Ukucutshungulwa kwe-MEMS - Ukubophezela: Isicelo kanye nokusebenza embonini ye-Semiconductor, Isevisi eyenziwe ngokwezifiso ye-Semicera

Ezimbonini ze-microelectronics kanye ne-semiconductor, ubuchwepheshe be-MEMS (micro-electromechanical systems) buye baba obunye bobuchwepheshe obuyinhloko obuqhuba izinto ezintsha nezisebenza kahle kakhulu. Ngokuthuthuka kwesayensi nobuchwepheshe, ubuchwepheshe be-MEMS buye basetshenziswa kabanzi kuzinzwa, ama-actuator, imishini yokubona, imishini yezokwelapha, ugesi wezimoto neminye imikhakha, futhi kancane kancane sebuyingxenye ebalulekile yobuchwepheshe besimanje. Kule mikhakha, inqubo yokuhlanganisa (I-Bonding), njengesinyathelo esibalulekile ekucubunguleni i-MEMS, idlala indima ebalulekile ekusebenzeni nasekuthembekeni kwedivayisi.

I-Bonding ubuchwepheshe obuhlanganisa ngokuqinile izinto ezimbili noma ngaphezulu ngezindlela ezibonakalayo noma zamakhemikhali. Ngokuvamile, izendlalelo zezinto ezihlukene zidinga ukuxhunywa ngokuxhunywa kumadivayisi we-MEMS ukuze kuzuzwe ubuqotho besakhiwo kanye nokufezeka kokusebenza. Enqubweni yokukhiqiza amadivaysi e-MEMS, ukubopha akuyona nje inqubo yokuxhuma, kodwa futhi kuthinta ngokuqondile ukuzinza kokushisa, amandla omshini, ukusebenza kukagesi nezinye izici zedivayisi.

Ekucubunguleni okunemba okuphezulu kwe-MEMS, ubuchwepheshe bokubopha kufanele buqinisekise ukuhlangana okusondelene phakathi kwezinto ngenkathi kugwema noma yiziphi izinkinga ezithinta ukusebenza kwedivayisi. Ngakho-ke, ukulawulwa okunembile kwenqubo yokubopha kanye nezinto zokubopha zekhwalithi ephezulu yizici ezibalulekile zokuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso zomkhakha.

Izicelo zokuhlanganisa i-MEMS embonini ye-semiconductor

Embonini ye-semiconductor, ubuchwepheshe be-MEMS busetshenziswa kakhulu ekukhiqizeni amadivaysi amancane njengezinzwa, ama-accelerometers, izinzwa zokucindezela, nama-gyroscopes. Ngokukhula kwesidingo semikhiqizo emincane, ehlanganisiwe, nehlakaniphile, izidingo zokunemba nokusebenza kwamadivayisi we-MEMS nazo ziyakhula. Kulezi zinhlelo zokusebenza, ubuchwepheshe bokubambisana busetshenziselwa ukuxhuma izinto ezahlukene ezifana nama-silicon wafers, ingilazi, izinsimbi, nama-polymers ukuze kuzuzwe imisebenzi ephumelelayo nezinzile.

1. Izinzwa zokucindezela kanye nama-accelerometer

Emkhakheni wezimoto, i-aerospace, i-electronics yabathengi, njll., izinzwa zokucindezela kwe-MEMS kanye nama-accelerometers asetshenziswa kakhulu ekulinganiseni nasekulawuleni izinhlelo. Inqubo yokubopha isetshenziselwa ukuxhuma ama-silicon chips nezici zezinzwa ukuze kuqinisekiswe ukuzwela okuphezulu nokunemba. Lezi zinzwa kufanele zikwazi ukumelana nezimo ezidlulele zemvelo, futhi izinqubo zokubopha zekhwalithi ephezulu zingavimbela ngokuphumelelayo izinto ukuthi zingabambi noma zingasebenzi kahle ngenxa yokushintsha kwezinga lokushisa.

2. Imishini ye-Micro-optical kanye nama-switch optical we-MEMS

Emkhakheni wezokuxhumana optical kanye namadivayisi we-laser, amadivaysi optical we-MEMS kanye nokushintsha optical kudlala indima ebalulekile. Ubuchwepheshe be-Bonding busetshenziselwa ukufeza ukuxhumana okunembile phakathi kwamadivayisi we-MEMS asekelwe ku-silicon kanye nezinto ezifana namafiber optical nezibuko ukuze kuqinisekiswe ukusebenza kahle nokuzinza kokudluliswa kwesignali ye-optical. Ikakhulukazi ezinhlelweni ezinefrikhwensi ephezulu, umkhawulokudonsa obanzi kanye nokudluliswa kwebanga elide, ubuchwepheshe bokubopha obusebenza kahle bubalulekile.

