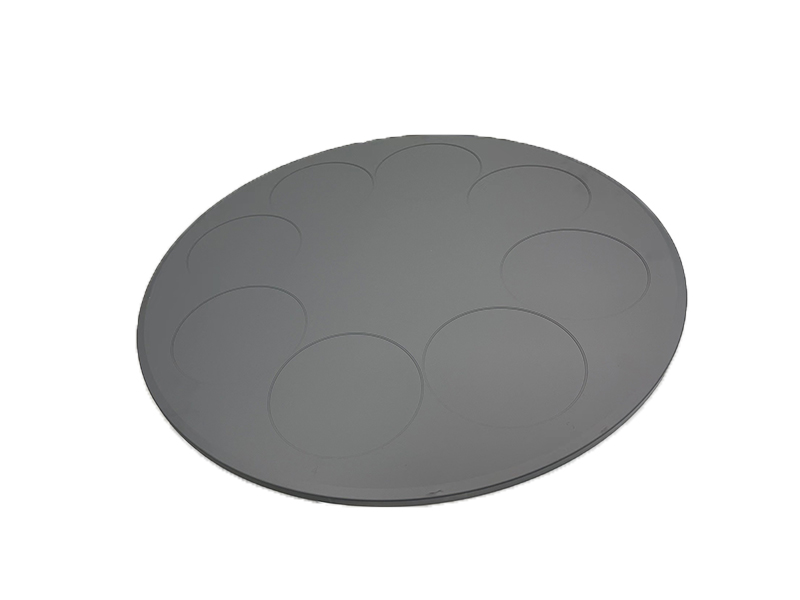

I-Semicera izimeleIngxenye yeSiC Ceramic Sealyakhelwe ukuhlangabezana namazinga aphezulu okukhiqizwa kwe-semiconductor yesimanje. Le ngxenye yokuvala isebenzisa ukusebenza okuphezului-silicon carbide (SiC)impahla enokumelana okuhle kakhulu nokuqina kwamakhemikhali ukuze kuqinisekiswe ukusebenza okuhle kakhulu kokuvala ezindaweni ezidlulele. Kuhlanganiswe nei-aluminium oxide (Al2O3)futhii-silicon nitride (Si3N4), le ngxenye isebenza kahle ekusetshenzisweni kwezinga lokushisa eliphezulu futhi ingavimbela ngokuphumelelayo ukuvuza kwegesi noketshezi.

Uma isetshenziswa kanye nemishini efanaizikebhe ezilucwecwekanye nabathwali be-wafer, i-Semicera'sIngxenye yeSiC Ceramic Sealingathuthukisa kakhulu ukusebenza kahle nokuthembeka kohlelo lonke. Ukumelana kwayo nezinga lokushisa okuphakeme nokumelana nokugqwala kuyenza ibe yingxenye ebaluleke kakhulu ekukhiqizeni i-semiconductor enembayo ephezulu, eqinisekisa ukuzinza nokuphepha phakathi nenqubo yokukhiqiza.

Ngaphezu kwalokho, ukuklanywa kwale ngxenye yokubeka uphawu kwenziwe ngokucophelela ukuze kuqinisekiswe ukuhambisana nemishini ehlukahlukene, okwenza kube lula ukuyisebenzisa emigqeni ehlukene yokukhiqiza. Ithimba le-R&D le-Semicera liyaqhubeka nokusebenza kanzima ukuze likhuthaze ukuqanjwa kabusha kwezobuchwepheshe ukuze kuqinisekiswe ukuncintisana kwemikhiqizo yalo embonini.

Ukukhetha i-Semicera'sIngxenye yeSiC Ceramic Seal, uzothola inhlanganisela yokusebenza okuphezulu nokuthembeka, okukusiza ukufeza izinqubo zokukhiqiza ezisebenza kahle kakhulu kanye nekhwalithi yomkhiqizo omuhle kakhulu. I-Semicera ihlale izibophezele ekunikezeni amakhasimende izixazululo nezinsizakalo ezingcono kakhulu ze-semiconductor ukukhuthaza ukuthuthukiswa okuqhubekayo kanye nenqubekela phambili yomkhakha.

