Izinzuzo

Ukumelana nokushisa okuphezulu kwe-oxidation

Ukumelana ne-Corrosion okuhle kakhulu

Ukumelana okuhle kwe-Abrasion

I-coefficient ephezulu ye-conductivity yokushisa

Ukuzithambisa, ukuminyana okuphansi

Ukuqina okuphezulu

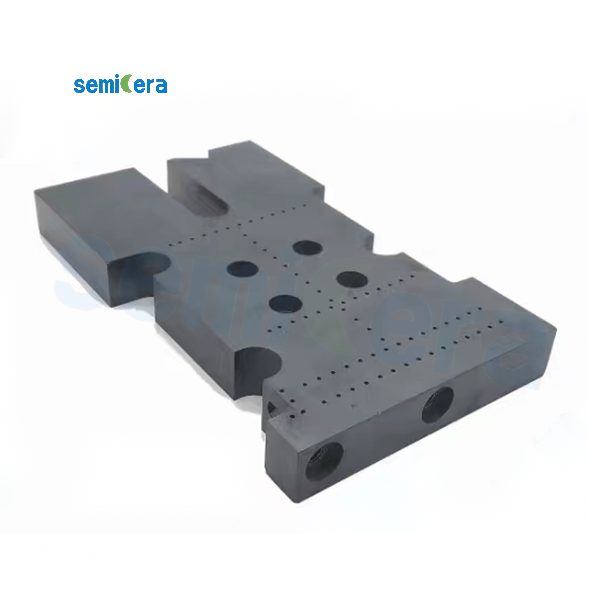

Umklamo ngokwezifiso.

Izinhlelo zokusebenza

-Inkundla ekwazi ukumelana nokugqokwa: ukubhodloza, ipuleti, umlomo wombhobho wokuqhumisa isihlabathi, ulwelwesi lwesishingishane, umgqomo wokugaya, njll.

-Inkundla Yokushisa Ephakeme: I-siC Slab, Ishubhu Lokucisha Isithando, Ishubhu elikhazimulayo, i-crucible, i-Heating Element, i-roller, i-Beam, i-Heat Exchanger, i-Cold Air Pipe, i-Burner Nozzle, i-Thermocouple Protection Tube, isikebhe se-SiC, i-Kiln car Structure, i-Setter, njll.

-I-Silicon Carbide Semiconductor: Isikebhe se-SiC wafer, i-sic chuck, i-sic paddle, i-sic cassette, i-sic diffusion tube, i-wafer fork, ipuleti lokumunca, umgwaqo, njll.

-I-Silicon Carbide Seal Field: zonke izinhlobo zendandatho yokubeka uphawu, ukuthwala, i-bushing, njll.

-Inkambu ye-Photovoltaic: I-Cantilever Paddle, i-Grinding Barrel, i-Silicon Carbide Roller, njll.

-I-Lithium Battery Field

Izakhiwo Zomzimba ze-SiC

| Impahla | Inani | Indlela |

| Ukuminyana | 3.21 g/cc | Sink-float kanye nobukhulu |

| Ukushisa okuqondile | 0.66 J/g °K | I-Pulsed laser flash |

| Amandla e-Flexural | 450 MPa560 MPa | 4 iphuzu ukugoba, RT4 iphuzu ukugoba, 1300° |

| Ukuqina kokuphuka | 2.94 MPa m1/2 | I-Microindentation |

| Ukuqina | 2800 | Vicker, 500g umthwalo |

| I-Elastic ModulusYoung's Modulus | 450 GPA430 GPA | 4 pt ukugoba, RT4 pt ukugoba, 1300 °C |

| Usayizi wokusanhlamvu | 2 - 10 µm | I-SEM |

Izakhiwo ezishisayo ze-SiC

| I-Thermal Conductivity | 250 W/m °K | Indlela ye-Laser flash, RT |

| I-Thermal Expansion (CTE) | 4.5 x 10-6 °K | Izinga lokushisa legumbi liye ku-950 °C, i-silica dilatometer |

Imingcele Yezobuchwepheshe

| Into | Iyunithi | Idatha | ||||

| I-RBSiC(SiSiC) | I-NBSiC | I-SSiC | I-RSiC | I-OSIC | ||

| Okuqukethwe kwe-SiC | % | 85 | 75 | 99 | 99.9 | ≥99 |

| Okuqukethwe kwe-silicon yamahhala | % | 15 | 0 | 0 | 0 | 0 |

| Izinga lokushisa eliphezulu lesevisi | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Ukuminyana | g/cm3 | 3.02 | 2.75-2.85 | 3.08-3.16 | 2.65-2.75 | 2.75-2.85 |

| I-porosity evulekile | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Amandla okugoba 20 ℃ | Mpa | 250 | 160 | 380 | 100 | / |

| Amandla okugoba 1200 ℃ | Mpa | 280 | 180 | 400 | 120 | / |

| I-modulus ye-elasticity engu-20 ℃ | I-Gpa | 330 | 580 | 420 | 240 | / |

| I-modulus ye-elasticity 1200 ℃ | I-Gpa | 300 | / | / | 200 | / |

| Thermal conductivity 1200 ℃ | W/mK | 45 | 19.6 | 100-120 | 36.6 | / |

| I-coefficient yokwanda kwe-thermal | K-1X10-6 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | Kg/mm2 | 2115 | / | 2800 | / | / |

I-CVD silicon carbide coating endaweni engaphandle yemikhiqizo ye-ceramic ye-silicon carbide ceramic ingafinyelela ubumsulwa obungaphezu kuka-99.9999% ukuze kuhlangatshezwane nezidingo zamakhasimende embonini ye-semiconductor.