Izinzuzo zokucutshungulwa kwe-LMJ

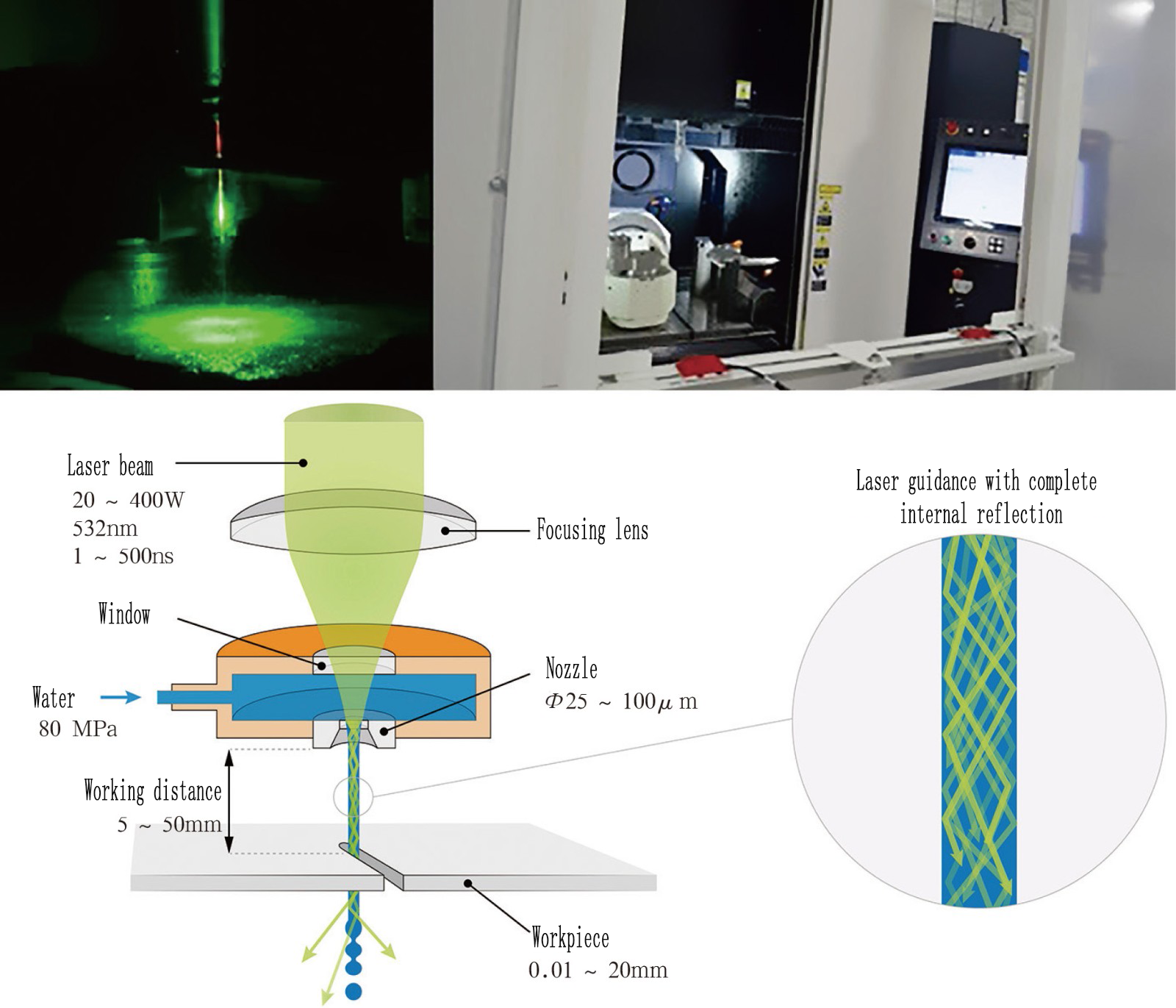

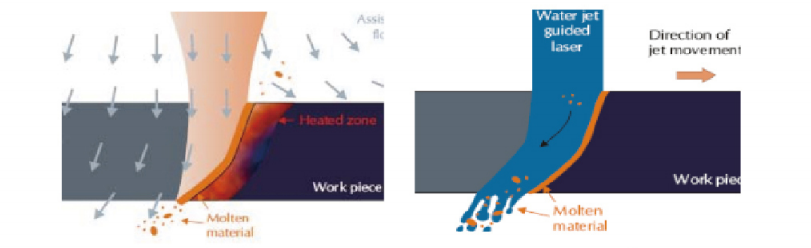

Ukukhubazeka okungokwemvelo kokucutshungulwa kwe-laser okujwayelekile kunganqotshwa ngokusebenzisa ubuchwepheshe be-laser Laser micro jet (LMJ) ukusabalalisa izici zokubona kwamanzi nomoya. Lobu buchwepheshe buvumela ama-laser pulses abonakale ngokugcwele kujethi yamanzi ahlanzekile acutshungulwe ngendlela engaphazamiseki ukuze afinyelele endaweni yomshini njengakufiber optical.

