I-Semicerayethula izinga layo eliphezuluI-Epitaxyamasevisi, aklanyelwe ukuhlangabezana nezindinganiso eziqondile zomkhakha wanamuhla we-semiconductor. Izendlalelo ze-silicon ye-Epitaxial zibalulekile ekusebenzeni nasekuthembekeni kwemishini kagesi, futhi izixazululo zethu ze-Si Epitaxy ziqinisekisa ukuthi izingxenye zakho zithola ukusebenza kahle.

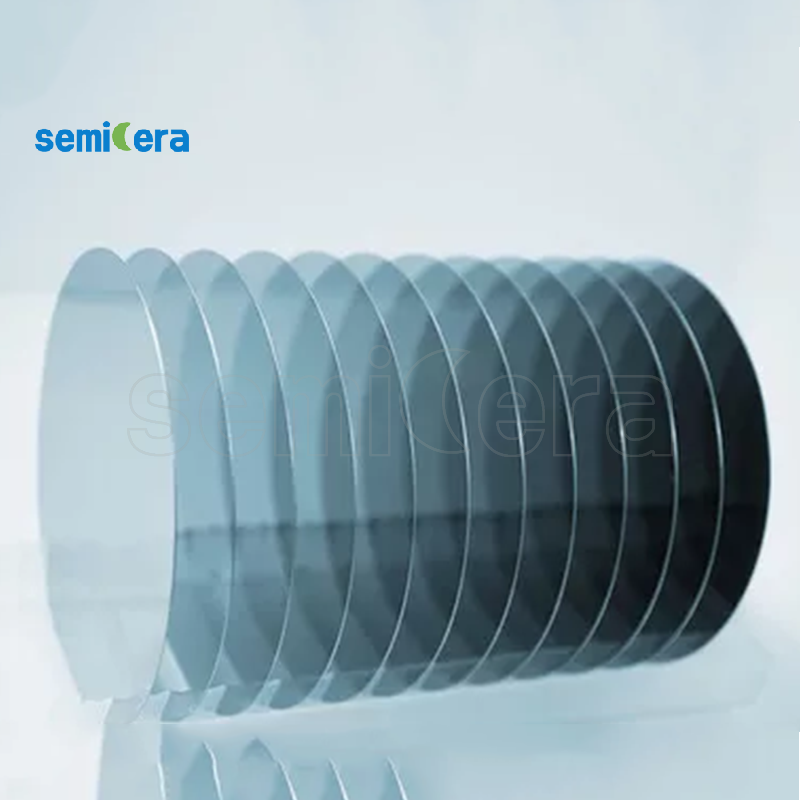

Izendlalelo zeSilicon Ezikhule Ngokunemba I-Semicerauyaqonda ukuthi isisekelo samadivayisi asebenza kahle silele kwikhwalithi yezinto ezisetshenziswayo. EyethuI-Epitaxyinqubo ilawulwa ngokucophelela ukuze ikhiqize izendlalelo ze-silicon ezinokufana okuyingqayizivele nobuqotho bekristalu. Lezi zendlalelo zibalulekile ezinhlelweni zokusebenza ezisukela kuma-microelectronics kuya kumadivayisi kagesi athuthukile, lapho ukuvumelana nokuthembeka kubaluleke kakhulu.

Ilungiselelwe Ukusebenza KwedivayisiII-Epitaxyamasevisi ahlinzekwa i-Semicera enzelwe ukuthuthukisa izici zikagesi zamadivayisi akho. Ngokukhulisa izendlalelo ze-silicon ezihlanzeke kakhulu ezinokuminyana okuncane, siqinisekisa ukuthi izingxenye zakho zisebenza kahle kakhulu, ngokuhamba okuthuthukisiwe kwenkampani yenethiwekhi kanye nokuncishiswa ukumelana nogesi. Lokhu kulungiselelwa kubalulekile ukuze kuzuzwe izici zejubane eliphezulu nezisebenza kahle kakhulu ezifunwa ubuchwepheshe besimanje.

Ukuhlukahluka Kwezinhlelo Zokusebenza I-Semicera'sI-Epitaxyilungele uhla olubanzi lwezinhlelo zokusebenza, okuhlanganisa ukukhiqizwa kwama-CMOS transistors, amandla e-MOSFET, nama-bipolar junction transistors. Inqubo yethu eguquguqukayo ivumela ukwenziwa ngendlela oyifisayo ngokusekelwe ezindingweni ezithile zephrojekthi yakho, noma ngabe udinga izendlalelo ezincane zezinhlelo zokusebenza zefrikhwensi ephezulu noma izendlalelo eziwugqinsi zamadivayisi kagesi.