3. Ama-gyroscope we-MEMS nezinzwa ezinertial

Ama-gyroscopes we-MEMS nezinzwa ezinertial zisetshenziswa kakhulu ekuzulazuleni okunembayo nokubeka endaweni ezimbonini ezisezingeni eliphezulu njengokushayela okuzenzakalelayo, amarobhothi, kanye ne-aerospace. Izinqubo zokubopha ezinemba okuphezulu zingaqinisekisa ukwethembeka kwamadivayisi futhi zigweme ukuwohloka kokusebenza noma ukwehluleka phakathi nokusebenza kwesikhathi eside noma ukusebenza kwemvamisa ephezulu.

Izidingo zokusebenza ezibalulekile zobuchwepheshe bokubambisana ekucubunguleni kwe-MEMS

Ekucubunguleni kwe-MEMS, ikhwalithi yenqubo yokuhlanganisa inquma ngokuqondile ukusebenza, impilo kanye nokuzinza kwedivayisi. Ukuze kuqinisekiswe ukuthi amadivayisi we-MEMS angasebenza ngokwethembeka isikhathi eside ezimeni ezihlukahlukene zohlelo, ubuchwepheshe bokubopha kufanele bube nokusebenza okubalulekile okulandelayo:

1. Ukuzinza okuphezulu kokushisa

Izindawo eziningi ezisetshenziswayo embonini ye-semiconductor zinezimo zokushisa eziphezulu, ikakhulukazi emikhakheni yezimoto, i-aerospace, njll. Ukuzinza okushisayo kwempahla yokubopha kubalulekile futhi kungamelana nokushintsha kwezinga lokushisa ngaphandle kokuwohloka noma ukwehluleka.

2. Ukumelana nokugqoka okuphezulu

Imishini ye-MEMS ivamise ukubandakanya ukwakheka kwemishini emincane, futhi ukungqubuzana nokunyakaza kwesikhathi eside kungabangela ukuguga kwezingxenye zokuxhuma. Impahla yokubopha idinga ukuba nokumelana okuhle kakhulu kokugqoka ukuze kuqinisekiswe ukuzinza nokusebenza kahle kwedivayisi ekusetshenzisweni kwesikhathi eside.

3. Ukuhlanzeka okuphezulu

Imboni ye-semiconductor inezidingo eziqinile kakhulu mayelana nobumsulwa bezinto ezibonakalayo. Noma yikuphi ukungcola okuncane kungase kubangele ukwehluleka kwedivayisi noma ukonakala kokusebenza. Ngakho-ke, izinto ezisetshenziselwa inqubo yokubopha kufanele zibe nokuhlanzeka okuphezulu kakhulu ukuze kuqinisekiswe ukuthi idivayisi ayithinteki ukungcola kwangaphandle ngesikhathi sokusebenza.