Izici eziyinhloko zobuchwepheshe be-LMJ yilezi:

1. I-laser beam iyisakhiwo sekholomu (efanayo).

2. I-laser pulse idluliselwa kujethi yamanzi njenge-fiber optical, ngaphandle kokuphazanyiswa kwemvelo.

3. I-laser beam igxile emishinini ye-LMJ, futhi ukuphakama kwendawo yomshini akushintshi phakathi nayo yonke inqubo yokucubungula, ngakho-ke ayidingi ukuqhubeka nokugxila ekushintsheni kokujula kokucubungula ngesikhathi sokucubungula.

4. Hlanza ubuso ngokuqhubekayo.

5. Ngaphezu kokukhishwa kwempahla yokusebenza ngomshini we-laser ngamunye, isikhathi ngasinye seyunithi eyodwa kusukela ekuqaleni kokushaya ngakunye kuya ekushayeni okulandelayo, okokusebenza okucutshunguliwe kusesimweni sangempela samanzi okupholisa isikhathi esingaba ngu-99% wesikhathi. , ecishe iqede indawo ethintekile ekushiseni kanye nongqimba lwe-remelt, kodwa igcina ukusebenza kahle okuphezulu kokucubungula.

| Ukucaciswa okujwayelekile | I-LCSA-100 | I-LCSA-200 |

| Ivolumu ye-Countertop | 125 x 200 x 100 | 460×460×300 |

| I-eksisi yomugqa XY | Injini yomugqa. Injini yomugqa | Injini yomugqa. Injini yomugqa |

| I-eksisi yomugqa Z | 100 | 300 |

| Ukubeka ukunemba μm | +/- 5 | +/- 3 |

| Ukunemba kokuma okuphindaphindiwe μm | +/- 2 | +/- 1 |

| Ukusheshisa G | 0.5 | 1 |

| Ukulawula izinombolo | 3-eksisi | 3-eksisi |

| Li-aser |

|

|

| Uhlobo lwe-laser | I-DPSS Nd: YAG | I-DPSS Nd: YAG, ishayela |

| Ubude begagasi nm | 532/1064 | 532/1064 |

| Amandla alinganiselwe W | 50/100/200 | 200/400 |

| Indiza yamanzi |

|

|

| Ububanzi benozili μm | 25-80 | 25-80 |

| Ibha yokucindezela yeNozzle | 100-600 | 0-600 |

| Ubukhulu/Isisindo |

|

|

| Ubukhulu (Umshini) (W x L x H) | 1050 x 800 x 1870 | 1200 x 1200 x 2000 |

| Ubukhulu (ikhabethe lokulawula) (W x L x H) | 700 x 2300 x 1600 | 700 x 2300 x 1600 |

| Isisindo (impahla) kg | 1170 | 2500-3000 |

| Isisindo (ikhabethe lokulawula) kg | 700-750 | 700-750 |

| Ukusetshenziswa kwamandla okuphelele |

|

|

| Input | I-AC 230 V +6%/ -10%, i-unidirectional 50/60 Hz ±1% | I-AC 400 V +6%/-10%, 3-phase50/60 Hz ±1% |

| Inani eliphakeme | 2.5kVA | 2.5kVA |

| Juwoni | 10 m ikhebula lamandla: P+N+E, 1.5 mm2 | 10 m ikhebula lamandla: P+N+E, 1.5 mm2 |

| Ibanga lesicelo somsebenzisi wemboni ye-semiconductor | ≤4 amayintshi ingot eyindilinga ≤4 amayintshi ama-ingot tincetu ≤4 amayintshi ama-ingot scribing

| ≤6 amayintshi ayindilinga ayindilinga ≤6 intshi izingcezu zengot ≤6 amayintshi ingot scribing Umshini uhlangabezana nevelu yethiyori eyindilinga engu-8-intshi/ukusika/ukusika, futhi imiphumela ethile ephathekayo idinga isu lokusika elithuthukisiwe. |