Incazelo

Sigcina ukubekezelelana okuseduze kakhulu lapho sifaka isiceloUkufakwa kwe-SiC, usebenzisa ukunemba okuphezulu ukuze uqinisekise iphrofayili ye-susceptor efanayo. Siphinde sikhiqize izinto ezinezakhiwo ezifanelekile zokumelana nogesi ukuze zisetshenziswe kumasistimu ashisayo ashisayo. Zonke izingxenye eziqediwe ziza nesitifiketi sokuhambisana nobumsulwa nesilinganiselo.

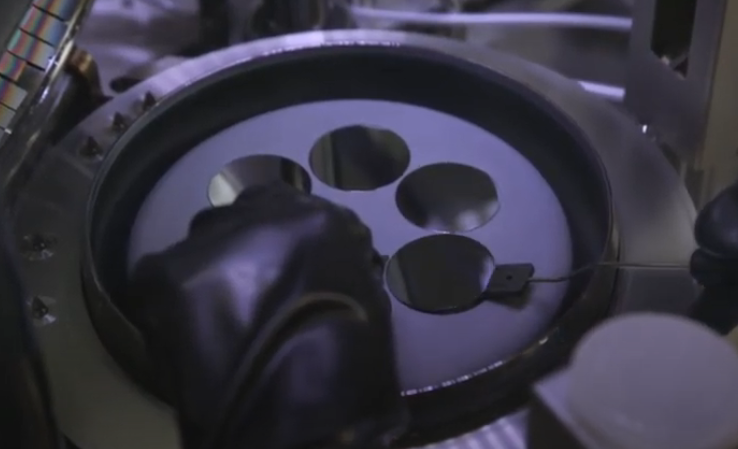

Inkampani yethu ihlinzekaUkufakwa kwe-SiCinqubo yezinsizakalo nge-CVD indlela ebusweni be-graphite, izitsha zobumba nezinye izinto, ukuze amagesi akhethekile aqukethe ikhabhoni ne-silicon asabele ekushiseni okuphezulu ukuze athole ukuhlanzeka okuphezulu kwama-molecule e-SiC, ama-molecule afakwe ebusweni bezinto eziboshwe, akha ungqimba lokuvikela lwe-SIC. I-SIC eyakhiwe ihlanganiswe ngokuqinile nesisekelo se-graphite, inikeze isisekelo se-graphite izakhiwo ezikhethekile, ngaleyo ndlela yenza ubuso be-graphite compact, i-Porosity-free, ukumelana nokushisa okuphezulu, ukumelana nokugqwala kanye nokumelana ne-oxidation.

Inqubo ye-CVD iletha ubumsulwa obuphezulu kakhulu kanye nokuminyana kwethiyoriUkufakwa kwe-SiCngaphandle kwe-porosity. Ngaphezu kwalokho, njengoba i-silicon carbide inzima kakhulu, ingapholishwa endaweni efana nesibuko.I-CVD silicon carbide (SiC) yokugqokailethe izinzuzo ezimbalwa ezihlanganisa i-ultra-high purity surface kanye nokuqina okugqokile okwedlulele. Njengoba imikhiqizo ehlanganisiwe isebenza kahle ku-vacuum ephezulu kanye nezimo zokushisa okuphezulu, ilungele ukusetshenziswa embonini ye-semiconductor nakwenye indawo ehlanzekile kakhulu. Siphinde sihlinzeke ngemikhiqizo ye-pyrolytic graphite (PG).

Izici Eziyinhloko

1. Ukumelana nokushisa okuphezulu kwe-oxidation:

ukumelana ne-oxidation kusekuhle kakhulu lapho izinga lokushisa liphezulu njenge-1600 C.

2. Ukuhlanzeka okuphezulu: okwenziwe yi-chemical vapor deposition ngaphansi kwesimo sokushisa okuphezulu kwe-chlorination.

3. Ukumelana nokuguguleka: ubulukhuni obuphezulu, indawo ehlangene, izinhlayiya ezinhle.

4. Ukumelana nokugqwala: i-asidi, i-alkali, usawoti kanye nama-organic reagents.

Ukucaciswa Okuyinhloko kwe-CVD-SIC Coatings

| I-SiC-CVD | ||

| Ukuminyana | (g/cc) | 3.21 |

| Amandla e-Flexural | (Mpa) | 470 |

| Ukunwetshwa kwe-thermal | (10-6/K) | 4 |

| I-Thermal conductivity | (W/mK) | 300 |

Isicelo

I-CVD silicon carbide coating isisetshenziswe ezimbonini ze-semiconductor kakade, njengethreyi ye-MOCVD, i-RTP ne-oxide etching chamber njengoba i-silicon nitride inokumelana nokushaqeka okukhulu okushisayo futhi ingamelana ne-plasma yamandla aphezulu.

-I-Silicon carbide isetshenziswa kabanzi ku-semiconductor kanye ne-coating.

Isicelo

Ikhono Lokuhlinzeka:

10000 Ucezu/Izingcezu Ngenyanga

Ukupakishwa Nokulethwa:

Ukupakisha:Ukupakisha Okujwayelekile & Okuqinile

Isikhwama sePoly + Ibhokisi + Ibhokisi + Iphalethi

Imbobo:

Ningbo/Shenzhen/Shanghai

Isikhathi esiholayo:

| Ubuningi(Izingcezu) | 1 - 1000 | > 1000 |

| Est. Isikhathi(izinsuku) | 30 | Kuzoxoxiswana |