Ukugaya i-disc iyithuluzi elibalulekile lenqubo yokukhiqiza ama-wafers e-silicon kumasekhethi ahlanganisiwe we-ultra-large embonini ye-semiconductor. I-cast cast iron noma i-carbon steel grinding disc evame ukusetshenziswa inempilo ephansi yesevisi kanye ne-coefficient enkulu yokwandisa okushisayo. Enqubweni yokucubungula ama-wafers e-silicon, ikakhulukazi enqubweni yokugaya ngesivinini esiphezulu noma ukupholishwa, ukuqina nokuhambisana kwama-silicon wafers kunzima ukuqinisekisa ngenxa yokuguga nokuguquka okushisayo kwediski yokugaya.

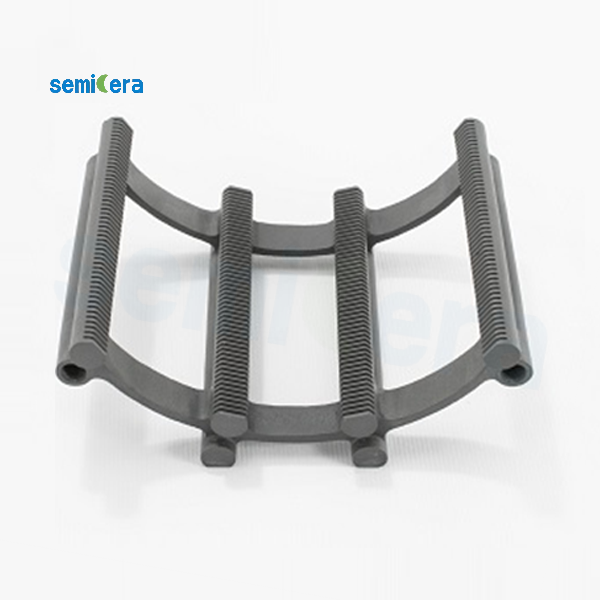

Idiski yokugaya ye-silicon carbide ceramic ingagaywa futhi ipholishwe ngesivinini esikhulu ngenxa yokuqina okuphezulu nokuguga okuncane kwediski yokugaya, futhi i-coefficient yokwandisa okushisayo ngokuyisisekelo iyafana naleyo ye-silicon wafer. Ikakhulukazi eminyakeni yakamuva, usayizi we-silicon wafer uya ngokuya uba mkhulu, obeka phambili izidingo eziphakeme zekhwalithi nokusebenza kahle kokugaya i-silicon wafer.

Ukusetshenziswa kwe-silicon carbide ceramic grinding disc kuzothuthukisa kakhulu ikhwalithi nokusebenza kahle kwe-silicon wafer grinding. Ngesikhathi esifanayo, i-silicon carbide ceramic grinding disk ingasetshenziswa futhi ukugaya nokupholisha indiza yezinye izinto ezifana ne-flake noma izinto zokuvimba. Ngokuthuthuka kwezimboni, ikakhulukazi ukuqaliswa kwezinga le-ISO14000 lamazwe ngamazwe, kuye kwabekwa izidingo eziphakeme zokuthuthwa koketshezi olungahambisani nokuvikelwa kwemvelo.

Esinye sezici ezibaluleke kakhulu ze-silicon carbide ceramics amandla ayo okushisa aphezulu, okungukuthi, amandla ngokuyisisekelo awancishisiwe kuma-degree angu-1600, futhi ukumelana ne-oxidation kuhle kakhulu, ngakho-ke kungasetshenziswa ezingxenyeni zokushisa eziphakeme zesakhiwo. Okufana nepuleti eliphezulu leziko lokushisa eliphezulu, ukusekela, nokuhlolwa kwezinga lokushisa eliphezulu.

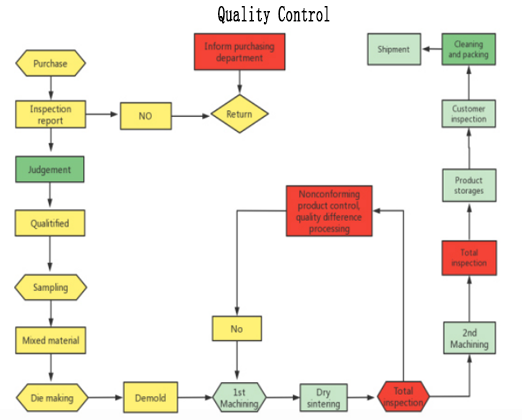

I-SemiceraI-Energy Technology Co., Ltd iwucwaningo lobungcweti, ukuthuthukiswa, ukukhiqizwa nokudayiswa kwemikhiqizo ye-silicon carbide ceramic.Kusukela yasungulwa ngo-2016,I-SemiceraAmandla aphumelele inqubo yokubumba yokucindezela kwe-isostatic, inqubo yokubumba eyinkulungwane, inqubo yokubumba i-grouting kanye nenqubo yokubumba i-vacuum extrusion. Inkampani yethu isebenzisa imigqa yokukhiqiza engu-6 ye-silicon carbide ceramic sintering, ine-8 CNC, imishini yokugaya eyi-6 enembayo, ingakunikeza nemikhiqizo ye-silicon carbide ceramic sintered, kodwa futhi ingahlinzeka nge-silicon carbide ceramics, i-alumina ceramics, i-aluminium nitride ceramics, izinsizakalo zokucubungula i-zirconia ceramics. .

-

Izinkampani Zokukhiqiza Ze-Graphite Soft Felt ...

-

Isaphulelo esikhulu se-Polyacrylonitrile Thermal Insul...

-

2019 Ikhwalithi ephezulu yeSilicon Carbide Liner Sisic T...

-

Isephulelo Esijwayelekile Sogesi Esiphindwe Kabili ICerami...

-

I-Professional China Silicon Carbide Graphite Cru...

-

Isampula yamahhala Yohlobo Olukhethekile Lwemikhiqizo ye-Sic kabili...