✓Ikhwalithi ephezulu emakethe yaseChina

✓Isevisi enhle njalo kuwe, amahora angu-7*24

✓Idethi emfishane yokulethwa

✓I-MOQ encane yamukelekile futhi yamukelwe

✓Amasevisi angokwezifiso

I-Epitaxy Growth Susceptor

Amawafa e-silicon/silicon carbide adinga ukudlula ezinqubweni eziningi okufanele asetshenziswe kumishini kagesi. Inqubo ebalulekile i-silicon/sic epitaxy, lapho amawafa e-silicon/sic athwalwa khona ngesisekelo segraphite. Izinzuzo ezikhethekile ze-Semicera's silicone carbide-coated graphite base zifaka ukuhlanzeka okuphezulu kakhulu, ukunamathela okufanayo, nempilo yesevisi ende kakhulu. Futhi banokuphikiswa okuphezulu kwamakhemikhali kanye nokuzinza kokushisa.

Ukukhiqizwa kwe-chip ye-LED

Ngesikhathi sokumbozwa okubanzi kwe-reactor ye-MOCVD, isisekelo seplanethi noma umthwali uhambisa i-wafer ye-substrate. Ukusebenza kwezinto eziyisisekelo kunethonya elikhulu kwikhwalithi yokugqoka, okubuye kuthinte izinga le-scrap ye-chip. Isisekelo esihlanganiswe ne-silicon carbide se-Semicera sinyusa ukusebenza kahle kokukhiqizwa kwamawafa e-LED ekhwalithi ephezulu futhi sinciphisa ukuchezuka kwamaza. Siphinde sinikeze izingxenye ezengeziwe ze-graphite zazo zonke iziphehlisi ze-MOCVD ezisetshenziswayo njengamanje. Singakwazi ukugqoka cishe noma iyiphi ingxenye nge-silicon carbide coating, noma ngabe ububanzi bengxenye bufika ku-1.5M, sisengakwazi ukugqoka nge-silicon carbide.

Inkambu yeSemiconductor, Inqubo Yokusabalalisa Kwe-oxidation, njll.

