Ukuhlanzwa kanye namamephu

Insizakalo yethu ihlanganisa ukuhlanzwa kanye nokwenza imephu kwezinhlobonhlobo zezinto zokwakha ze-semiconductor, ngenhloso yokuletha izinto ezisezingeni eliphezulu ze-semiconductor yezinhlelo zokusebenza ezahlukahlukene. Ngokusebenzisa ubuchwepheshe bethu bokuhlanza obuthuthukisiwe kanye nemishini yesimanjemanje, siqeda ngempumelelo ukungcola, ngaleyo ndlela sithuthukisa ukuhlanzeka kwezinto zokwakha ze-semiconductor. Inqubo yethu yokuhlanza iklanywe ngokucophelela, ehlanganisa izinyathelo eziningi nezindlela eziqinile zokulawula ikhwalithi ukuze kuqinisekiswe ubumsulwa obukhethekile nokuzinza kwezinto esizinikezayo.

Ukwengeza, sizinikele ekuhlinzekeni amakhasimende ethu ngamasevisi emephu anembe nethembekile. Sihlomeke ngezinto ezithuthukisiwe zokuhlola namathuluzi, futhi sisekelwa ithimba lochwepheshe abanolwazi, siyakwazi ukwenza izilinganiso eziphelele kanye nokuhlaziya izici zempahla ye-semiconductor. Amasevisi ethu okwenza imephu ahlanganisa inhlobonhlobo yokuhlola, okuhlanganisa izakhiwo zikagesi, ukwakheka, ubumsulwa, izici ezibonakalayo, kanye nophenyo olunzulu ngesakhiwo nokwakheka kwezinto. Ngokwenza imephu okucophelelayo, siqoqa idatha enemininingwane nolwazi, okusivumela ukuthi sinikeze amakhasimende ukuhlolwa okunembile kwezimpawu zezinto ezibonakalayo nezincomo ezifanele.

