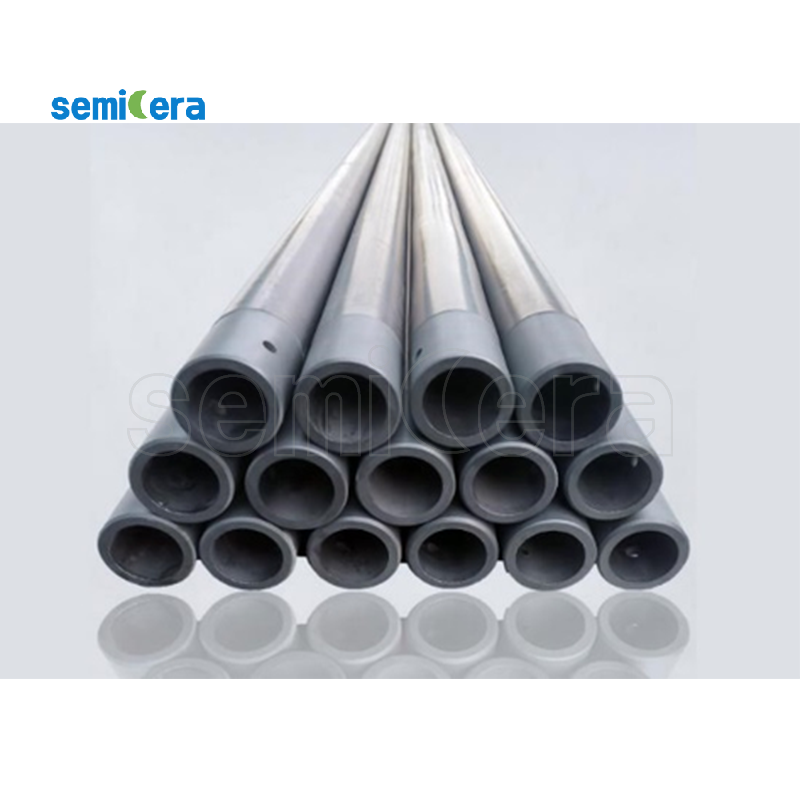

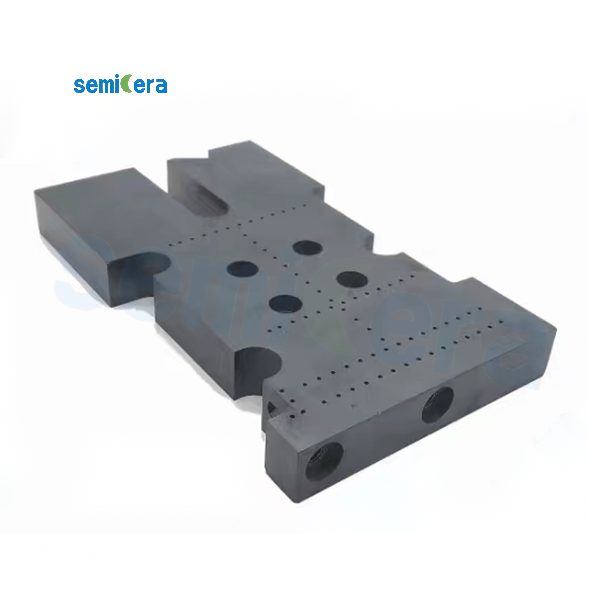

I-Silicon carbide ceramic mandrel iyisici esimise okwenduku esenziwe nge-silicon carbide ceramic material. I-Silicon carbide ceramic mandrel inezakhiwo ezinhle kakhulu zomzimba namakhemikhali futhi isetshenziswa kabanzi emikhakheni yezimboni ngaphansi kwamazinga okushisa aphezulu, ingcindezi ephezulu kanye nezindawo ezonakalisayo.

I-Silicon carbide iwuhlobo olusha lwe-ceramics olusebenza ngezindleko eziphakeme kanye nezakhiwo ezinhle kakhulu zezinto ezibonakalayo. Ngenxa yezici ezinjengamandla aphezulu nobulukhuni, ukumelana nokushisa okuphezulu, ukuguquguquka okukhulu kokushisa kanye nokumelana nokubola kwamakhemikhali, i-Silicon Carbide icishe imelane nayo yonke into yamakhemikhali. Ngakho-ke, i-SiC isetshenziswa kakhulu ezimayini zikawoyela, amakhemikhali, imishini kanye ne-airspace, ngisho namandla enuzi kanye nezempi banezidingo zabo ezikhethekile ku-SIC. Olunye uhlelo olujwayelekile esingalunikeza izindandatho zophawu lwepompo, i-valve nezikhali zokuzivikela njll.

Umumo nosayizi kungenziwa egcizelele ngokuvumelana nezidingo

Ukuqina okuphezulu kakhulu(HV10): 22.2(Gpa)

Ukuminyana okuphansi kakhulu (3.10-3.20 g/cm³)

Emazingeni okushisa afinyelela ku-1400 ℃, iSiC ingagcina amandla ayo

Ngenxa yokuqina kwayo kwamakhemikhali nokomzimba, i-SiC inobunzima obuphezulu nokumelana nokugqwala.

Izici eziyinhloko:

1. Ukuqina kokushisa okuphezulu: I-Silicon carbide ceramic mandrel ingagcina ukuqina kwesakhiwo sayo nokusebenza endaweni yokushisa ephezulu. Ingakwazi ukumelana namazinga okushisa aphakeme kakhulu futhi inokumelana nokushisa okuhle kakhulu, okulungele ukusetshenziswa ezinkambisweni zokushisa okuphezulu kanye nemishini.

2. Ukumelana nokugqwala: I-silicon carbide mandrel ye-ceramic inokumelana nokugqwala okuhle kakhulu futhi ingamelana nokuguguleka kwama-acids, ama-alkali, izinyibilikisi neminye imithombo yezindaba egqwalayo. Ngeke isabele ngamakhemikhali noma igqwale endaweni egqwalile, igcine ukusebenza kwayo kwasekuqaleni nokuzinza.

3. Ukumelana nokugqoka: I-silicon carbide mandrel ye-ceramic inobunzima obuphakeme kakhulu nokumelana nokugqoka, futhi ingagcina izinga eliphansi lokugqoka ngaphansi kwejubane eliphezulu nezimo zokungqubuzana okuphezulu. Lokhu kuyenza ibe nempilo ende kanye nokuthembeka endaweni yokugqoka enzima.

4. Ukusebenza okuhle kakhulu kwe-insulation: I-Silicon carbide mandrel ye-ceramic inokusebenza okuhle kokufakwa futhi inganikeza ukuvikelwa okuthembekile kokuvikela ngaphansi kwe-voltage ephezulu kanye nezimo eziphezulu zensimu kagesi. Isetshenziswa kabanzi emishinini yamandla kagesi aphezulu kanye nezingxenye zokufakelwa emikhakheni yamandla, ama-electronics kanye nama-semiconductors.

5. Amandla angasindi futhi aphezulu: Ama-mandrels e-silicon carbide ceramic anomthamo ophansi namandla aphezulu, futhi anezakhiwo ezinhle kakhulu zemishini. Ziyakwazi ukugoba okuphezulu namandla aqinile futhi zingamelana nokucindezela okuphezulu nokucindezeleka kwemishini.