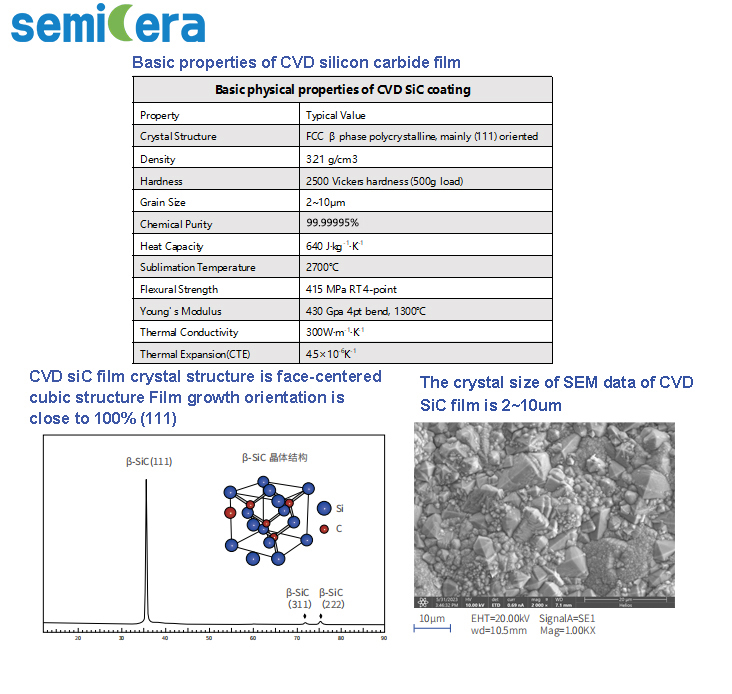

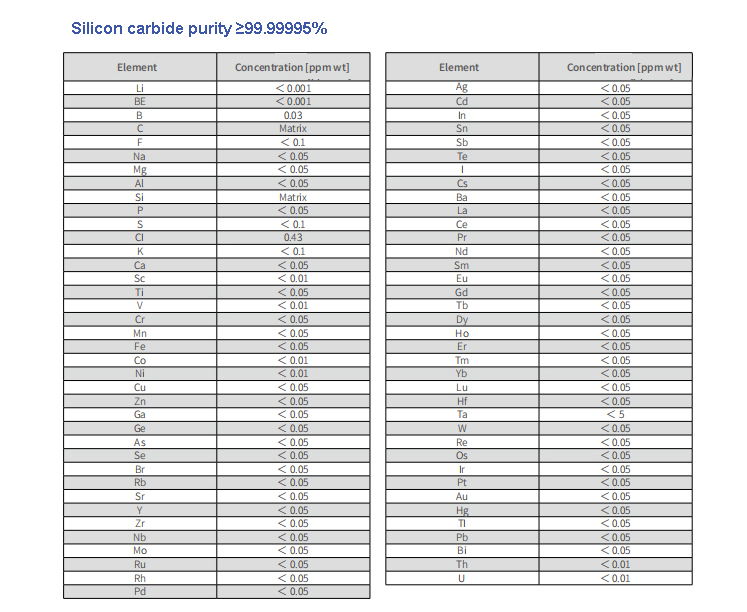

Enqubweni ye-semiconductor, inqubo yokunwetshwa kwe-oxidation idinga ukuhlanzeka okuphezulu komkhiqizo, futhi kwa-Semicera sinikeza inkambiso nezinsizakalo zokumboza ze-CVD zeningi lezingxenye ze-silicon carbide.

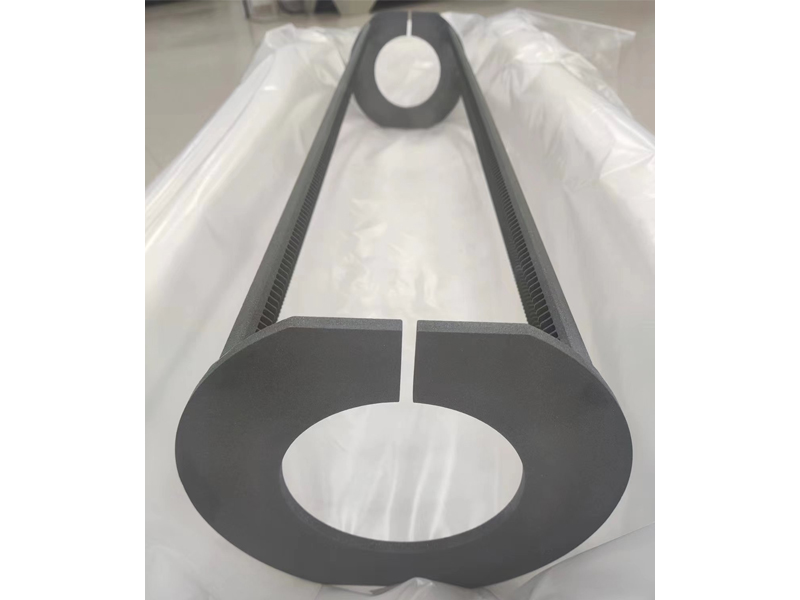

Isithombe esilandelayo sibonisa udaka lwe-silicon carbide olucutshungulwe kahle lwe-Semicea kanye neshubhu le-silicon carbide furnace elihlanzwa ku-1000-izingaengenalo uthuliigumbi. Abasebenzi bethu basebenza ngaphambi kokugqoka. Ukuhlanzeka kwe-silicon carbide yethu kungafinyelela ku-99.99%, futhi ubumsulwa be-sic coating bukhulu kuno-99.99995%.

I-Raw Silicon Carbide Paddle kanye ne-SiC Process Tube in Cleaing

I-Silicon Carbide Wafer Boat CVD SiC Coated

-

I-silicon carbide cera imelana nokushisa okuphezulu...

-

I-silico ukumelana nokugqwala kanye nezinga lokushisa eliphezulu...

-

I-High Wear Resistance Silicon Carbide Ceramic Li...

-

I-silicon carbide ceramic saggar ekwazi ukumelana nokugqwala

-

Izindandatho zokuvala ze-SiC

-

I-silicon carbide saggar ekwazi ukumelana nokugqoka okuphezulu