Imishini yokudonsa ikristalu eyodwa ye-silicon embonini ye-photovoltaic idlala indima ebalulekile ekukhiqizeni amaseli elanga. Ngokuqinisa ngokuqinile nokulawula ngokunembile inqubo yokwelula nokuqinisa izinduku ze-silicon eyodwa yekristalu, ukulungiswa kusiza ukufeza ukukhiqizwa kwekristalu eyodwa ye-silicon yekhwalithi ephezulu nokusebenza kahle kakhulu. Ukuklama nokusebenza kwe-fixture kuthinta ngokuqondile ukusebenza kanye nekhwalithi yamangqamuzana elanga, ngakho-ke embonini ye-photovoltaic, ucwaningo nokuthuthukiswa kanye nemibono emisha kwenziwa njalo ukuze kuthuthukiswe ukunemba, ukuzinza nokusebenza kahle kwesakhiwo.

Isingeniso:

1. Idizayini yokulungisa: Izinto zokudonsa i-silicon single crystal embonini ye-photovoltaic zivame ukuklanywa ngokunembile futhi zenziwe ngomshini ukuze kuqinisekiswe ukubamba okuvikelekile nokubeka okunembile kwe-silicon single crystal rod. I-fixture ngokuvamile yenziwe ngezinto zensimbi (njengensimbi engagqwali) enamandla aphezulu kanye nokuqina ukuze imelane namandla aphezulu namazinga okushisa.

2. I-clamping mechanism: I-fixture ibopha i-silicon single crystal rod ngesakhiwo esithile sokusebenza noma idivayisi yokubopha. Ngokuvamile, idizayini ye-fixture ibheka ububanzi nokuma kwe-silicon single crystal rod ukuze kuqinisekiswe ukugoqa okuzinzile futhi kuvimbele i-silicon single crystal rod ukuthi ingasheleli noma isonteke phakathi nenqubo yokwelula.

3. Ukulawula izinga lokushisa: I-silicon single crystal edonsa izinto embonini ye-photovoltaic ngokuvamile inemisebenzi yokulawula izinga lokushisa ukuze kuqinisekiswe ukuthi izimo zokushisa ezifanele zigcinwa ngesikhathi senqubo yokwelula nokuqinisa. Ukulawulwa kwezinga lokushisa kungafinyelelwa ngokusebenzisa isistimu yokushisisa noma yokupholisa ku-fixture ngokwayo, noma isistimu yokulawula izinga lokushisa ehlanganiswe nezinto zokusebenza ezelulayo.

4. Ukuma okunembile nokuqondanisa: Imishini yokudonsa i-silicon eyodwa ye-crystal embonini ye-photovoltaic idinga ukunikeza imisebenzi enembile yokumisa nokuqondisa ukuze kuqinisekiswe ukuthi i-silicon single crystal rod igcina isiqondiso esifanele kanye nesimo ngesikhathi senqubo yokwelula nokuqinisa. Ukuma okunembile nokuqondanisa kusiza ukuthola usayizi wekristalu ongaguquki we-silicon kanye nokuma kwekristalu.

5. Ukumelana nokushisa nokumelana nokugqwala: Ngenxa yokushisa okuphezulu kanye nokusabela kwamakhemikhali okuhilelekile enqubweni yokwelula nokuqiniswa, i-silicon single crystal edonsa izinto embonini ye-photovoltaic idinga ukuba nokumelana nokushisa okuhle nokumelana nokugqwala. Lokhu kusiza ukuqinisekisa ukuzinza nokuthembeka kwesikhathi eside kwesakhiwo.

-

I-Crucible yokudonsa i-silicon single crystal

-

I-Graphite three-petal crucible ye-semiconductor...

-

Ama-Semiceras Enziwe Ngokwezifiso I-Isostatic Graphite Compone...

-

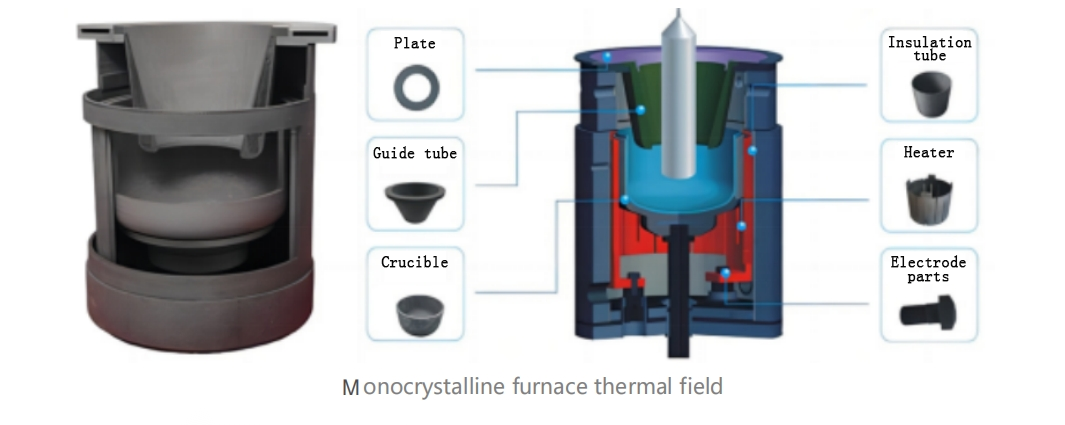

Izesekeli ze-graphite zenkundla eshisayo ye-single cr...

-

I-graphite ye-three-lobe cauldron enhle kakhulu ...

-

I-Isostatic PECVD Graphite Boat