys ethusi, ama-alloys e-aluminium, nezinye izinsimbi.

2. Imboni ye-semiconductor:

▪I-Polycrystalline kanye ne-Single Crystal Silicon Manufacturing: Embonini ye-semiconductor, imikhiqizo ye-graphite ye-Semicera isetshenziselwa ukukhiqizwa kwe-polycrystalline ephezulu yokuhlanzeka kanye ne-silicon eyodwa ye-crystal, iqinisekisa ukunemba kanye nekhwalithi ephezulu.

▪Ukwenziwa Kwe-LED Emhlophe: I-Graphite ye-thermal conductivity enhle kakhulu iyenza ibe yinto ekahle yokupakishwa kwe-LED nokukhipha ukushisa.

3. Imboni yokubumba:

▪I-Precision Mold Processing: Izinto ze-graphite ze-Semicera zisetshenziswa kabanzi ekukhiqizeni isikhunta ngokunemba, ikakhulukazi ku-Electrical Discharge Machining (EDM), lapho ukunemba okuphezulu kubaluleke kakhulu.

4. Ezinye izinhlelo zokusebenza:

▪Imboni Furnaces: Isetshenziswa ezindaweni ezinezinga lokushisa eliphezulu njengeziko lokusansimbi nokucutshungulwa kwezinto.

▪Ukusakaza Okuqhubekayo Kuyafa: Izinto zethu ze-graphite zisetshenziselwa ukukhishwa okuqhubekayo kokufa kwama-alloys ethusi, ama-alloys e-aluminium, nezinye izinsimbi.

Kungani Khetha i-Semicera?

Njengomholi wemboni ekukhiqizeni okukhethekile kwe-graphite, i-Semicera ineminyaka yobungcweti bezobuchwepheshe kanye nesipiliyoni sembonini. Sisebenzisa izinqubo ezithuthukisiwe zokukhiqiza ukuletha izixazululo zekhwalithi ephezulu, ezenziwe ngezifiso kumakhasimende ethu. Noma ngabe okokukhiqiza okunemba okuphezulu kwe-semiconductor noma izinhlelo zokusebenza zezimboni ezinezinga eliphezulu lokushisa, imikhiqizo ye-graphite ekhethekile ye-Semicera inikeza ukwesekwa okuthembekile okudingwa yibhizinisi lakho.