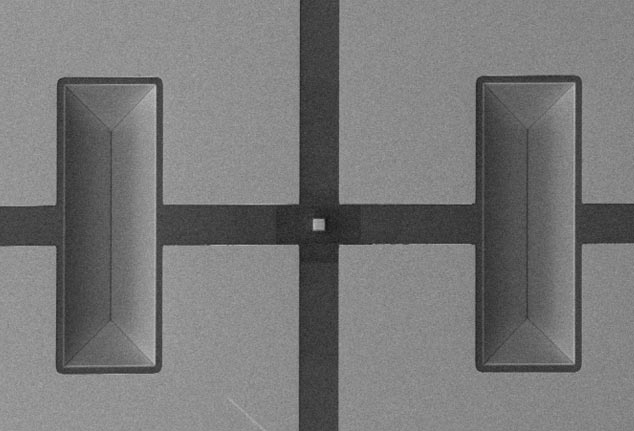

4. Ukunemba okunembayo kwesibopho

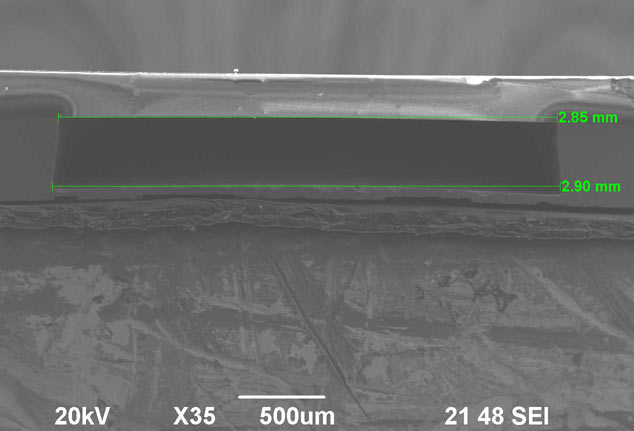

Amadivayisi we-MEMS ngokuvamile adinga ukunemba kokucubungula kwezinga le-micron noma ngisho neleveli ye-nanometer. Inqubo yokuhlanganisa kufanele iqinisekise ukudotshwa okunembile kwesendlalelo ngasinye sezinto ukuze kuqinisekiswe ukuthi ukusebenza nokusebenza kwedivayisi akuthinteki.

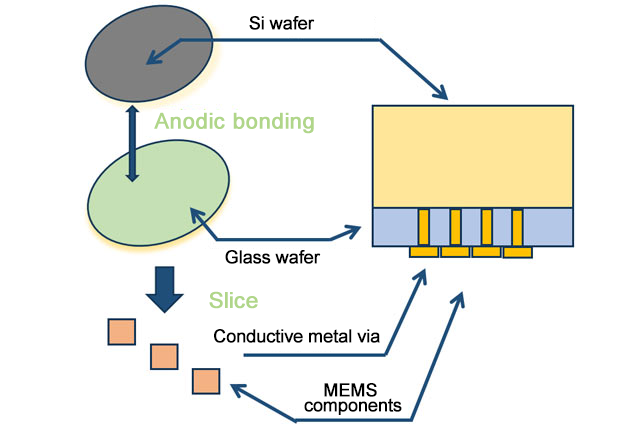

Ukuhlanganiswa kwe-anodic

Ukuhlanganiswa kwe-Anodic:

● Kusebenza ekuhlanganeni phakathi kwamawafa e-silicon nengilazi, insimbi nengilazi, isemiconductor nealloy, kanye nesemiconductor nengilazi.

Ukuhlanganiswa kwe-Eutectoid:

● Kusebenza ezintweni ezifana ne-PbSn, i-AuSn, i-CuSn, ne-AuSi

I-Glue bonding:

● Sebenzisa i-glue ekhethekile yokubopha, elungele iglue ekhethekile yokuhlanganisa njenge-AZ4620 ne-SU8

● Isebenza ku-4-intshi no-6-intshi

Isevisi ye-Semicera Custom Bonding

Njengomhlinzeki ohamba phambili embonini wezixazululo zokucubungula ze-MEMS, i-Semicera izimisele ukuhlinzeka amakhasimende ngezinsizakalo zokubopha ezenziwe ngokwezifiso ezinembayo, ezizinzile kakhulu. Ubuchwepheshe bethu bokubambisana bungasetshenziswa kabanzi ekuxhumaneni kwezinto ezihlukahlukene, okuhlanganisa i-silicon, ingilazi, insimbi, i-ceramics, njll., ukuhlinzeka ngezixazululo ezintsha zezinhlelo zokusebenza ezisezingeni eliphezulu emkhakheni we-semiconductor kanye ne-MEMS.

I-Semicera inemishini yokukhiqiza ethuthukisiwe kanye namaqembu ezobuchwepheshe, futhi inganikeza izixazululo zokubopha ngezifiso ngokuya ngezidingo ezithile zamakhasimende. Kungakhathaliseki ukuthi iwuxhumano oluthembekile ngaphansi kwezinga lokushisa eliphezulu nendawo yokucindezela okuphezulu, noma ukubopha okunembile kwedivayisi encane, i-Semicera ingahlangabezana nezidingo zenqubo eyinkimbinkimbi ehlukahlukene ukuze kuqinisekiswe ukuthi umkhiqizo ngamunye ungahlangabezana namazinga aphezulu kakhulu.

Isevisi yethu yokubopha ngokwezifiso ayinqunyelwe ezinqubweni ezivamile zokubopha, kodwa ihlanganisa ukubopha kwensimbi, ukubopha kokucindezela okushisayo, i-adhesive bonding nezinye izinqubo, ezinganikeza ukusekelwa kobuchwepheshe obuchwepheshile bezinto ezihlukahlukene, izakhiwo kanye nezidingo zohlelo lokusebenza. Ngaphezu kwalokho, i-Semicera ingaphinde inikeze amakhasimende isevisi egcwele kusukela ekuthuthukisweni kwe-prototype kuya ekukhiqizeni ngobuningi ukuze kuqinisekiswe ukuthi zonke izidingo zobuchwepheshe zamakhasimende zingafezeka ngokunembile.