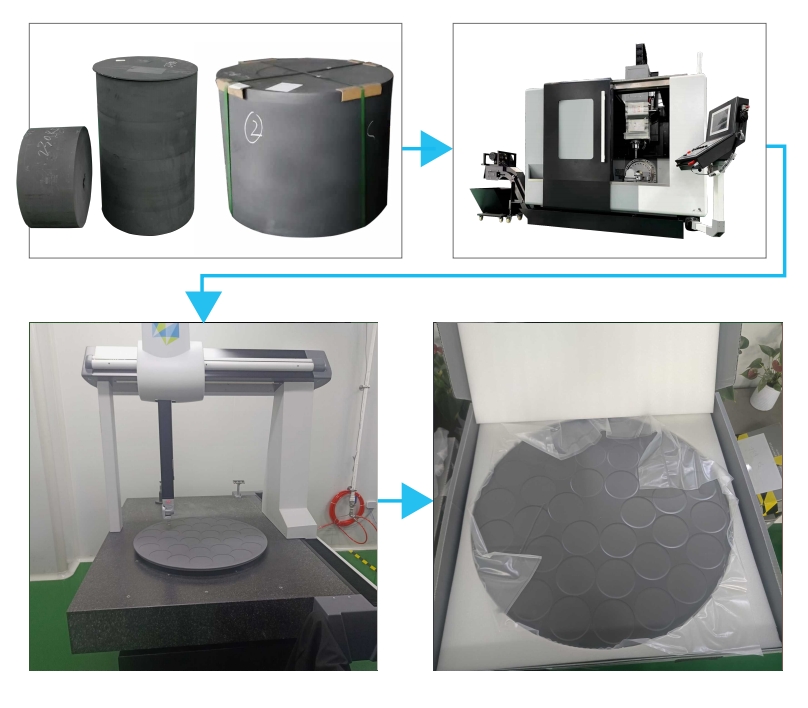

Amandla Emishini

I-Semicera Semiconductor inenkambu ehamba phambili ye-semiconductor ye-graphite, i-silicon carbide namanye amakhono omshini nolwazi, ingahlangana namakhasimende emikhiqizo ye-semiconductor yokunemba okuphezulu, ukuhlanzeka okuphezulu, izinga eliphezulu nezinye izidingo zokucubungula. Amathuluzi esiwasebenzisayo, inqubo yokusika kanye nokukhethwa kwezinto zokwakha nakho kwenziwa ngokucophelela ukuze kuzuzwe ukulawula usayizi we-micron kanye nekhwalithi ephezulu yendawo. Sinaka ukulawulwa kwekhwalithi kanye nokwenza ngcono inqubo enqubweni yokucubungula, ukuqapha kwesikhathi sangempela kanye nokulawula amapharamitha abalulekile enqubweni yokucubungula ukuze siqinisekise ukuvumelana komkhiqizo nokuzinza. Siphinde sisebenzisa uhlelo lokuphatha ikhwalithi oluqinile ukuze siqinisekise ukuthi imikhiqizo icutshungulwa ngokuhambisana nezidingo zamakhasimende kanye namazinga omkhakha, futhi sihlole ikhwalithi ephelele.

Sizoqhubeka nokutshala imali ekuthuthukisweni kwemishini nasekusunguleni izinto ezintsha zobuchwepheshe ukuze sihlangabezane nezidingo ezikhulayo zamakhasimende ethu futhi siwanikeze izisombululo nokusekelwa okuphezulu.

Isixazululo Sokuguqulwa Kwensimu Eshisayo

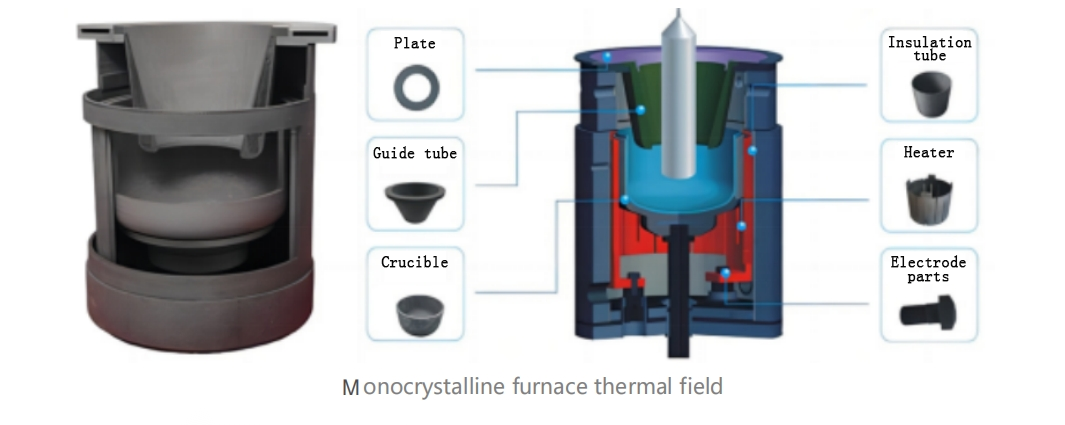

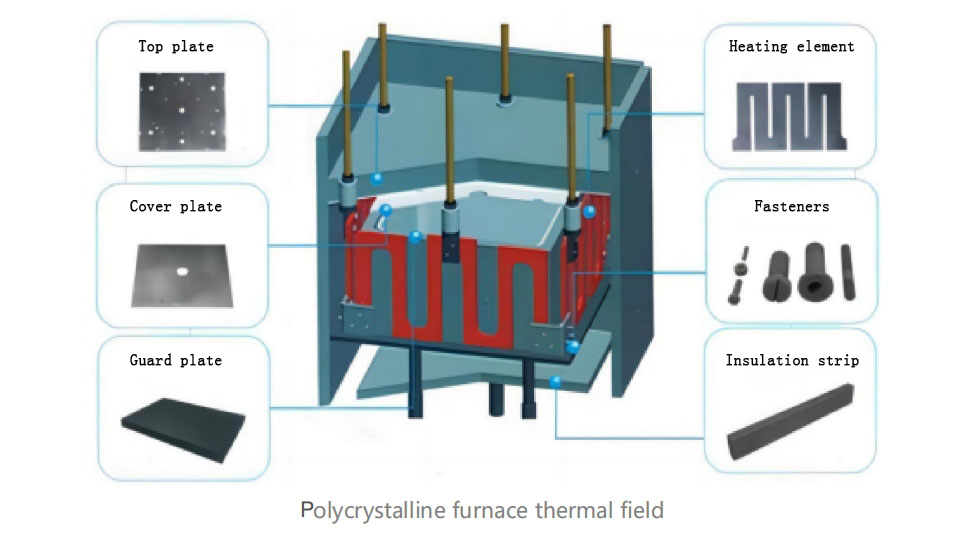

Mayelana nomklamo noguquko lwenkundla eshisayo, inkampani yethu ingaqedela ukwakhiwa kanye nokuhlinzekwa kwenqwaba ku-Czochra single crystal, i-polycrystal ephonsa, i-gallium arsenide, i-zinc selenide, isafire, i-silicon carbide nezinye izisetshenziswa zemboni ezahlukene. Ngesikhathi esifanayo, ekubalweni kokushisa okushisayo kwezakhiwo ezihlukahlukene, izingxenye kanye nomkhathi ngaphansi kwezimo ezihlukene zokushisa okuphezulu, siphinde sibe nekhono lobuchwepheshe lokumodela kanye nokulingiswa kwekhompuyutha, okungahlinzeka amakhasimende ngezinhlelo ezisebenzayo zokuklama nokusikisela.

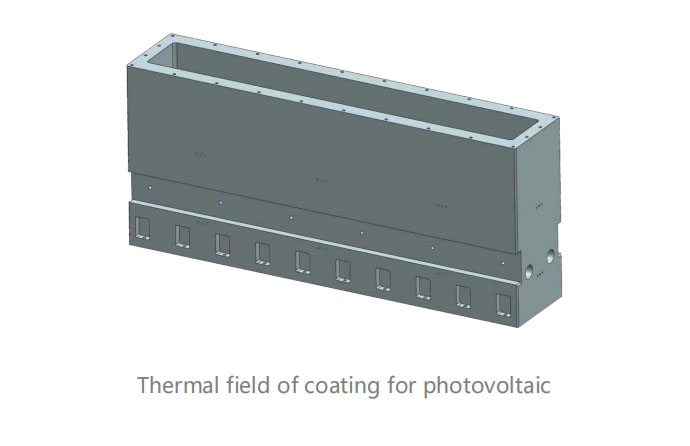

Enqubweni yokukhiqiza amaseli elanga, ukulungiswa kwamafilimu aphikisayo kuyinqubo ebalulekile. Amafilimu amakhulu e-anti reflective ahlanganisa i-silicon nitride/silicon oxide, engagcini nje ngokuba nomsebenzi wamafilimu aphikisayo kodwa futhi anemiphumela yokudlula. Ukulungiswa kwamafilimu e-anti reflective ikakhulukazi kuncike endleleni ye-plasma enhanced vapor deposition (PECVD).

Sihlinzeka ngezixazululo ezisebenza kahle ngokusebenzisa izithwali ze-silicon wafer ze-PECVD eziklanywe zakamuva ezenziwe nge-isostatic graphite noma izinto eziqiniswe nge-carbon fibre, njengezikebhe ze-graphite namafreyimu e-graphite, futhi sihlinzeka ngezinsizakalo zokuhlanza nokumboza, ukuze kuthuthukiswe ukusebenza kwempahla.

Amakhithi Okuhlola Umkhiqizo We-Semiconductor

Sizibophezele ekuhlinzekeni amakhithi okuhlola umkhiqizo we-semiconductor ashisayo ukuze sihlangabezane nezidingo ezahlukene zamakhasimende. Ukuhlolwa kwethu kuhlanganisa inqwaba yezinto zokwakha ze-semiconductor, okubandakanya i-silicon carbide, i-graphite, i-tantaluml carbide, njll., ukuze kuhlolwe ngokuphelele izakhiwo zikagesi, ukwakheka, ubumsulwa, izakhiwo ezingokomzimba, usayizi, nesakhiwo se-andl crystal. Lawa makhithi okuhlola aklanywe futhi akhiqizwa ithimba lochwepheshe, elihlome ngemishini yokuhlola i-Advancedl namathuluzi ukuze kuqinisekiswe ukunemba okuphezulu nokwethembeka. Ikhithi yethu yokuhlola umkhiqizo ayihlinzeki nje kuphela ngohlelo oluphelele lokuhlola, kodwa futhi ihlanganisa imibiko yokuhlola enemininingwane nokuhlaziya ukusiza amakhasimende aqonde ukusebenza nezinkinga ezingaba khona zomkhiqizo.

I-GDMS

I-D-SIMS