Amarola e-ceramic e-SiC anokumelana okuhle kakhulu nokugqokwa futhi angakwazi ukumelana nokucindezela okuphezulu nokungqubuzana ngaphandle kokulahlekelwa ikhwalithi ephezulu. Ukuqina kwayo kuseduze nokwedayimane, okwenza kube lula ukunciphisa ukugqoka kokuxhumana nezinto zensimbi futhi kwandise impilo yesevisi ye-roller. I-coefficient ephansi ye-friction ye-SiC ceramic rollers nayo inciphisa ukulahlekelwa kwamandla nokukhiqizwa kokushisa, ithuthukise ukusebenza kahle kokukhiqiza.

Ngaphezu kwalokho, ama-roller e-ceramic e-SiC anokumelana okuhle kakhulu nokushisa okuphezulu. Ingasebenza ngokuzinzile ezindaweni zokushisa okuphezulu ngaphandle kokuthambisa noma ukubola. Lokhu kwenza ama-roller e-ceramic e-SiC afaneleke kakhulu ezinkambisweni zokucubungula izinga lokushisa eliphezulu njengokuginqika okushisayo kwensimbi nokusakazwa okuqhubekayo, okuqinisekisa ukuthi ama-roller agcina ukusebenza okuhle kakhulu nokuzinza kwe-dimensional ngaphansi kwamazinga okushisa aphezulu.

Amarola e-ceramic e-SiC nawo anokumelana nokugqwala okuhle kakhulu. Ingakwazi ukumelana nokuguguleka kwamakhemikhali anjengama-asidi, ama-alkali, izinyibilikisi namagesi abolayo, igcine isiphetho esingaphezulu nokusebenza kwamarola. Lokhu kwenza amarola e-ceramic e-SiC asebenze kahle ezinhlelweni ezifana nokucutshungulwa kwamakhemikhali kanye ne-electroplating, andise impilo yesevisi yemishini kanye nokwenza ngcono izinga lokukhiqiza.

Izici ezingasindi zama-SiC ceramic rollers ziwanikeza izici ezinhle kakhulu ze-inertial namandla okunciphisa ukudlidliza, ngaleyo ndlela anciphise ukudlidliza nomsindo, athuthukise ukuqina kwemishini kanye nokunethezeka kokusebenza. Ubukhulu bayo obunembile kanye nendawo eyisicaba kuqinisekisa ukuzinza kwe-roller nokushelela, kuhlinzeka ngemiphumela emihle kakhulu yezinqubo zensimbi nokunyathelisa.

I-non-pressure sintered silicon carbide roller, i-atmospheric pressure sintered silicon carbide ceramic products, ukusetshenziswa kwe-high purity ultra-fine silicon carbide powder, efakwe ku-2450℃ izinga lokushisa eliphezulu, okuqukethwe kwe-silicon carbide okungaphezu kuka-99.1%, ukuminyana komkhiqizo ≥3.10g/ cm3, akukho ukungcola kwensimbi okufana ne-silicon yensimbi.

► Okuqukethwe kwe-silicon carbide --≥99%;

► Ukumelana nokushisa okuphezulu - ukusetshenziswa okujwayelekile ku-1800 ℃;

► High conductivity ezishisayo - kuqhathaniswa conductivity ezishisayo of graphite materials;

► Ukuqina okuphezulu - ubulukhuni okwesibili kuphela kwedayimane, i-cubic boron nitride;

► Ukumelana nokugqwala - i-asidi eqinile ne-alkali ayinakho ukugqwala, ukumelana nokugqwala kungcono kune-tungsten carbide ne-alumina;

► Isisindo esilula - ukuminyana 3.10g/cm3, eduze ne-aluminium;

► Akukho ukuguqulwa - i-coefficient encane kakhulu yokwandisa ukushisa;

► Ukumelana nokushaqeka kwe-thermal - impahla ingamelana nezinguquko zokushisa ezisheshayo, ukumelana nokushisa okushisayo, ukumelana nokubanda nokushisa, ukusebenza okuzinzile.

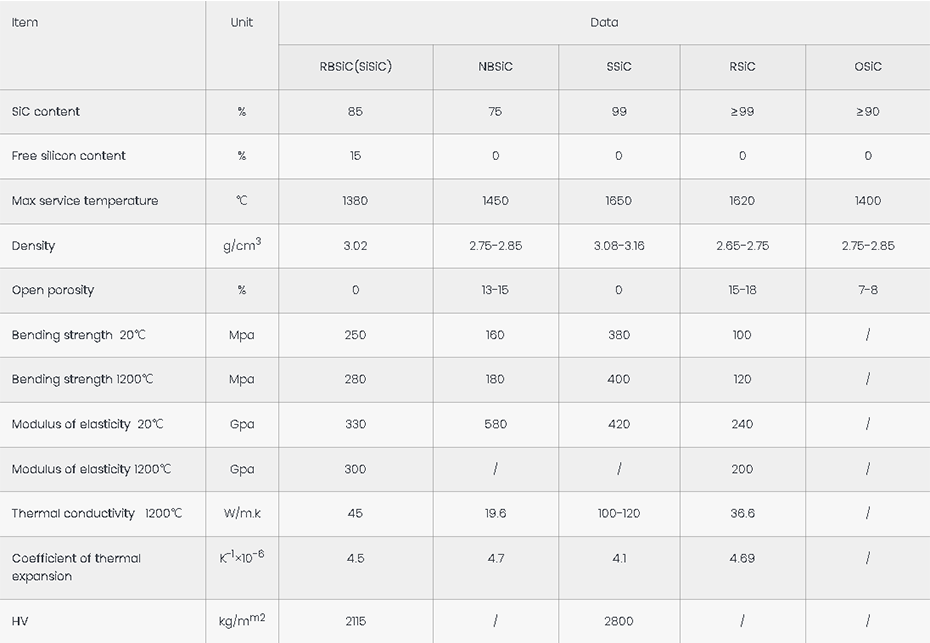

Amapharamitha wobuchwepheshe: