Uhlolojikelele Lomkhiqizo

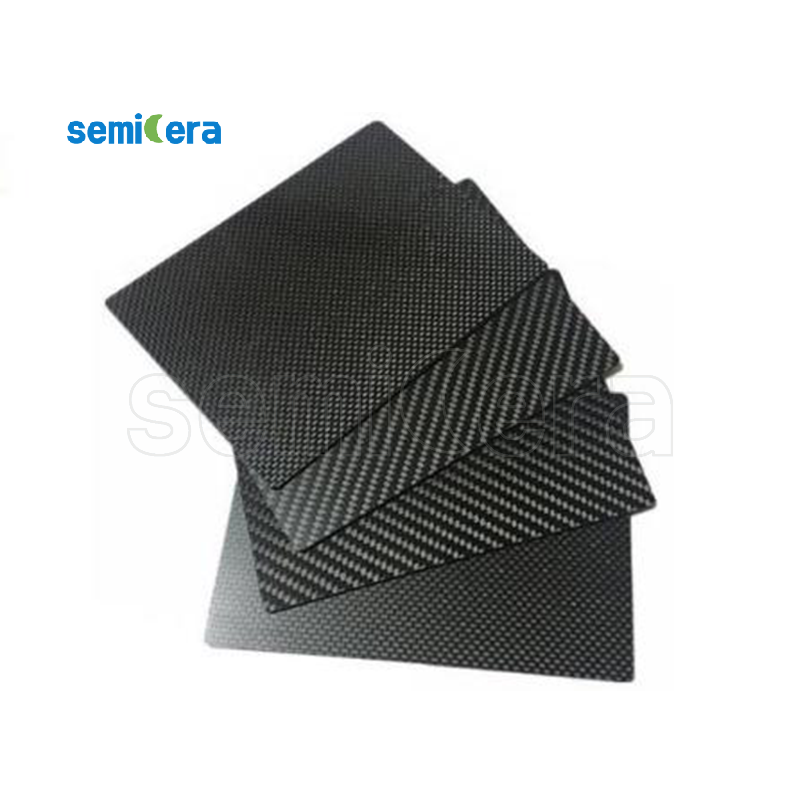

II-Silicon-Impregnated Silicon Carbide (SiC) Paddle and Wafer Carrieryakhelwe ukuhlangabezana nezidingo ezidingekayo ze-semiconductor ezishisayo zokucubungula izinhlelo zokusebenza. Waklanywa nge-SiC ehlanzeke kakhulu futhi wathuthukiswa ngokufakwa kwe-silicon, lo mkhiqizo unikeza inhlanganisela eyingqayizivele yokusebenza kwezinga lokushisa eliphezulu, ukuqhutshwa kwe-thermal okuhle kakhulu, ukumelana nokugqwala, namandla avelele emishini.

Ngokuhlanganisa isayensi yezinto ezithuthukisiwe nokukhiqizwa okunembayo, lesi sixazululo siqinisekisa ukusebenza okuphezulu, ukwethembeka, nokuqina kwabakhiqizi be-semiconductor.

Izici Eziyinhloko

1.Ukumelana Nezinga Lokushisa Okuphakeme

Ngephuzu lokuncibilika elingaphezu kuka-2700°C, izinto ze-SiC zizinzile ngokwemvelo ngaphansi kokushisa okukhulu. Ukufakwa kwe-silicon kuthuthukisa futhi ukuqina kwazo okushisayo, kuzivumela ukuthi zimelane nokuchayeka isikhathi eside kumazinga okushisa aphezulu ngaphandle kokuncipha kwesakhiwo noma ukuwohloka kokusebenza.

2.I-Superior Thermal Conductivity

I-thermal conductivity ehlukile ye-silicon-impregnated SiC iqinisekisa ukusatshalaliswa kokushisa okufanayo, kunciphisa ukucindezeleka okushisayo phakathi nezigaba zokucubungula ezibucayi. Lesi sakhiwo sandisa isikhathi sokuphila kwemishini futhi sinciphisa isikhathi sokukhiqiza, siyenze ilungele ukucutshungulwa kwezinga lokushisa eliphezulu.

3.I-Oxidation kanye Nokumelana Nokugqwala

Ungqimba oluqinile lwe-silicon oxide lwakha ngokwemvelo ngaphezulu, lunikeza ukumelana okuvelele ekuhlanganiseni nokugqwala. Lokhu kuqinisekisa ukwethembeka kwesikhathi eside ezindaweni zokusebenza ezinokhahlo, kuvikela kokubili impahla kanye nezingxenye ezizungezile.

4.Amandla Emishini Ephezulu kanye Nokumelana Nokugqoka

I-Silicon-impregnated SiC ifaka amandla acindezelayo amahle kakhulu nokumelana nokugqoka, igcina ubuqotho bayo besakhiwo ngaphansi komthwalo ophezulu, izimo ezishisa kakhulu. Lokhu kunciphisa ingcuphe yokulimala okuhlobene nokugqokwa, kuqinisekisa ukusebenza okungaguquguquki emijikelezweni yokusetshenziswa eyandisiwe.

Imininingwane

| Igama Lomkhiqizo | I-SC-RSiC-Si |

| Okubalulekile | I-Silicon Impregnation Silicon Carbide Compact (ukuhlanzeka okuphezulu) |

| Izinhlelo zokusebenza | Izingxenye Zokwelapha Ukushisa Kwe-Semiconductor, Izingxenye Zesisetshenziswa Sokukhiqiza Semiconductor |

| Ifomu lokulethwa | Umzimba obunjiwe (Umzimba ohlanganisiwe) |

| Ukwakheka | Impahla Mechanical | I-Young's Modulus (GPA) | Ukugoba Amandla (MPa) | ||

| Ukwakhiwa (vol%) | I-α-SiC | I-α-SiC | RT | 370 | 250 |

| 82 | 18 | 800°C | 360 | 220 | |

| Ukuminyana kwenqwaba (kg/m³) | 3.02 x 103 | 1200°C | 340 | 220 | |

| Izinga Lokushisa Ezingangenisi Ukushisa°C | 1350 | Isilinganiso sikaPoisson | 0.18(RT) | ||

| Impahla Eshisayo | I-Thermal Conductivity (W/(m· K)) | Amandla Okushisa athize (kJ/(kg·K)) | I-Coefficient of Thermal Expansion (1/K) | ||

| RT | 220 | 0.7 | RT~700°C | 3.4 x 10-6 | |

| 700°C | 60 | 1.23 | 700~1200°C | 4.3 x10-6 | |

| Okuqukethwe Ukungcola ((ppm) | |||||||||||||

| Isici | Fe | Ni | Na | K | Mg | Ca | Cr | Mn | Zn | Cu | Ti | Va | Ai |

| Izinga Lokuqukethwe | 3 | <2 | <0.5 | <0.1 | <1 | 5 | 0.3 | <0.1 | <0.1 | <0.1 | <0.3 | <0.3 | 25 |

Izinhlelo zokusebenza

▪I-Semiconductor Thermal Processing:Ilungele izinqubo ezifana ne-chemical vapor deposition (CVD), ukukhula kwe-epitaxial, kanye ne-annealing, lapho ukulawulwa okunembile kwezinga lokushisa nokuqina kwempahla kubalulekile.

▪Izithwali ze-Wafer & Paddles:Idizayinelwe ukubamba ngokuphephile futhi ithuthe amawafa ngesikhathi sokwelashwa okushisayo okunokushisa okuphezulu.

▪Izindawo Ezisebenza Kakhulu: Ifanele izilungiselelo ezidinga ukumelana nokushisa, ukuchayeka kumakhemikhali, kanye nengcindezi yokusebenza kwemishini.

Izinzuzo ze-Silicon-Impregnated SiC

Inhlanganisela ye-high-purity silicon carbide kanye nobuchwepheshe obuthuthukisiwe be-silicon impregnation iletha izinzuzo zokusebenza ezingenakuqhathaniswa:

▪Ukunemba:Ithuthukisa ukunemba nokulawula ukucubungula kwe-semiconductor.

▪Ukuzinza:Imelana nezindawo ezinokhahlo ngaphandle kokuphazamisa ukusebenza.

▪Ukuphila isikhathi eside:Inweba impilo yesevisi yemishini yokukhiqiza i-semiconductor.

▪Ukusebenza kahle:Ithuthukisa ukukhiqiza ngokuqinisekisa imiphumela ethembekile futhi engaguquki.

Kungani Khetha Izixazululo Zethu Ze-Silicon-Impregnated SiC?

At I-Semicera, sisebenza ngokukhethekile ekuhlinzekeni izixazululo ezisebenza kahle kakhulu ezihambisana nezidingo zabakhiqizi be-semiconductor. I-Silicon-Impregnated Silicon Carbide Paddle yethu kanye ne-Wafer Carrier zihlolwa kanzima nokuqinisekiswa kwekhwalithi ukuze kuhlangatshezwane namazinga embonini. Ngokukhetha i-Semicera, uthola ukufinyelela ezintweni ezisezingeni eliphezulu eziklanyelwe ukuthuthukisa izinqubo zakho zokukhiqiza nokuthuthukisa amakhono akho okukhiqiza.

Imininingwane Yezobuchwepheshe

▪Ukwakhiwa Kwezinto:I-high-purity silicon carbide ene-silicon impregnation.

▪I-Operating Temperature Range:Kufika ku-2700°C.

▪ I-Thermal Conductivity:Iphezulu kakhulu ekusabalaliseni ukushisa okufanayo.

▪Izici Zokumelana:I-oxidation, ukugqwala, nokungagugi.

▪Izicelo:Ihambisana nezinhlelo ezihlukahlukene zokucubungula ezishisayo ze-semiconductor.

Xhumana nathi

Ingabe usukulungele ukuphakamisa inqubo yakho yokukhiqiza i-semiconductor? Oxhumana nayeI-Semiceranamuhla ukuze ufunde kabanzi mayelana ne-Silicon-Impregnated Silicon Carbide Paddle yethu kanye ne-Wafer Carrier.

▪I-imeyili: sales01@semi-cera.com/sales05@semi-cera.com

▪Ucingo: +86-0574-8650 3783

▪Indawo:No.1958 Jiangnan Road, Ningbo High tech, Zone, Zhejiang Province, 315201, China