I-Epitaxy Wafer Carrier iyingxenye ebalulekile ekukhiqizweni kwe-semiconductor, ikakhulukazi kuI-EpitaxyfuthiI-SiC Epitaxyizinqubo. I-Semicera iklama futhi ikhiqize ngokucophelelaI-waferAbathwali ukumelana namazinga okushisa aphezulu kakhulu kanye nezindawo zamakhemikhali, ukuqinisekisa ukusebenza okuhle kakhulu ezinhlelweni ezifanaI-MOCVD Susceptorkanye ne-Barrel Susceptor. Kungakhathaliseki ukuthi ukufakwa kwe-silicon ye-monocrystalline noma izinqubo ze-epitaxy eziyinkimbinkimbi, I-Epitaxy Wafer Carrier ye-Semicera inikeza ukufana okuhle kakhulu nokuzinza.

I-Semicera'sI-Epitaxy Wafer Carrieryenziwe ngezinto ezithuthukisiwe ezinamandla kakhulu emishini kanye ne-thermal conductivity, enganciphisa ngempumelelo ukulahlekelwa nokungazinzi phakathi nenqubo. Ngaphezu kwalokho, ukwakheka kwe-I-waferInkampani yenethiwekhi ingakwazi futhi ukuzivumelanisa nezisetshenziswa ze-epitaxy ezinosayizi abahlukahlukene, ngaleyo ndlela ithuthukise ukusebenza kahle kokukhiqiza kukonke.

Kumakhasimende adinga ukunemba okuphezulu nezinqubo ze-epitaxy zokuhlanzeka okuphezulu, I-Epitaxy Wafer Carrier ye-Semicera iyinketho enokwethenjelwa. Sihlale sizibophezele ekuhlinzekeni amakhasimende ngekhwalithi yomkhiqizo enhle kakhulu kanye nokwesekwa okuthembekile kwezobuchwepheshe ukusiza ukuthuthukisa ukwethembeka nokusebenza kahle kwezinqubo zokukhiqiza.

✓Ikhwalithi ephezulu emakethe yaseChina

✓Isevisi enhle njalo kuwe, amahora angu-7*24

✓Idethi emfishane yokulethwa

✓I-MOQ encane yamukelekile futhi yamukelwe

✓Amasevisi angokwezifiso

I-Epitaxy Growth Susceptor

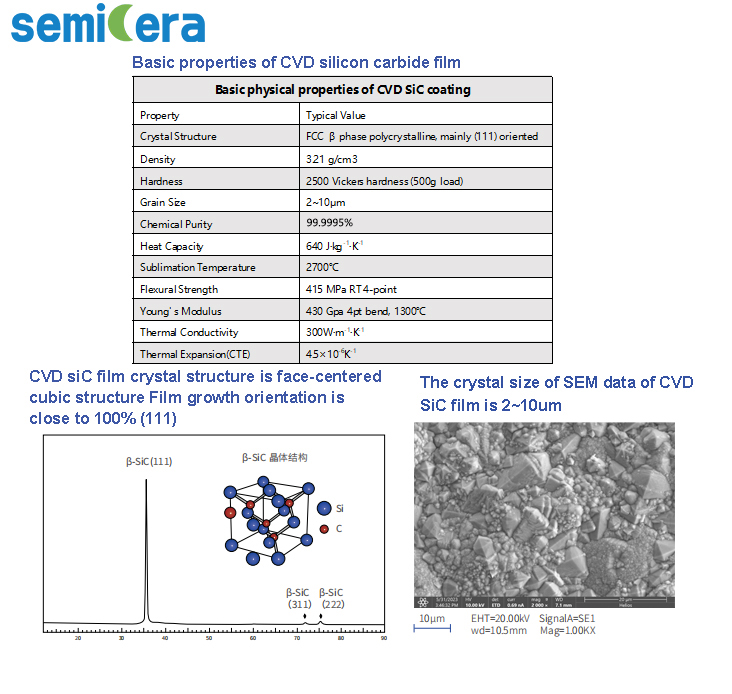

Amawafa e-silicon/silicon carbide adinga ukudlula ezinqubweni eziningi okufanele asetshenziswe kumishini kagesi. Inqubo ebalulekile i-silicon/sic epitaxy, lapho amawafa e-silicon/sic athwalwa khona ngesisekelo segraphite. Izinzuzo ezikhethekile ze-Semicera's silicone carbide-coated graphite base zifaka ukuhlanzeka okuphezulu kakhulu, ukunamathela okufanayo, nempilo yesevisi ende kakhulu. Futhi banokuphikiswa okuphezulu kwamakhemikhali kanye nokuzinza kokushisa.

Ukukhiqizwa kwe-chip ye-LED

Ngesikhathi sokumbozwa okubanzi kwe-reactor ye-MOCVD, isisekelo seplanethi noma umthwali uhambisa i-wafer ye-substrate. Ukusebenza kwezinto eziyisisekelo kunethonya elikhulu kwikhwalithi yokugqoka, okubuye kuthinte izinga le-scrap ye-chip. Isisekelo esihlanganiswe ne-silicon carbide se-Semicera sinyusa ukusebenza kahle kokukhiqizwa kwamawafa e-LED ekhwalithi ephezulu futhi sinciphisa ukuchezuka kwamaza. Siphinde sinikeze izingxenye ezengeziwe ze-graphite zazo zonke iziphehlisi ze-MOCVD ezisetshenziswayo njengamanje. Singakwazi ukugqoka cishe noma iyiphi ingxenye nge-silicon carbide coating, noma ngabe ububanzi bengxenye bufika ku-1.5M, sisengakwazi ukugqoka nge-silicon carbide.

Inkambu yeSemiconductor, Inqubo Yokusabalalisa Kwe-oxidation, njll.

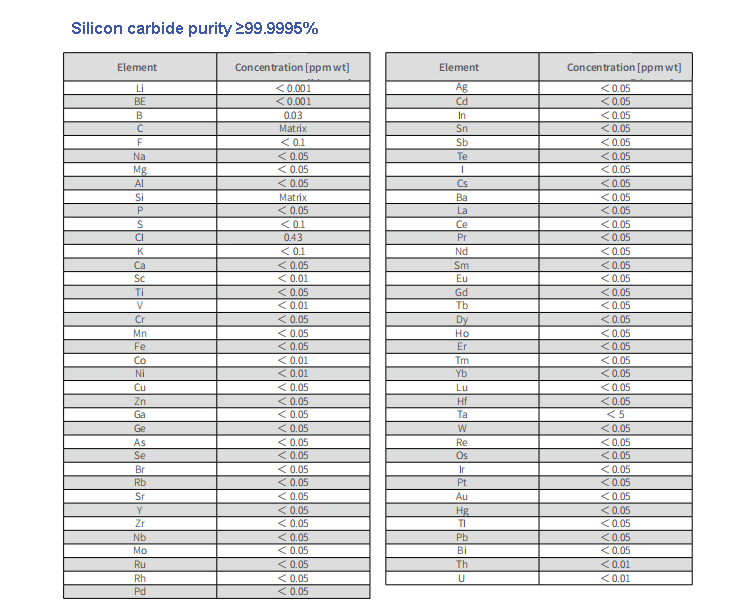

Enqubweni ye-semiconductor, inqubo yokunwetshwa kwe-oxidation idinga ukuhlanzeka okuphezulu komkhiqizo, futhi kwa-Semicera sinikeza inkambiso nezinsizakalo zokumboza ze-CVD zeningi lezingxenye ze-silicon carbide.

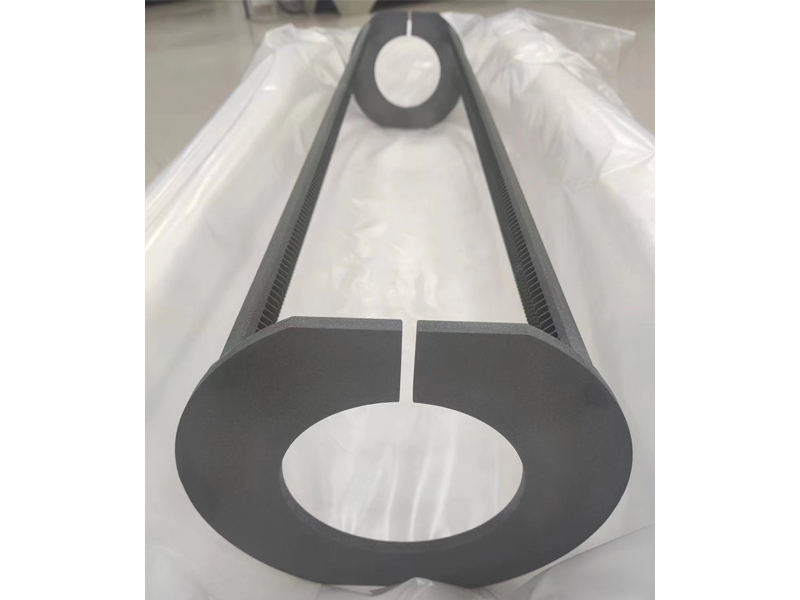

Isithombe esilandelayo sibonisa udaka lwe-silicon carbide olucutshungulwe kahle lwe-Semicea kanye neshubhu le-silicon carbide furnace elihlanzwa ku-1000-izingaengenalo uthuliigumbi. Abasebenzi bethu basebenza ngaphambi kokugqoka. Ukuhlanzeka kwe-silicon carbide yethu kungafinyelela ku-99.98%, futhi ubumsulwa be-sic coating bukhulu kuno-99.9995%.

I-Raw Silicon Carbide Paddle kanye ne-SiC Process Tube in Cleaing

I-Silicon Carbide Wafer Boat CVD SiC Coated