Ikhwalithi Yezinto EziphakemeIkhwalithi isenhliziyweni yakho konke esikwenzayo kwa-Semicera. EyethuI-Epitaxyinqubo isebenzisa imishini yesimanje nezindlela zokuqinisekisa ukuthi ungqimba lwe-silicon ngalunye luhlangabezana nezindinganiso eziphakeme kakhulu zokuhlanzeka nobuqotho besakhiwo. Lokhu kunakekela emininingwaneni kunciphisa ukuvela kweziphambeko ezingase zibe nomthelela ekusebenzeni kwedivayisi, okuholela ezingxenyeni ezithembeke kakhulu nezihlala isikhathi eside.

Ukuzibophezela Ekusungulweni Okusha I-Semicerauzibophezele ngokuhlala eqhulwini kubuchwepheshe be-semiconductor. EyethuI-Epitaxyamasevisi abonisa lokhu kuzibophezela, okufaka intuthuko yakamuva kumasu okukhula kwe-epitaxial. Sihlala sicwenga izinqubo zethu ukuze silethe izendlalelo ze-silicon ezihlangabezana nezidingo eziguqukayo zemboni, siqinisekisa ukuthi imikhiqizo yakho ihlala inokuncintisana emakethe.

Izixazululo Ezihlanganisiwe Zezidingo ZakhoUkuqonda ukuthi yonke iphrojekthi ihlukile,I-SemiceraIzipesheli ezenziwe ngokwezifisoI-Epitaxyizixazululo ezihambisana nezidingo zakho ezithile. Kungakhathaliseki ukuthi udinga amaphrofayili athile e-doping, ukujiya kwezingqimba, noma ukuqedwa kwendawo, ithimba lethu lisebenza eduze nawe ukuletha umkhiqizo ohlangabezana nezimfuneko zakho ezinembile.

| Izinto | Ukukhiqiza | Ucwaningo | Dummy |

| I-Crystal Parameters | |||

| I-Polytype | 4H | ||

| Iphutha lokuma kobuso | <11-20 >4±0.15° | ||

| Amapharamitha kagesi | |||

| I-Dopant | n-uhlobo lweNitrojeni | ||

| Ukungazweli | 0.015-0.025ohm · cm | ||

| Mechanical Parameters | |||

| Ububanzi | 150.0±0.2mm | ||

| Ubukhulu | 350±25 μm | ||

| Umumo oyisicaba oyinhloko | [1-100]±5° | ||

| Ubude obuyisicaba obuyisisekelo | 47.5±1.5mm | ||

| Ifulethi lesibili | Lutho | ||

| I-TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| I-LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Khothama | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| I-Wap | ≤35 μm | ≤45 μm | ≤55 μm |

| Front(Si-face) roughness(AFM) | I-Ra≤0.2nm (5μm*5μm) | ||

| Isakhiwo | |||

| Ukuminyana kwe-Micropipe | <1 eya/cm2 | <10 kwe/cm2 | <15 kwe/cm2 |

| Ukungcola kwensimbi | ≤5E10 ama-athomu/cm2 | NA | |

| I-BPD | ≤1500 i-e/cm2 | ≤3000 i-e/cm2 | NA |

| I-TSD | ≤500 i-e/cm2 | ≤1000 i-e/cm2 | NA |

| Ikhwalithi Yangaphambili | |||

| Ngaphambili | Si | ||

| Ukuqedwa kobuso | I-Si-face CMP | ||

| Izinhlayiya | ≤60ea/wafer (usayizi≥0.3μm) | NA | |

| Ukuklwebheka | ≤5ea/mm. Ubude obuqongelelwe ≤Ububanzi | Ubude obuqongelelwe≤2*Ububanzi | NA |

| Ikhasi eliwolintshi/imigodi/amabala/imifantu/ukungcola | Lutho | NA | |

| Ama-Edge chips/indents/fracture/hex plate | Lutho | ||

| Izindawo ze-Polytype | Lutho | Indawo eqoqiwe≤20% | Indawo eqoqiwe≤30% |

| Ukumaka kwe-laser yangaphambili | Lutho | ||

| Ikhwalithi Emuva | |||

| Emuva ekupheleni | C-face CMP | ||

| Ukuklwebheka | ≤5ea/mm, Ubude obuqongelelayo≤2*Ububanzi | NA | |

| Ukukhubazeka kwasemuva (ama-edge chips/indents) | Lutho | ||

| Ukuhwalala emuva | I-Ra≤0.2nm (5μm*5μm) | ||

| Ukumaka kwe-laser emuva | 1 mm (kusuka emaphethelweni aphezulu) | ||

| Umphetho | |||

| Umphetho | I-Chamfer | ||

| Ukupakisha | |||

| Ukupakisha | I-Epi-ilungele ukupakishwa kwe-vacuum Ukupakishwa kwamakhasethi ama-wafer amaningi | ||

| *Amanothi: "NA" kusho ukuthi asikho isicelo Izinto ezingashiwongo zingabhekisa ku-SEMI-STD. | |||